Nitrosation and nitration method for iron and carbon, reactor using the method and sewage denitrogenation method

A technology of iron-carbon nitrosation and nitrification reactor, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as difficult control, many influencing factors, and complex reaction process , to achieve the effect of short start-up time, simple maintenance and few influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

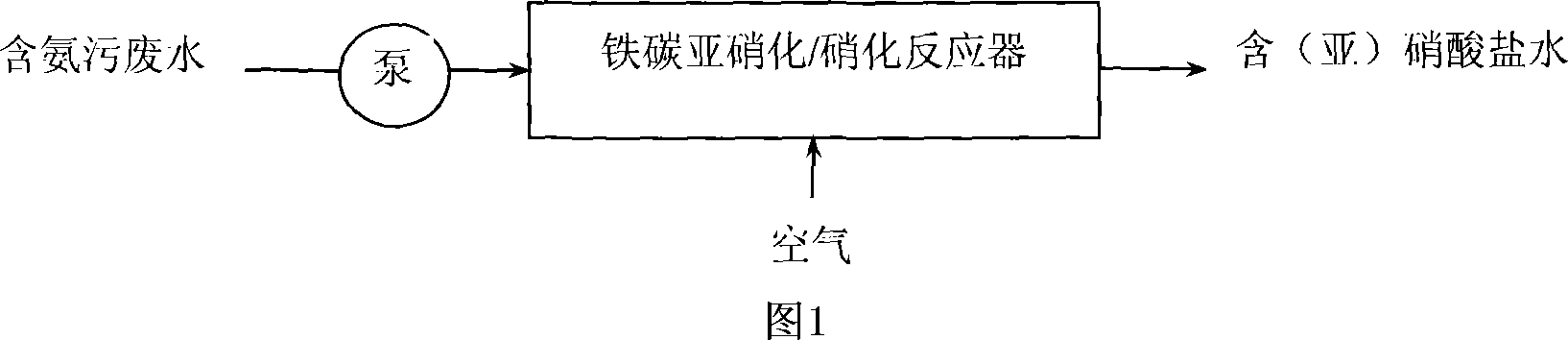

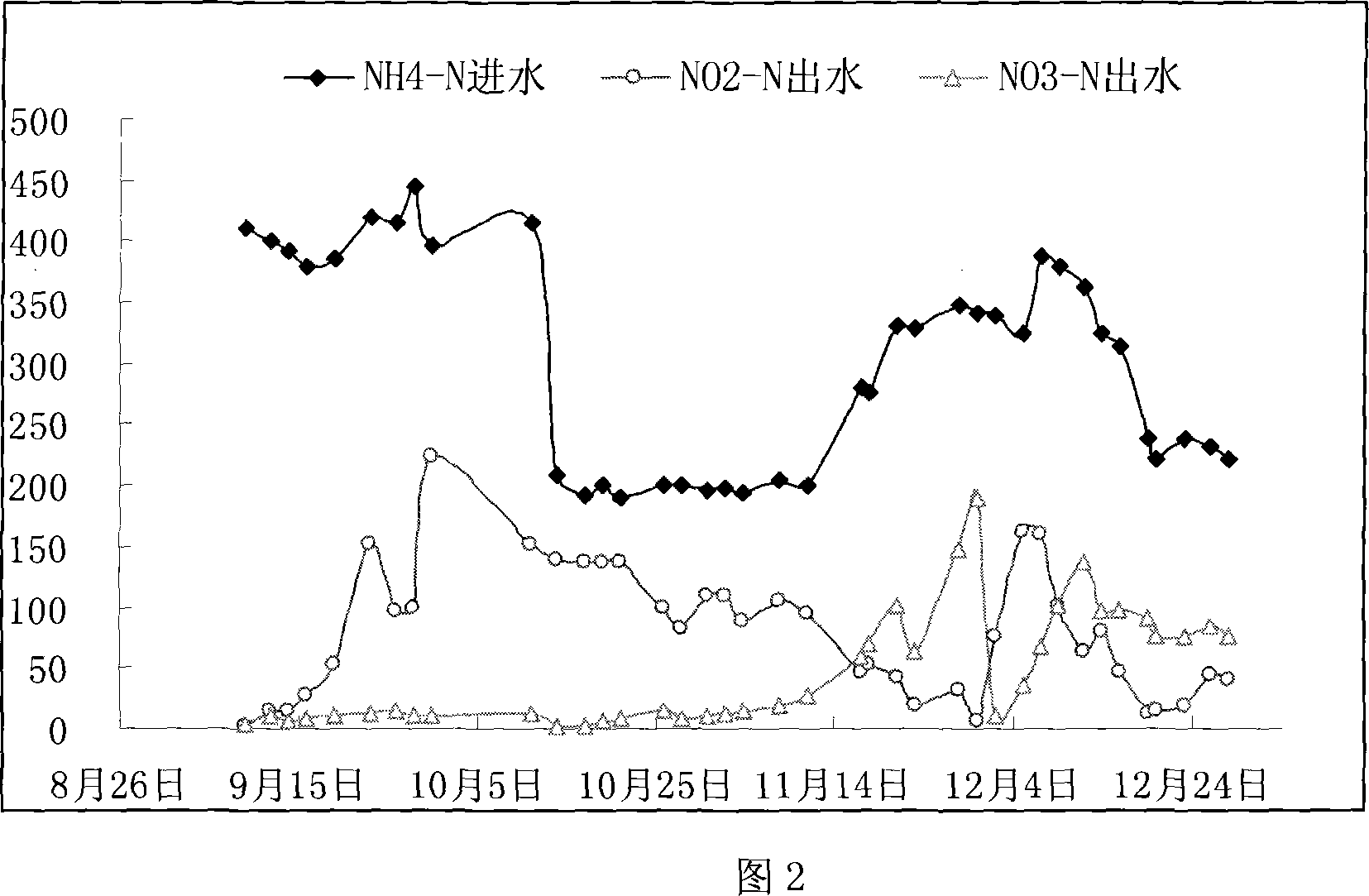

[0046] Iron carbon nitrosation and nitrification process

[0047] In the present invention, iron filings and activated carbon are layered or mixed into the reactor, water containing ammonia nitrogen is pumped into the reactor, and oxygen-enriched air is blown into the reactor to control the different pH and dissolution of the reactor. Oxygen, the operating conditions of this reaction are nitrosation requires the pH value of the reaction to be 7-9.5, the pH value of the nitration reaction is 5-7.5, SS4 + -N oxidation load is 0~10kgNH 4 + -N / (m 3 .d), the ascending (or descending) velocity of the empty tower is 0.1-0.5m / h, the hydraulic retention time is 0.4-2h, and the dissolved oxygen concentration in the reactor is greater than 0.5mg / l. The three systems of iron, carbon, and oxygen act synergistically, and electrochemical nitrosation and nitration reactions occur with ammonia to generate a certain amount of nitrite or nitrate, forming a certain proportion of ammonia nitrog...

