Annular standing wave linear ultrasonic motor oscillator

A linear ultrasonic motor, vibrator technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of high manufacturing cost, complex structure, inconvenient design, etc. Achieve the effect of low manufacturing cost, simple driving circuit and easy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

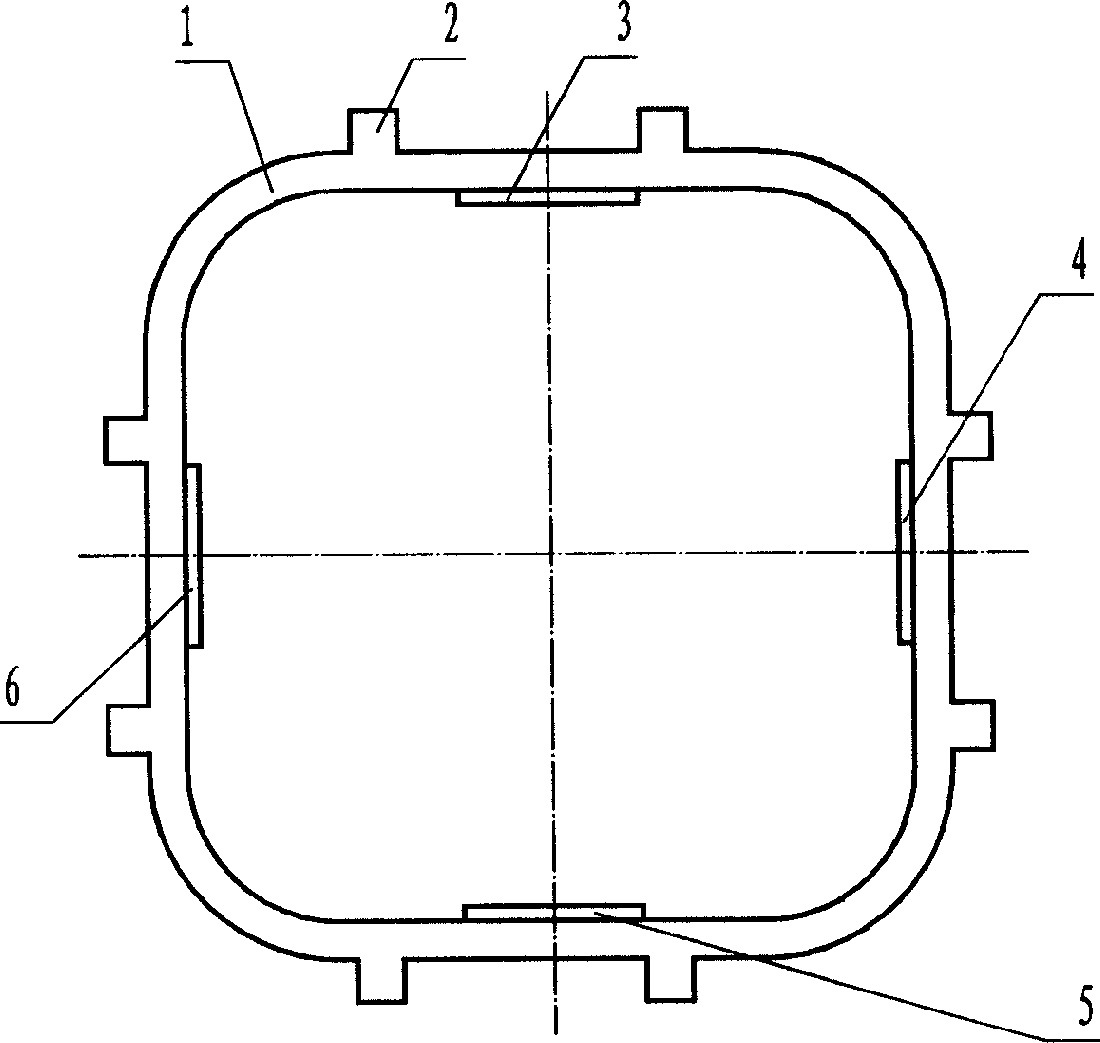

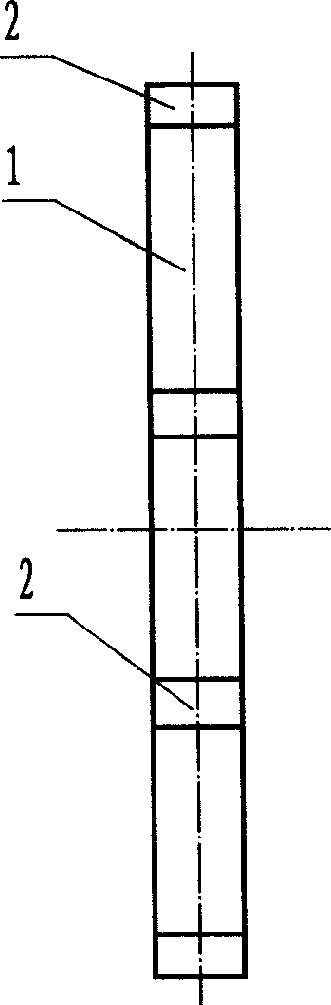

[0034] Such as figure 1 with figure 2 As shown, the present invention is made of metal elastic body 1 and piezoelectric ceramic sheets 3, 4, 5, 6, and several oscillator teeth 2 are arranged on metal elastic body 1, and described metal elastic body 1 is made of four straight beams The square ring formed by one section and four circular arc sections is closed, and the straight beam section is connected by circular arc transition, and the two in-plane bending vibration modes of the same order and frequency or approximately the same frequency of the ring oscillator are used to work; the pressure The electric ceramic sheets 3, 4, 5, and 6 are 4 pieces or a multiple of 4, and the piezoelectric ceramic sheets 3, 4, 5, and 6 are pasted on the inner side of the straight beam section of the square annular metal elastomer 1, and the piezoelectric ceramic sheets 3, 4 , 5, and 6 are divided into two groups, piezoelectric ceramic sheets 3 and 5 form a group, and piezoelectric ceramic sh...

