Spraying mechanism based on four-degree-of-freedom spraying module

A technology of spraying mechanism and degrees of freedom, which is applied in the direction of devices and coatings for coating liquids on the surface, and can solve the problems of difficult to reach the requirements of fairing spraying equipment and the level of controlled research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

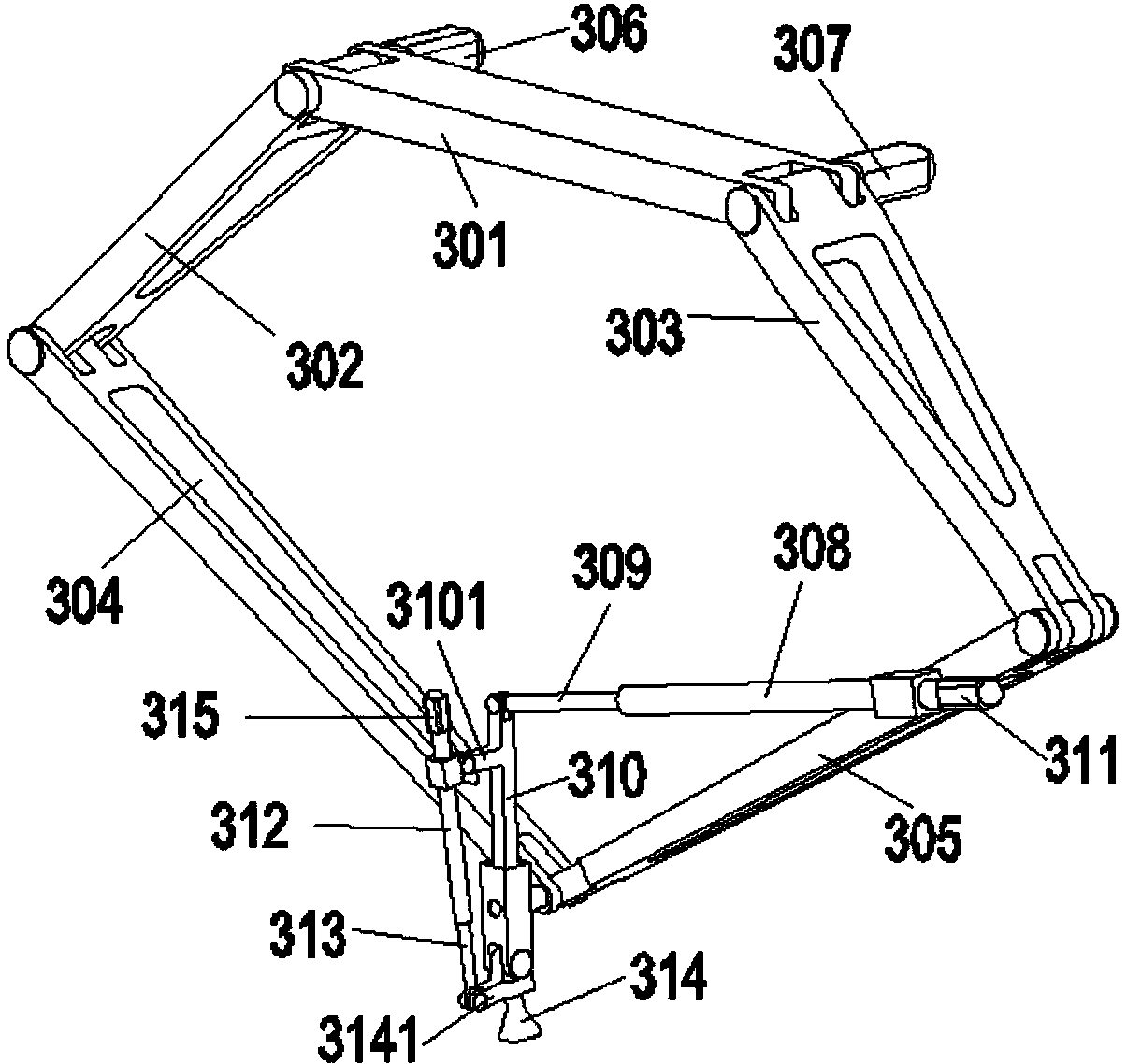

[0018] The spraying mechanism of the present invention based on the four-degree-of-freedom spraying module is described in detail as follows in conjunction with the accompanying drawings and embodiments:

[0019] The present invention is described by taking the spraying mechanism of a carrier rocket fairing as an example, but it can be understood that those skilled in the art can properly adjust the structure and quantity of the spraying module according to the requirements on the basis of the above structure, or adjust the overall structure Obvious replacements or modifications should be within the protection scope of the technical solutions of the present invention.