Embodiment 2

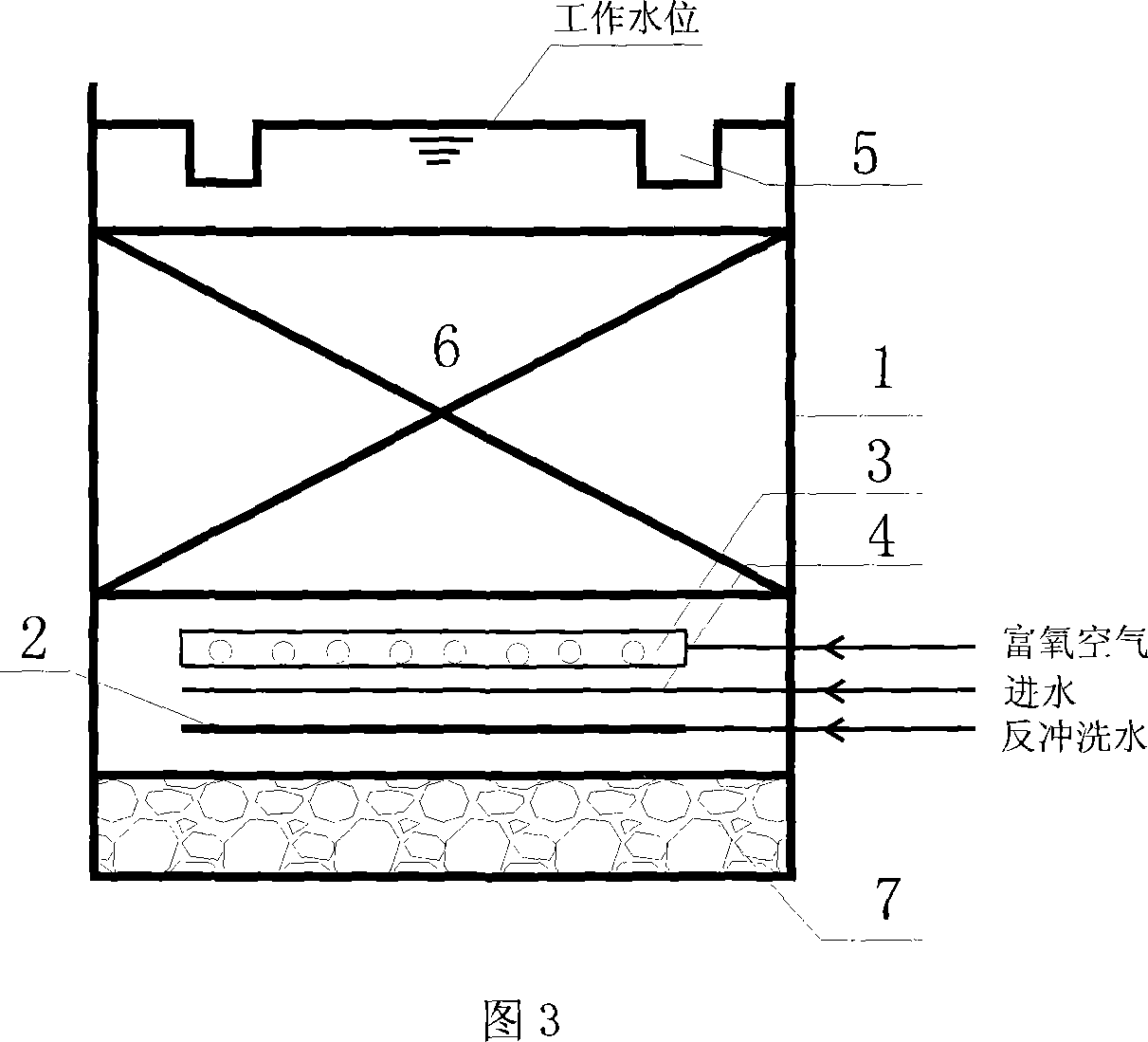

[0050] The nitrosation and nitration reactor using the above reaction principle can adopt two modes of upflow and downflow. The structure of the upward flow reactor is shown in Figure 3. From bottom to top, there are supporting layer 7, backwashing device 2, water inlet and distribution device 4, air diffusion device 3, iron / carbon composite material 6, water collection The device 5 is arranged in the bed (1).

[0051] The structure of the downflow reactor is shown in Figure 4. From bottom to top, there are supporting layer (7), water collecting device (5), backwashing device (2), air diffusion device (3), iron / carbon The composite material (6) and the water inlet and distribution device (4) are arranged in the reactor bed (1).

[0052] The iron-carbon composite material described in an upflow reactor or a downflow reactor is composed of 80% to 90% (volume) iron filings / carbon mixture and 20% to 10% (volume) filler, wherein Iron filings are oil-free carbon steel with a diame...

Embodiment 3

[0059] Nitrosation of iron and carbon—combined process of traditional biological denitrification

[0060] The present invention combines the iron-carbon nitrosation process and the traditional biological denitrification process into a complete new denitrification process. The process flow is shown in Figure 5, and the denitrification effect of the combined process is shown in Figure 6. After ammonia-containing wastewater passes through the iron-carbon nitrosation reactor, control the appropriate pH value and appropriate amount of dissolved oxygen to convert ammonia nitrogen into nitrite, and then use traditional denitrifying bacteria to perform biological denitrification of nitrite-containing wastewater Nitrification and denitrification, through this process, the denitrification treatment of ammonia nitrogen-containing wastewater has been successfully realized. This process is an organic combination of iron-carbon nitrosation process and biological denitrification process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com