Automatic slurry deferrization machine

A technology of iron remover and slurry, which is applied in magnetic separation, solid separation, wet separation, etc., can solve the problems of poor iron removal effect, high power consumption, inaccurate positioning of drums, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

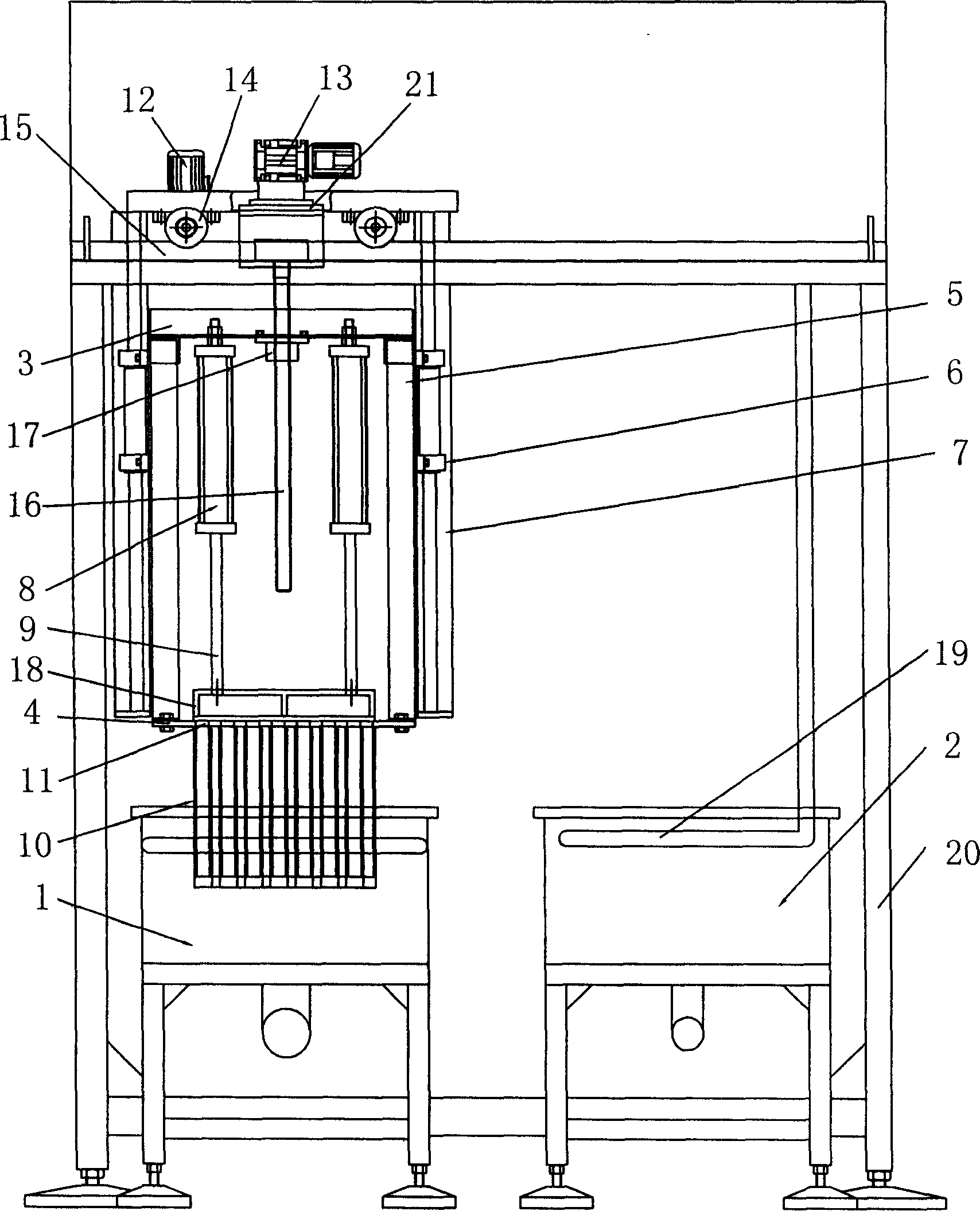

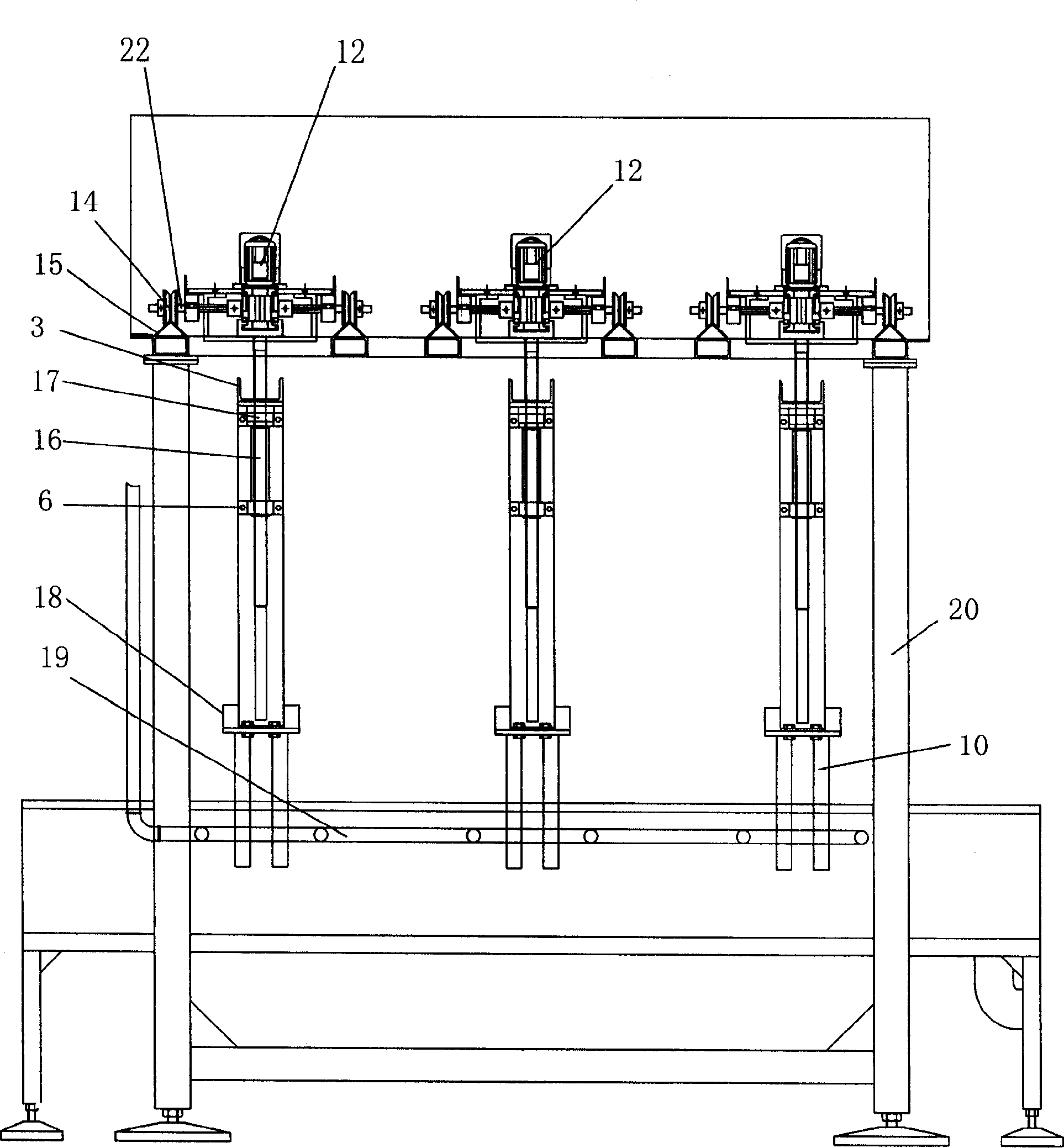

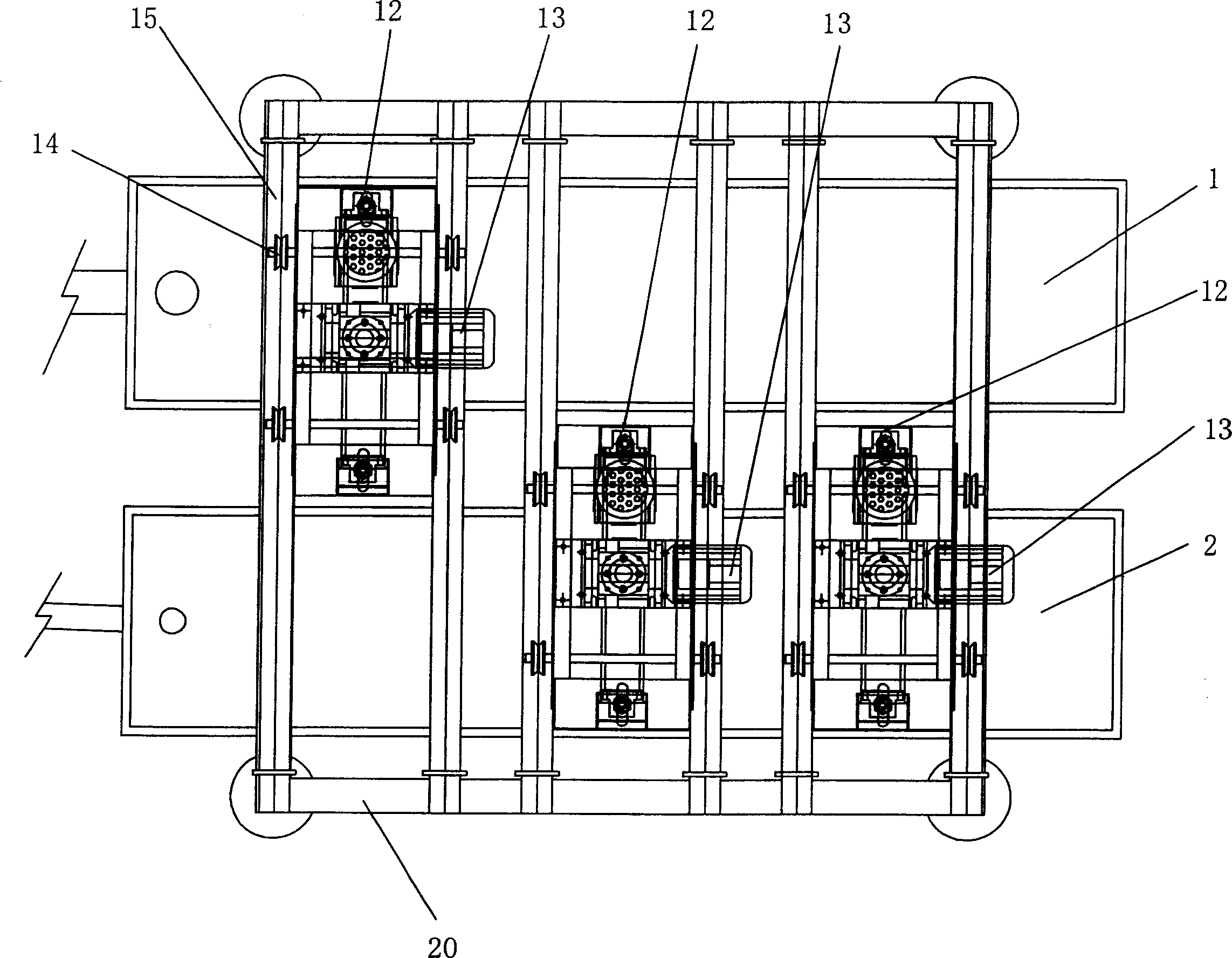

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0021] This automatic slurry iron remover mainly includes:

[0022] A slurry tank 1 for removing iron filings in the slurry, one end of the slurry tank 1 is provided with a slurry inlet, and the other end is provided with a slurry outlet;

[0023] A cleaning tank 2 is used to clean the iron filings adsorbed on the magnetic bar casing 10. The cleaning tank 2 is provided with a flushing water pipe 19, and the flushing water pipe 19 is connected to the water pump;

[0024] An iron frame assembly mainly includes a top plate 3, a bottom plate 4 and side plates 5 on both sides, the side plates 5 are slidingly matched with the upper and lower guide sliding rods 7 through the sliding sleeve 6;

[0025] A group of permanent magnet rods 11 are fixedly connected with the up and down lifting device;

[0026] A group of magnetic rod sleeves 10 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com