Scrap iron recycling device for milling machine

A recovery device and milling machine technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as polluting the working environment, low work efficiency, and difficulty in cleaning, so as to improve the working environment and improve recycling efficiency , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

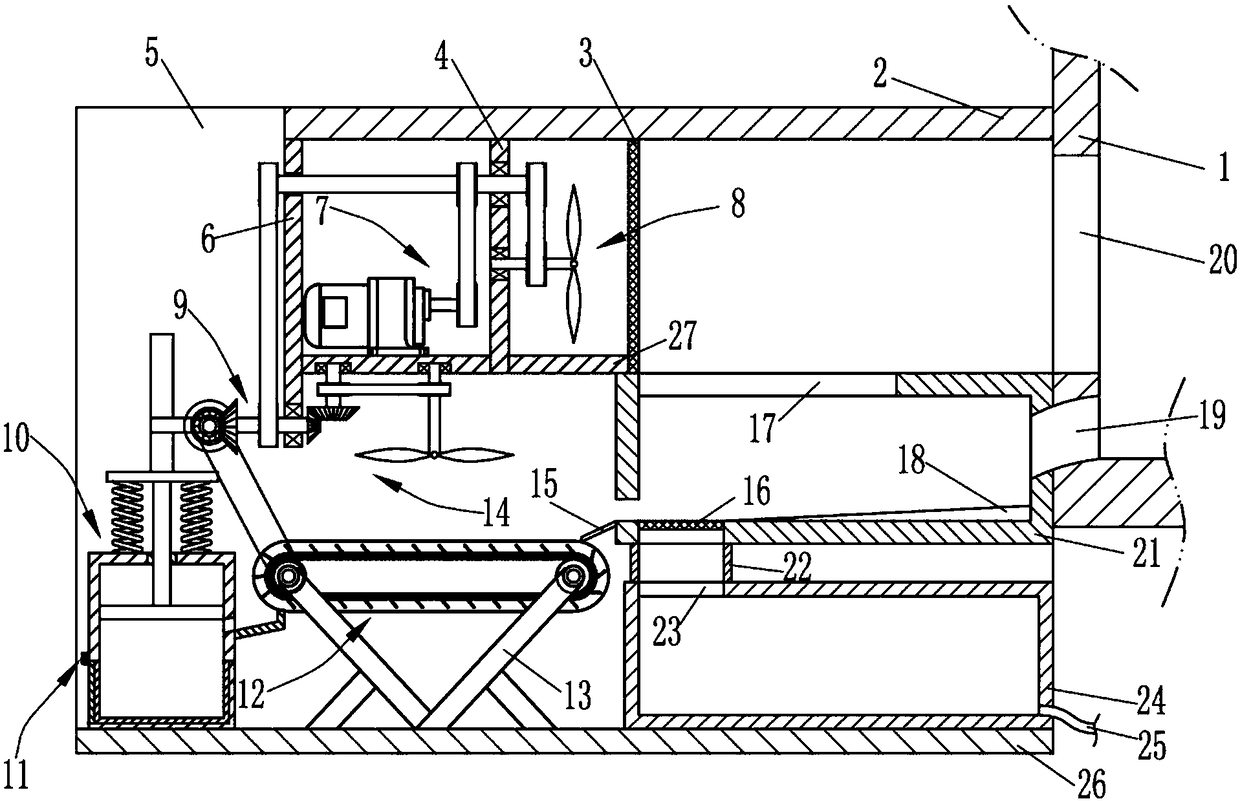

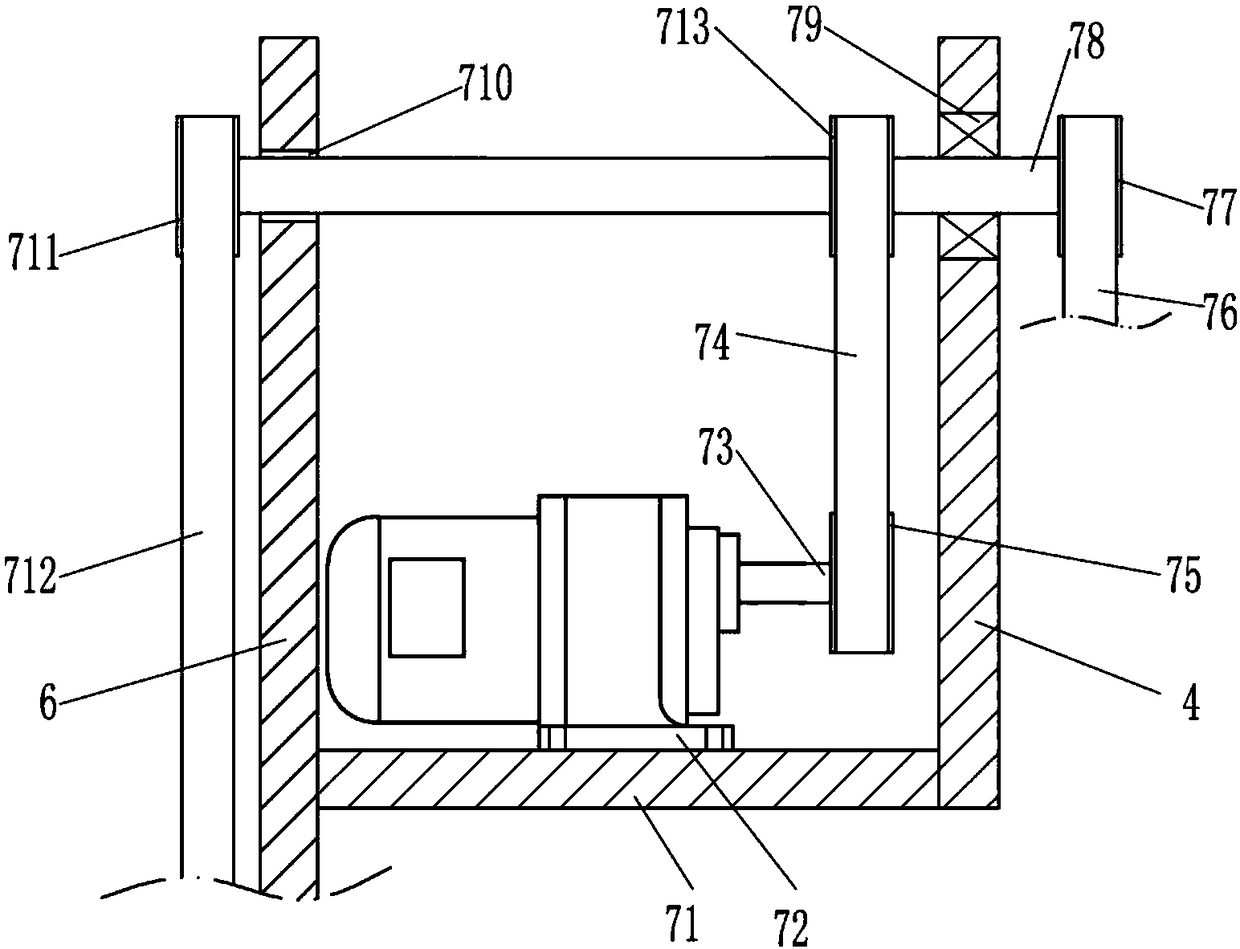

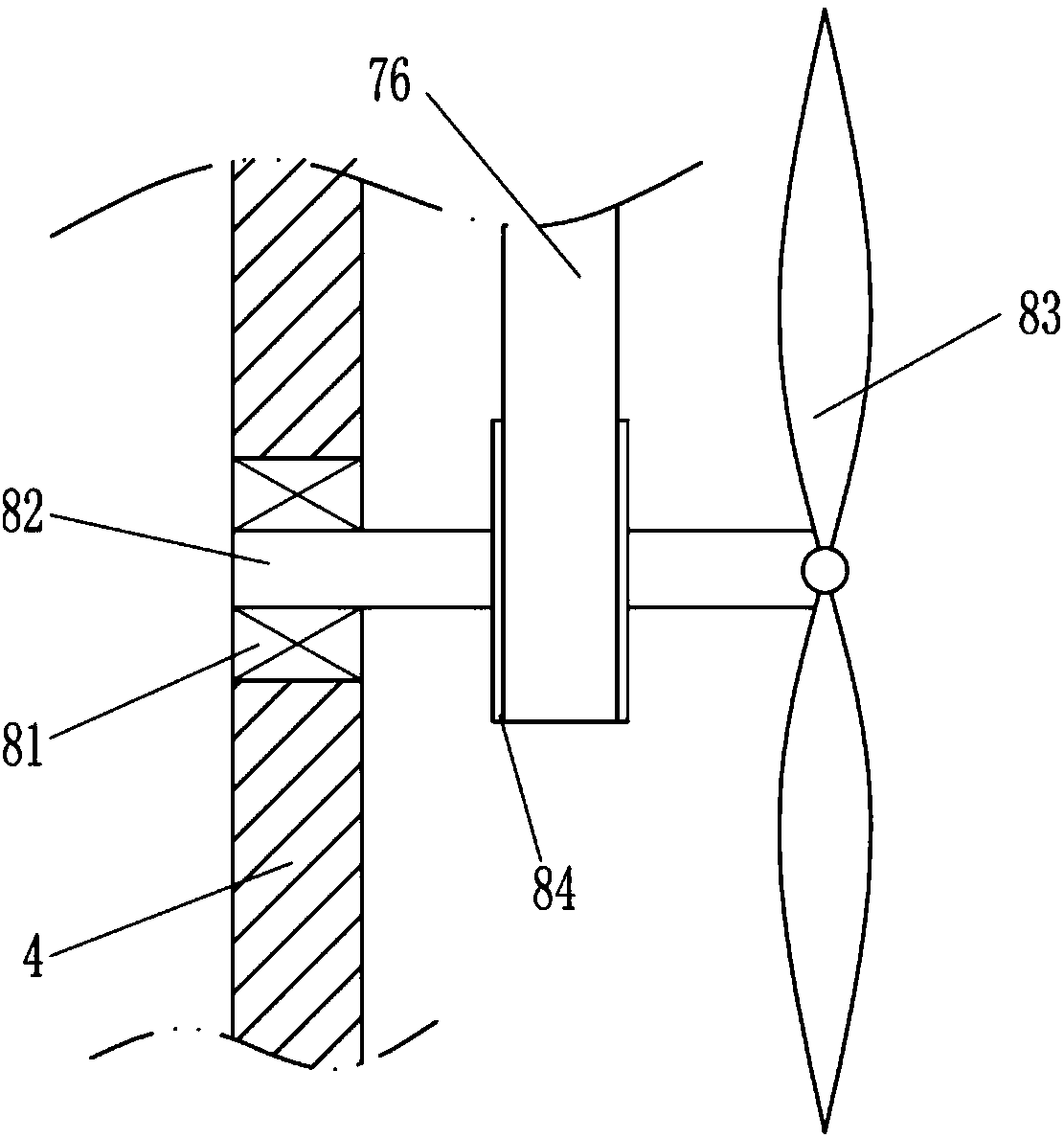

[0030] The present invention will be further described below in conjunction with accompanying drawing:

[0031] A milling machine scrap iron recovery device, such as Figure 1-10 As shown, it includes a milling machine 1, a top plate 2, a first mesh plate 3, a first mounting plate 4, a second mounting plate 5, a third mounting plate 6, a driving mechanism 7, a dust suction mechanism 8, a driven mechanism 9, a compression Mechanism 10, first fixing mechanism 11, transmission mechanism 12, support frame 13, drying mechanism 14, deflector plate 15, second mesh plate 16, inclined plate 18, feeding pipe 19, collection frame 21, infusion tube 22, The liquid storage frame 24, the liquid outlet pipe 25, the bottom plate 26 and the first connecting plate 27; the top plate 2 is fixed on one side of the milling machine 1, the second mounting plate 5 is fixed on the rear side of the bottom plate 26, and the bottom plate 26 is fixed on the The bottom of the second mounting plate 5, the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com