Cross-shaped test piece biaxial tensile test based yield criterion evaluation method

A biaxial stretching, cross-shaped technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of not being able to analyze the yield criterion well, predicting accuracy, poor continuity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

[0060] Evaluate the prediction accuracy of Hill48 yield criterion with a kind of yield criterion evaluation method based on cross-shaped specimen biaxial tensile test of the present invention, the method steps are as follows:

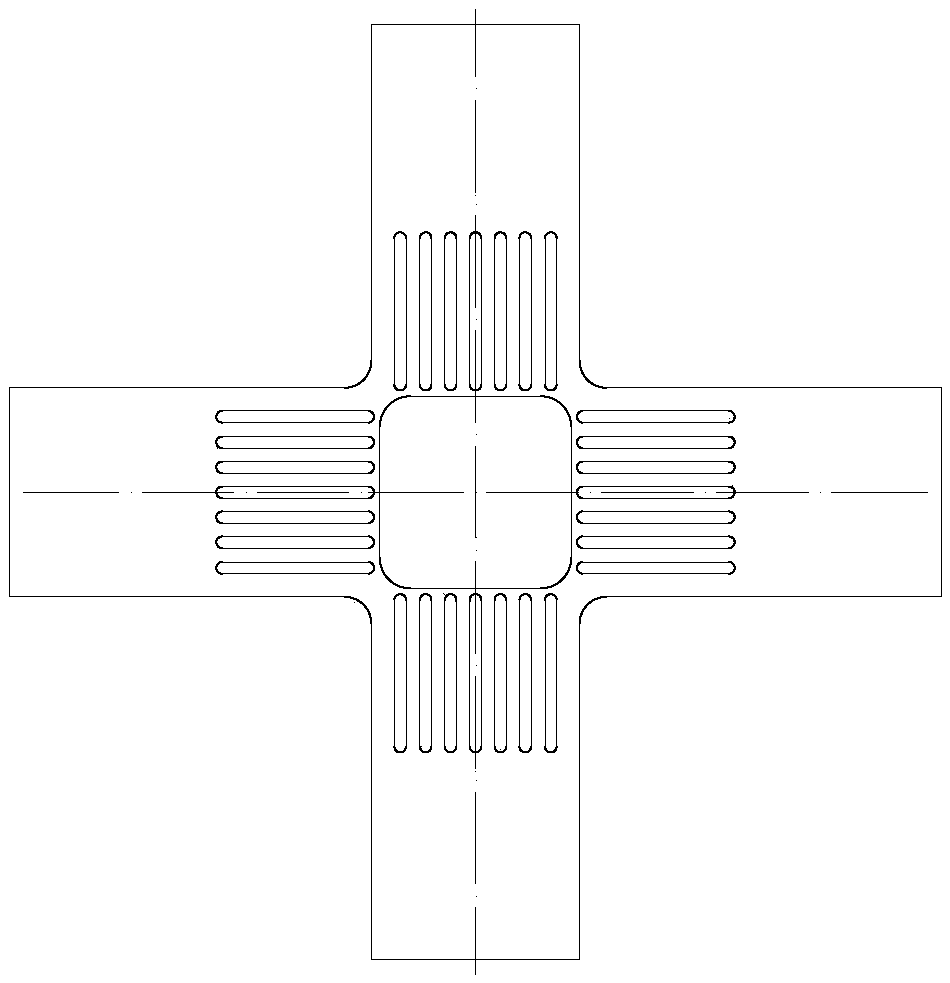

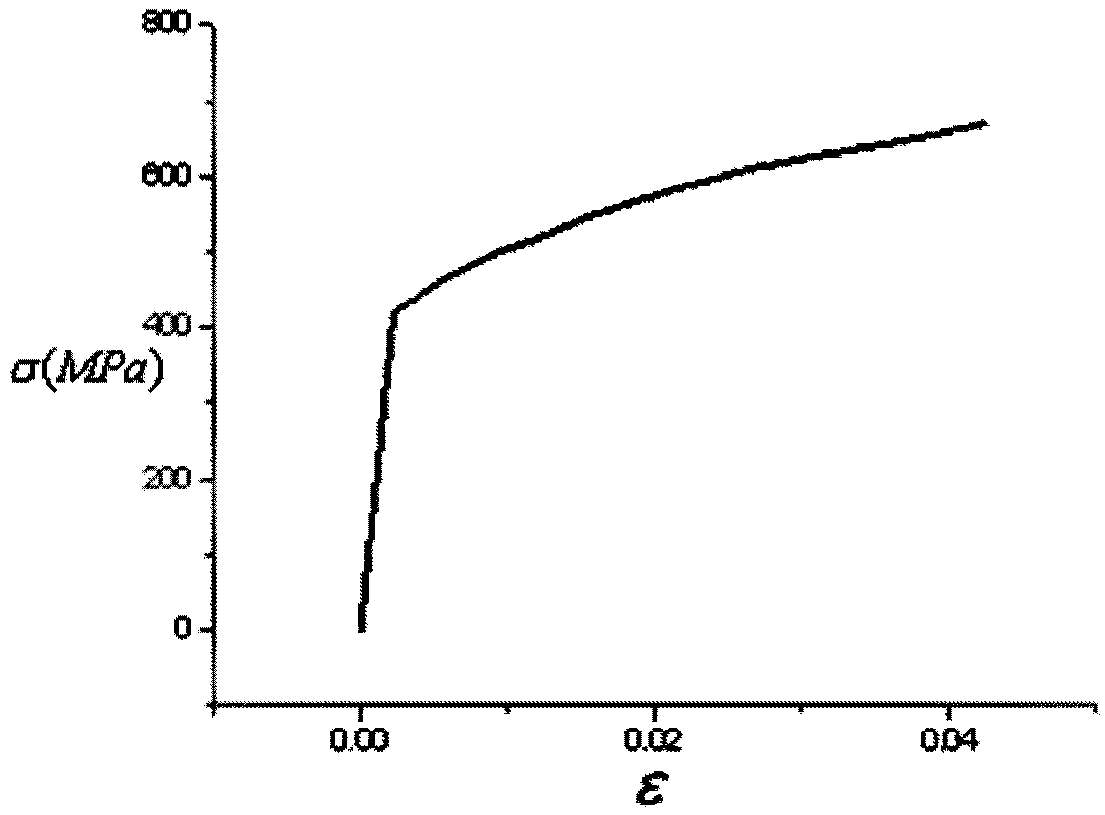

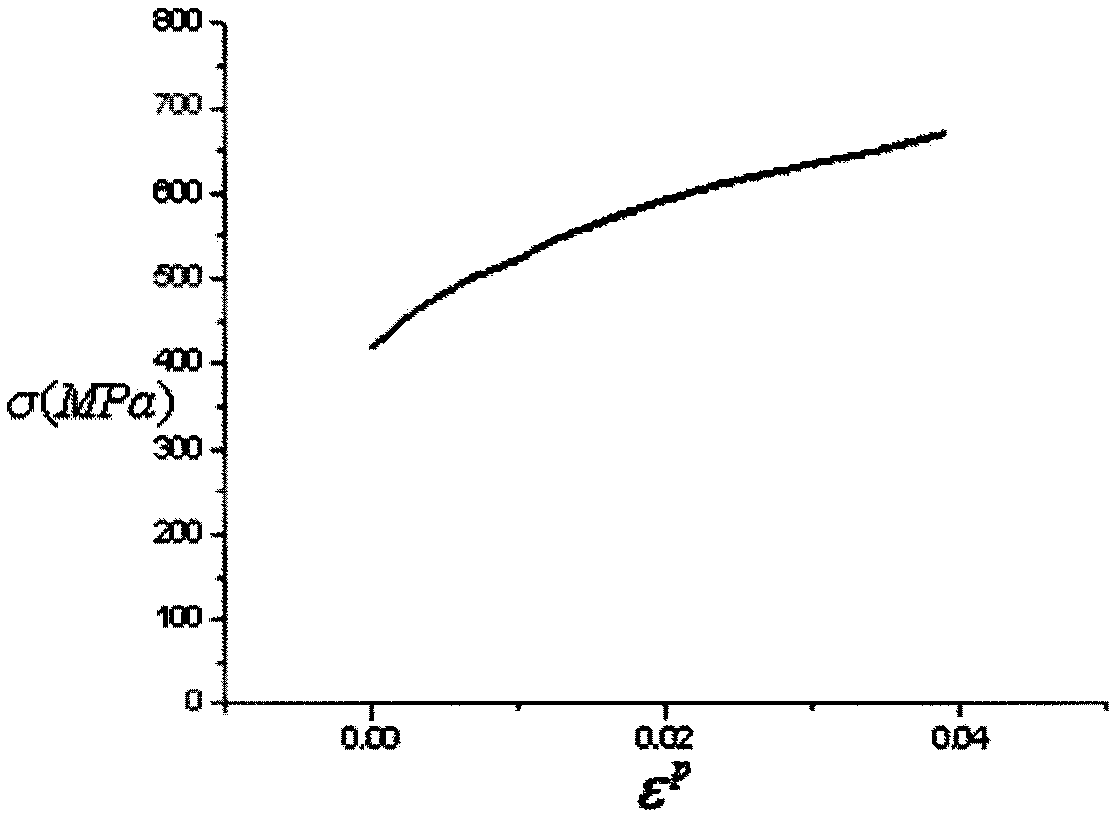

[0061] Step 1: Prepare as figure 1 For the cross-shaped test piece shown, the rolling direction coincides with one of the axial directions; the unidirectional tensile test is carried out on the test piece along the rolling direction, and the relationship between the real stress and the real strain in this direction is obtained, as shown in figure 2 shown. Obtaining the stress-strain relationship in the rolling direction of the specimen includes the following steps:

[0062] Step 1.1: Clamp the cross-shaped specimen on the biaxial tensile testing machine, and clamp the extenso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com