Combined magnetic force separating mechanism for removing iron dust in plastic

A magnetic separation and composite technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of small effective working surface, iron filings do not have the separation function, can not achieve fast and effective, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

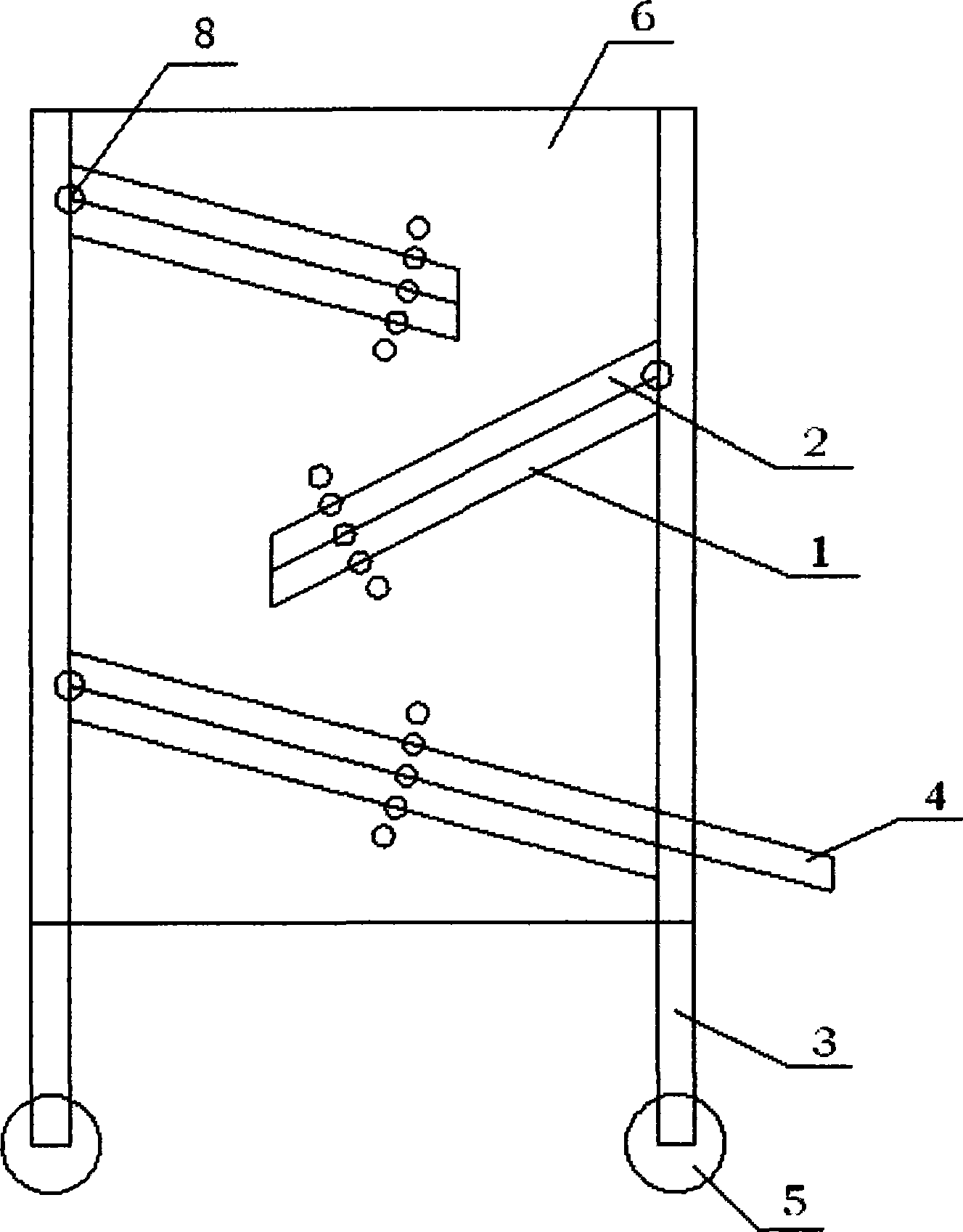

[0021] This composite magnetic separation device for removing iron scraps from plastics consists of five parts: a permanent magnet block, a separation plate, a support frame, a baffle plate, and a discharge port. It is characterized in that:

