Method for measuring interface bonding strength of thermal barrier coating layer

A technology of interfacial bonding strength and thermal barrier coating, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., to achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

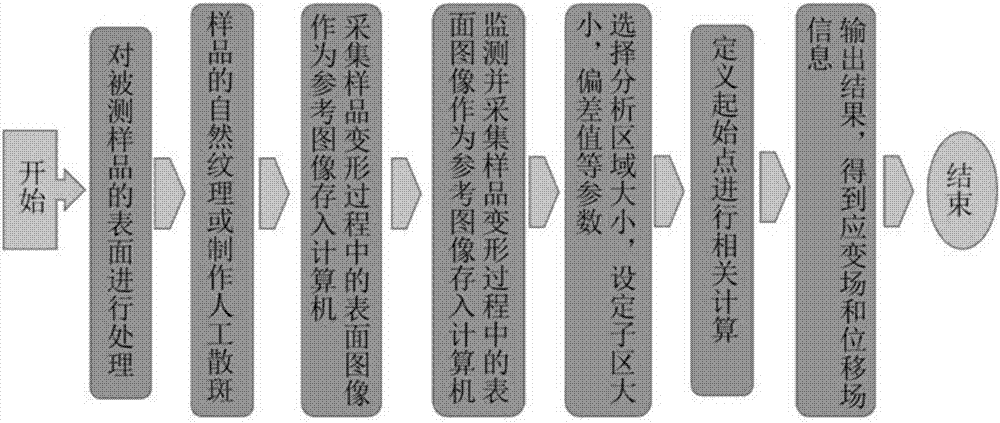

[0045] Such as figure 1 , figure 2 As shown, a method for measuring the interfacial bonding strength of a thermal barrier coating comprises the following steps:

[0046] A method for measuring the interfacial bond strength of a thermal barrier coating, characterized in that it comprises the following steps:

[0047] Step 1. Acquisition of stress-strain data: first prepare the measurement specimen, then use the three-point bending method to obtain and record the load-displacement curve to obtain stress-strain data;

[0048] (3) Preparation of measurement specimens;

[0049] (4) Three-point bending fracture;

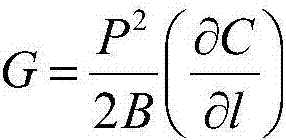

[0050] Step 2. Calculation of crack length: use the digital image correlation method to characterize and measure the deformation of the test piece, and determine the position of the crack tip in combination with the opening angle displacement, thereby calculating the crack length;

[0051] (3) Utilize the digital image correlation method to calculate the deformed pict...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com