Method for predicting tensile strength of nickel-base superalloy gap

A nickel-based high-temperature alloy, tensile strength technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as unsatisfactory matching, achieve the effect of precise strength limit and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

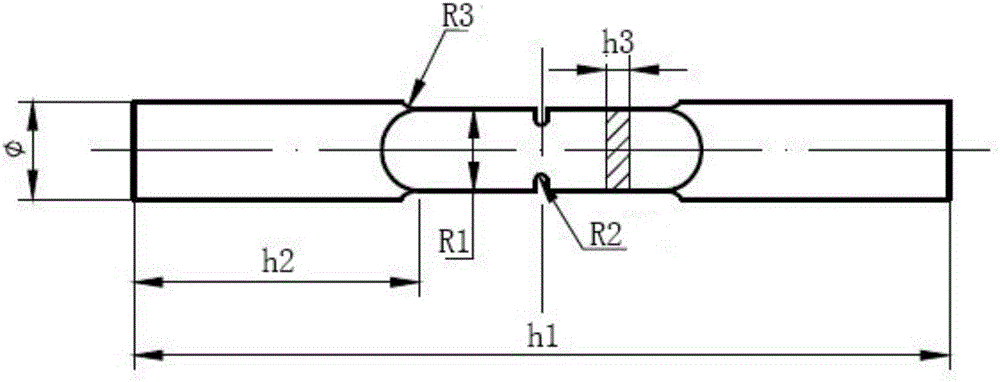

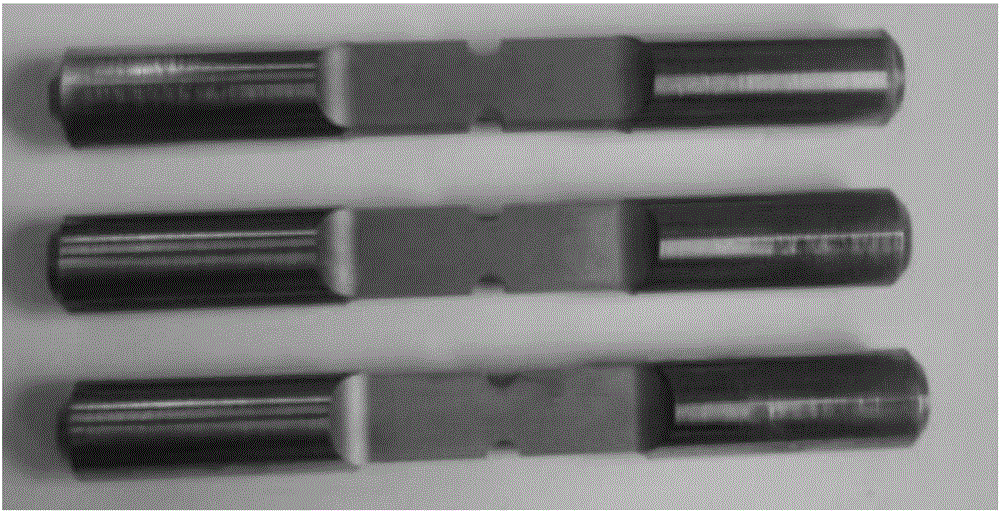

[0066] The present invention takes nickel-based superalloy GH4169 double-sided notched flat plate sample as an example, and predicts the notched tensile strength of the notched sample with a thickness of 0.75 mm and a notch radius of 3 mm at room temperature. Sample drawings and physical pictures such as figure 1 As shown, the dimensions in the figure are: h1=100mm, h2=35mm, h3=3mm, Φ=12mm, R1=10mm, R2=0.75mm, R3=3mm.

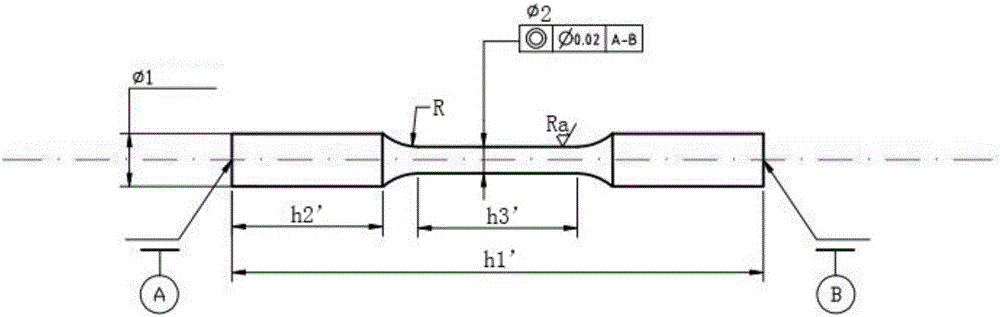

[0067] (1) In order to obtain accurate material properties, that is, the engineering stress-strain curve of the material, it is necessary to conduct a smooth sample tensile test first, and the sample drawings and photos are as follows: figure 2 shown.

[0068] During the actual tensile test, the deformation of the notched specimen is mainly concentrated in the root region of the notch, resulting in that the actual tensile strain rate of the material in the local region of the notch will be much greater than the nominal strain rate of the test load, which will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com