Creep deformation-fatigue crack growth testing device and corresponding testing method

A fatigue crack growth and test device technology, applied in the field of measurement equipment, can solve the problems of complex operation, affecting the measurement accuracy of the flexibility method, and the inability to realize high-temperature crack growth testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

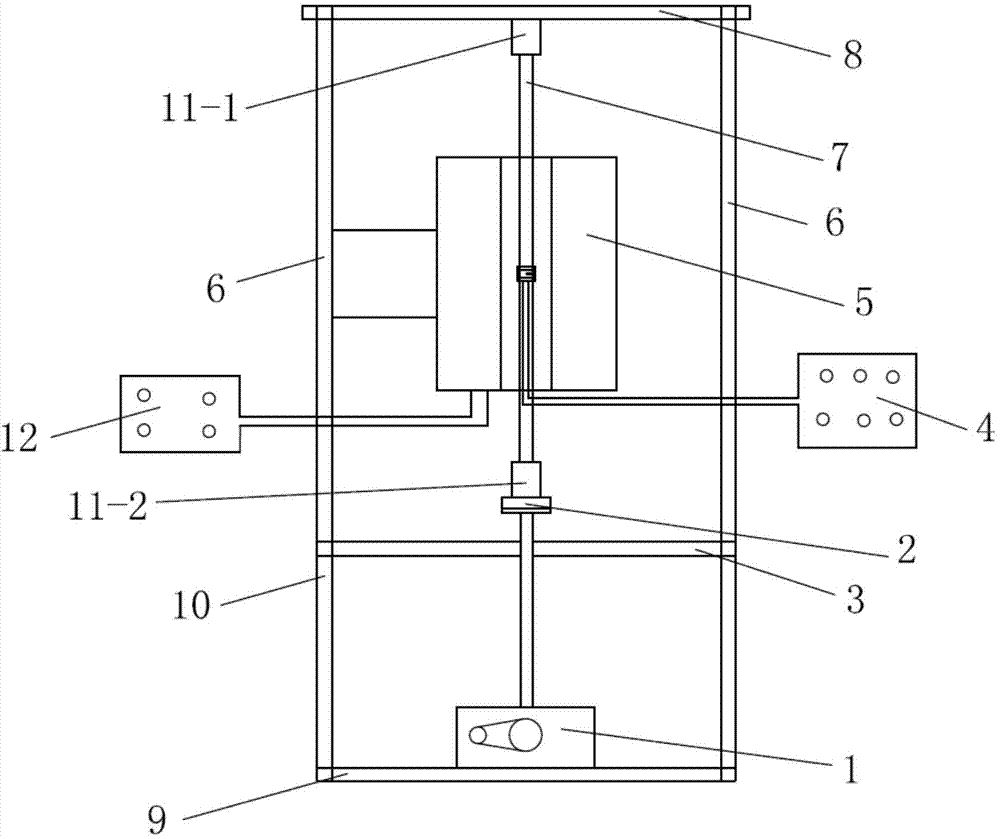

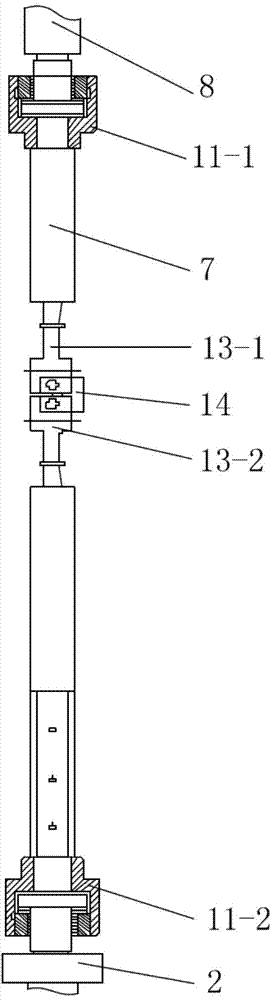

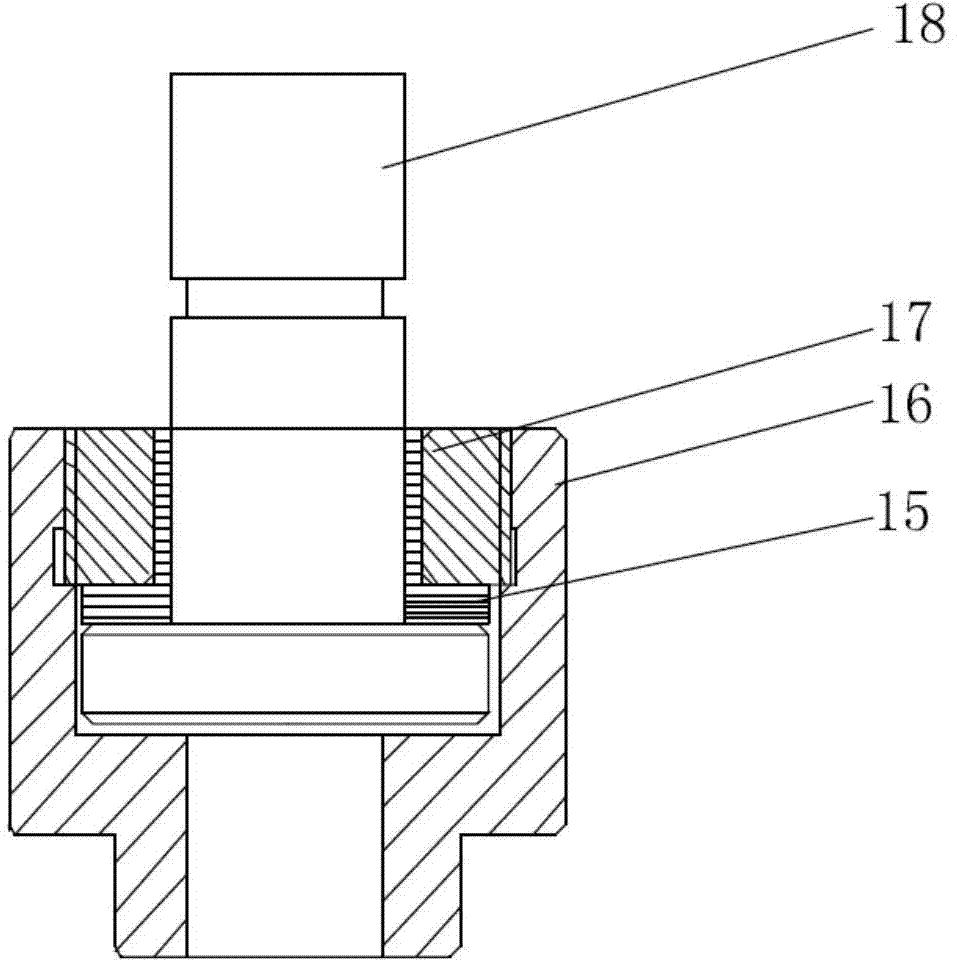

[0043] The creep-fatigue crack growth test device includes a loading system, a temperature control system 12 and a measurement acquisition system 4, the measurement acquisition system 4 includes a load line displacement measurement system and a crack length measurement system, and the loading system includes a fixture 13-1, 13-2, connecting rod device 7, force sensor 2 and insulating head 11-1, 11-2, the fixture includes upper fixture 13-1 and lower fixture 13-2, the upper and lower ends of the sample are respectively connected with the upper fixture 13-1 It is fixedly connected with the lower fixture 13-2, one end of the upper fixture 13-1 is connected with the sample 14, the other end of the upper fixture 13-1 is fixedly connected with the connecting rod device 7, and the upper connecting rod device 7 is connected with the upper insulating h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com