Centralized processor for iron shaving in ball-grinding feed liquid

A technology of centralized treatment and liquid supply, applied in magnetic separation, solid separation, sedimentation tank, etc., can solve the problems of backward technology, dependence, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

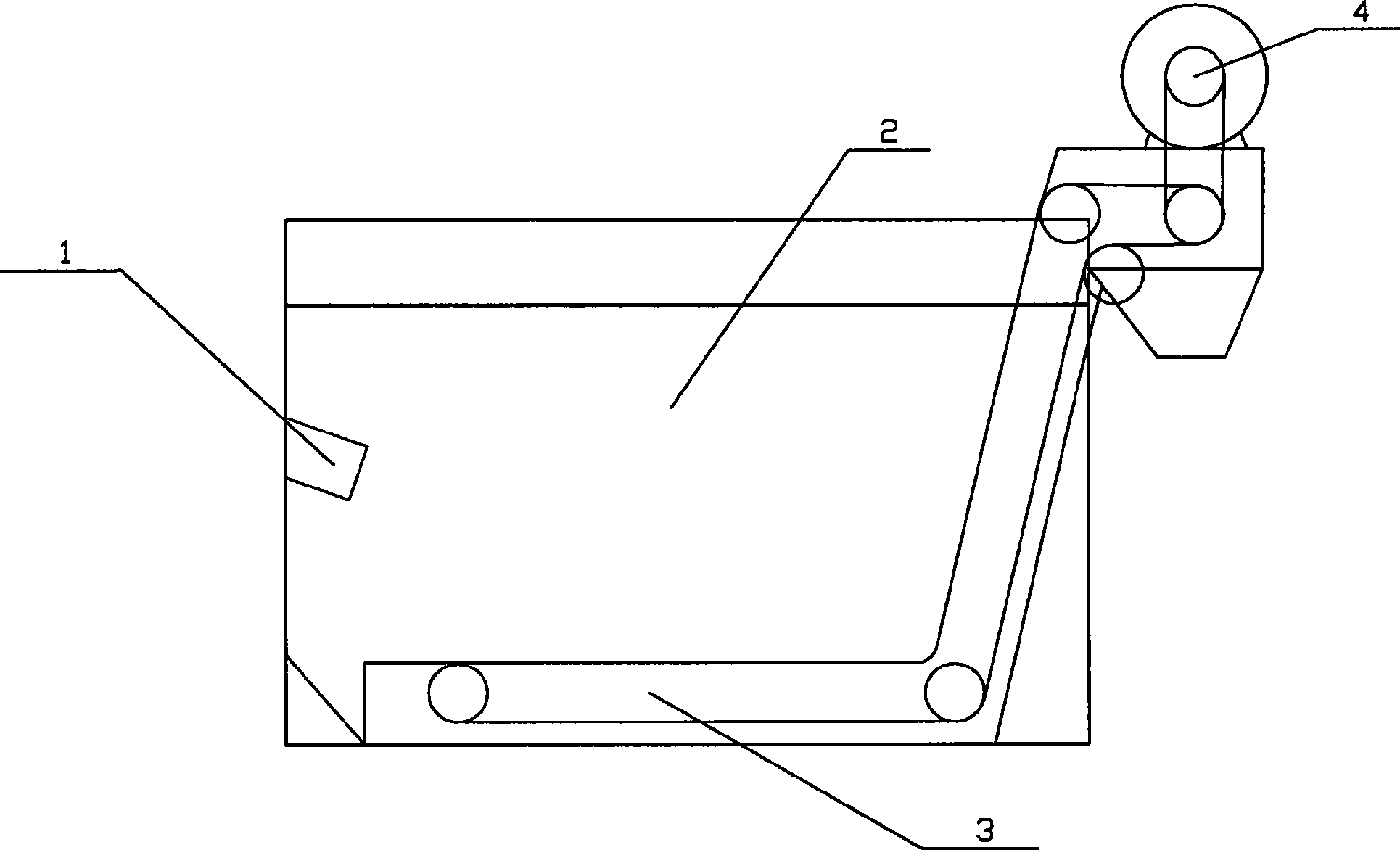

[0011] Such as figure 1 As shown, the steel ball grinding fluid enters the sedimentation slag removal tank 2 through the liquid return port 1, and due to its own gravity, most of the grinding slag falls on the scraper 3, which is a continuous cycle metal scraper Plate, installed on the hoist 4, so the grinding slag is lifted to the outside of the sedimentation slag pool 2.

