Device and method for testing ultrahigh-temperature indentation load-displacement curve

A displacement curve and testing device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as low working temperature, failure to reach the ultra-high temperature range, and failure to work normally, so as to improve measurement accuracy and reduce Effect of thermal oxidation and thermal drift, high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific structure and implementation mode of the present invention will be further described through examples below in conjunction with the accompanying drawings, but the scope of the present invention will not be limited in any way.

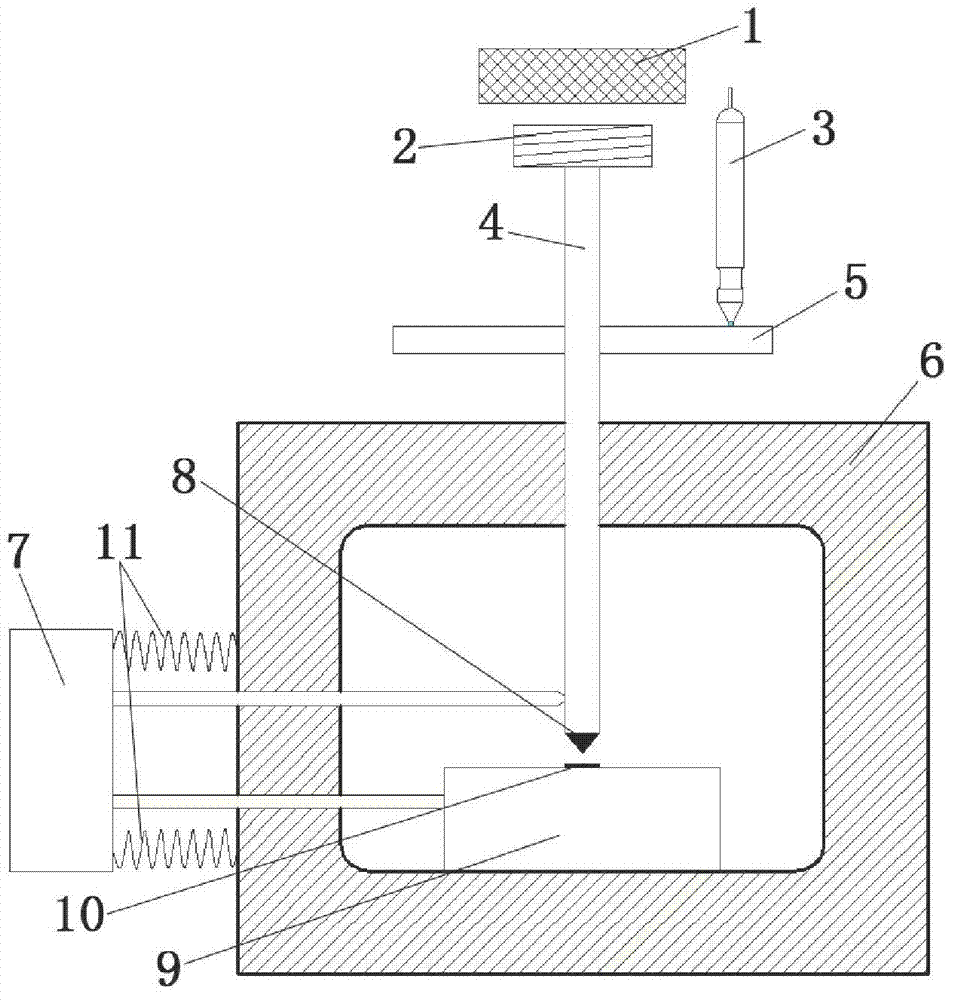

[0019] refer to figure 1 , the ultra-high temperature indentation load-displacement curve test device based on dual displacement sensors provided in this embodiment includes a permanent magnet 1, an energized coil 2, a linear variable differential transformer (LVDT) 3, and a high-temperature-resistant ceramic-based loading rod 4, Displacement measurement platform 5, high temperature furnace 6, ultra-high temperature extensometer 7, ultra-high temperature eutectic ceramic indenter 8, specimen loading platform 9 and tension spring 11. Among them, the specimen loading platform 9 is placed in the high-temperature furnace 6 for placing the ultra-high temperature material specimen 10 to be tested; one end of the high-temperature-resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com