Crossed test piece for biaxial stretching strength test and manufacturing method thereof

A biaxial tensile and strength test technology, which is applied in the direction of strength characteristics, preparation of test samples, and application of stable tension/compression to test material strength, etc., can solve problems such as inability to use fabric film biaxial tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

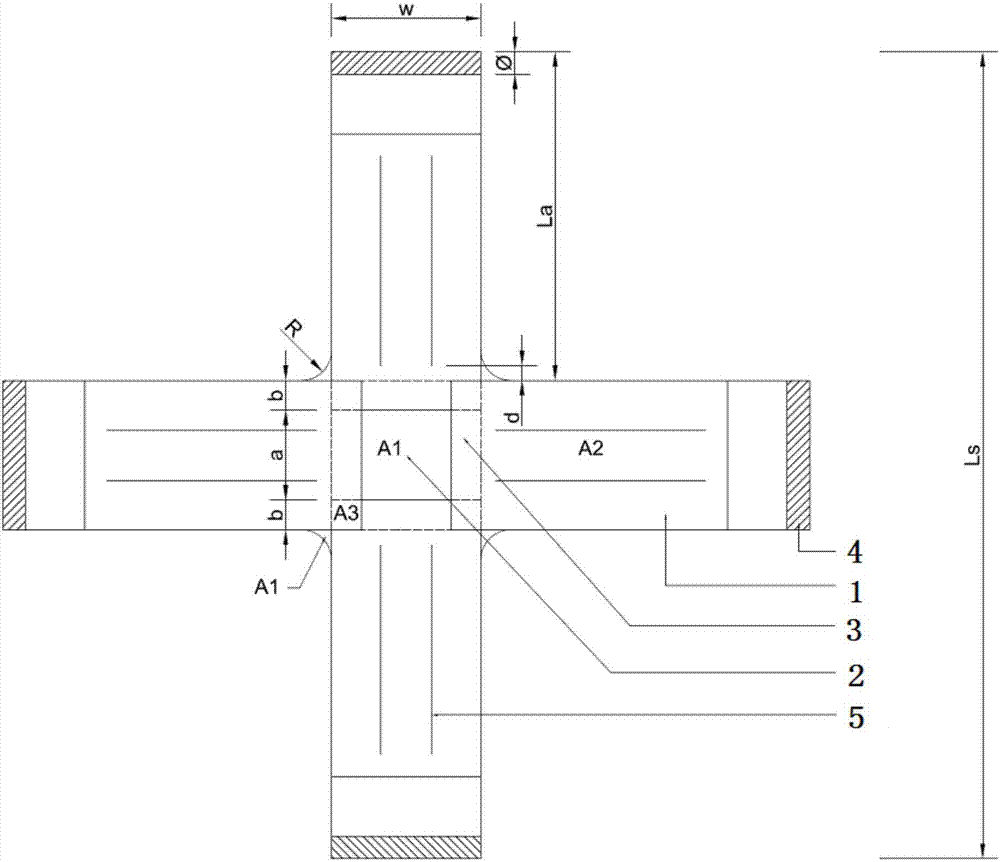

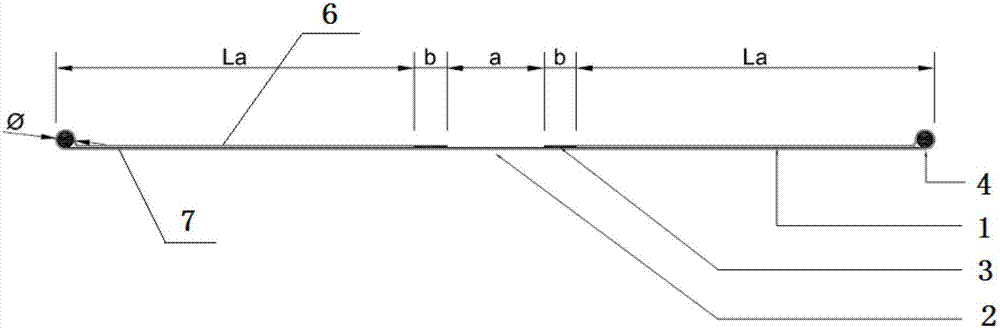

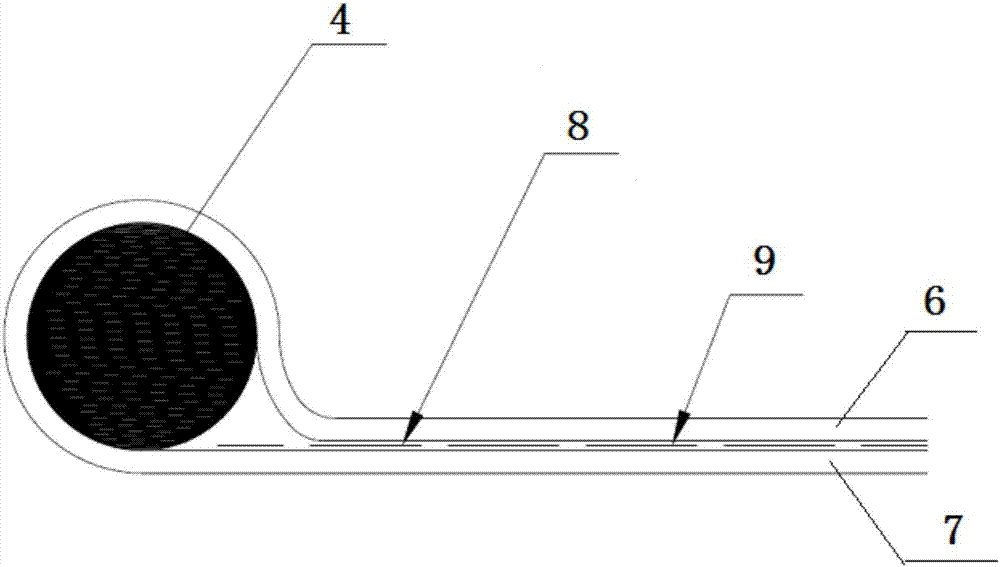

[0032] Such as Figure 1~3 As shown, a preferred embodiment of the present invention provides a cross-shaped specimen for biaxial tensile strength testing, including a central core area 2 and four outriggers 1, and four outrigger arms 1 surround the central core area 2 outwards Extend and form a cross shape, each outrigger 1 is connected to the central core area 2 through the transition zone 3, the end of the outrigger 1 is the clamping end 9, and the clamping end 9 is provided with a clamping end rubber rod 4, and the clamping end The rubber rod 4 is used to connect the fixture of the biaxial tensile testing machine; the central core area 2 is a single layer, and the outrigger 1 and the transition area 3 are double layers. The biaxial tensile strength test cross-shaped specimen of this embodiment is set as follows: when performing a biaxial tensile strength test, the outrigger 1 transmits the tensile force of the biaxial testing machine to the transition zone 3, and finally a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com