Method for testing elasticity moduli of coatings

A technique of elastic modulus and elastic modulus, which is applied in the preparation of test samples and the use of stable tension/pressure to test the strength of materials, etc. The effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

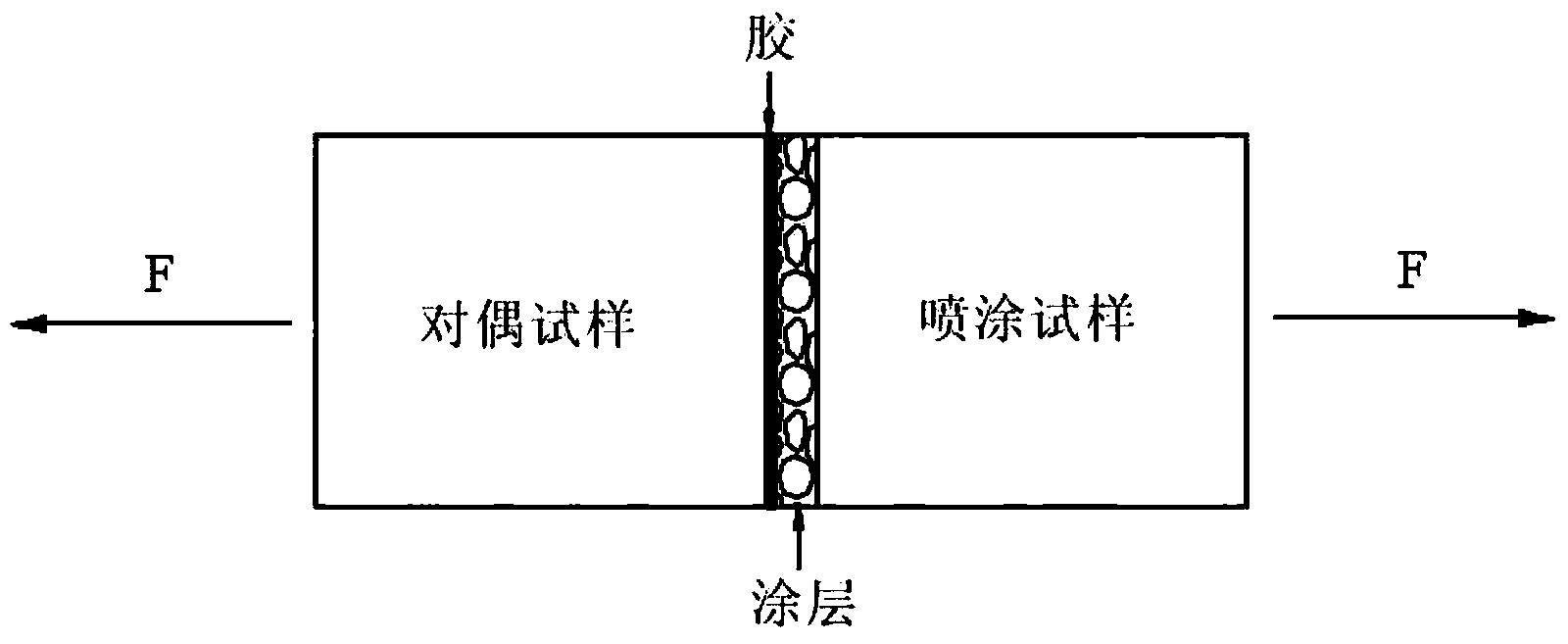

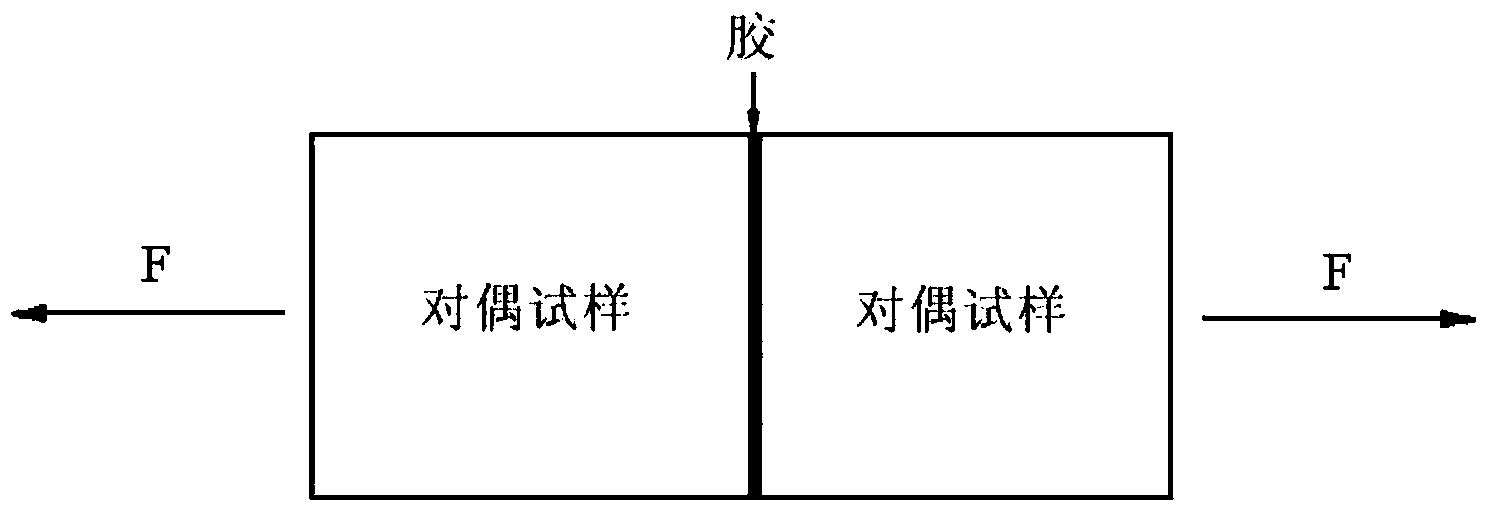

[0029] A method for testing the modulus of elasticity of the coating provided by the present invention mainly consists of four steps: prepare the samples used for the samples, including coating deposition samples and dual samples, and use glue to make a coated sample. and tensile samples without coating; carry out tensile samples, record experimental