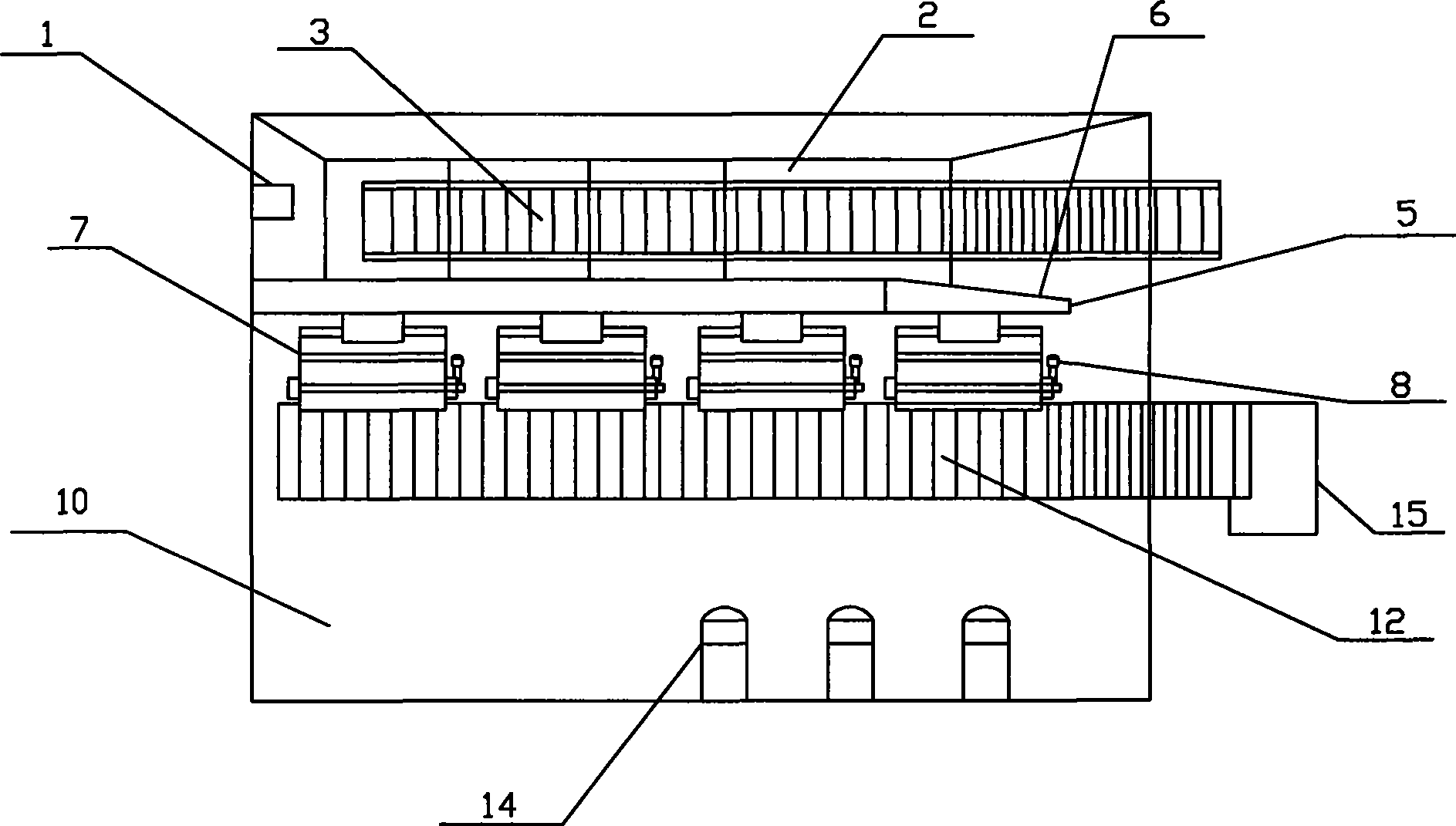

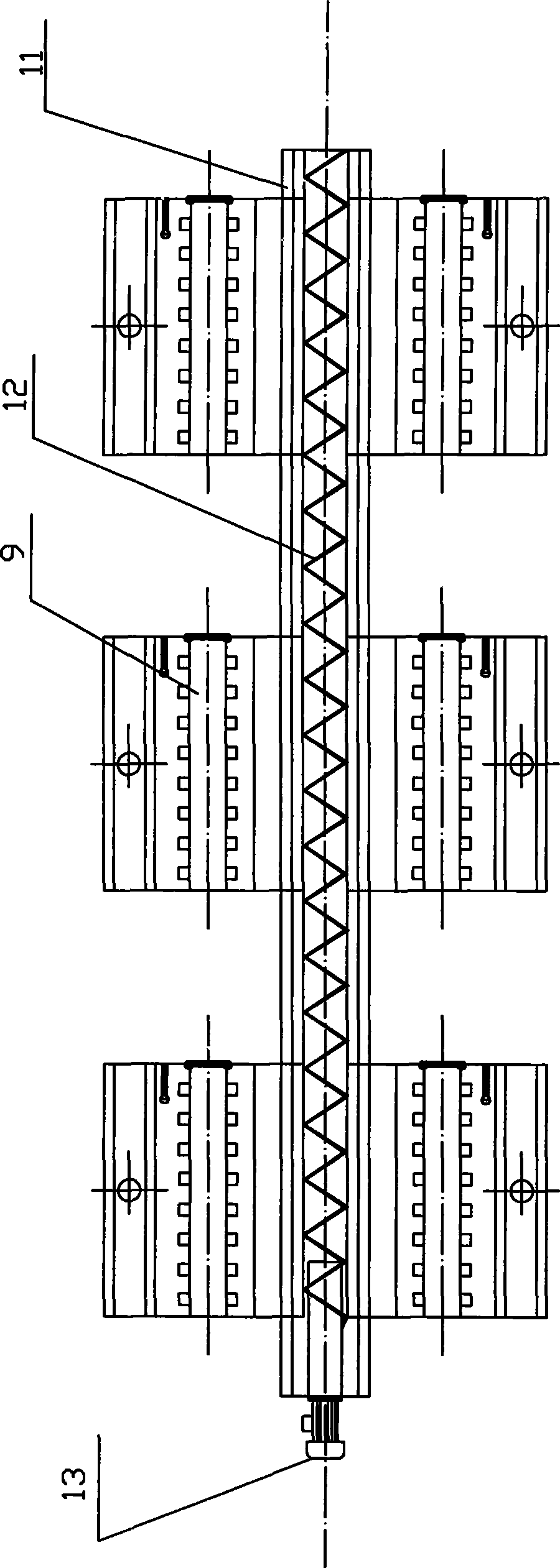

[0012] Such as figure 2 , image 3 As shown, due to the different horizontal positions, the steel ball grinding fluid in the sedimentation slag removal tank 2 flows into the magnetic separator 7 through the water inlet 5 and flows into the magnetic separation tank 10 through the water inlet 5 through the baffle plate 6 to make the water flow gentle. The magnetic separator 7 is driven by the magnetic pump 8 to rotate the magnetic drum 9. The scraper 3 is fixed and close to the magnetic drum 9. The magnetic drum 9 is a group or several groups, which can be arranged according to the size of the magnetic se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com