Four-position full automatic locker moulding machine and method thereof

A fully automatic, four-station technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as being unfavorable to daily management and maintenance, increasing the complexity of the molding mechanism, and unfavorable to surrounding environmental protection. and replacement, improve the utilization rate and production efficiency, the effect of stable operation of trimming feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

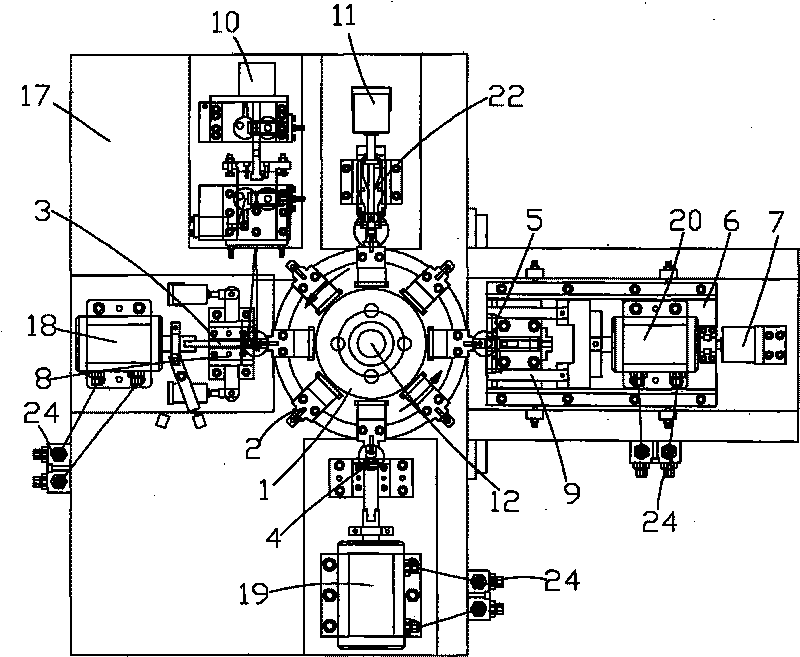

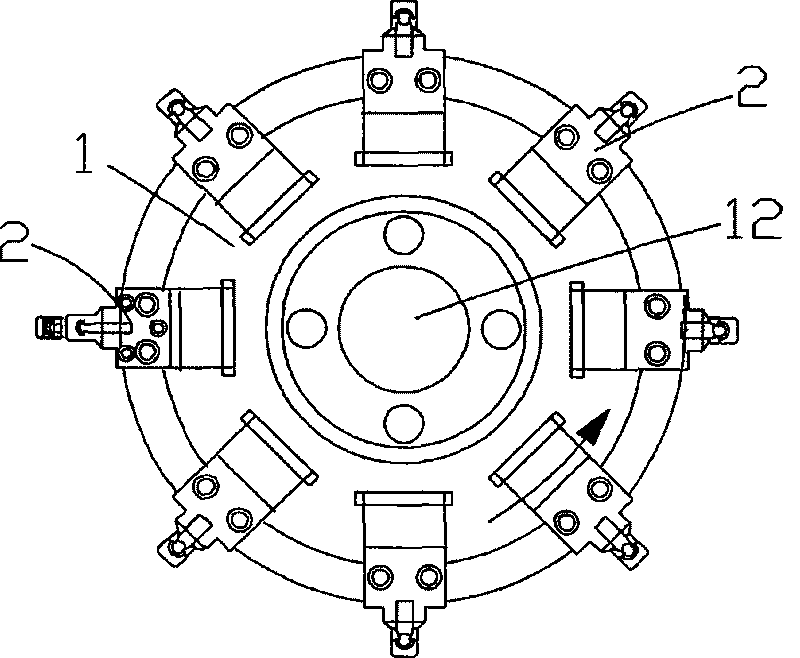

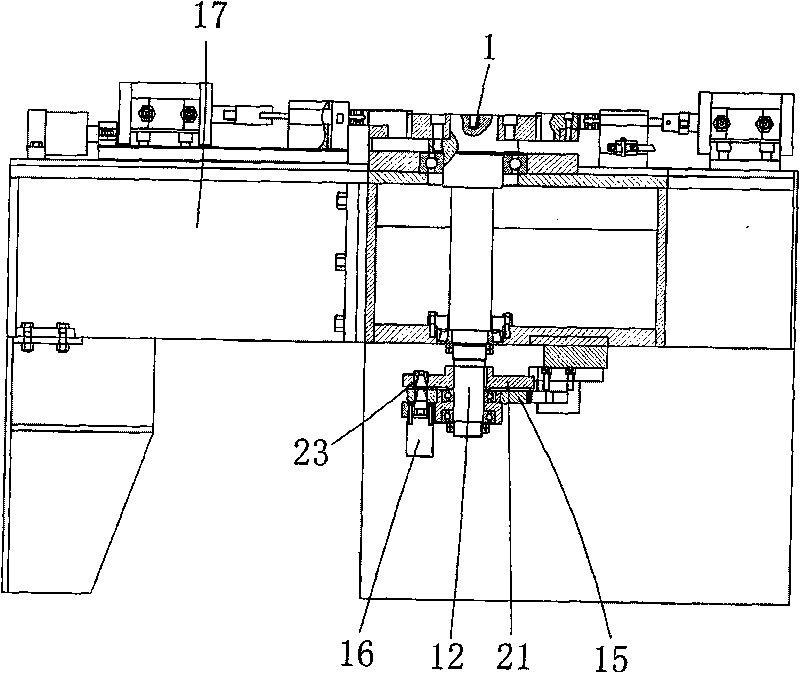

[0029] Such as Figure 1 to Figure 4 As shown, the description of the icon numbers is as follows: core turntable 1, core seat 2, cutting knife 3, forming die 4, trimming knife 5, loose block 6, push loose block cylinder 7, movable knife seat 8, trimming bevel Block 9, feeding cylinder 10, unloading cylinder 11, rotating shaft 12, indexing cylinder 13, rack 14, indexing fan gear 15, latch cylinder 16, platform 17, cutting cylinder 18, forming cylinder 19 , Trimming cylinder 20, positioning disc 21, unloading platform 22, positioning sleeve 23, pneumatic valve 24.

[0030] In the embodiment of the present invention, the four-station automatic lock clip forming machine includes a feeding mechanism, a cutting mechanism, a forming mechanism, a discharge mechanism and a station changing mechanism installed on the same platform 17; the station chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com