Experimental platform of parallel mechanism with 3 and 4 freedom and adjustable 3-UPU

An experimental platform, 3-UPU technology, applied in manipulators, program-controlled manipulators, metal processing machinery parts, etc., can solve the unexplainable self-motion phenomenon of three-translational 3-UPU mechanisms, single movement characteristics of parallel mechanisms, and unfavorable multiple structures Type parallel mechanism characteristics and kinematic characteristics and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

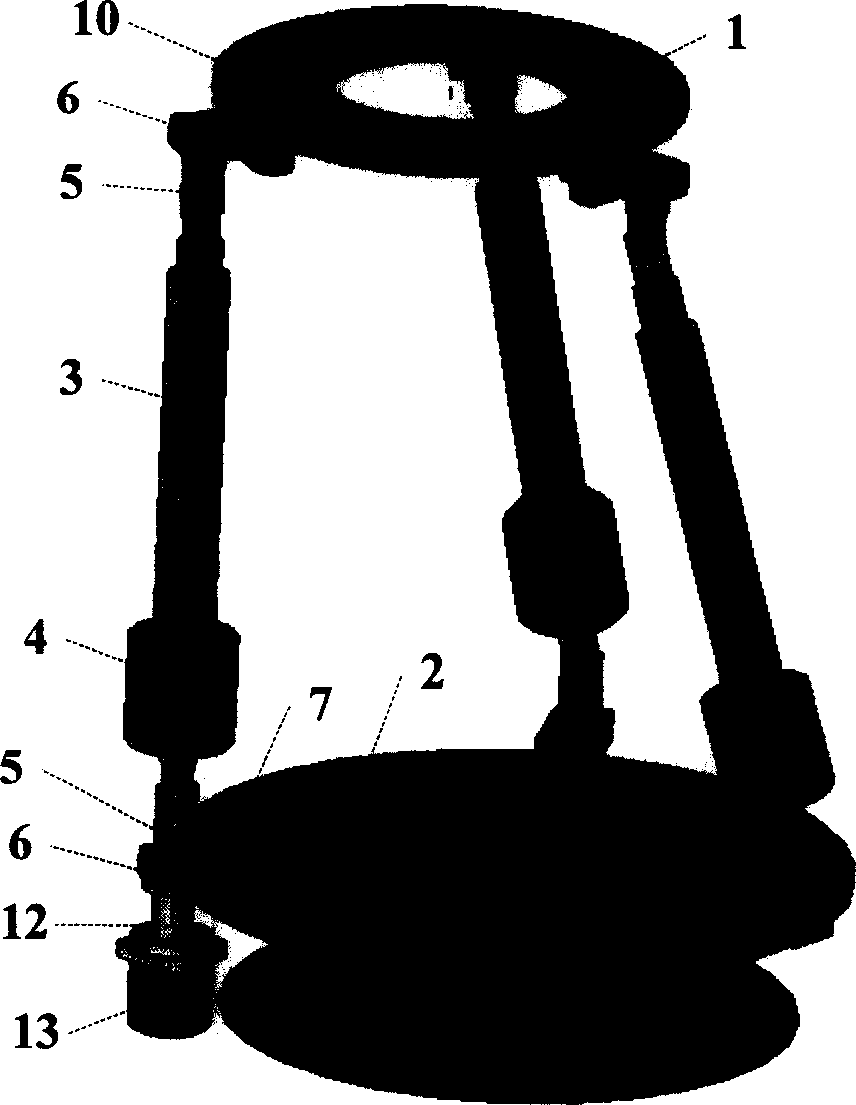

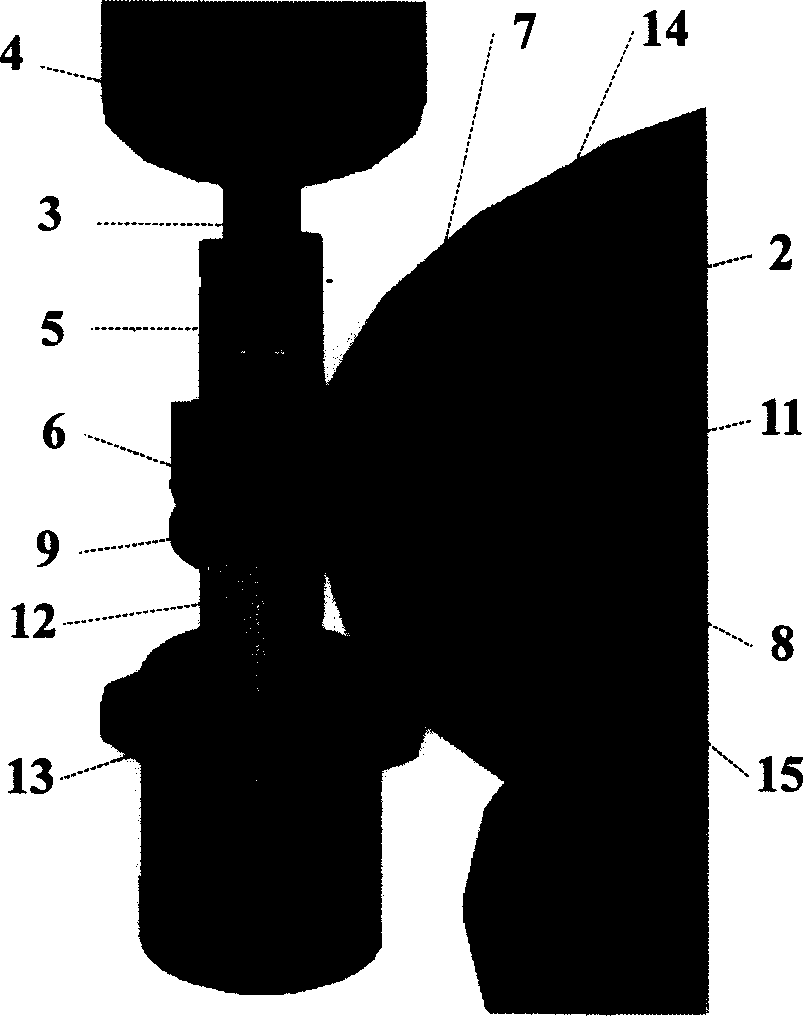

[0015] figure 1 It is the first embodiment disclosed by the present invention. The three linear drive branch kinematic chains have the same structure and are symmetrically distributed in an equilateral triangle. Each linear drive branch has a universal pair at both ends and a moving pair 3 in the middle. Overlap towards the center of the sub-center, and the moving sub-3 is driven by a stepping electromechanical drive device to realize telescopic movement. Each universal pair is composed of a rotating shaft 5, a bracket 6 and a fan seat 7, the bracket 6 is connected to the fan seat 7 at 0° by pins 8 and 9, and the fan seat 7 is connected to the upper platform by pins 10 and 11. 1 or the base 2 are connected at 0° for positioning and rotation, and each rotating shaft 5 connected with the upper platform 1 and the machine base 2 is kept perpendicular to the upper platform and the machine base respectively. At this time, the mechanism has 4 degrees of freedom, and the sleeve 12 Th...

