Dynamic crack length measurement method for machine vision fatigue crack propagation test

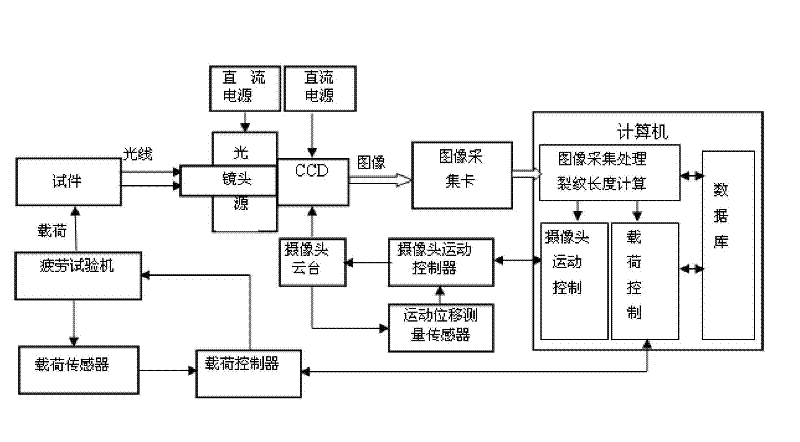

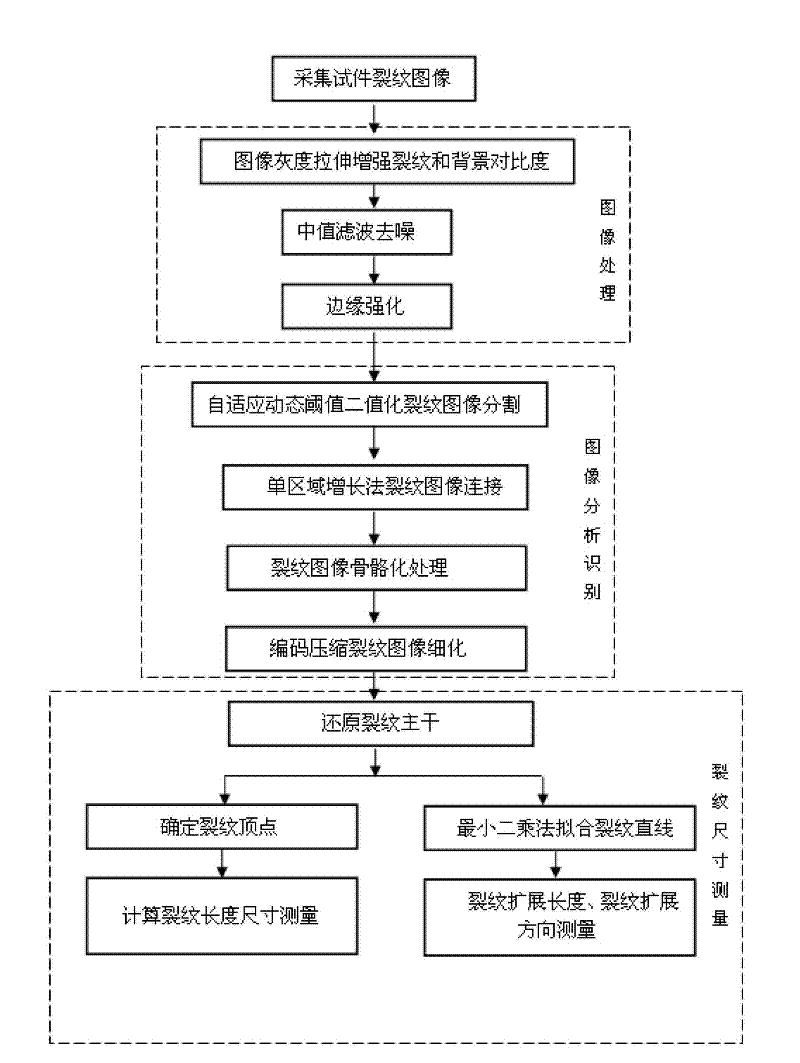

A technology of fatigue crack growth and crack length, which is applied in the direction of measuring device, using applied repetitive force/pulsation force to test material strength and strength characteristics, etc. It can solve the problems of cumbersome process, poor anti-interference, and inability to accurately measure crack length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0114] Step 1: This method combines Figure 4 The C(T) compact tensile fatigue test fixture shown in the figure is implemented by installing and positioning device, which consists of specimen 3, fixture 4, positioning sleeve 5, positioning screw 1, compression washer, lock nut 2, fixture installation and positioning method Composed of blue 6, the fixture assembly has two upper and lower fixtures, which are symmetrical with respect to the center line of the test piece. The test piece is installed in the middle of the upper and lower fixtures, through two equal-length positioning sleeves 5 and positioning screw 1, compression washers, and lock nuts 2 Install and position, make the force line HI of the test piece coincide with the center line of the fixture to ensure that the test load generated by the testing machine acts on the test piece along the force line of the test piece through the fixture superior. In the figure, 8 is the extended fatigue crack, and 7 is the prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com