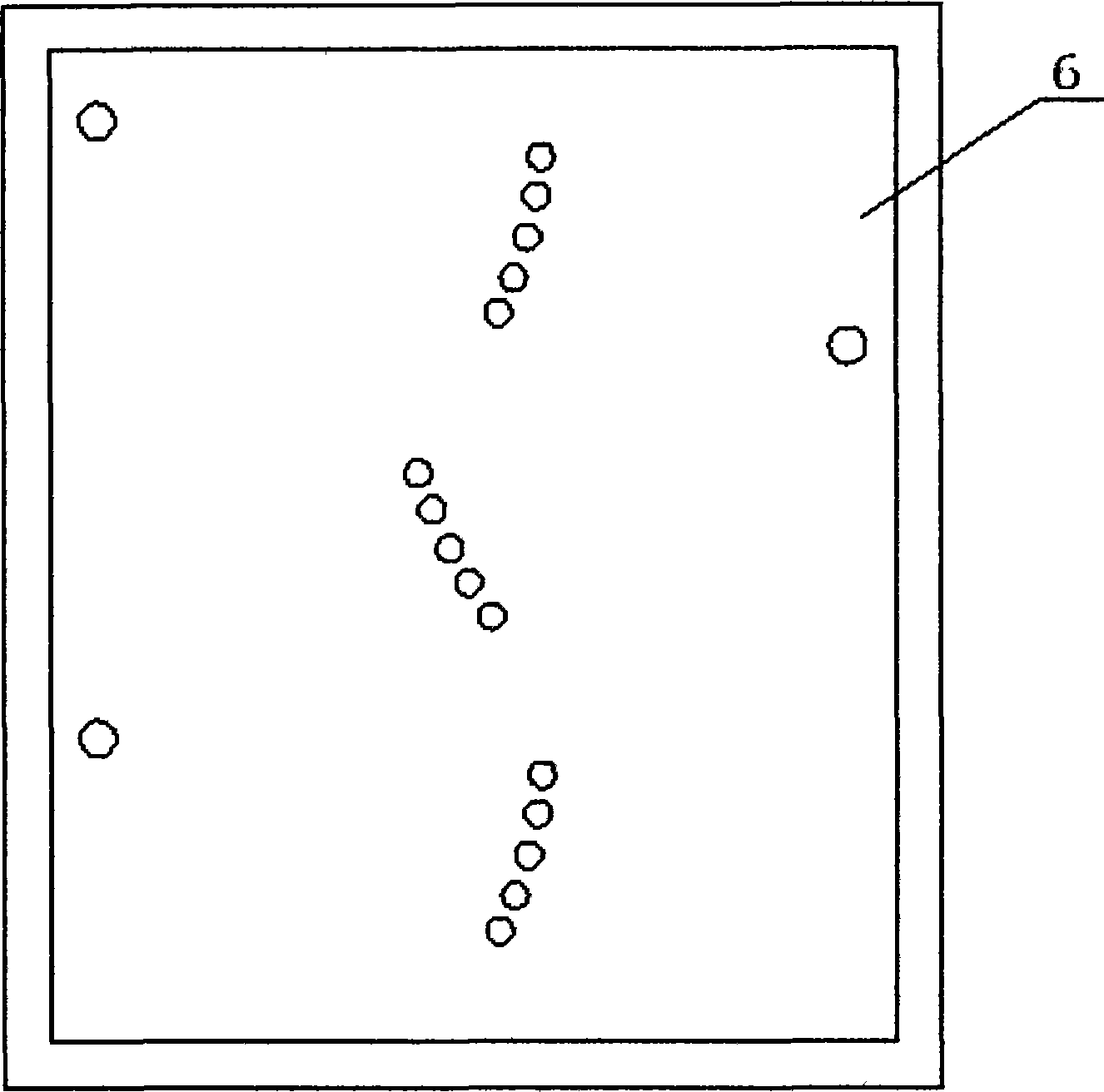

[0022] A. The separation plate 2 embedded with the permanent magnet block 1 is arranged on the support frame 3 from top to bottom in a dislocation shape from top to bottom by the screw rod 8, until the bottom separation plate is connected with the discharge port 4;

