Water-based drilling fluid for protecting high-permeability reservoirs, and preparation method and use thereof

a reservoir and water-based technology, applied in earth drilling, chemistry apparatus and processes, wellbore/well accessories, etc., can solve the problems of increased scope, increased cost, and increased permeability, and achieve good temperature resistance and lubrication properties, and low operation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

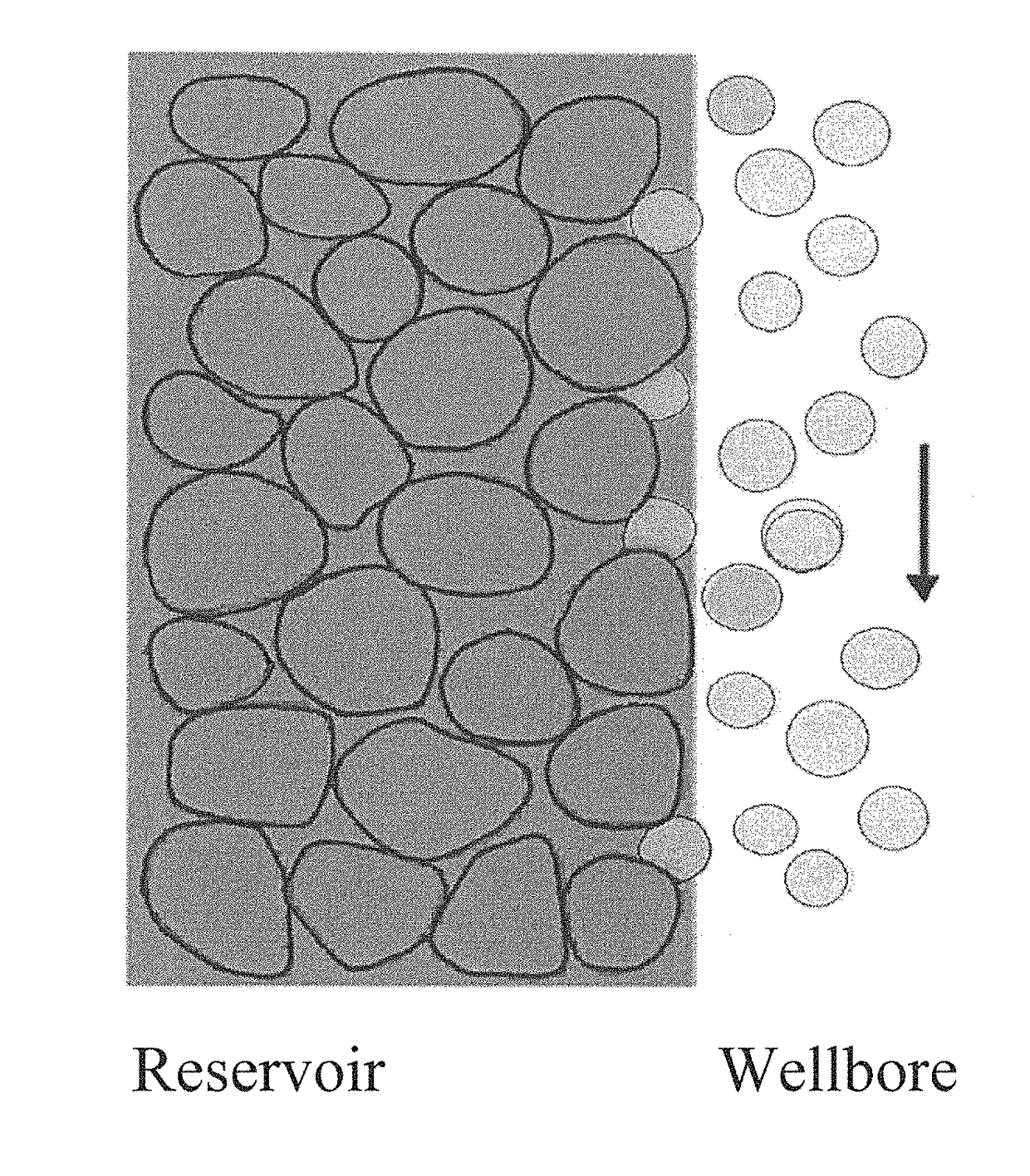

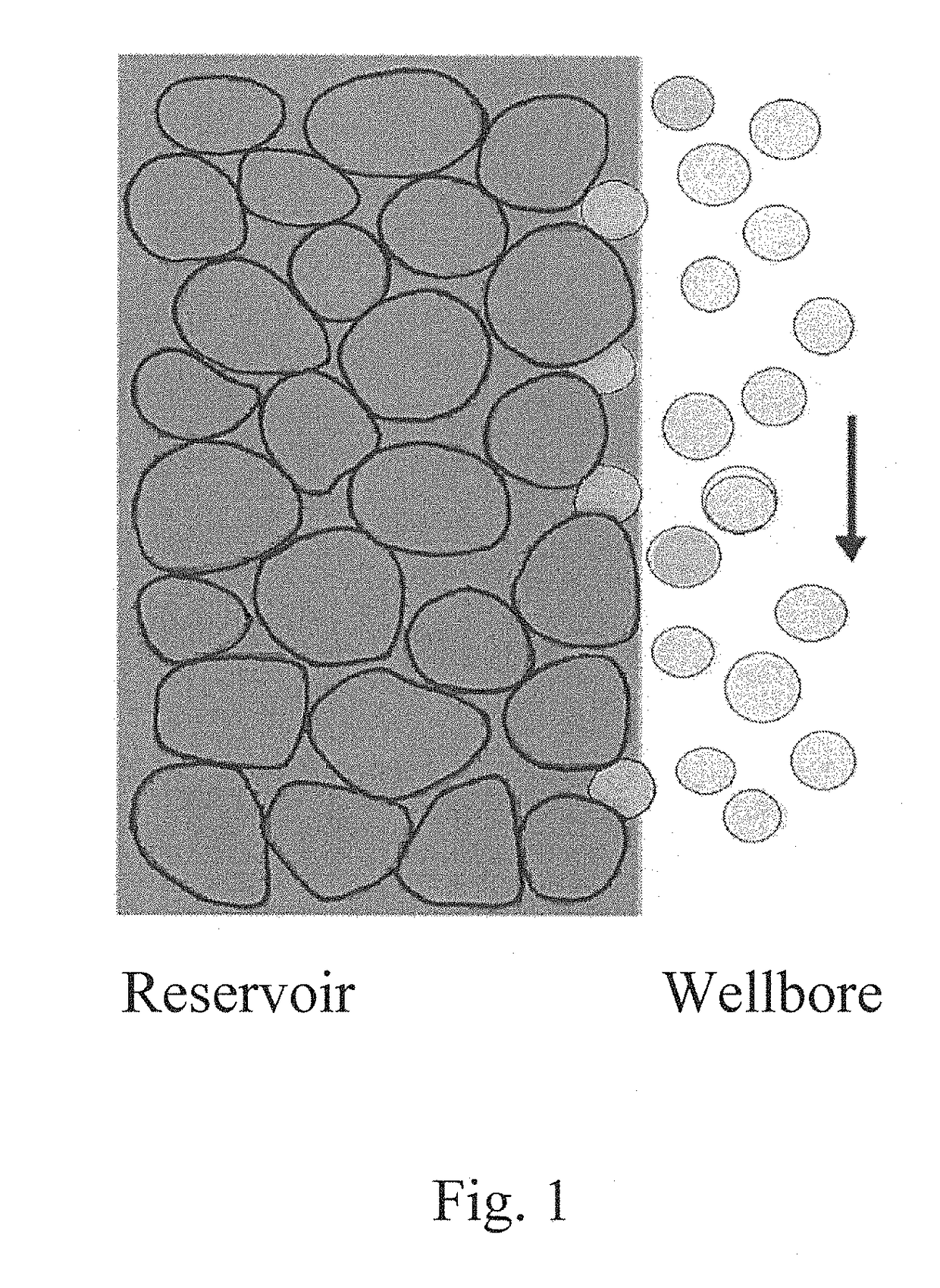

Problems solved by technology

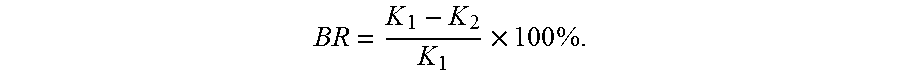

Method used

Image

Examples

preparation example 1

[0069]This preparation example is provided here to describe the preparation method of the polymer elastic granule of the reservoir protectant.

[0070]20 kg acrylamide, 4 kg dimethyldiallyl ammonium chloride and 0.01 kg N, N′-methylene-bis acrylamide are dissolved fully in 67.96 kg water, and then 8 kg sodium bentonite is added into the solution, and the mixture is stirred to a homogeneous state. The above-mentioned reaction liquid is loaded into a reactor equipped with a stirrer, a condenser tube and a thermometer, nitrogen is supplied for protection, the reaction liquid is stirred for 20 min., and then the temperature is adjusted to 60° C., 0.03 kg ammonium persulfate is added, the nitrogen supply and the stirring are stopped, and the reaction liquid is held for 3 h for reaction; the reaction product is taken out, dried for 15 h at 105° C., and pulverized to obtain a granular intermediate product of reservoir protectant.

[0071]10 kg intermediate product and 5 kg sodium carbonate are a...

preparation example 2

[0072]This preparation example is provided here to describe the preparation method of the polymer elastic granule of the reservoir protectant.

