Process for characterizing elastoplasticity of metal material through indentation method

A metal material, plastic mechanics technology, applied in the field of material mechanical properties research, can solve the problem of uniqueness and other problems that are not well solved, and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The specific implementation steps are as follows:

[0021] The first step is based on the conical indenter with a half-cone angle of 70.3°, and establishes a dimensionless functional relationship:

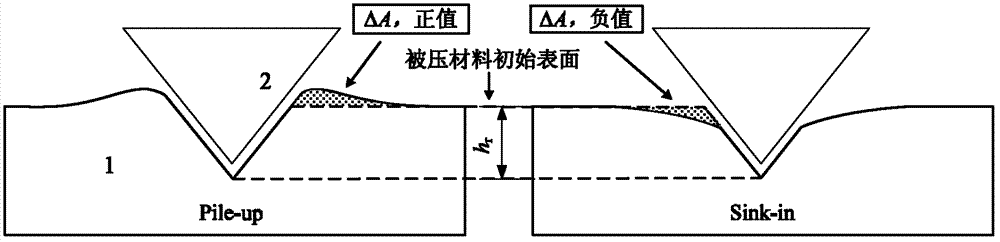

[0022] Using the П theorem, establish the dimensionless functional relationship between the parameters of the load-displacement curve and the parameters of the elastic-plastic mechanical properties of metal materials, and define the third dimensionless function П 3 =ΔA / A, so that:

[0023] P Eh 2 = Π 1 ( E σ y , n ) ...

Embodiment 2

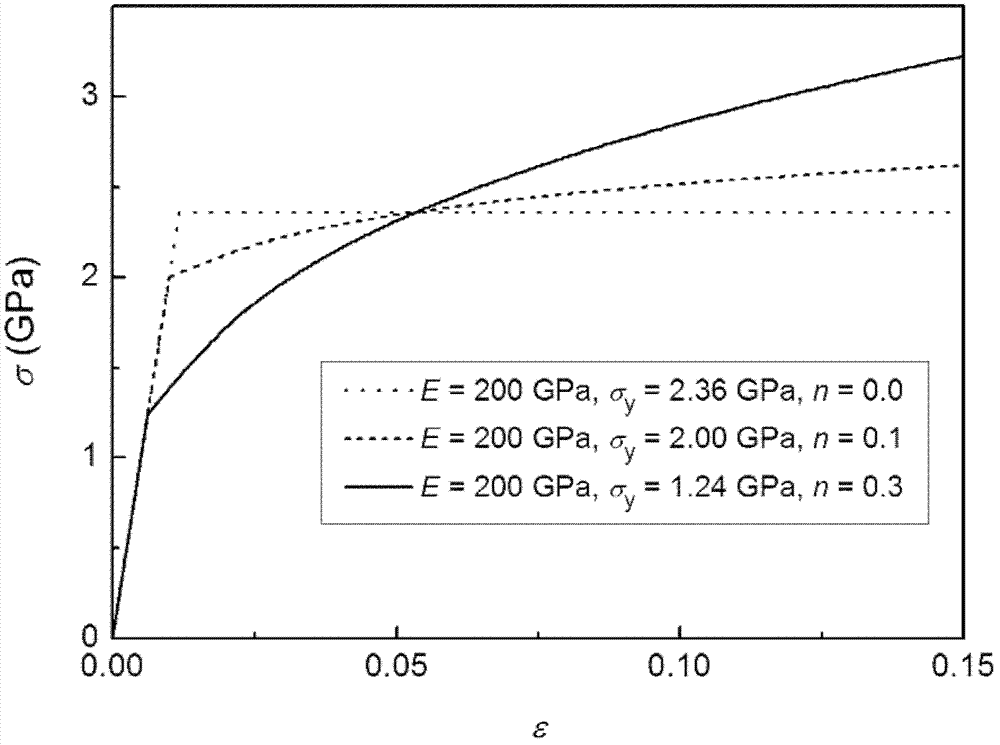

[0035] (1) Select three materials

[0036] The elastic modulus E of the three materials (Yang-Tse Cheng, Che-Min Cheng. Can stress-strain relationships be obtained from indentation curves using conical and pyramidal indenters? Journal of Materials Research. 1999, 14(9): 3495) 200GPa, yield strength σ y They are 2.36, 2.0 and 1.24GPa, respectively, and the hardening exponents n are 0, 0.1 and 0.3, respectively. The elastic-plastic mechanical properties of the three materials are completely different, such as figure 2 shown.

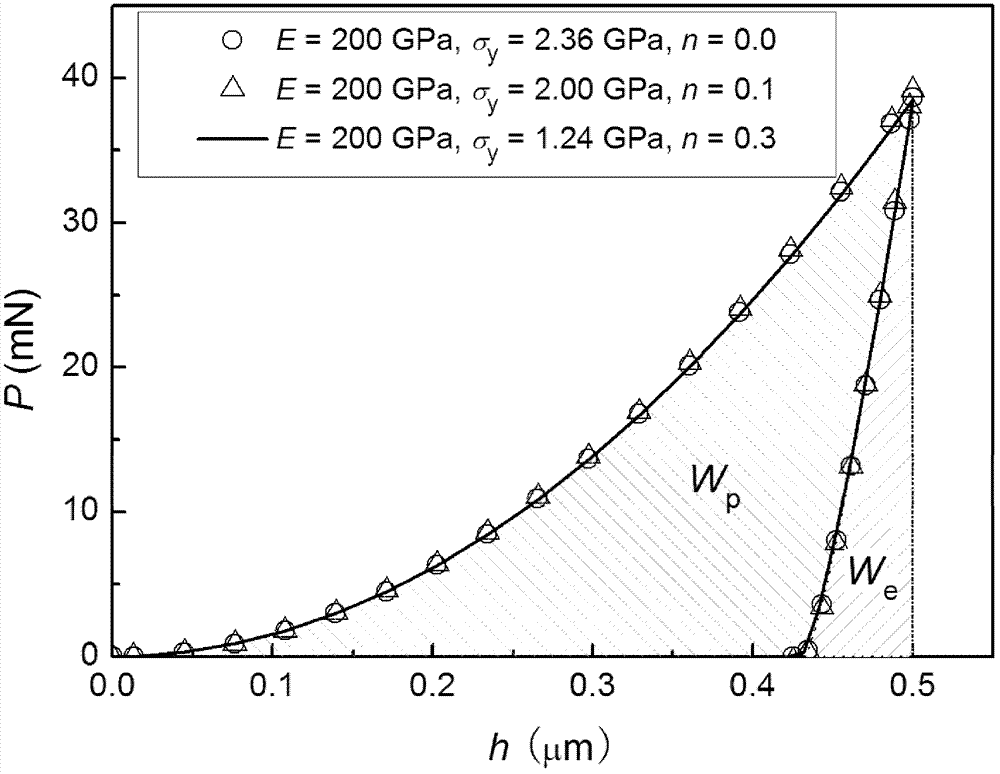

[0037] (2) Indentation of the three selected materials

[0038] Set the maximum indentation depth h max Both are 0.5 μm, and the indentation test is carried out on the three materials (using a conical indenter with a half-cone angle of 70.3°), and the corresponding load-displacement curves are obtained. from image 3 It can be seen that the load-displacement curves of the three materials almost coincide.

[0039] (3) Extract relevant parameters fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com