Test analysis method for bolt connecting piece fatigue crack expanding

A technology of fatigue crack growth and analysis method, which is applied in the field of experimental analysis of fatigue crack growth life prediction, and can solve problems such as unseen experimental analysis research methods and crack growth models

- Summary

- Abstract

- Description

- Claims

- Application Information

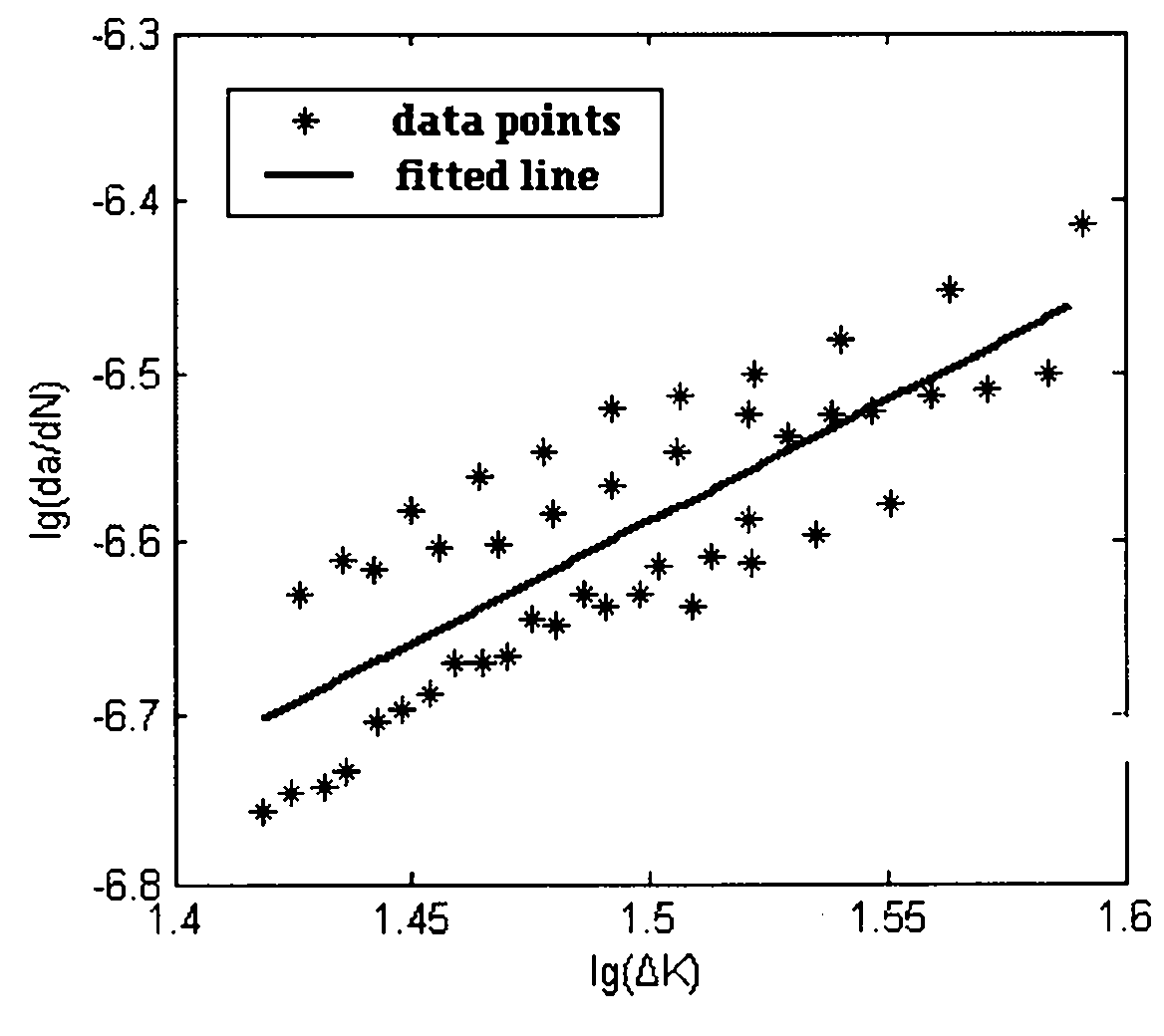

AI Technical Summary