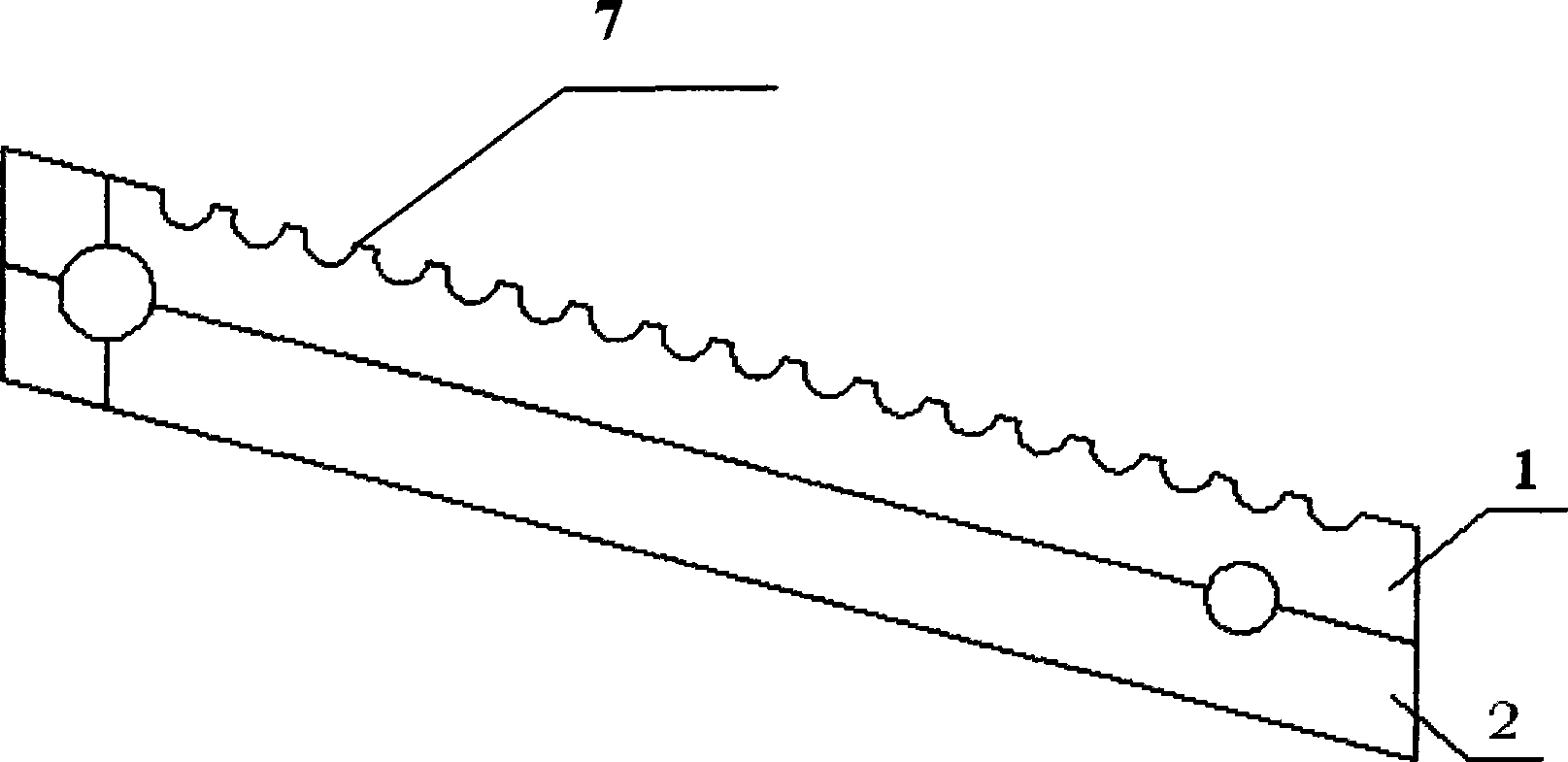

[0023] B. The surface of the separation plate 2 is provided with an adsorption groove 7 perpendicular to the material flow direction.

[0024] The adsorption groove 7 is a continuous through groove or a discontinuous pit.

[0025] The separation plate 2 is made of magnetically permeable material.

[0026] The permanent magnet block is made of permanent magnet material, and can be connected with the separation plate by screw thread or snap connection, or can be connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com