Gantry propeller integral blade abrasive belt grinding machine

A technology of integral blade and abrasive belt grinder, applied in the direction of abrasive belt grinder, grinding machine, grinding/polishing equipment, etc., can solve the problems of increased labor intensity, poor processing accuracy, uneven grinding thickness, etc., to ensure the processing accuracy and Surface quality, reduced management and production costs, uniform grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

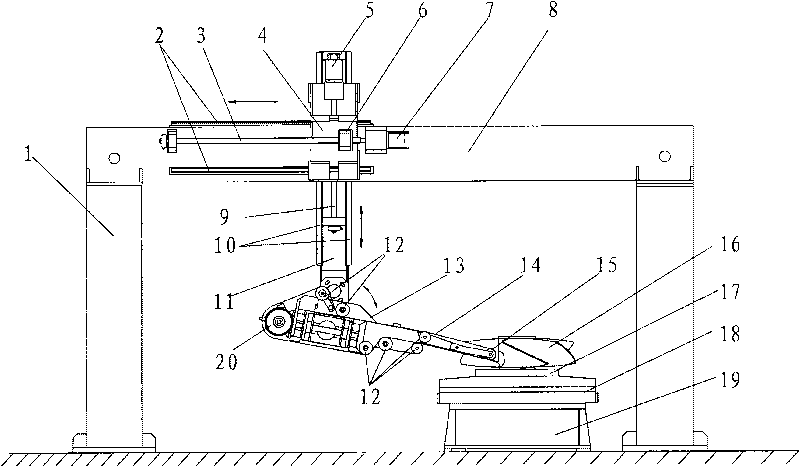

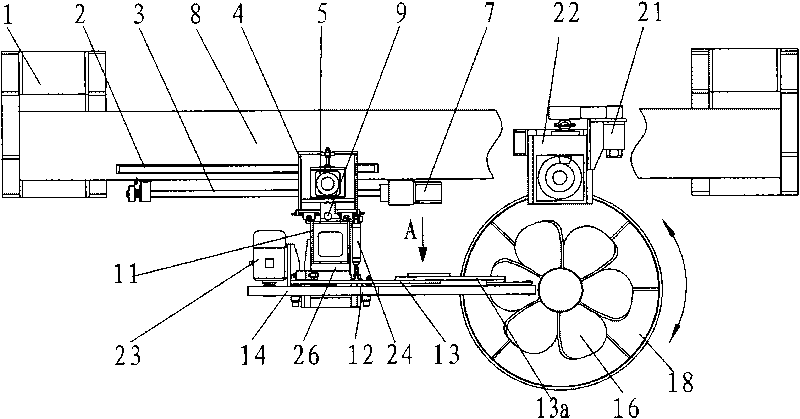

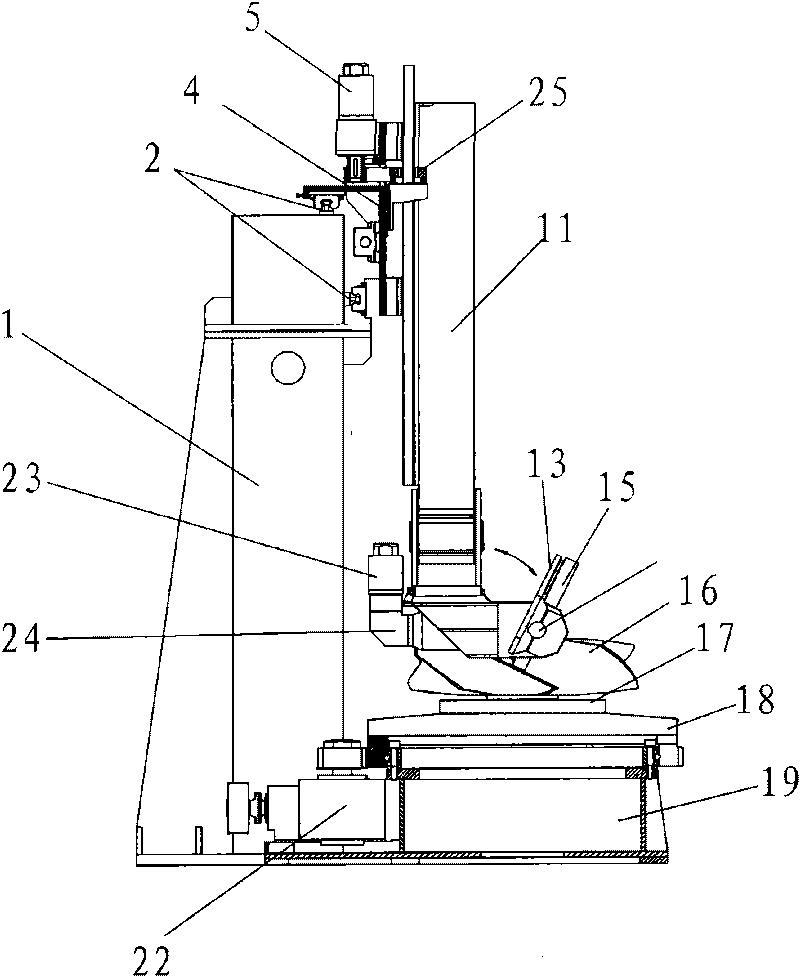

[0029] figure 1 It is a front view of the structure of the present invention, figure 2 It is a top view of the structure of the present invention, image 3 It is the left side view of the structure of the present invention (for convenience of viewing, this view omits the grinding head drive motor), Figure 4 for figure 2 View along the A direction, as shown in the figure: the gantry type propeller integral blade abrasive belt grinder of this embodiment includes a bed, a grinding head mechanism, a grinding head feeding mechanism and a workpiece orientation adjustment mechanism; the bed is composed of two A gantry structure composed of a brace 1 and a beam 1a;

[0030] Grinding head mechanism comprises grinding head frame 13 and the abrasive belt 14 that is arranged on the grinding head frame 13, driving wheel 20, contact wheel 15, tension pulley 12 and grinding head drive motor 23, and described abrasive belt 14 walks around driving wheel 20 And the contact wheel 15 is te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com