Problems solved by technology

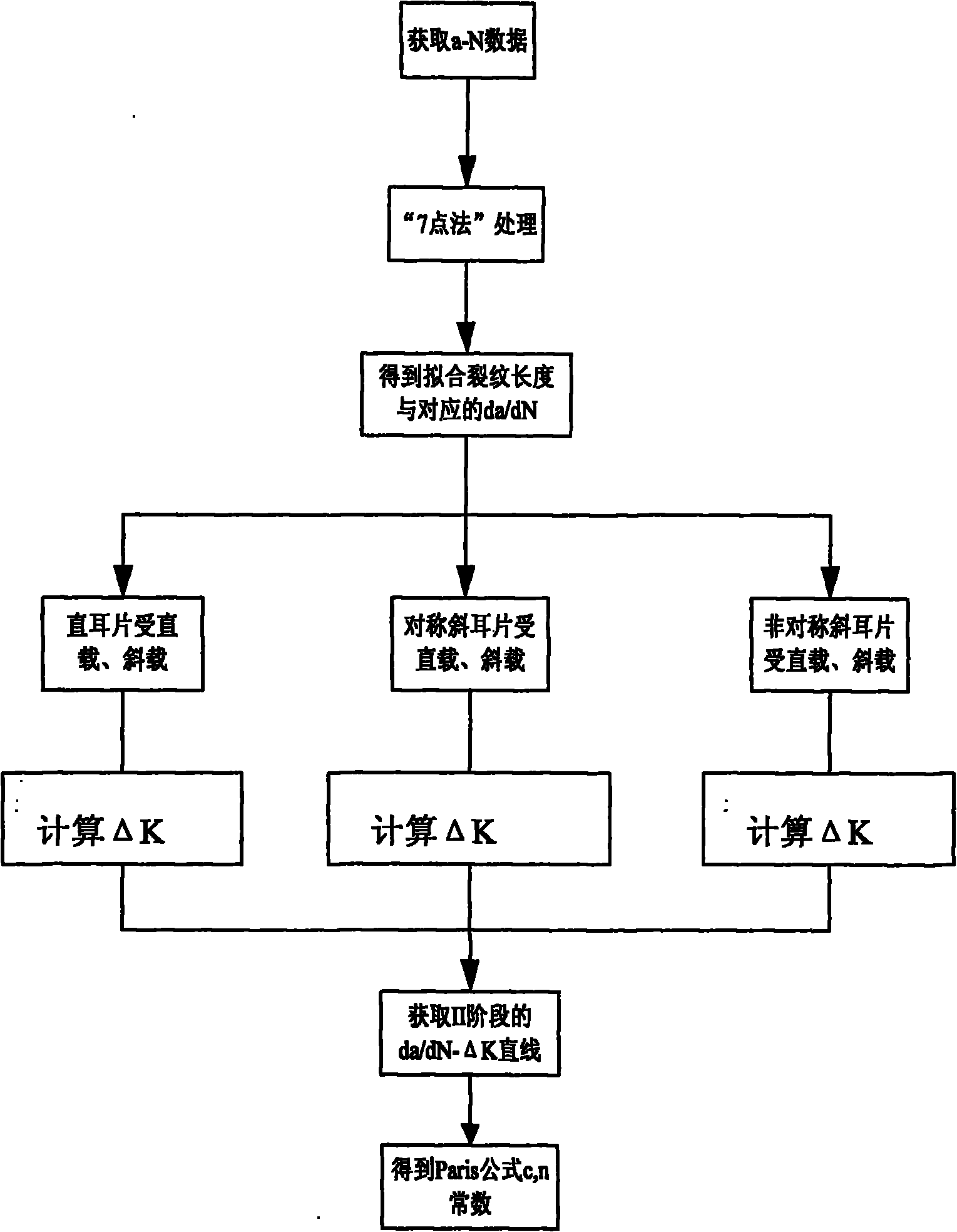

Method used

Image

Examples

Embodiment Construction

[0098] The present invention will now be further described in conjunction with the embodiments and accompanying drawings:

[0099] Test piece: the case where the straight lug is subjected to axial tensile load.

[0100] The ear piece material is 30CrMnSiA steel, with a thickness of 6.7, a total of 4 pieces. Size as shown? shown.

