Method for machining oblique angle holes distributed in shaft parts

A processing method and technology for angled holes, which are applied in metal processing equipment, drilling dies for workpieces, metal processing machinery parts, etc. The effect of production efficiency, convenient clamping and labor time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

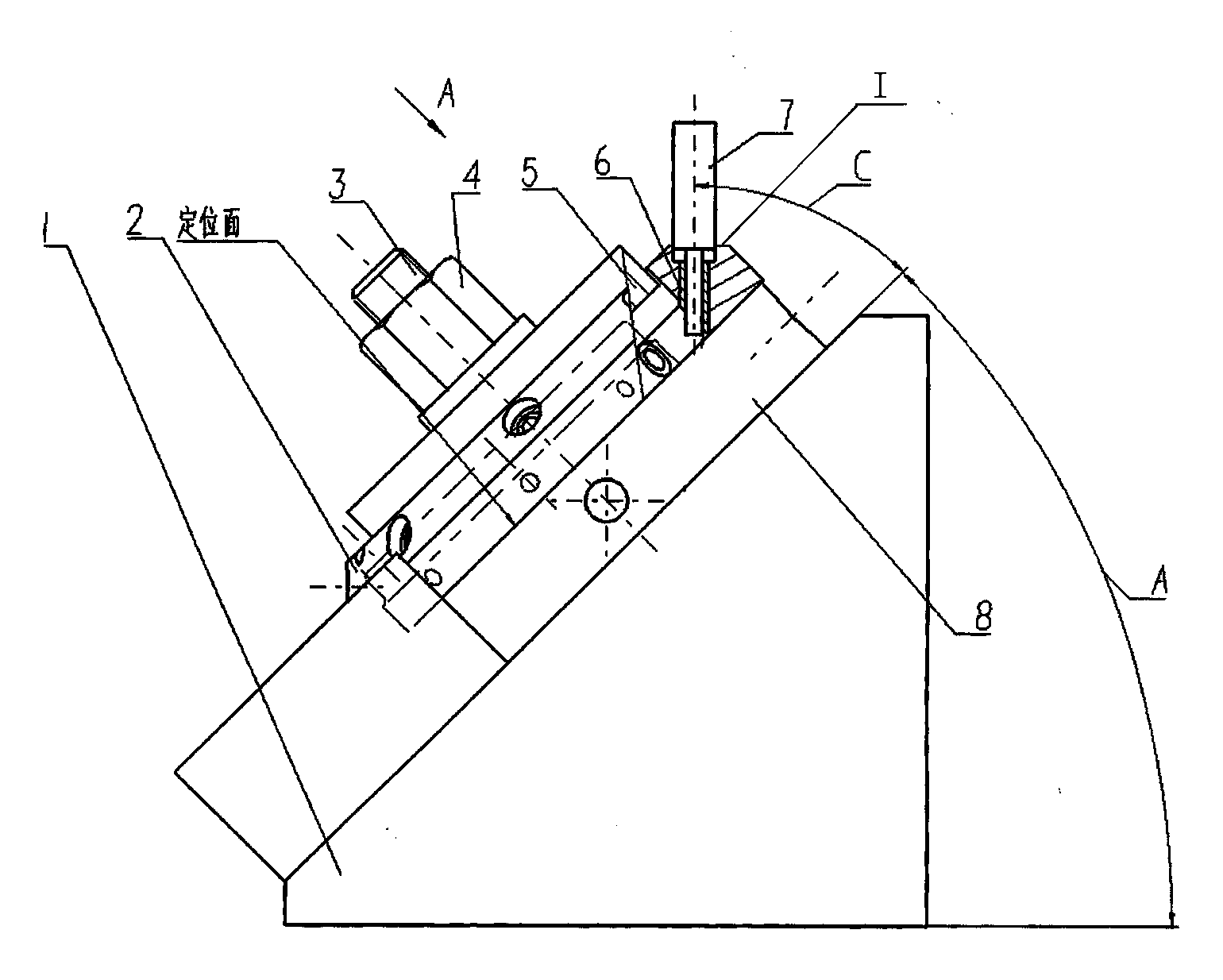

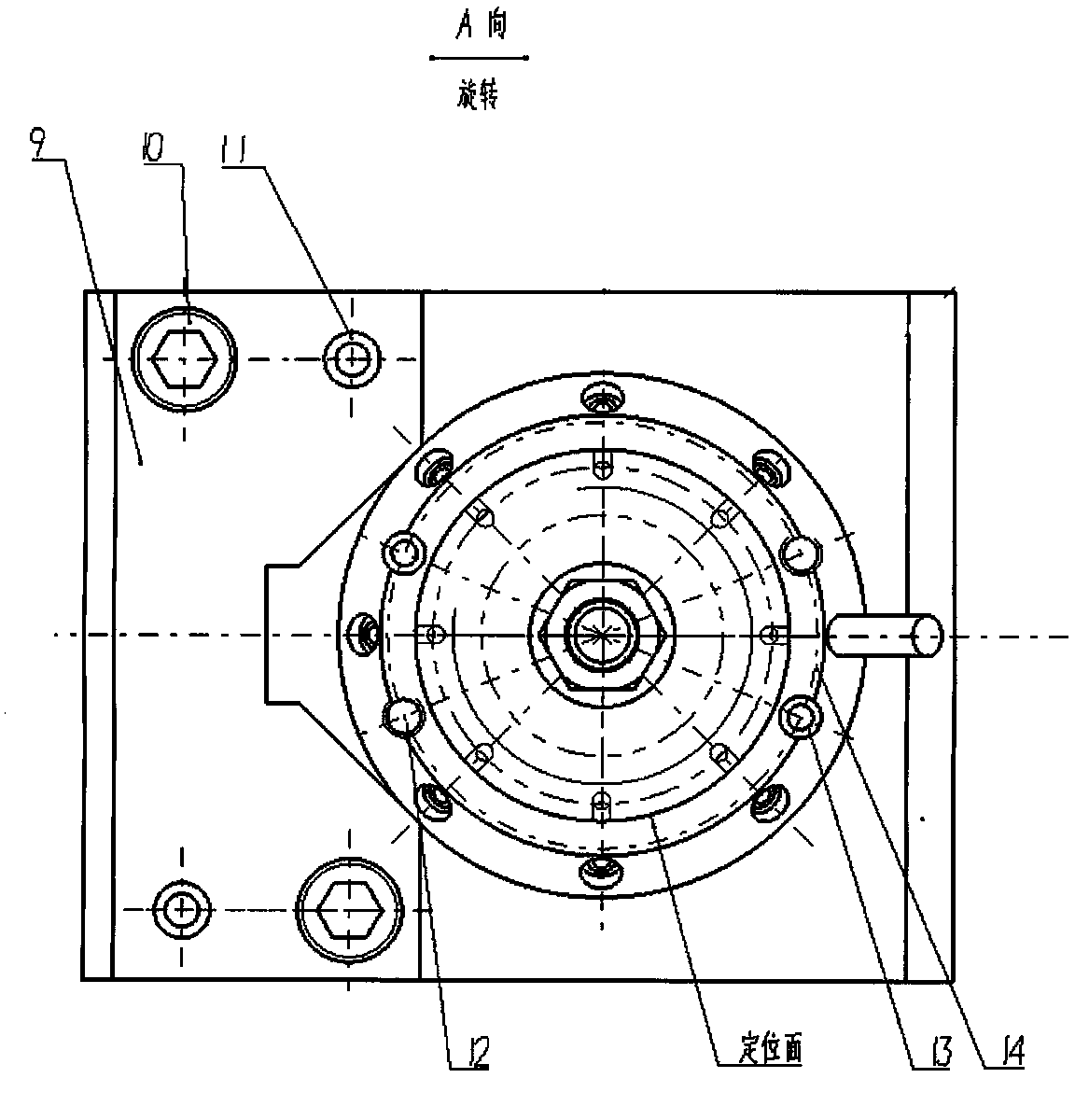

[0016] Such as figure 1 As shown, the flexible fixture for machining shaft parts with evenly distributed oblique angle holes is composed of three parts: angle plate 1, V-shaped block 9 and part positioning and clamping device, wherein V-shaped block 9 is fixed by hexagon socket head cap screws 10 and cylindrical pins 11 On the angle plate 1, the V-shaped notch of the V-shaped block 9 cooperates with the outer circle clearance of the part positioning clamping device; Placed on the slope of the angle plate 1 and limited by the V-shaped block 9, the hollow shaft part 14 is placed above the positioning plate 8, the hollow shaft part 14 is attached to the positioning plate 8, and the drilling template 2 is set on the hollow shaft On the part 14, the drilling template 2 is connected with the positioning plate 8 through the hexagon socket head cap screw 12 and the cylindrical pin 13, and the pressure plate 5 is arranged above the hollow shaft part 14, and the tail of the stud 3 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com