Full-automatic continuous feeding iron removing machine

An iron remover, fully automatic technology, applied in the field of magnetic separation, can solve the problems of inability to realize automatic continuous feeding, low work efficiency, etc., and achieve the effect of enhancing the iron removal effect without manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

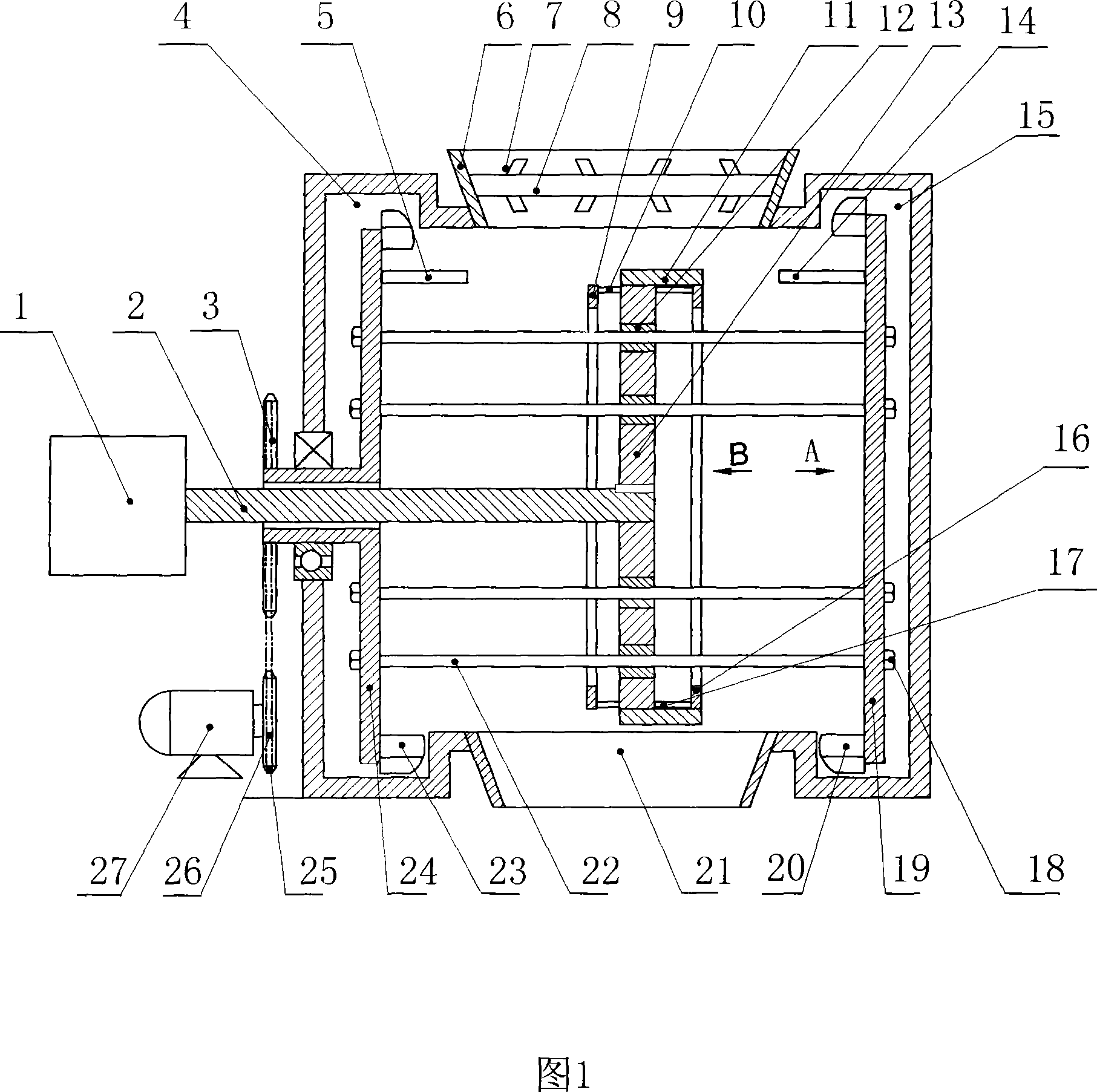

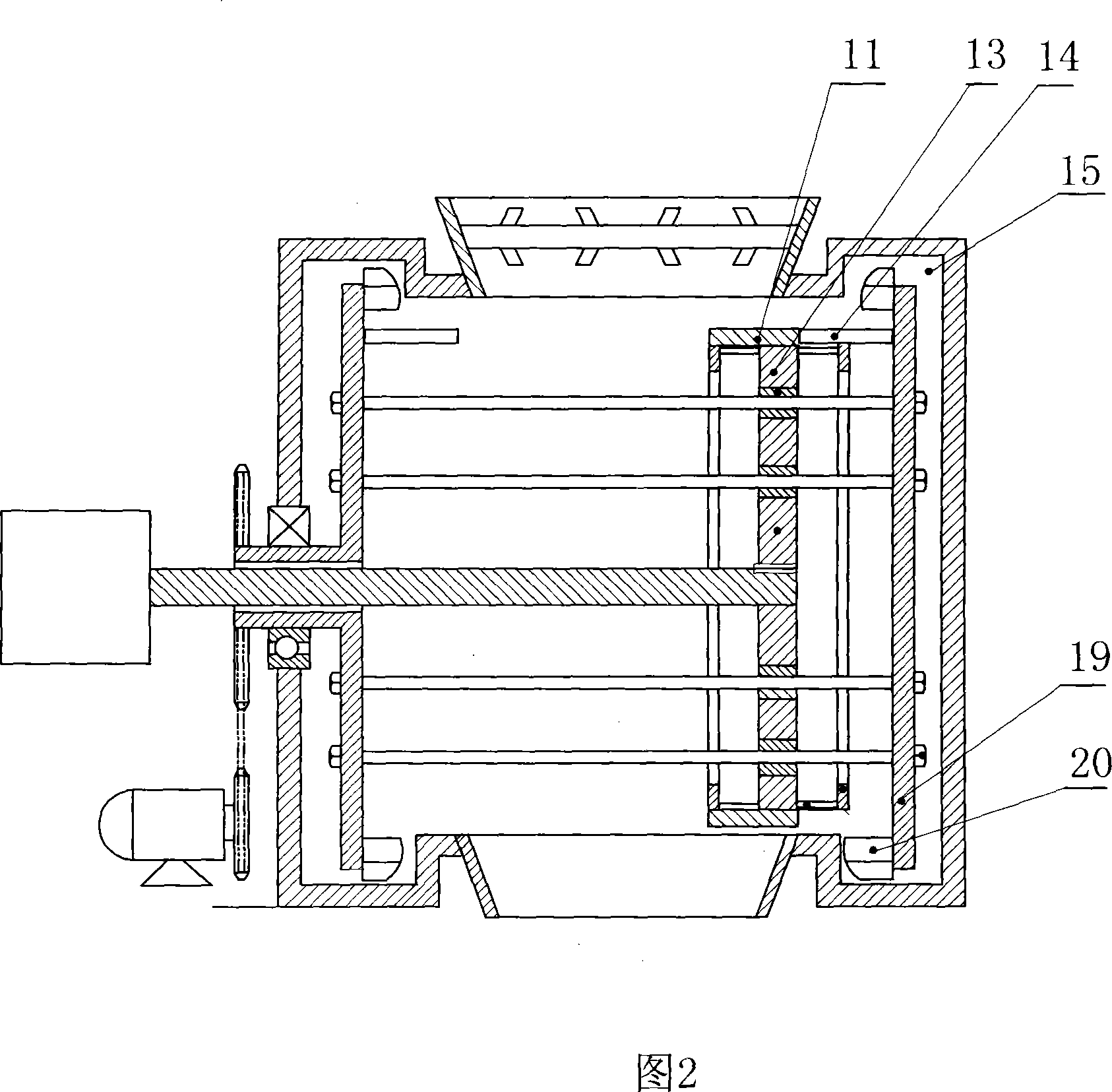

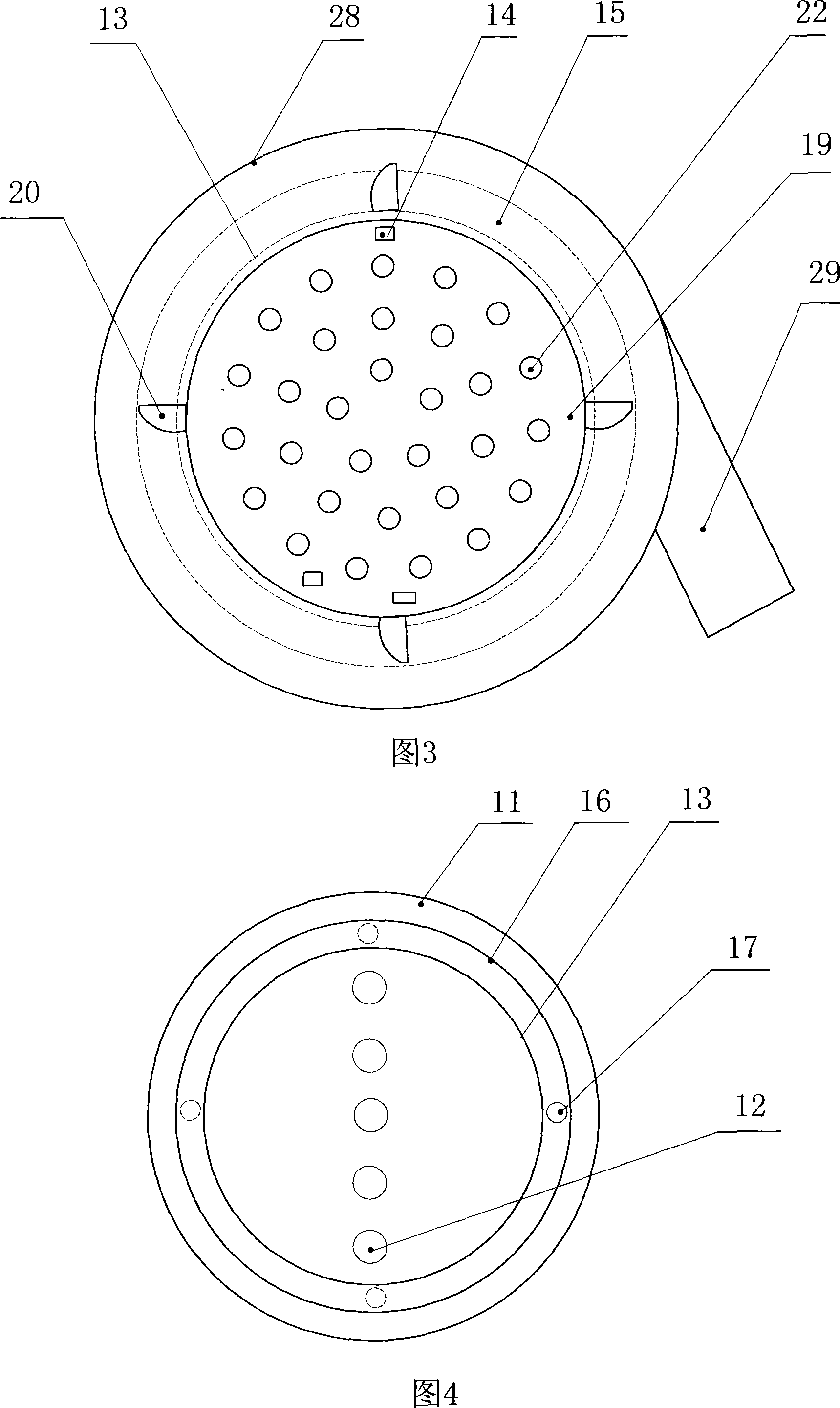

[0022] As shown in FIG. 1 , a plurality of magnetic rods 22 , connecting plates 19 and 24 form a group of magnetic rods, and both ends of the magnetic rods are fixed on the connecting plates by fastening bolts 18 . One end of connecting plate 24 is installed sprocket wheel 3, is jointly formed power transmission by sprocket wheel 3, chain 26, sprocket wheel 25, motor 27. The magnetic rods of the magnetic rod group are equipped with a scraper 13, and the connecting parts of each magnetic rod and the scraper 13 are provided with a sealing sleeve 12. The outer circumference of the scraper 13 is fitted with an iron ring 11, and the iron ring 11 is tightly pressed on the scraper 13. The width of the iron ring 11 is greater than that of the scraper 13 . Fix connecting brace 10, connecting brace 17 respectively on the left and right outer planes of scraper 13, respectively fix baffle plate 9, baffle plate 16 on connecting brace 10, connecting brace 17, offer through hole in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com