A biaxial tensile test device with third-direction stress provided by fluid pressure and its application

A fluid pressure, biaxial stretching technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the technical problems that cannot effectively solve the heat medium, the test of normal temperature materials and high temperature materials is not available, and the third dimension is not considered. Stress and other problems, to achieve the effect of small error, improve forming limit, improve service life and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and test steps.

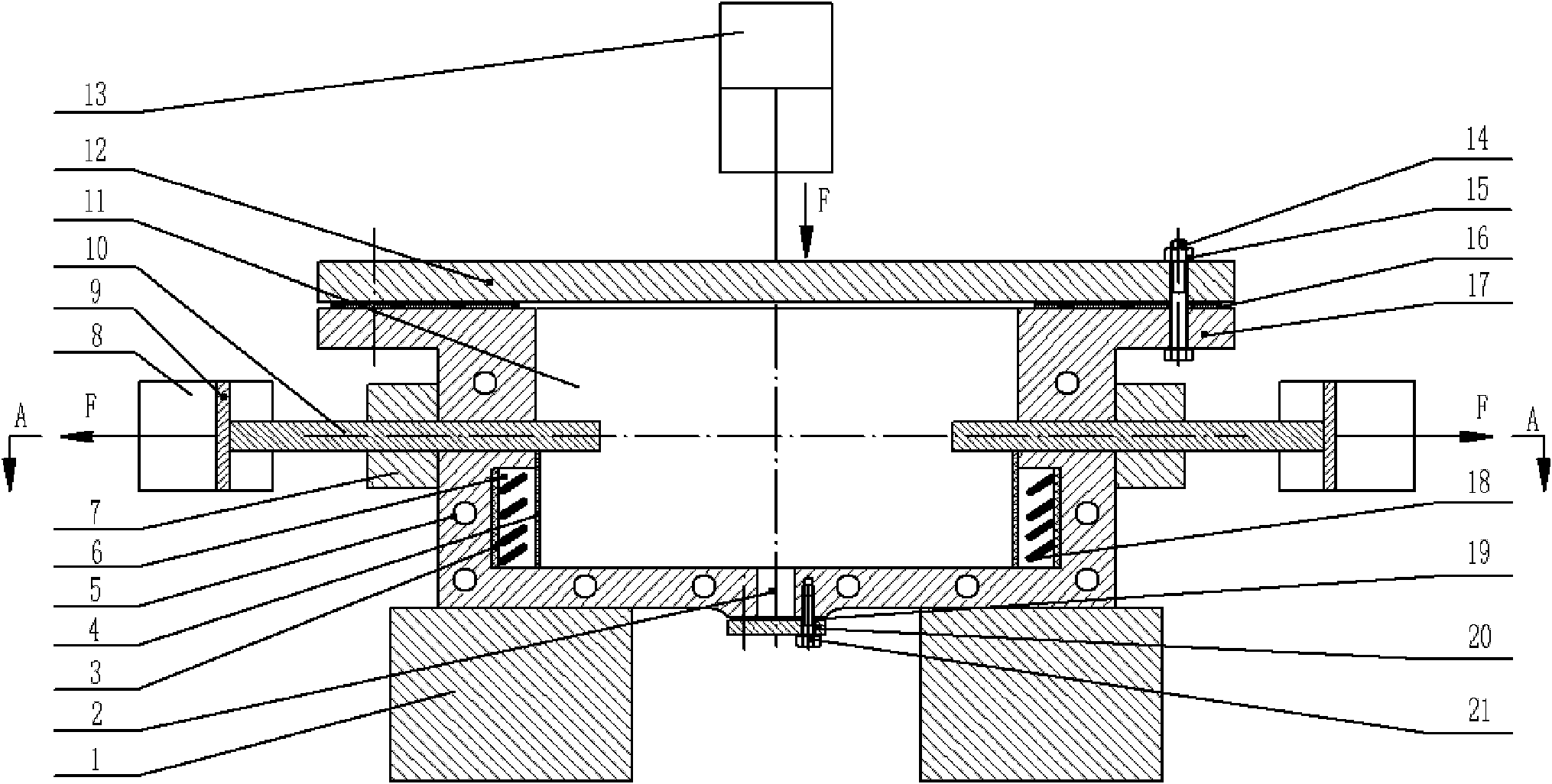

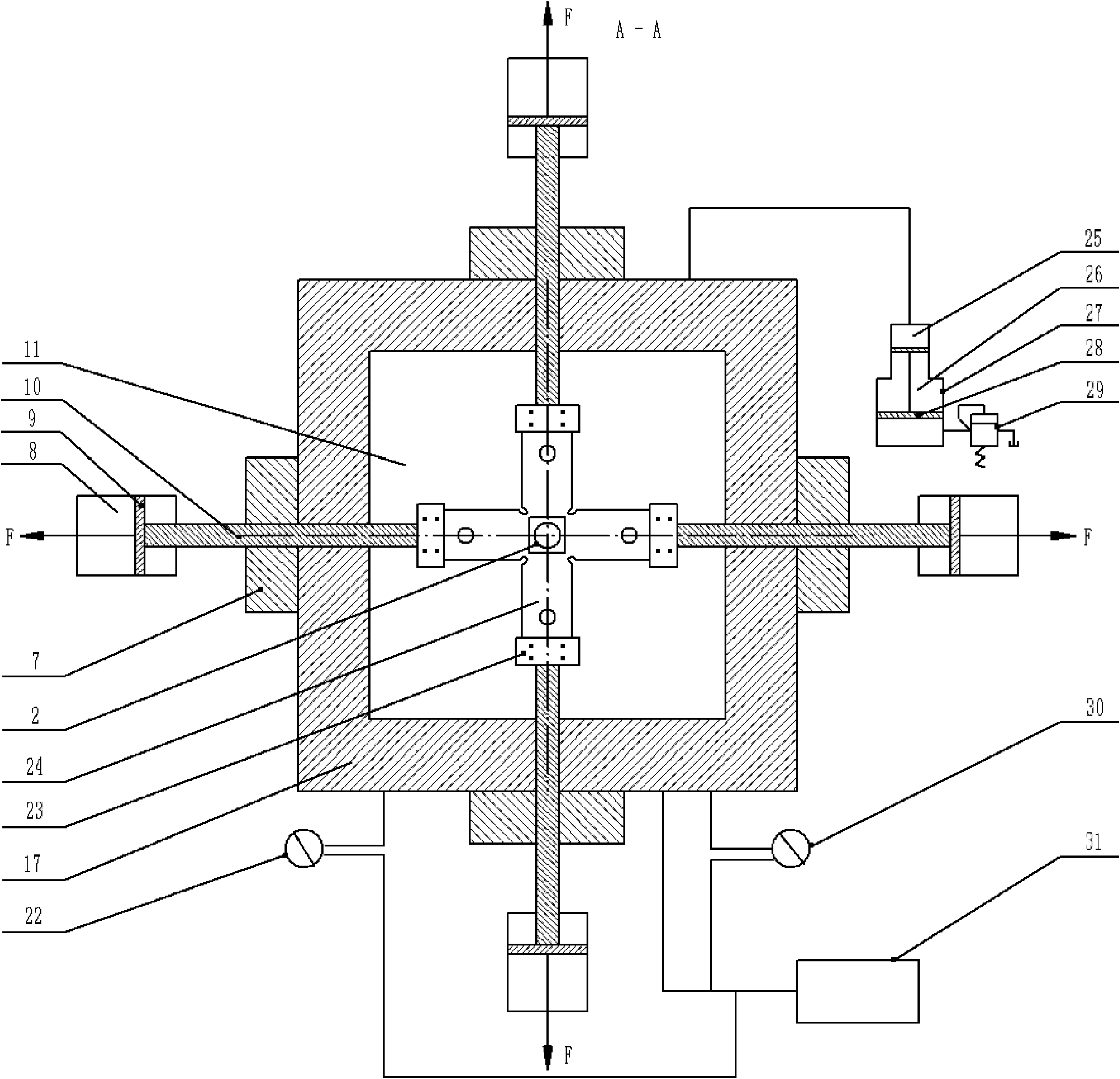

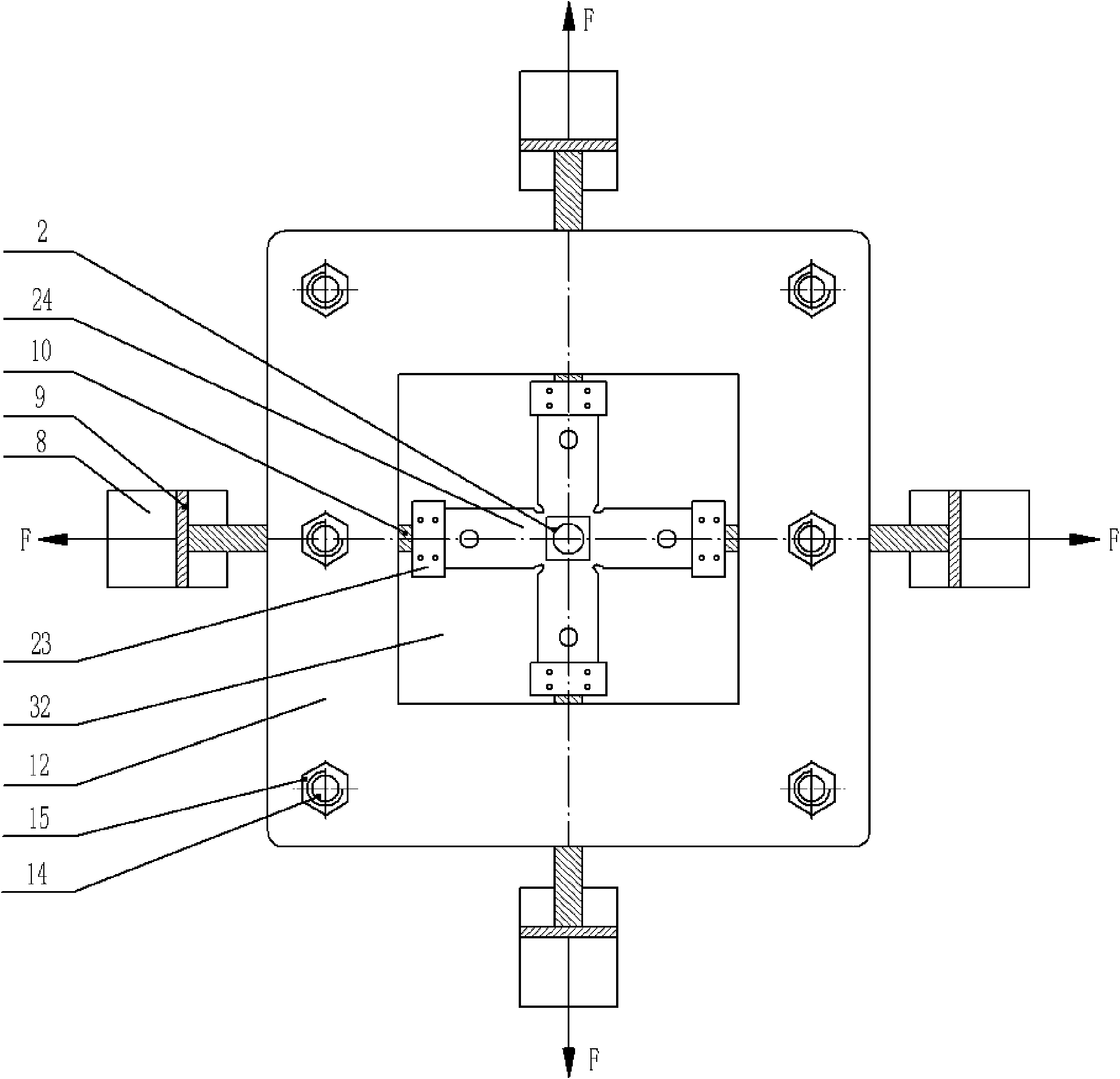

[0045] The present invention is a kind of bidirectional tensile test device that fluid pressure provides the third direction stress, such as figure 1 , figure 2 , image 3 As shown, it includes a stretching device, a closed box, a heating system, a fluid pressure system, a temperature detection device 22 , a pressure measurement device 30 , a cooling system and a data acquisition and processing device 31 .

[0046] The airtight box includes a box cover 12 , a viewing window 32 and a box 17 . The visible window 32 is made of transparent glass or transparent quartz plate material, and is assembled on the center position of the case cover 12 . The center of the box body 17 has a cavity, which is divided into two parts, an upper cavity and a lower cavity in the height direction, the size of the lower cavity is larger than the size of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com