Embodiment 2

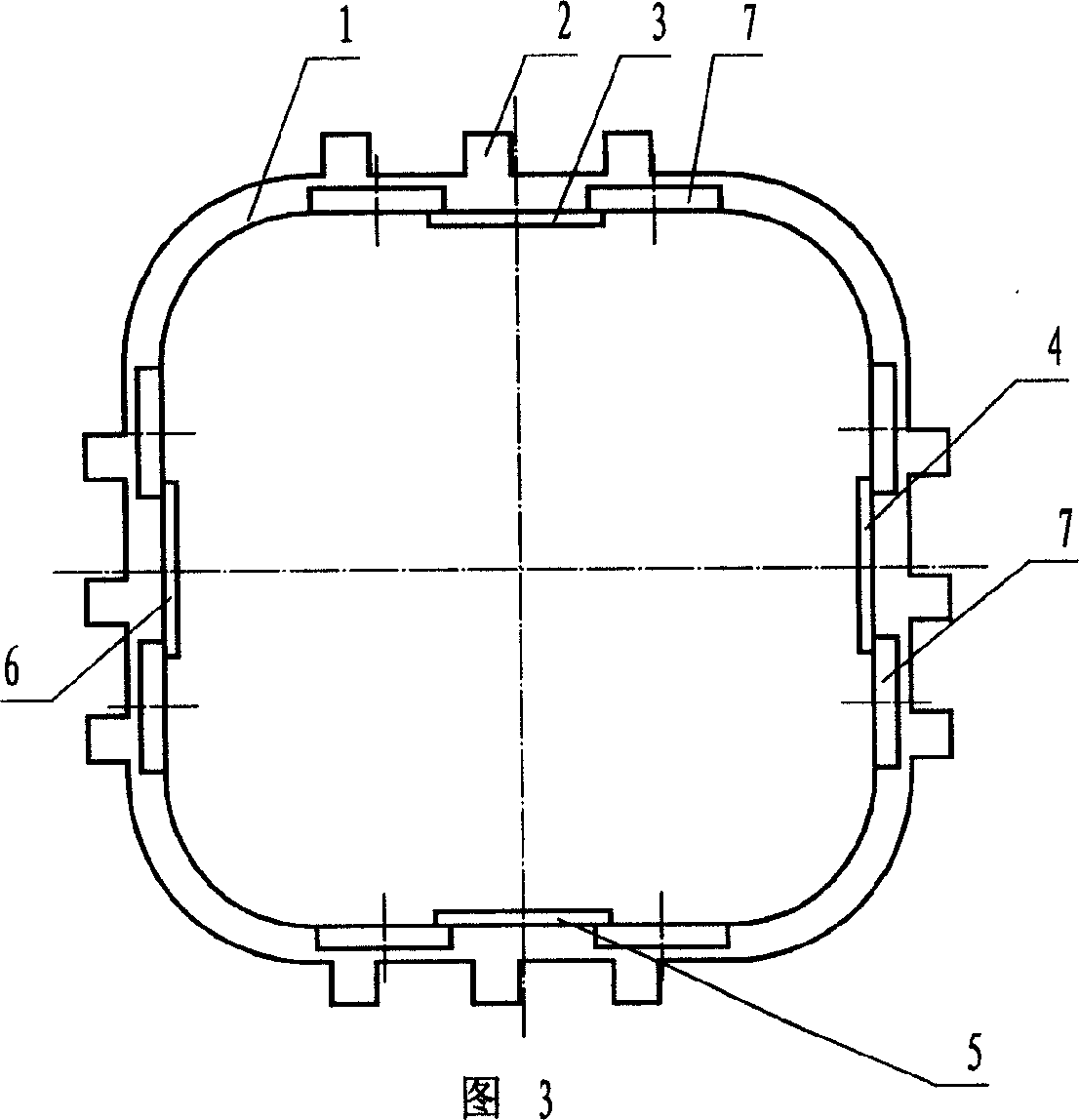

[0037] Figure 3 and Figure 4 As shown, its structure is as in Embodiment 1, the difference is that three vibrator teeth 2 are provided in each straight beam section, and multiple vibrator teeth 2 can also be provided in each straight beam section; There are also fixed wings 7 on both sides of the beam section, so as to fix it on the straight beam section. After the vibrator is fixed, it becomes a stator, which is suitable for non-self-propelled ultrasonic motors that drive the movement of the mover.

Embodiment 3

[0039] As shown in Fig. 5 and Fig. 6, the present invention is made of metal elastic body 10 and piezoelectric ceramic sheets 8, 9, and several vibrator teeth 2 are arranged on metal elastic body 10, and described metal elastic body 10 is made of two A long ring formed by a straight beam section and two circular arc sections closed, the straight beam section is connected by a circular arc transition, and two in-plane bending vibration modes of the same order and frequency or approximately the same frequency of the ring oscillator are used to work; the said The piezoelectric ceramic sheets 8 and 9 are 8 pieces or a multiple of 8, and the piezoelectric ceramic sheets 8 and 9 are pasted on the inner side of the straight beam section of the long annular metal elastic body 10, and the piezoelectric ceramic sheets 8 and 9 are divided into two groups, and the piezoelectric ceramic sheets 8 and 9 are divided into two groups, The electric ceramic sheet 8 is a group, and the piezoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com