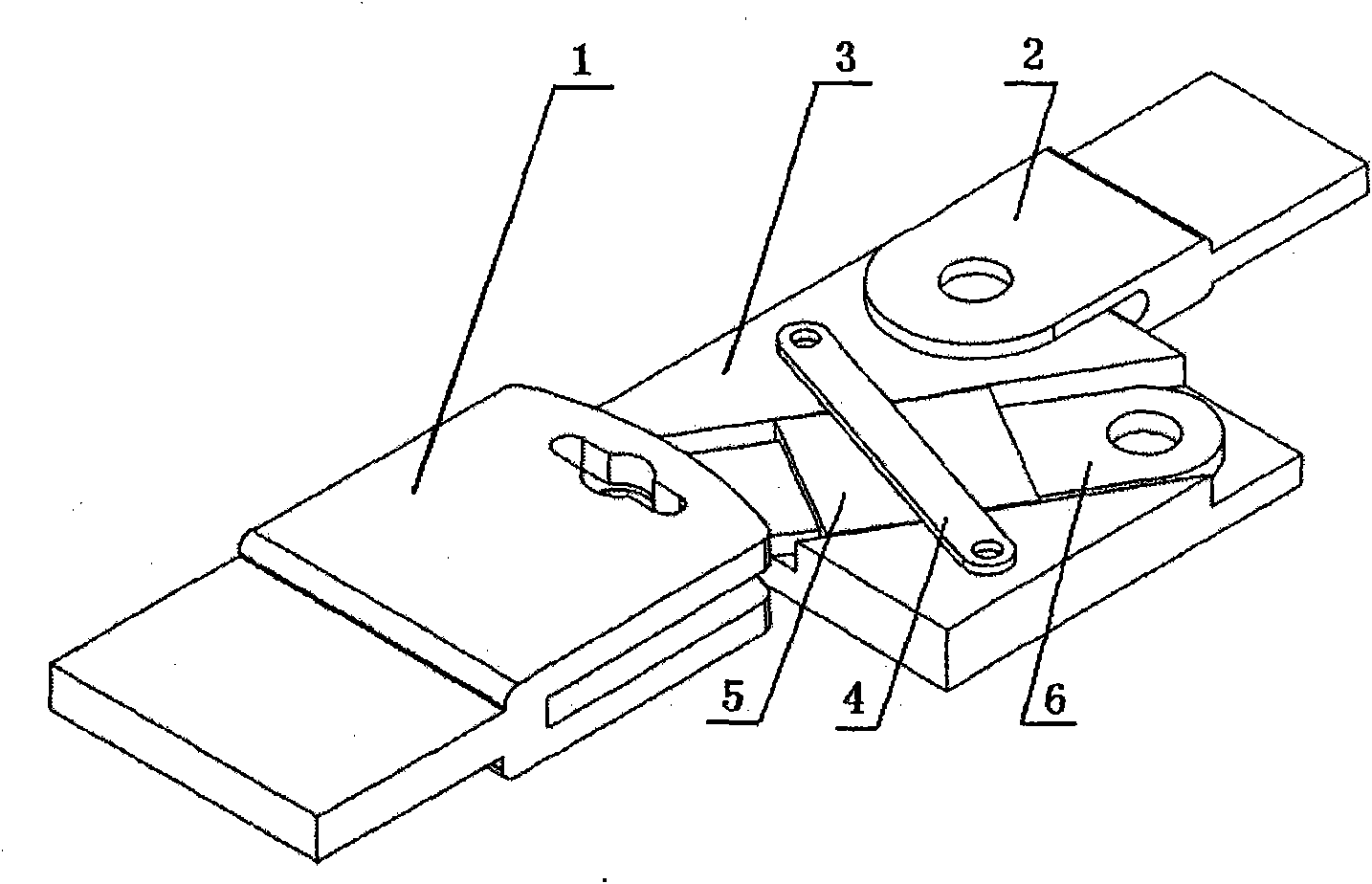

[0101] Step 1 Test the installation of the lugs:

[0102] Step (a): machining a penetrating notch with a depth of 1 mm along the radial direction at the edge of the hole at one end of the ear piece, the direction of which is perpendicular to the load direction; smooth the surface of the ear piece at the end of the notch along the load direction;

[0103] Step (b): connect the notch end of the lug with the fork ear of the crack end fixture (1) through bolts, and connect the other end with the fork ear of the crack-free end fixture (2;

[0104] Step (c): Use the lower chuck of the testing machine to clamp the end of the crack-end fixture (1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com