Composite ultrasonic elliptical vibratory cutting device suitable for making shark skin imitation structural skin

A technology of elliptical vibration and cutting device, which is applied in the direction of driving device, fluid using vibration, feeding device, etc., can solve the problems of low efficiency and diamond tool wear, and achieve the effect of processing a wide range of materials, increasing service life and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

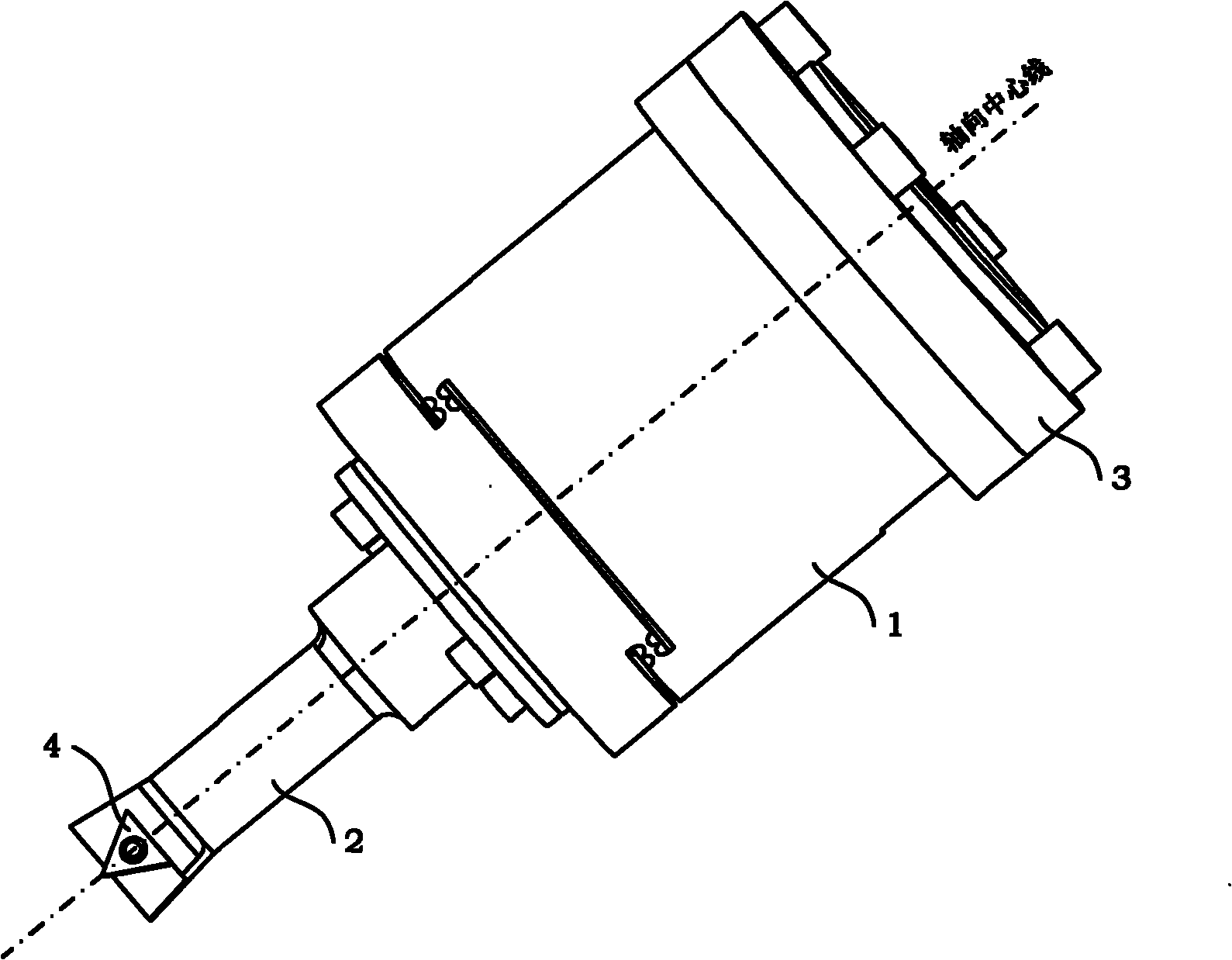

