Electromechanical hydraulic loading system for film biaxial tensile test

A biaxial stretching and loading system technology, applied in the direction of mechanical equipment, measuring devices, instruments, etc., can solve expensive and complicated problems, and achieve the effect of large tensile force, fast control response and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

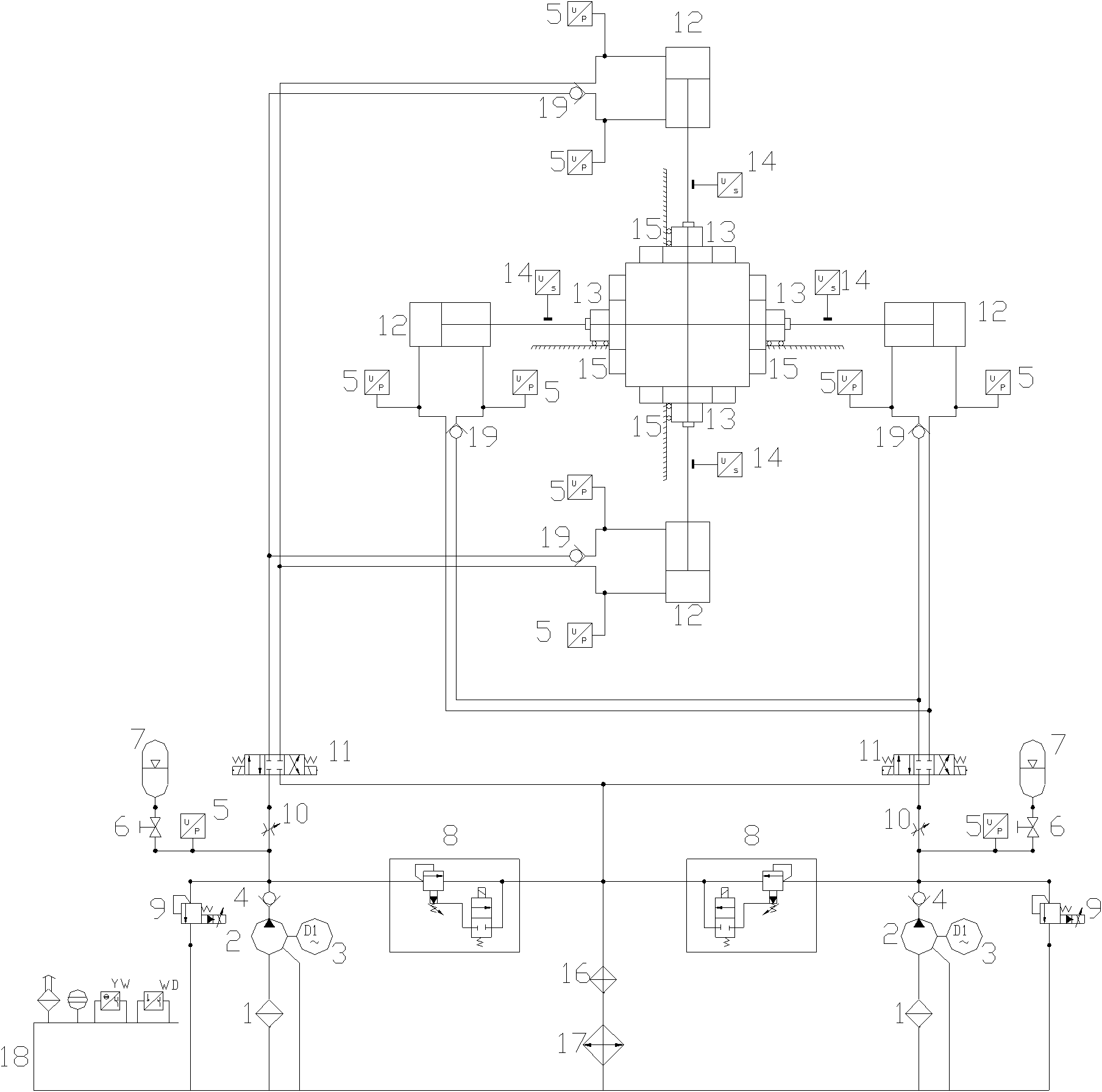

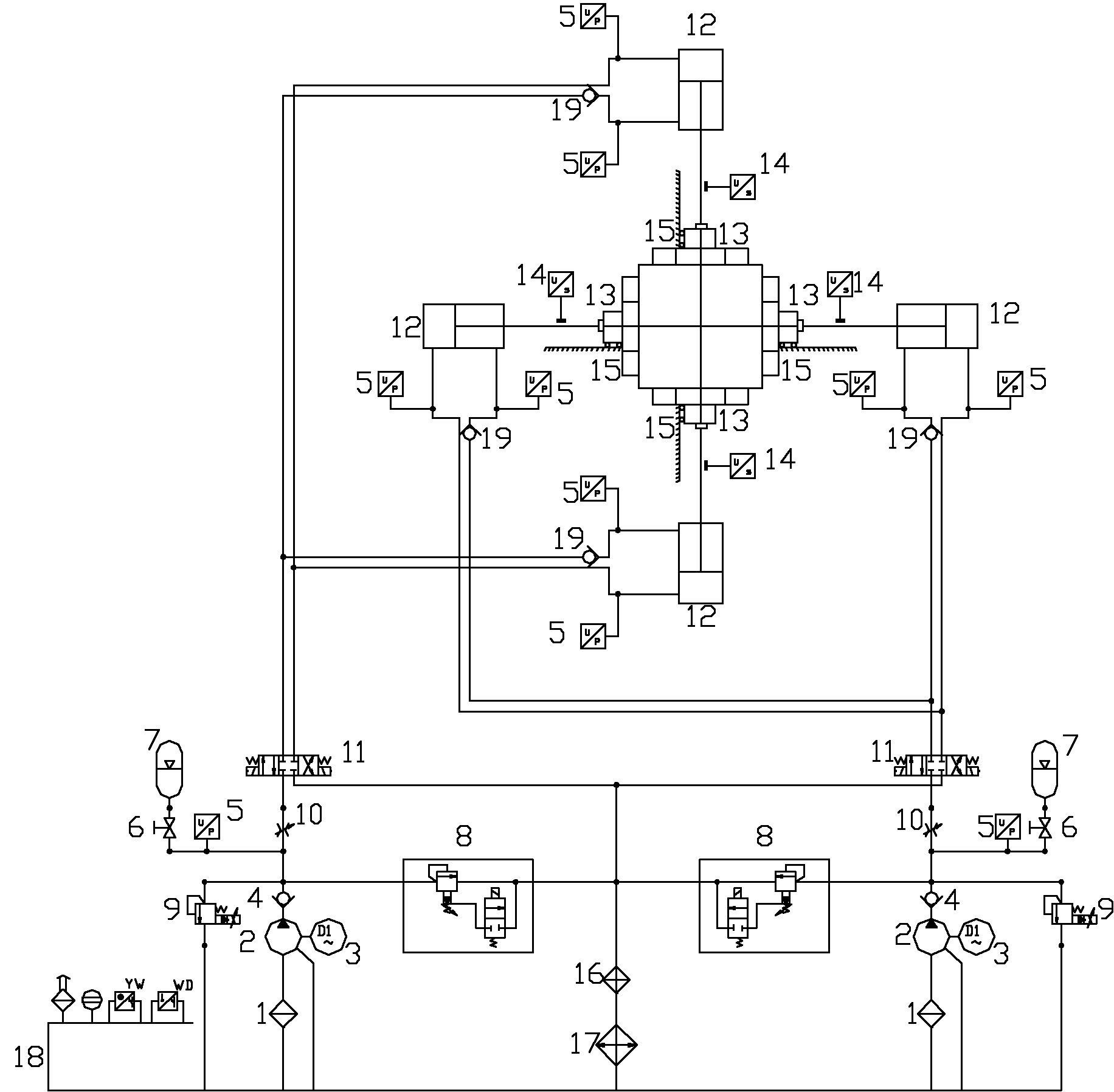

[0014] Such as figure 1 As shown, this embodiment includes a low-pressure filter 1, a hydraulic pump 2, a motor 3, a one-way valve 4, a pressure sensor 5, a stop valve 6, an energy storage device 7, an electromagnetic unloading valve 8, a proportional overflow valve 9, a throttle Flow valve 10, electromagnetic reversing valve 11, servo hydraulic cylinder 12, pull pressure sensor 13, displacement sensor 14, mechanical fixture 15, filter 16, cooler 17, oil tank 18, one-way shut-off valve 19, of which: four servo The hydraulic cylinders 12 are orthogonally arranged into four loading ends, each servo hydraulic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com