High-transparency polyurethane elastomer and preparation method thereof

A polyurethane elastomer and transparent technology, applied in the field of polymers, can solve the problems of transparency, high transparency and durability, unsatisfactory thermal stability, and the inability of polyurethane elastomers to have both transparency and good mechanical properties, optical transparency and barrier properties. and other problems to achieve the effect of overcoming the reduction of material uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

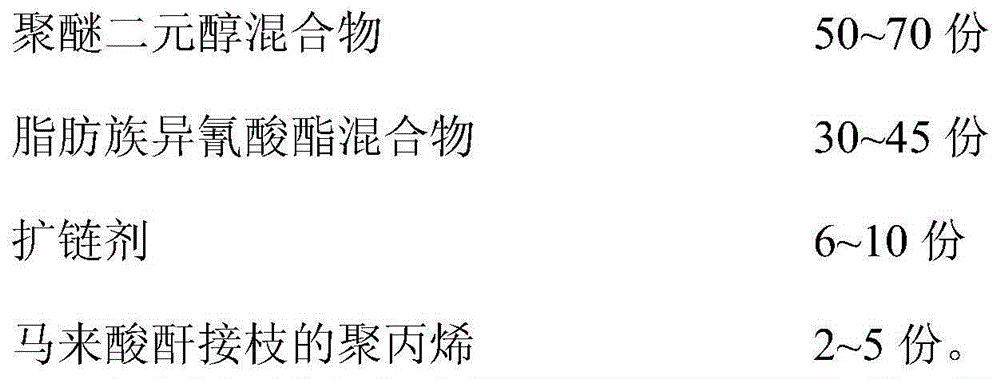

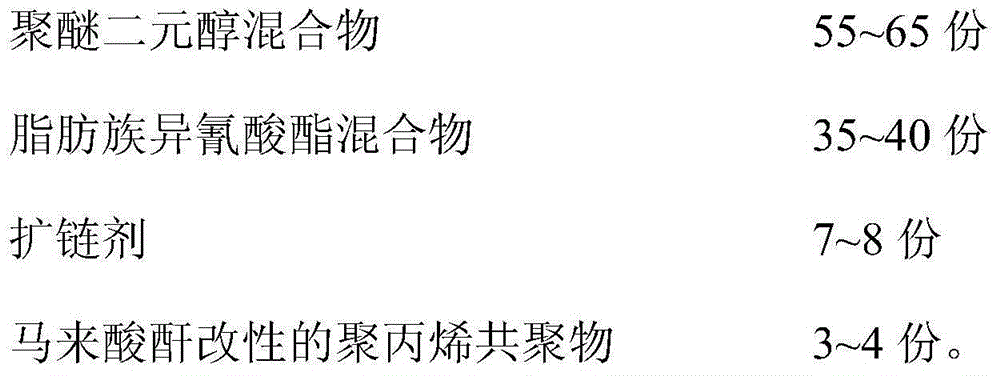

Method used

Image

Examples

Embodiment 1

[0063] (1) Preparation of maleic anhydride grafted polypropylene:

[0064] The mixture of 100 parts of polypropylene and 6 parts of maleic anhydride is added in the twin-screw extruder by weight, and the feeding section temperature, the mixing section temperature, the extrusion section temperature and the die temperature of the twin-screw extruder are set to be respectively 150°C, 150°C, 150°C and 135°C, after it melts, add a mixed solution of 13 parts of styrene and 0.7 parts of tert-butyl peroxylaurate for melt grafting reaction to obtain maleic anhydride grafted polypropylene .

[0065] (2) Prepare polyurethane elastomer:

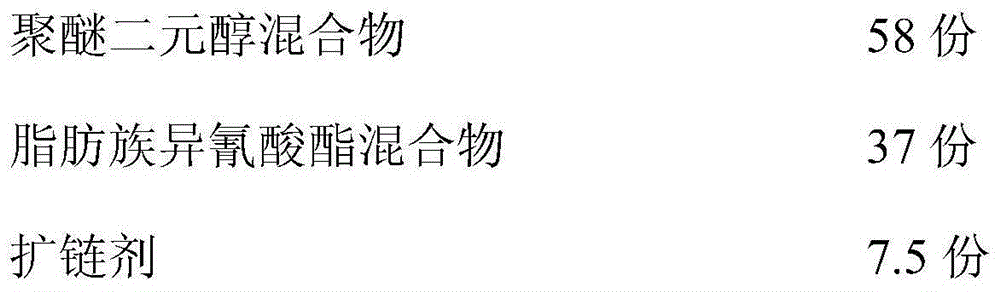

[0066] With 58 parts of polyether glycol mixture (wherein, the mass ratio of polytetrahydrofuran ether glycol, polyoxytetramethylene glycol and polyepoxypropylene glycol is 3:2:1) and 7.5 parts of chain extender ( Among them, the mass ratio of 1,4-butanediol and diethylene glycol (4:1) was added to the container, and the mixture was dehydrated at 55°C ...

Embodiment 2

[0071] (1) Preparation of maleic anhydride grafted polypropylene:

[0072] The mixture of 100 parts of polypropylene and 8 parts of maleic anhydride is added in the twin-screw extruder by parts by weight, and the feeding section temperature of the twin-screw extruder, the mixing section temperature, the extrusion section temperature and the machine head temperature are respectively set as 140°C, 140°C, 140°C and 130°C, after it melts, add a mixed solution of 15 parts of styrene and 1 part of tert-butyl peroxylaurate for melt grafting reaction to obtain maleic anhydride grafted polypropylene .

[0073] (2) Prepare polyurethane elastomer:

[0074] With 55 parts of polyether glycol mixtures (wherein, the mass ratio of polytetrahydrofuran ether glycol, polyoxytetramethylene glycol and polyepoxypropylene glycol is 2.5:2.5:1) and 7 parts of chain extender ( Among them, the mass ratio of 1,4-butanediol and diethylene glycol is 5:1) into the container, and the mixture is dehydrated ...

Embodiment 3

[0079] (1) Preparation of maleic anhydride grafted polypropylene:

[0080] The mixture of 100 parts of polypropylene and 4 parts of maleic anhydride is added in the twin-screw extruder by parts by weight, and the feeding section temperature, the mixing section temperature, the extrusion section temperature and the machine head temperature of the twin-screw extruder are set to be respectively 160°C, 160°C, 160°C and 140°C, after it melts, add a mixed solution of 10 parts of styrene and 0.5 parts of tert-butyl peroxylaurate for melt grafting reaction to obtain maleic anhydride grafted polypropylene .

[0081] (2) Prepare polyurethane elastomer:

[0082] With 65 parts of polyether glycol mixtures (wherein, the mass ratio of polytetrahydrofuran ether glycol, polyoxytetramethylene glycol and polyepoxypropylene glycol is 2:2:1) and 8 parts of chain extenders ( Among them, the mass ratio of 1,4-butanediol and diethylene glycol (3:1) was added to the container, and the mixture was d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com