Embodiment 2

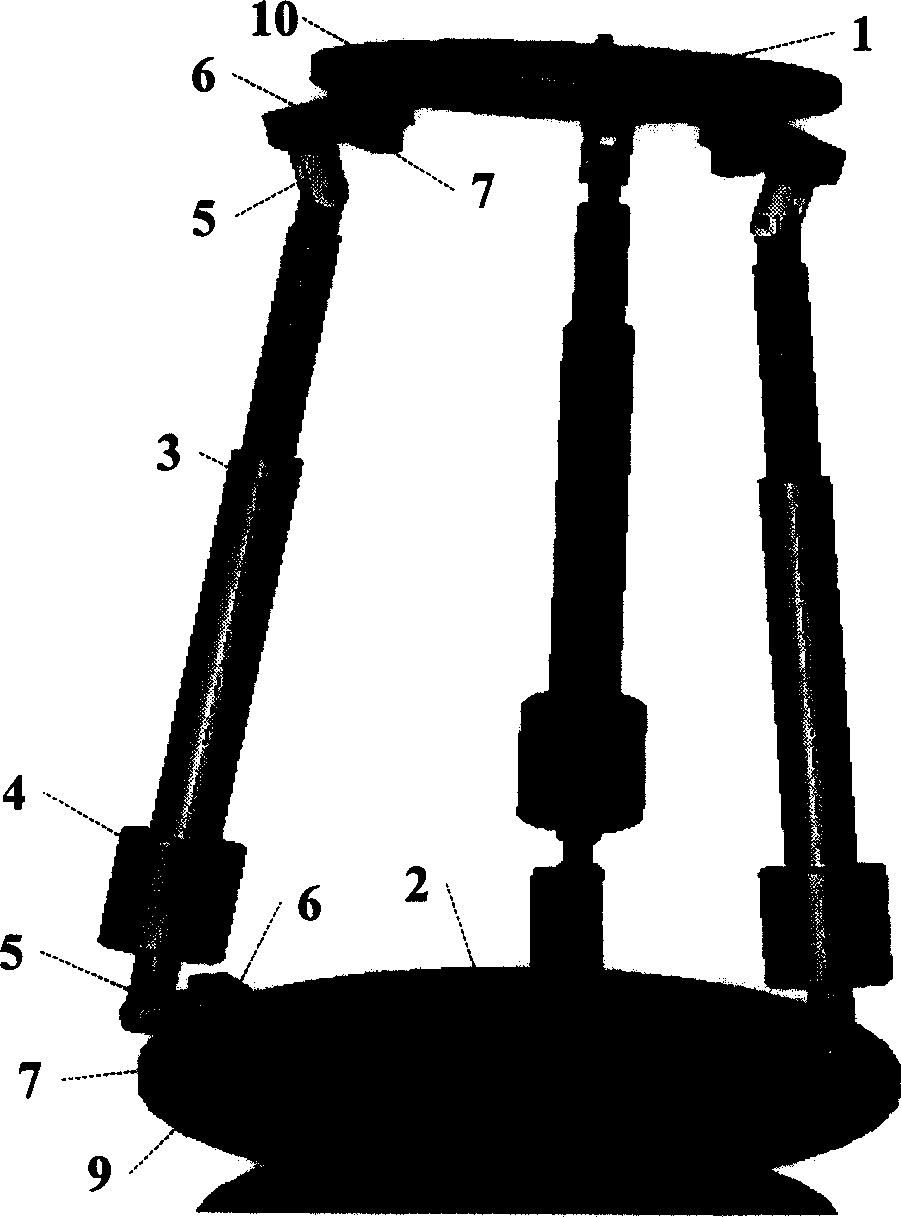

[0017] image 3 It is the second embodiment disclosed by the present invention. It differs from the first embodiment in that the bracket 6 on the upper platform 1 is connected with the fan seat 7 in a 45° rotational positioning by the pin 8 and the pin 9, and the pin 10 and pin 11 realize that the bracket 6 on the machine base 2 is connected with the fan base 7 in a 90° rotation orientation, and the fan base 7 is connected with the upper platform 1 or the base 2 in a 0° rotation orientation. This mechanism has 3 degrees of freedom.

[0018] There are 3 and 4 adjustable 3-UPU parallel mechanism I and II experimental platforms. In addition to the characteristics of high rigidity and high load capacity of the parallel mechanism, it also has the characteristics of relatively simple mechanism, symmetrical structure, high motion precision and adjustability. Good features. They can be used to design space parallel robots, parallel machine tools, micro robots and sensor elements for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com