Method of producing a plate spring

a production method and plate spring technology, applied in the direction of low internal friction springs, mechanical actuator clutches, mechanical apparatus, etc., can solve the problems of increased fatigue strength at the location, large residual stress of peening, and increased durability of the diaphragm spring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

in Which Compression Residual Stress is Applied

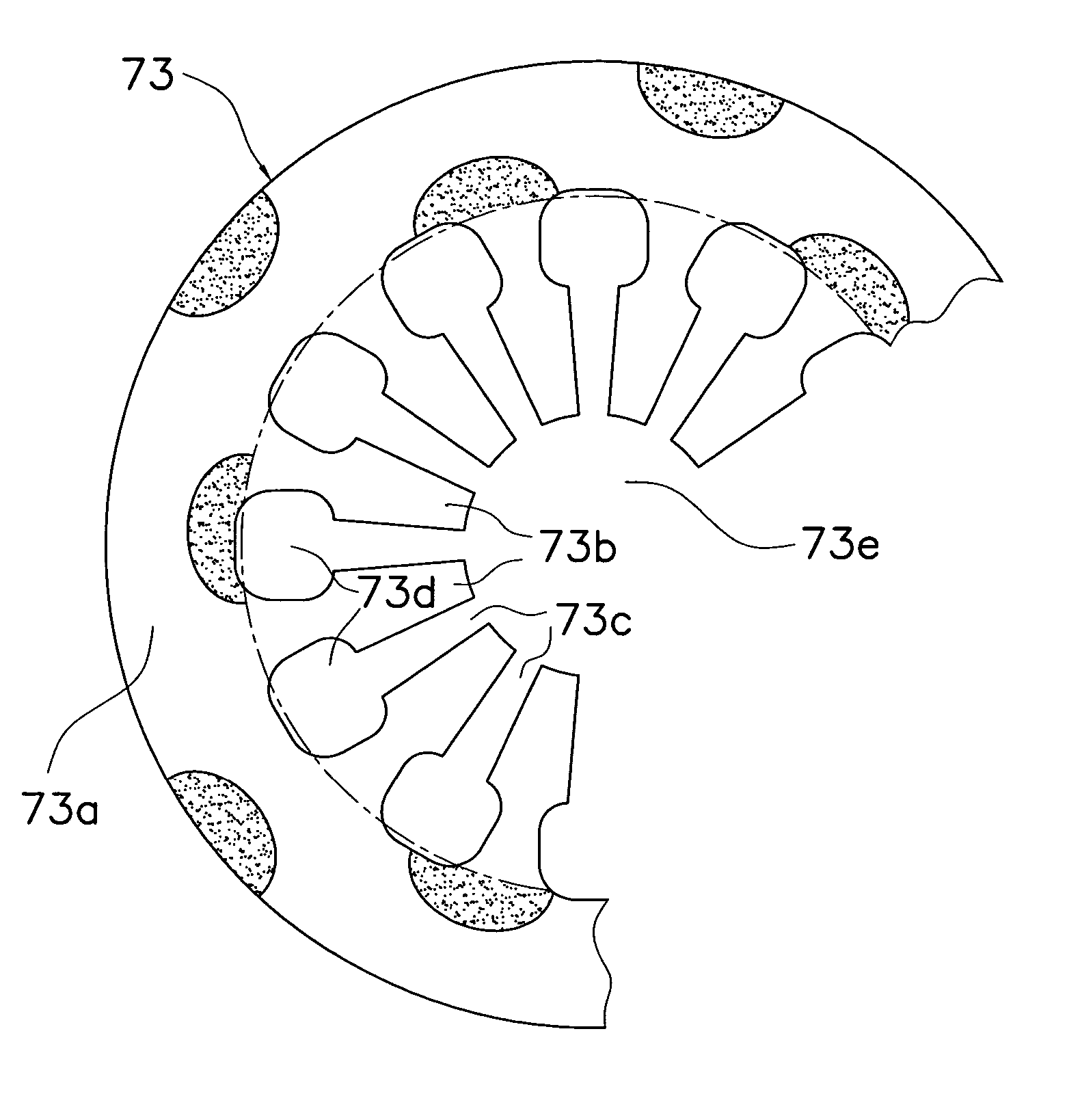

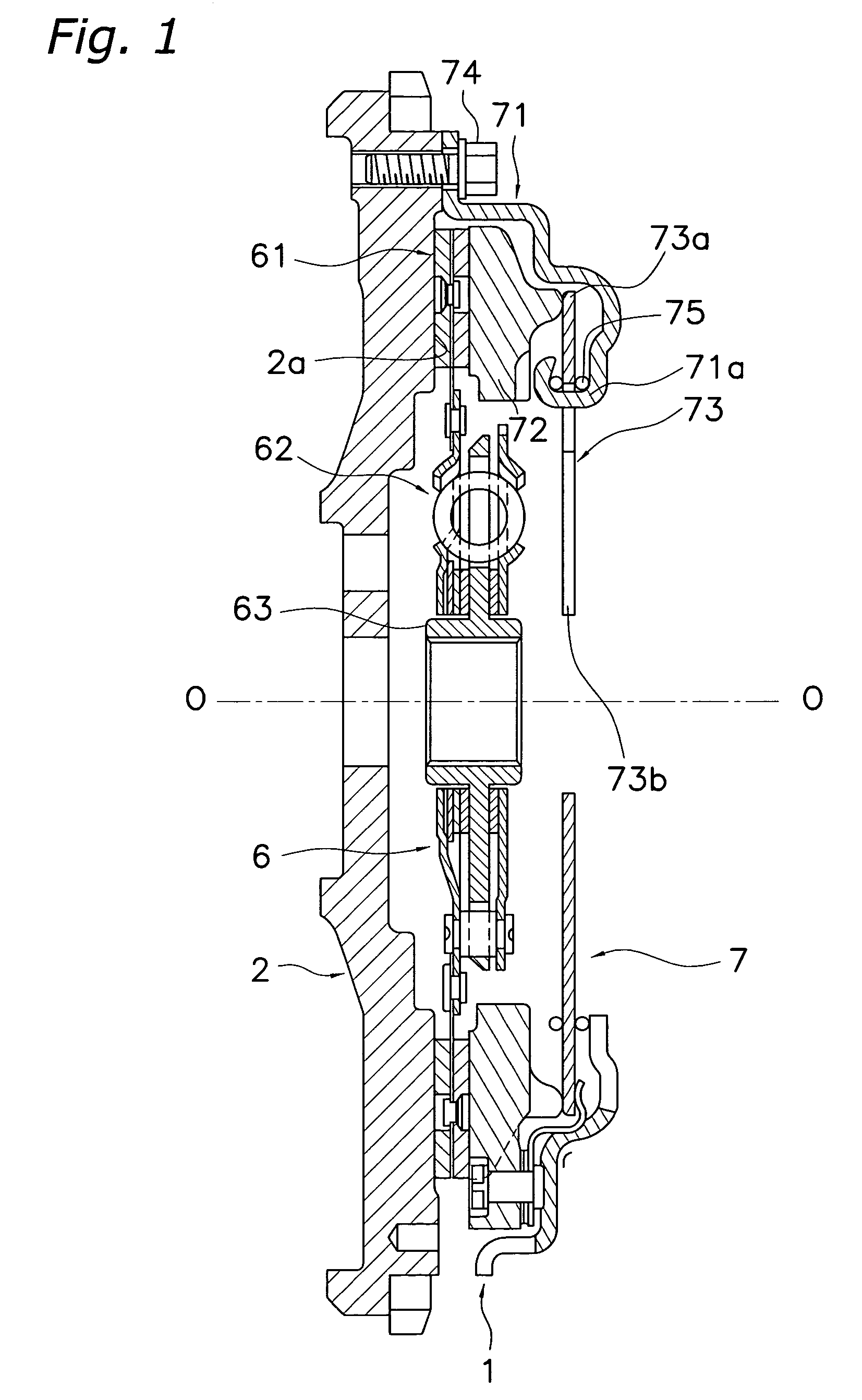

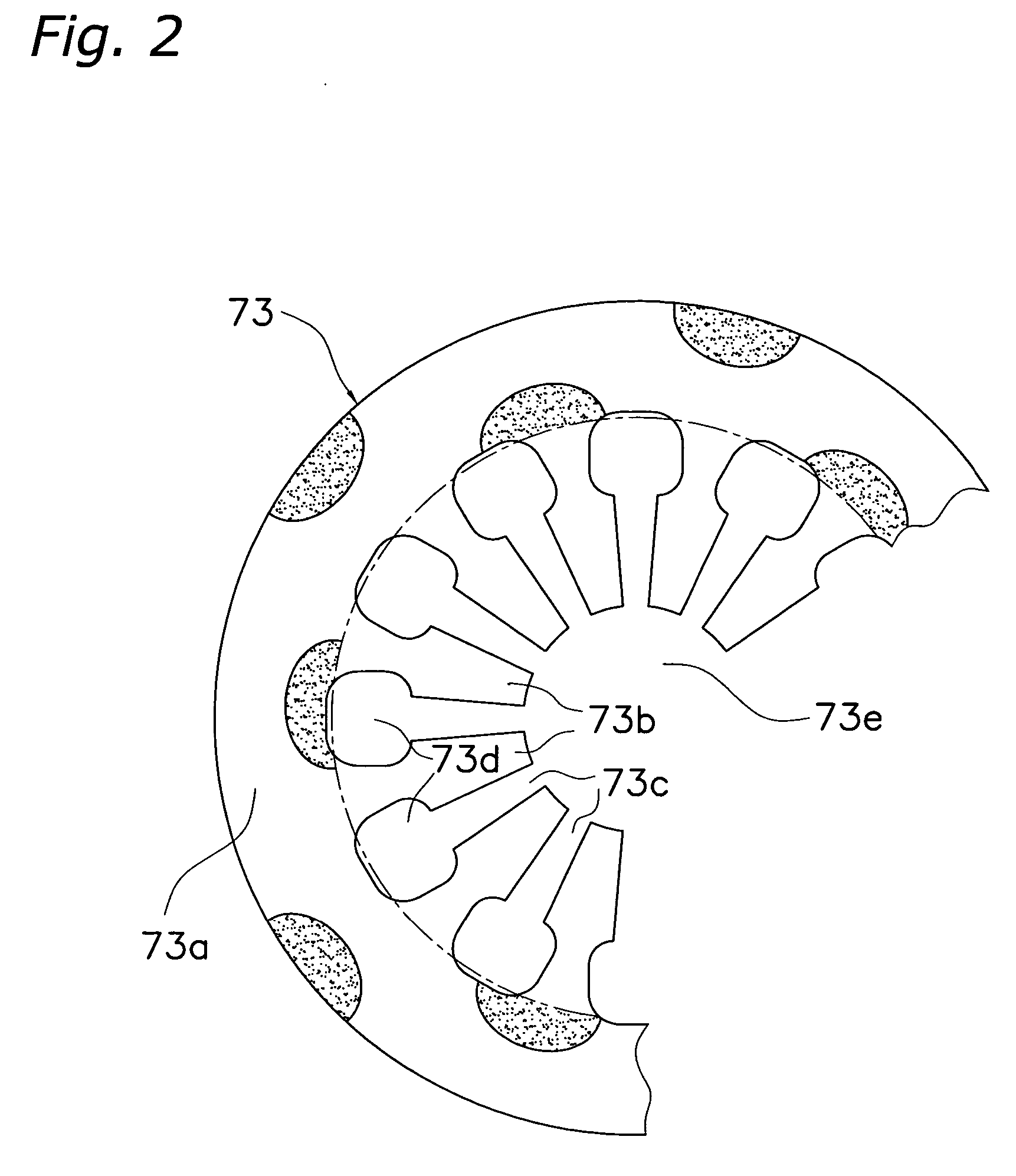

[0044] FIG. 9 will be used below to explain the change in the load-displacement characteristics when compression residual stress is applied to a portion of the resilient portion 73a of the diaphragm spring 73.

[0045] First, when compression residual stress is applied in a conventional manner to the entire surface of a concave surface 80 on the resilient portion 73a, the size of the load will be different than when shot-peening is not performed. However, the qualitative trend of the load-displacement will the same, and a widening of the flat portion near the high load peak shown in FIG. 9 will not be seen. Thus conventionally, an increase in the durability of the resilient portion 73a is possible even if compression residual stress is applied by shot-peening, but changing the load-displacement characteristics thereof was though to be difficult.

[0046] However, as noted above, it is now understood that when shot-peening is performed on only...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilient | aaaaa | aaaaa |

| compression residual stress | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com