data; process experimental data, calculate the elastic modulus of the coating perpendicular to the surface direction according to the corresponding mathematical model; repeat the sample at least 5 times, and take the average value as the final result of the test.

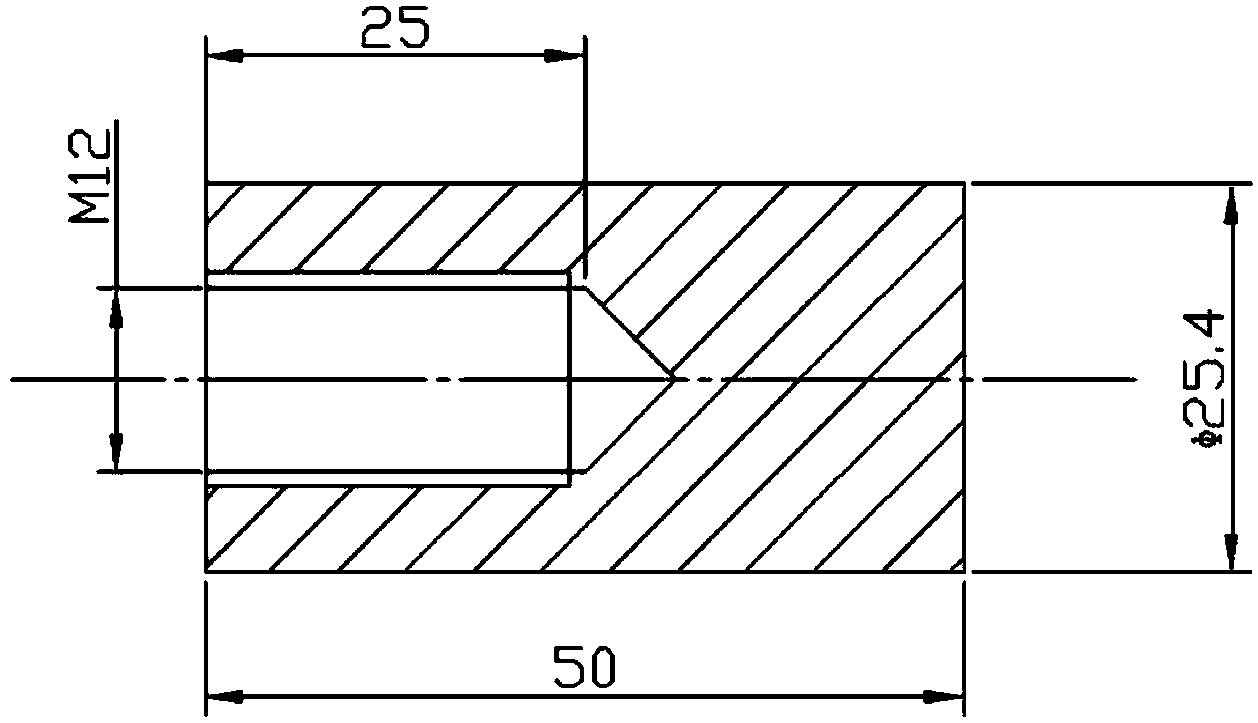

[0030] figure 1 Dimensions of substrate specimen machining required for testing spray coating specimens. This figure is only used as an illustration of an embodiment, and does not mean to limit the invention to the specific form disclosed. This solution is disclosed by way of example only, unless otherwise specified.

[0031] Both the sprayed sample and the dual sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com