System for testing fatigue crack propagation in corrosion environment

A technology of fatigue crack growth and test testing, which is applied in the direction of testing the ductility of materials, and can solve the problems of low precision fatigue crack growth performance testing and lack of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

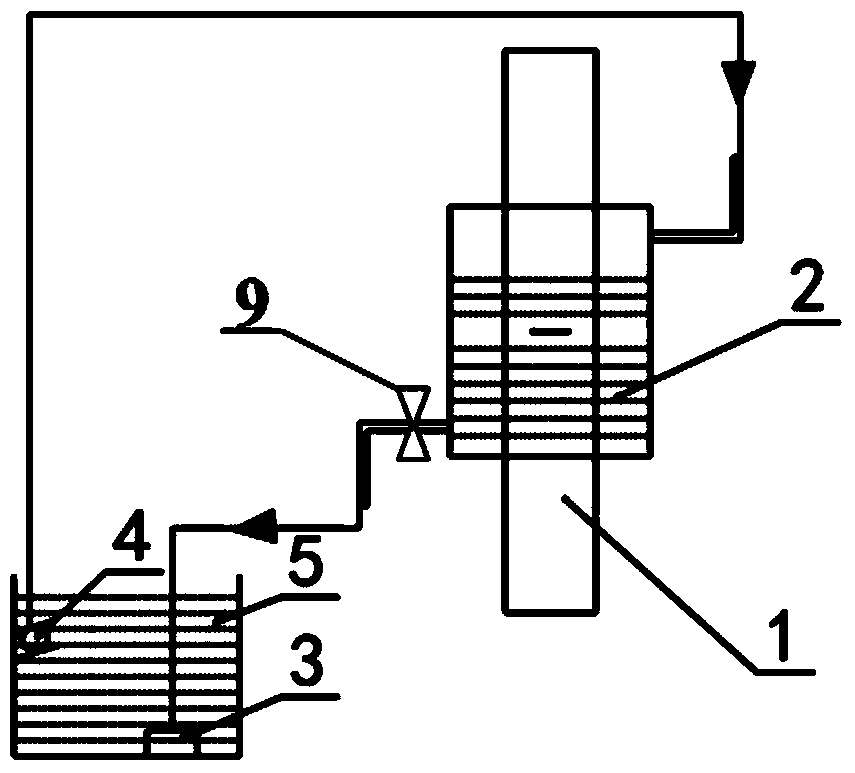

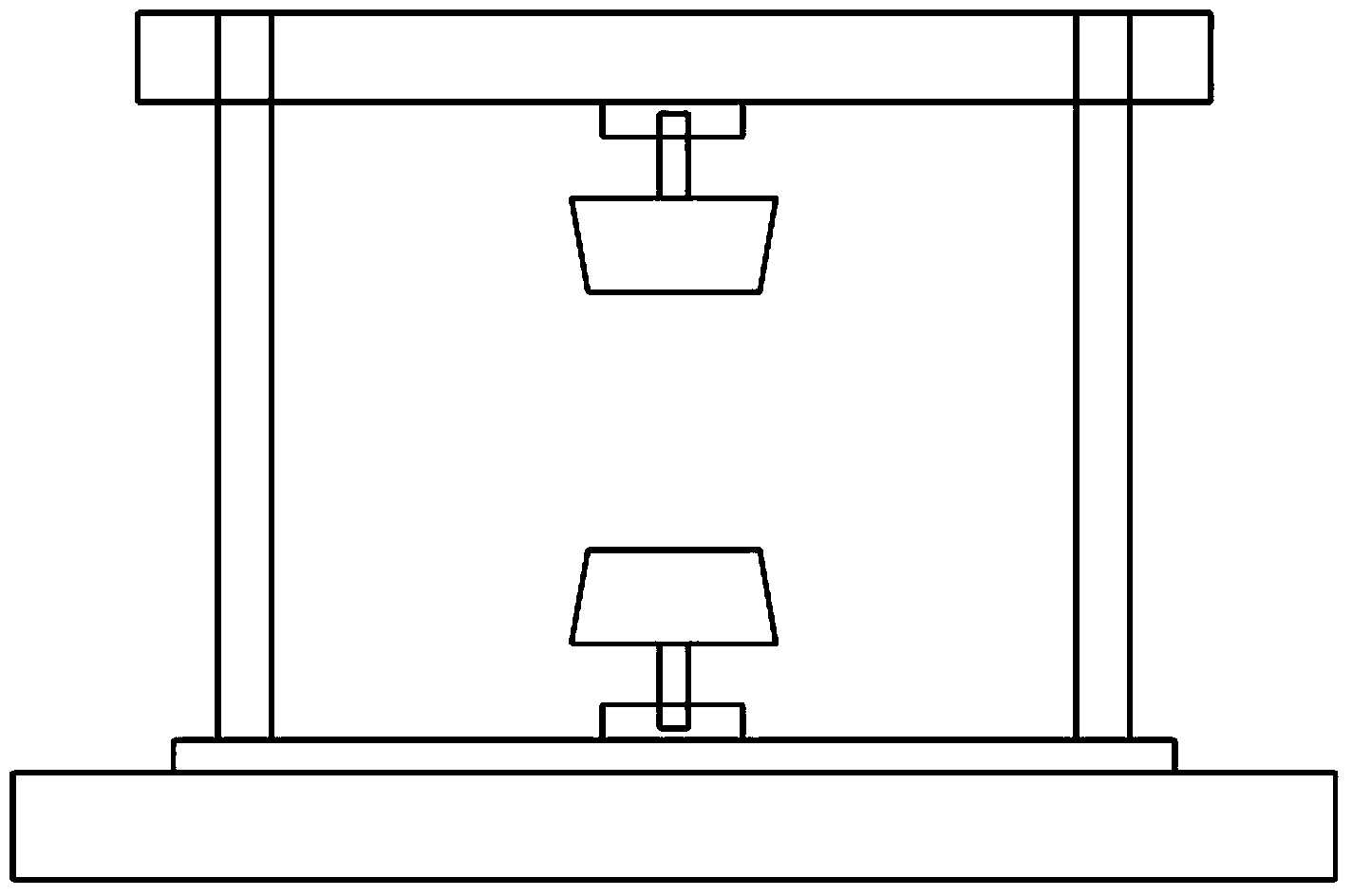

[0022] Specific implementation mode one: combine Figure 1 to Figure 4 Specific embodiments of the present invention will be described.

[0023] The present invention is a fatigue crack growth test system in a corrosive environment, which consists of a fatigue testing machine 7, a medium box 2, a solution circulation pump 4, a filter 3, a flow control valve 9, a solution tank 5, a fixture 8, and a crack observation system 6 and sample 1 composition. The connection relationship between them is as follows: the sample 1 is installed on the fixture 8, and the fixture 8 is connected to the fatigue testing machine 7; The circulation pump 4 transports the corrosion solution filtered by the filter 3 from the solution tank 5 to the medium box 2, and the solution in the medium box 2 flows back to the solution box 5 after the flow rate is controlled by the flow control valve 9; the crack observation system 6 passes The microscope records the crack growth by computer. The test system f...

specific Embodiment approach 2

[0032]Embodiment 2: The difference between this embodiment and Embodiment 1 lies in the design of sample 1. Sample 1 can be a plate with or without holes in the center, and the size parameters can be the same as those in Embodiment 1. The sample 1 can be in the shape of a rod or other structural forms, and the other design ideas and connection methods of the test system for fatigue crack growth test in a corrosive environment are the same as those in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 lies in the design of the corrosion solution. The corrosion solution can use NaCl brine solution of other concentrations, or other components of the corrosion solution. Fatigue crack growth test under corrosive environment Other design concepts and connection methods of the test system are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com