Multistable mechanism realizing method based on single bistable mechanism and external characteristics thereof

A realization method, bistable technology, applied in the field of realization of multi-stable mechanisms, can solve problems such as system failure, large energy, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

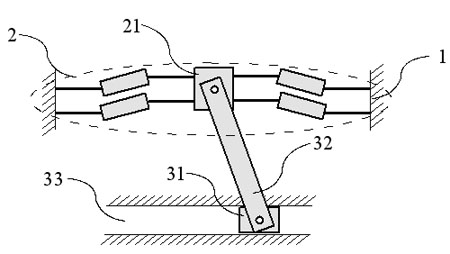

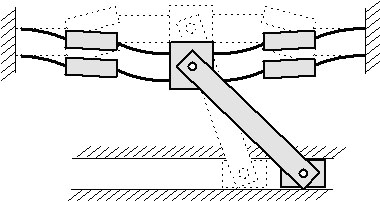

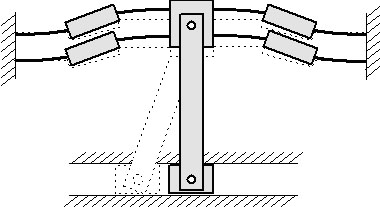

[0029] Such as figure 1 As shown, it includes at least the frame 1 and the flexible bistable mechanism 2 in the frame 1. The left and right ends of the flexible bistable mechanism 2 are fixed in the frame 1, and there is a first-stage connection parallel to the horizontal axis of the flexible bistable mechanism 2. Rod slider mechanism 3, the first stage linkage slider mechanism 3 includes a first stage guide rail 33, a first stage slider 31 and a first stage connecting rod 32, the first stage slider 31 is in the first stage guide rail 33, The first stage slider 31 and the shuttle 21 of the flexible bistable mechanism 2 are respectively connected to the first stage connecting rod 32 by a shaft; The position constitutes the first initial stable state. Through the position changes of the shuttle 21 and the first-stage slider 31, the flexible bistable mechanism 2 and the first-stage linkage slider mechanism form a four-stable mechanism. Its specific implementation or working sta...

Embodiment 2

[0034] Such as Figure 6 shown, with figure 1 The structure is different. In embodiment 2, there is a vertically fixed second-level guide rail 43 on the right (or left) of the first-level guide rail 33, and there is a second-level slider 41 inside the second-level guide rail 43. The second stage slide block 41 in the stage guide rail 43 and the first stage slide block 31 in the first stage guide rail 33 are respectively connected with the second stage connecting rod 42 by the shaft, so that the second stage slide block 41 is on the second stage guide rail 43 A position lower (or higher) than the horizontal axis of the first-stage slider 31 constitutes an initial stable state (first stable position) of the slider 41 . Also by the position changes of the shuttle 21 and the first stage slide block 31 and the position change of the second stage slide block 41, the flexible bistable mechanism 2, the first stage link slider mechanism and the second stage link slider mechanism form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com