Unilateral plastic film stretching test method and device based on constant strain rate

A plastic film, unidirectional stretching technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as excessive error, low precision, and difficult material clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments. Unless otherwise specified, the materials and processing methods used in the present invention are conventional materials and processing methods in the technical field.

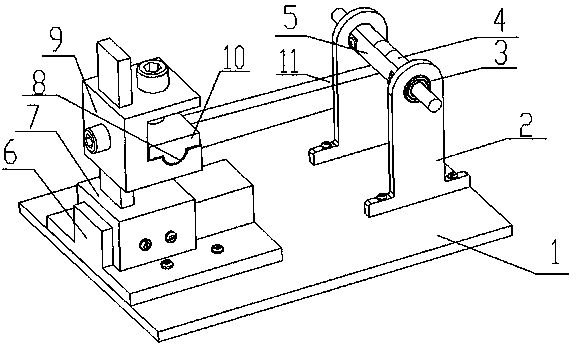

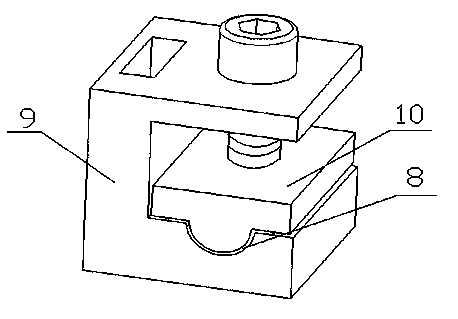

[0042] Such as figure 1 As shown, a plastic film uniaxial tensile test device based on a constant strain rate, including an electric heating system, a driving mechanism, a tensile mechanism and a computer. The electric heating system includes a constant temperature box, and the stretching mechanism is placed in the constant temperature box. The stretching mechanism includes a bottom plate 1 and a cylindrical roller 4 placed on the bottom plate 1 , a support 2 , a rolling bearing 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com