Downlink movable mould frame and walking method thereof

A technology of mobile formwork and lateral movement, which is applied in the erection/assembly of bridges, bridges, buildings, etc. It can solve the problems of high quality dispersion of finished beams, the inability of legs to realize self-promotion, and increased costs, so as to reduce lateral movement equipment, The effect of light weight and increased economic competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

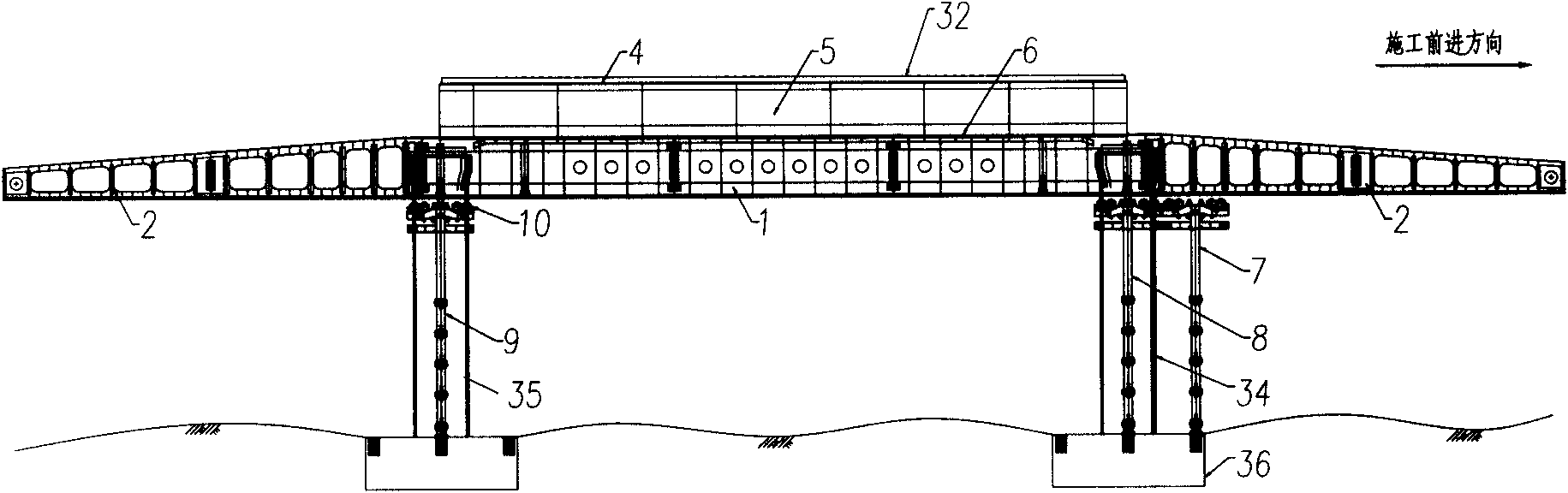

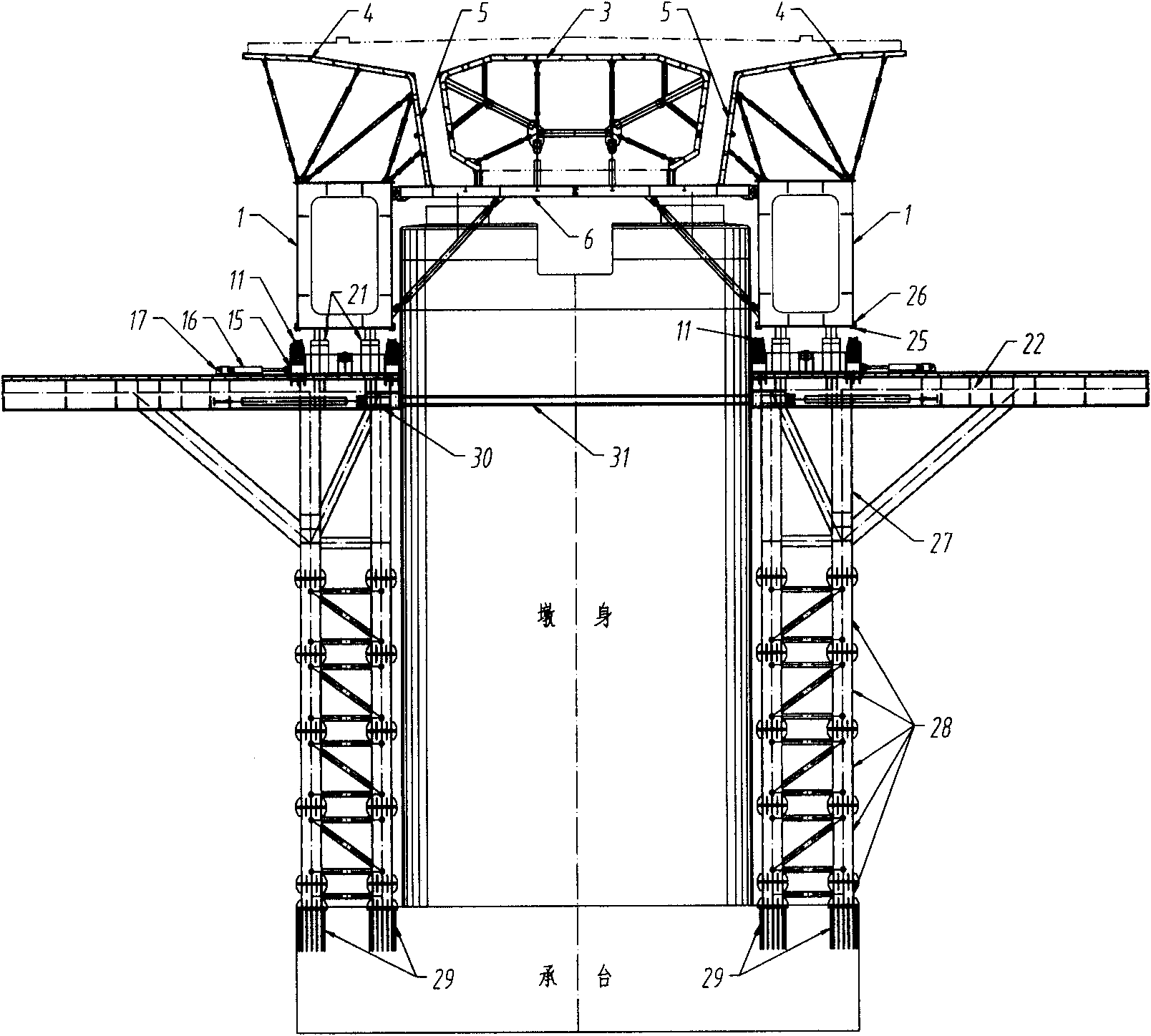

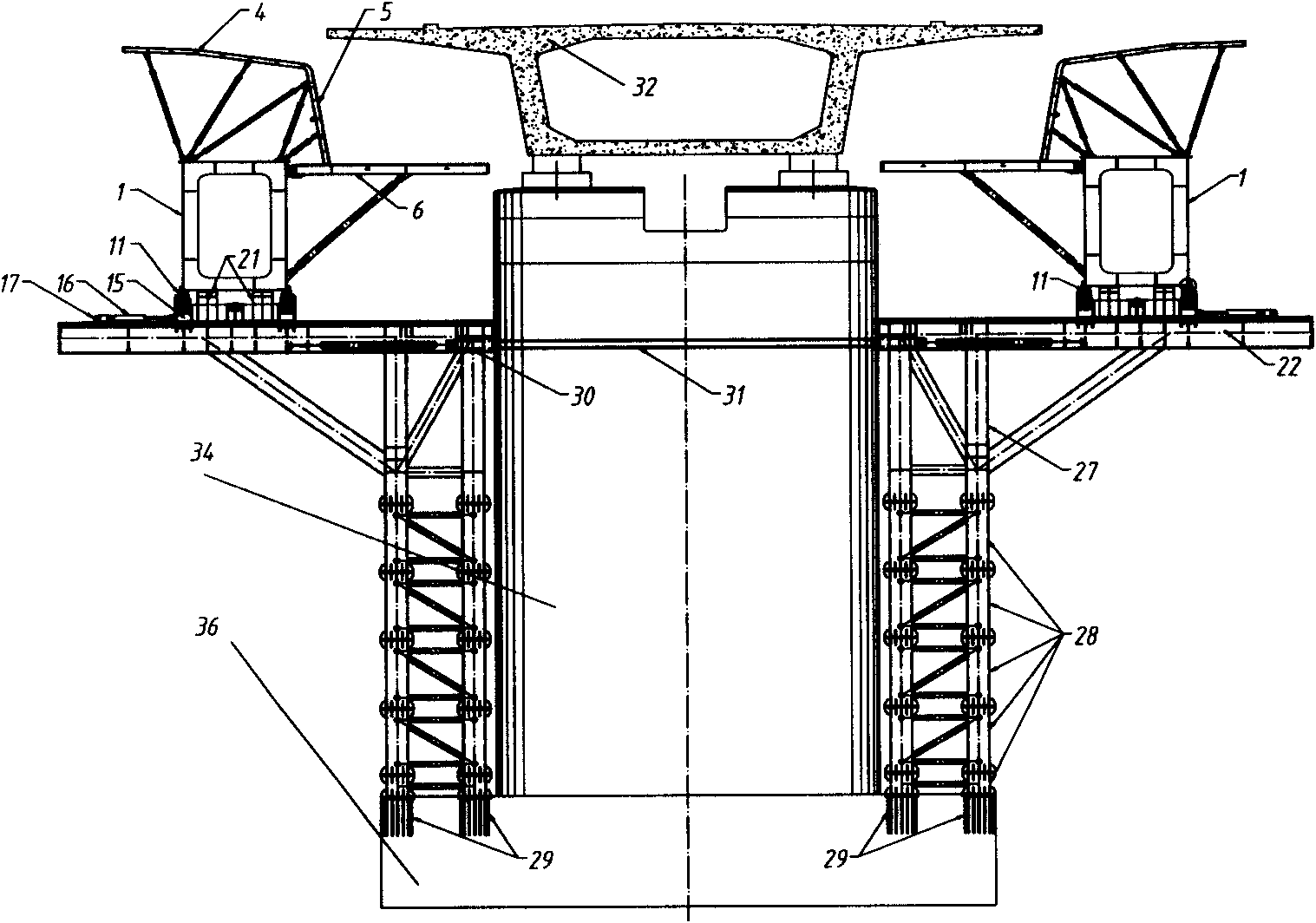

[0047] Such as figure 1 As shown, the concrete box girder 32 that has been poured between the rear pier body 35 and the middle pier body 34, the two main beams 1 below the concrete box girder and on both sides of the pier body, and the guide beams 2 ( is the front guide beam and the rear guide beam), the internal mold system 3 ( figure 2 Middle), the wing plate formwork system 4, the side formwork system 5, and the bottom formwork system 6 installed on the main beam 1, the two front outriggers 7 arranged under the guide beam 2, and the two front outriggers 7 arranged under the front end of the main beam 1 The middle outrigger 8, the two rear outriggers 9 arranged under the rear end of the main beam 1, and the longitudinal and lateral movement system 10 arranged between the main beam 1 and each outrigger.

[0048] Such as figure 2 As shown, the structure on the middle outrigger is used for illustration, and the structure of the front outrigger and the rear outrigger is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com