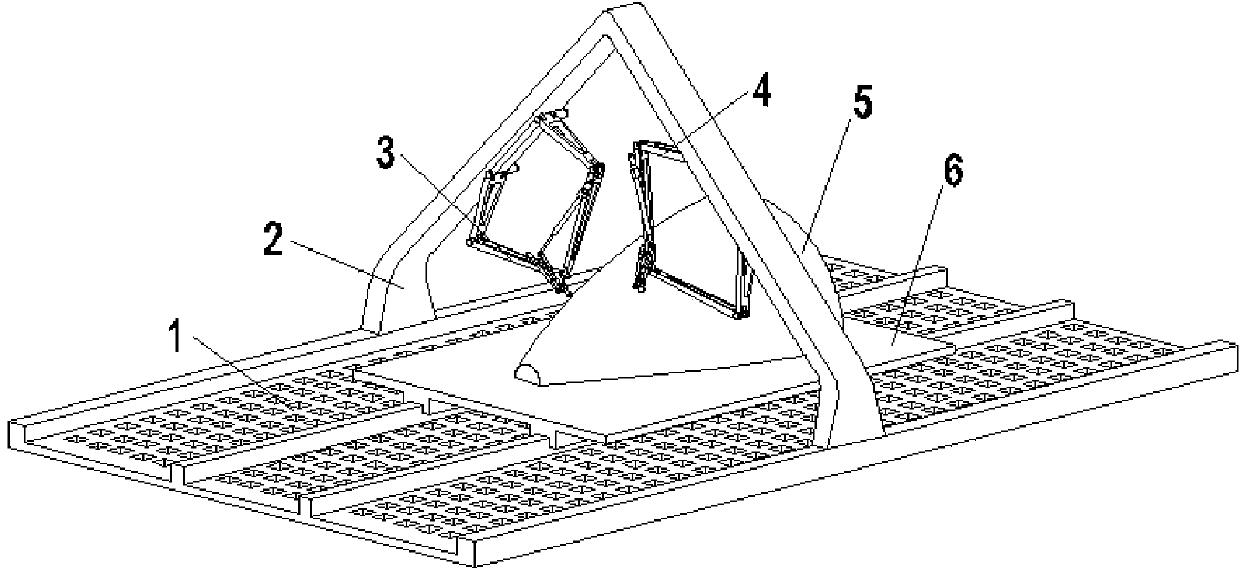

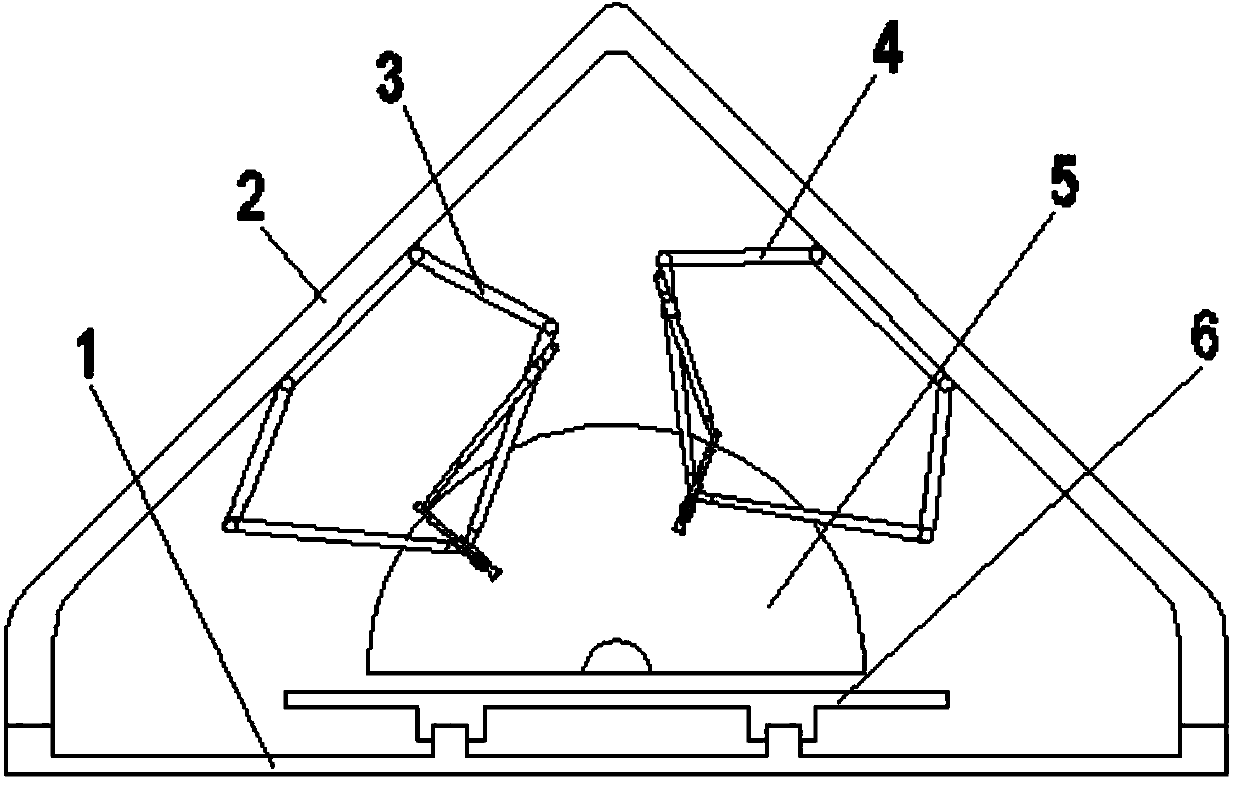

[0020] The structure of an embodiment of the spraying mechanism based on the four-degree-of-freedom spraying module of the present invention is as follows: figure 1 , 2 As shown, the spraying mechanism of the present invention mainly includes a base 1, a gantry frame 2, a moving platform 6 and a spraying opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com