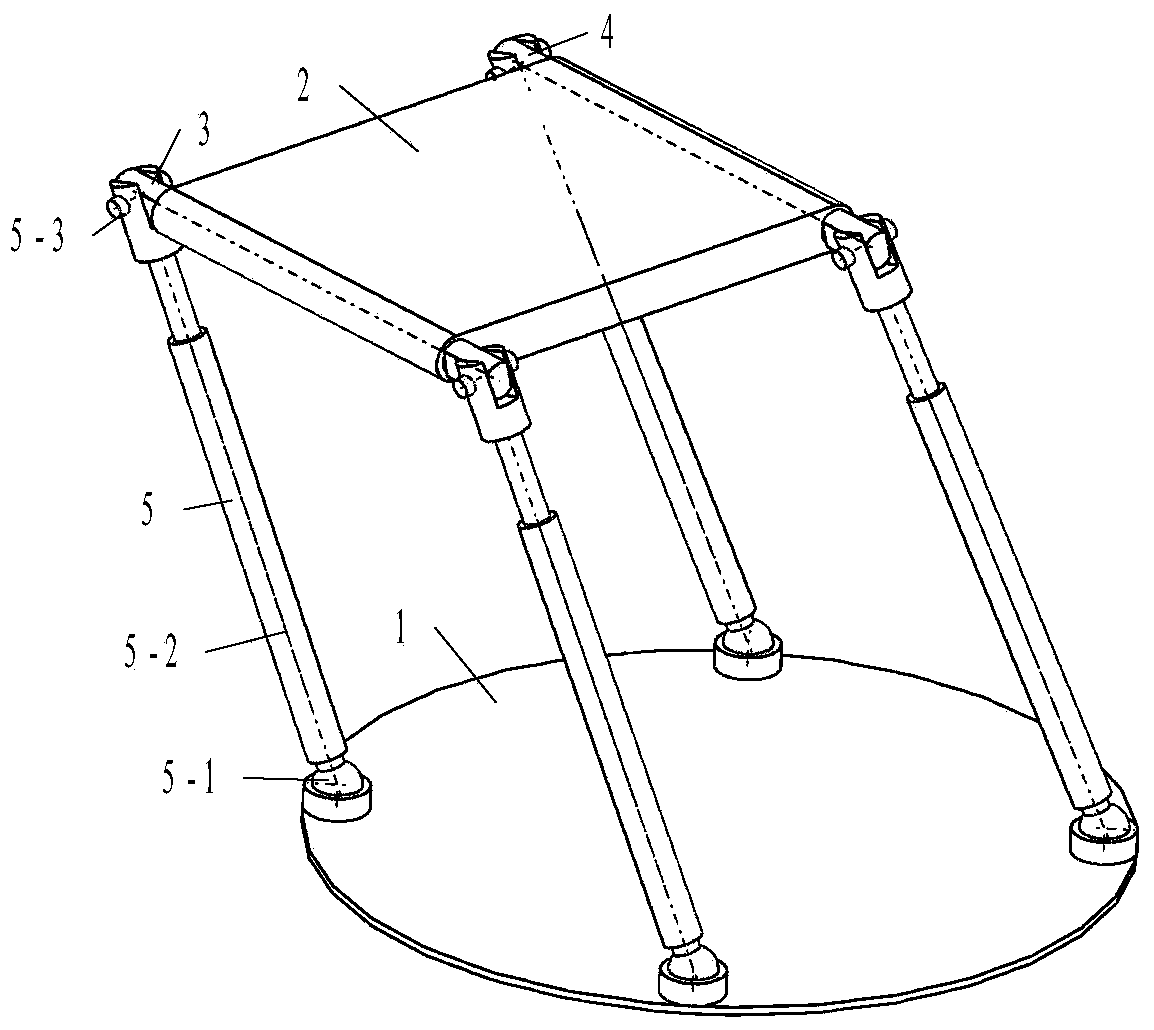

4SPR+2R type four-freedom-degree parallel mechanism

A degree of freedom, parallel technology, applied in the field of robotics, to achieve the effect of large working space, high rigidity, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] exist figure 1 In the schematic diagram of the 4SPR+2R type four-degree-of-freedom parallel mechanism, the base 1 is four sub-rods, and the circular plate of the base is provided with four ball sub-seats, and the four ball sub-seats are evenly distributed near the circle The circumference of the edge of the shaped plate; the moving platform 2 is a pair of secondary rods, and the two opposite sides of the regular quadrilateral plate of the moving platform are respectively provided with through holes parallel to each other, and the first transverse axis 3 and the second transverse axis 4 respectively pass through Through the through holes on both sides of the above-mentioned moving platform, through holes are provided at both ends of the two horizontal shafts protruding from the through holes, and the axes of the through holes at the two ends of each horizontal shaft are parallel to each other and perpendicular to the horizontal axis; the four structures are the same The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com