[0073]25 kg acrylamide, 5 kg methacryloyloxyethyl-trimethyl ammonium chloride and 0.02 kg N, N′-methylene-bis acrylamide are dissolved fully in 59.93 kg water, and then 10 kg starch is added into the solution, and the mixture is stirred to a homogeneous state. The above-mentioned reaction liquid is loaded into a reactor equipped with a stirrer, a condenser tube and a thermometer, nitrogen is supplied for protection, the reaction liquid is stirred for 30 min., and then the temperature is adjusted to 50° C., 0.05 kg potassium persulfate is added, the nitrogen supply and the stirring are stopped, and the reaction liquid is held for 4 h for reaction; the reaction product is taken out, dried for 12 h at 110° C., and pulverized to obtain a granular intermediate product of reservoir protectant.

[0074]20 kg intermediate product, 3 kg potassium hydroxid...

preparation example 3

[0075]This preparation example is provided here to describe the preparation method of the polymer elastic granule of the reservoir protectant.

[0076]10 kg acrylamide, 2 kg dodecyldimethylbenzyl ammonium chloride and 0.05 kg N, N′-methylene-bis acrylamide are dissolved fully in 72.93 kg water, and then 15 kg sodium bentonite is added into the solution, and the mixture is stirred to a homogeneous state. The above-mentioned reaction liquid is loaded into a reactor equipped with a stirrer, a condenser tube and a thermometer, nitrogen is supplied for protection, the reaction liquid is stirred for 25 min., and then the temperature is adjusted to 40° C., 0.02 kg sodium persulfate is added, the nitrogen supply and the stirring are stopped, and the reaction liquid is held for 5 h for reaction; the reaction product is taken out, dried for 18 h at 90° C., and pulverized to obtain a granular intermediate product of reservoir protectant.

[0077]30 kg intermediate product and 2 kg sodium hydroxide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com