Test method for J-R resistance curve of high-toughness material

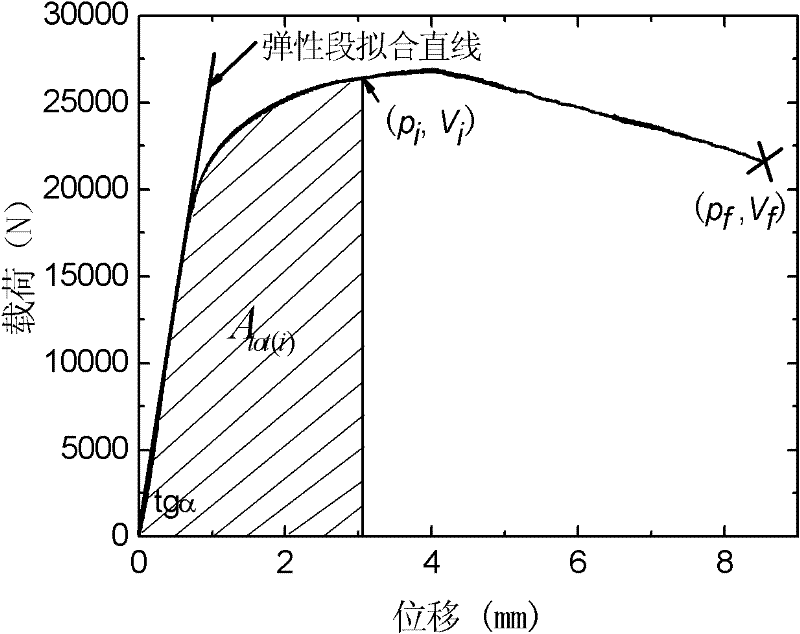

A technology of resistance curve and test method, which is applied in the direction of testing material strength by applying a stable bending force, and can solve problems such as unloading flexibility method is difficult to use, ductile crack initiation, large macroscopic deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

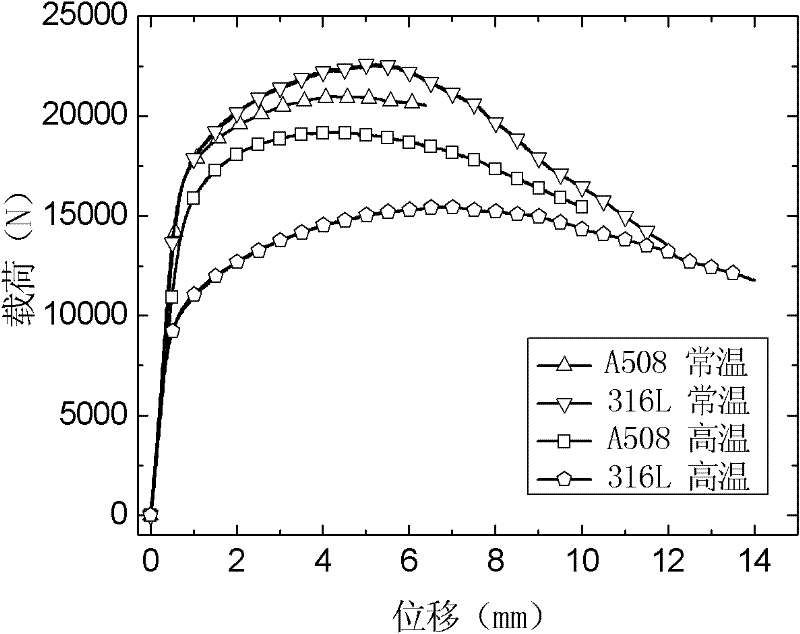

[0122] A nuclear power equipment design and manufacturing company needs to test the J-R resistance curves of high-toughness pressurized water reactor nuclear reaction pressure vessel ferritic steel A508 and primary circuit main pipe austenitic stainless steel 316L at room temperature and high temperature of 340 °C. The tensile mechanical properties of A508 and 316L at room temperature and 340°C measured by round bar tensile test are shown in Table 1:

[0123] Tensile property data of table 1 material

[0124]

[0125] Test the J-R resistance curves of above-mentioned 4 samples below by the method of the present invention.

[0126] (1) Sample processing

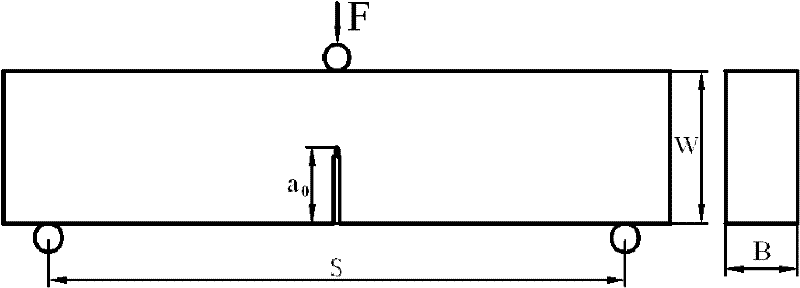

[0127] The two materials of A508 and 316L are processed into such as figure 1 The three-point bending sample shown; the sample height W=32mm, the sample thickness B=16mm, the three-point bending loading span S=4W=128mm, the total depth of the cutting notch and the prefabricated fatigue crack is about 16mm; the two materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com