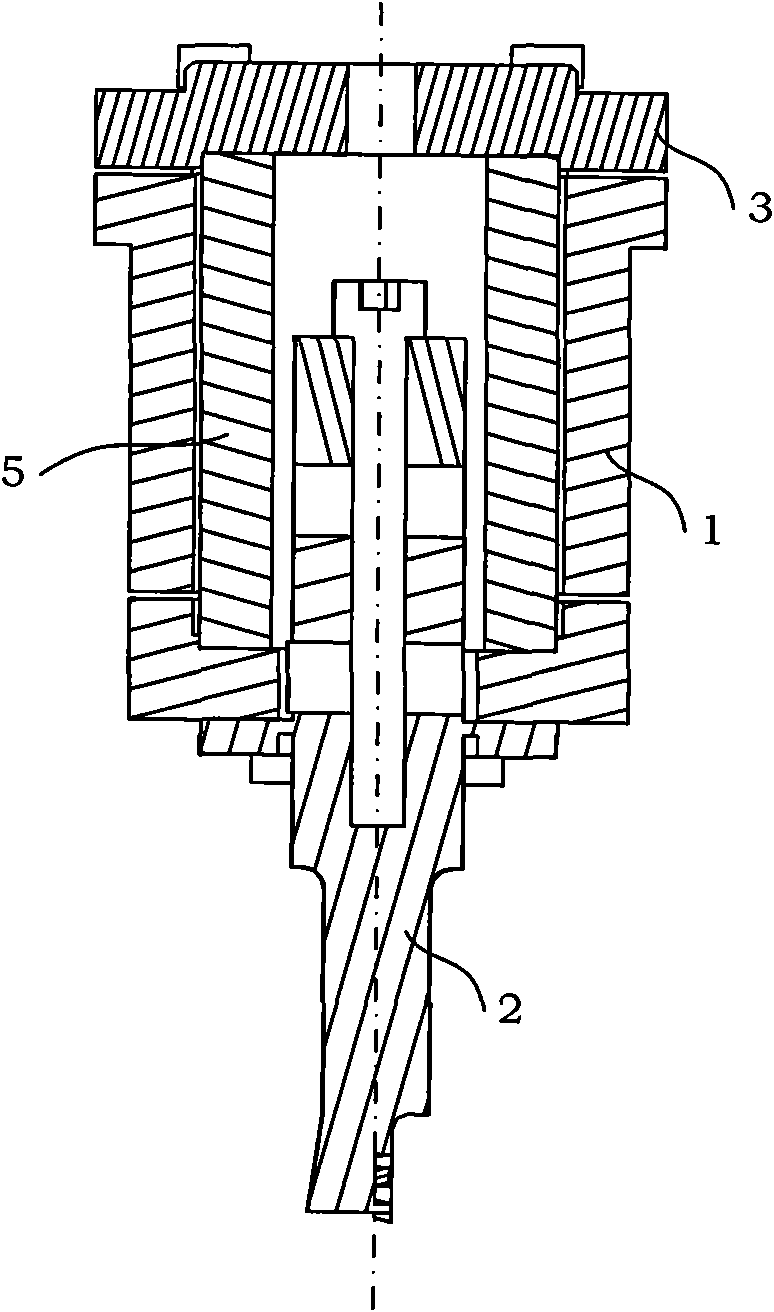

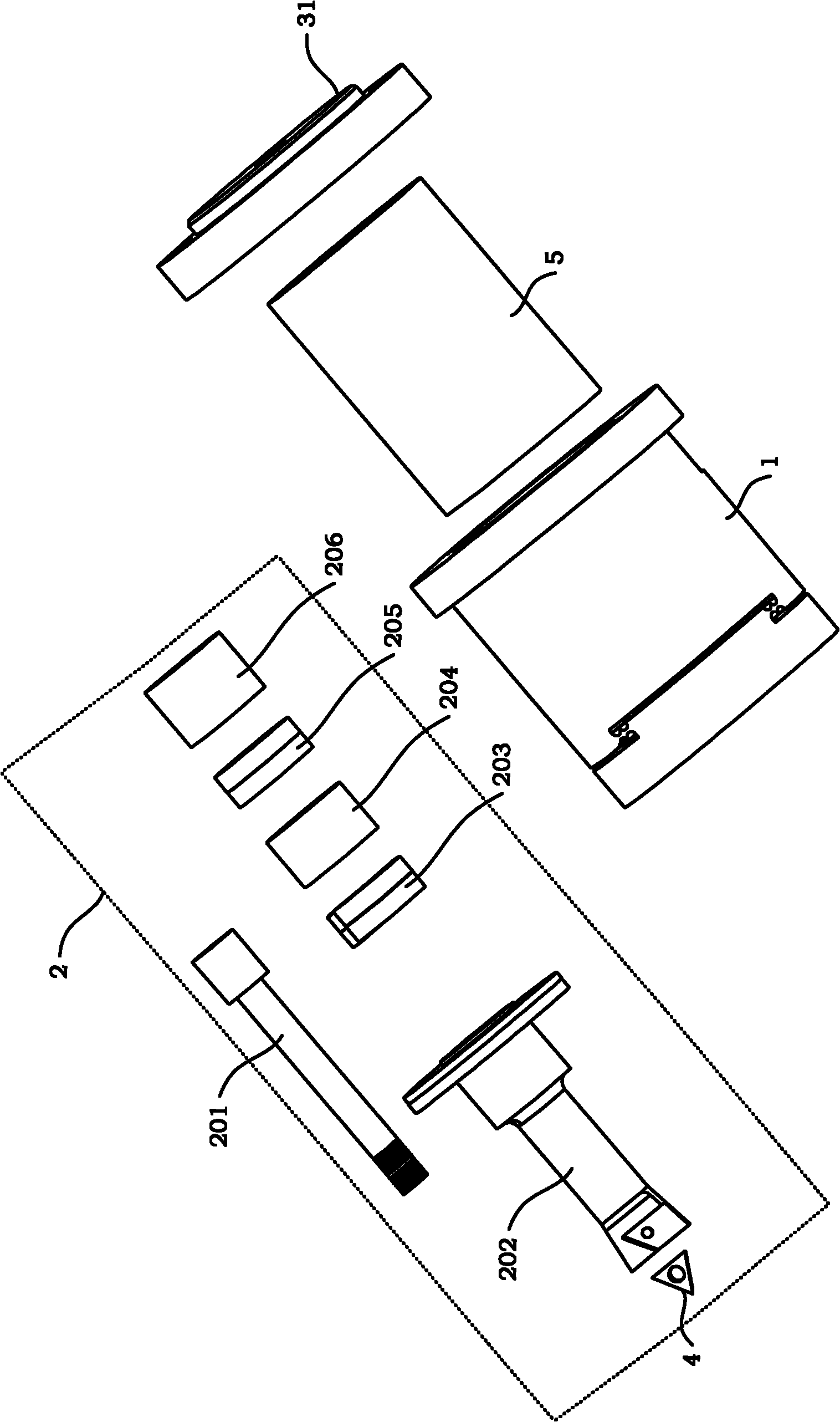

[0036] Sharks known as the "shark skin effect" have evolved through continuous self-adaptation, self-learning and self-organization to meet their own survival needs and to reasonably regulate the external fluid medium. The non-smooth grooved drag-reducing surface. It relies on microscale or nanoscale scale grooves and mucus secretion to achieve high-speed cruising and fast maneuvering. For this reason, people have tried various means to imitate or reproduce the drag reduction effect of shark skin, but its scale configuration mechanism and mucus secretion mechanism are difficult to achieve with existing human means. In order to obtain the topography of the imitation sharkskin surface, the present invention adopts the excitation source (the first excitation source 203, the second excitation source 205) that two different structures are set on the same fastening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com