Machining production line for sheet metal

A technology of sheet metal and production line, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as failure to provide, and achieve the effect of ensuring processing accuracy and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

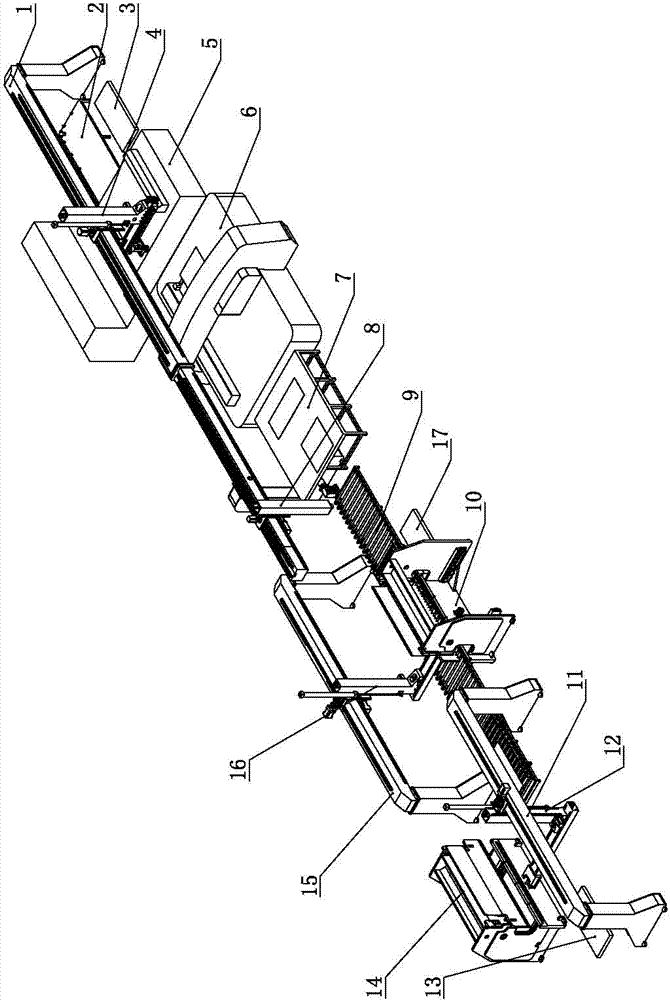

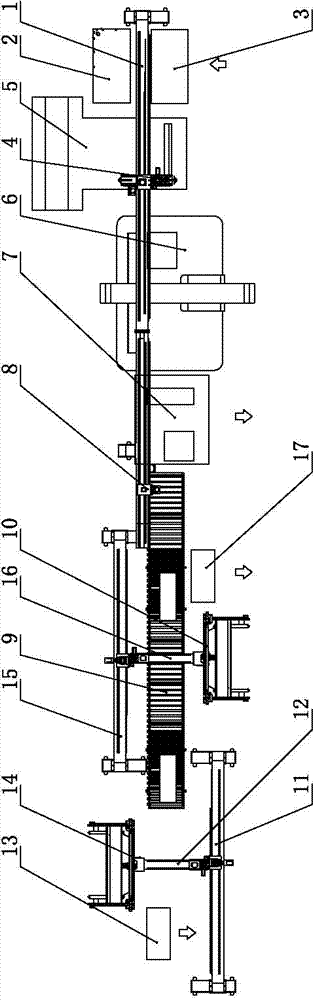

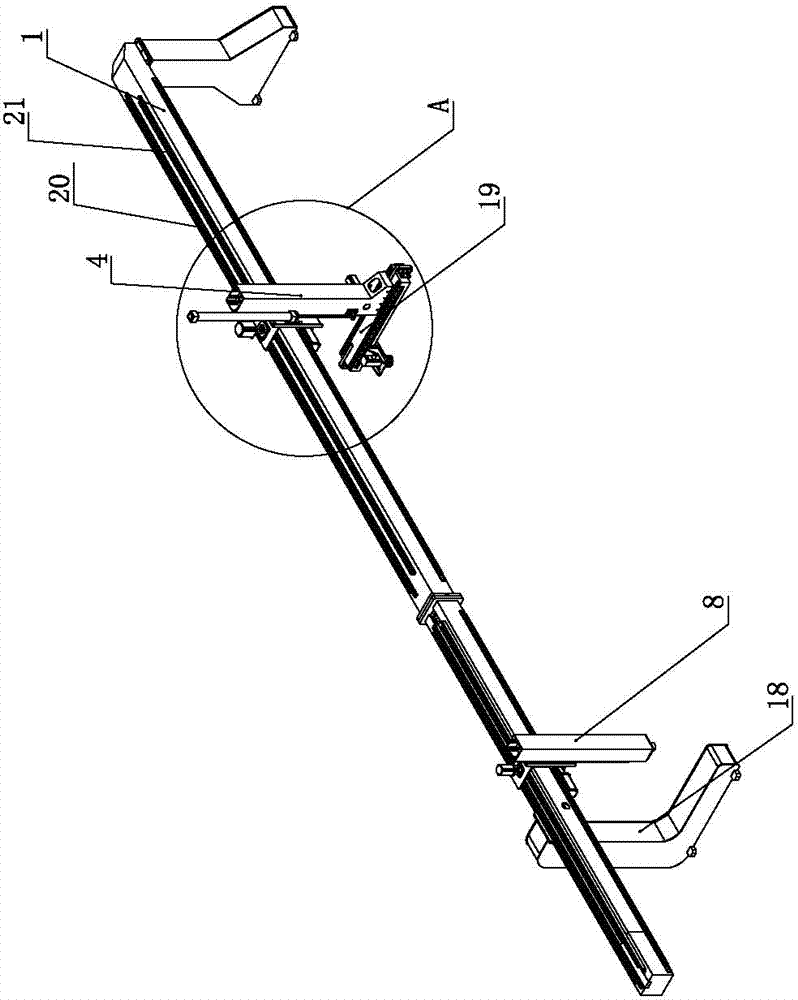

[0031] As shown in the figure, it is a sheet metal processing production line. Its structure mainly includes CNC shearing machine 5, CNC punching machine 6, CNC bending machine 10 and CNC bending machine two 14 arranged in sequence along the X axis. The feed side of the board machine 5 is provided with a raw material rack 3 and a positioning table 2. A first beam 1 is provided above the CNC shearing machine 5 and the CNC punching machine 6, and the first beam 1 crosses the CNC shearing machine 5 and the CNC punching machine at both ends 6. The raw material rack 3 and the positioning table 2 are respectively arranged below the two sides of the front end of the first cross beam 1. The front end of the first cross beam 1 is provided with a feeding manipulator 4 that can move along the first cross beam 1. The rear end of the first cross beam 1 The unloading manipulator 8 that can move along the first beam 1 is provided. The feeding manipulator 4 and the unloading manipulator 8 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com