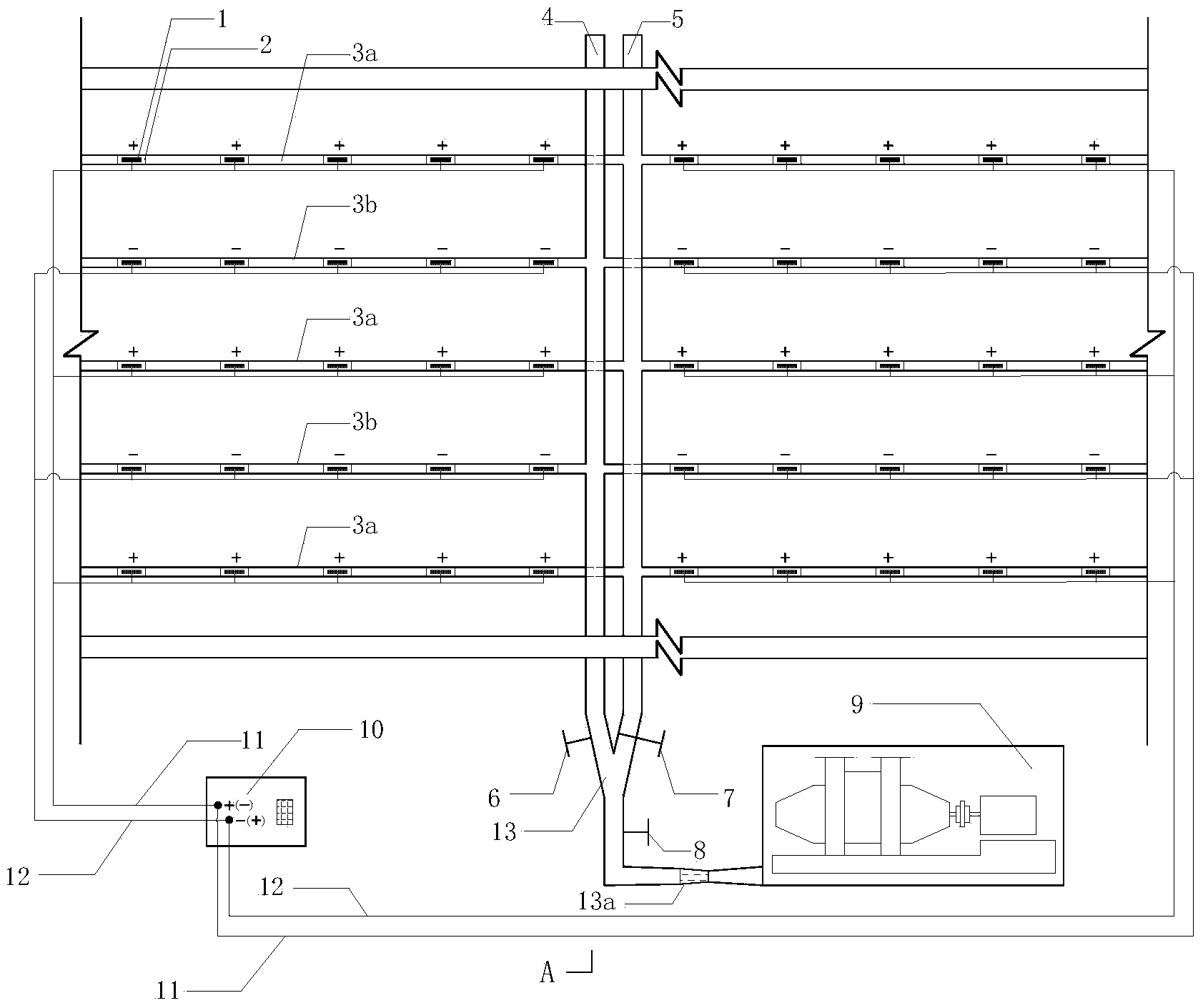

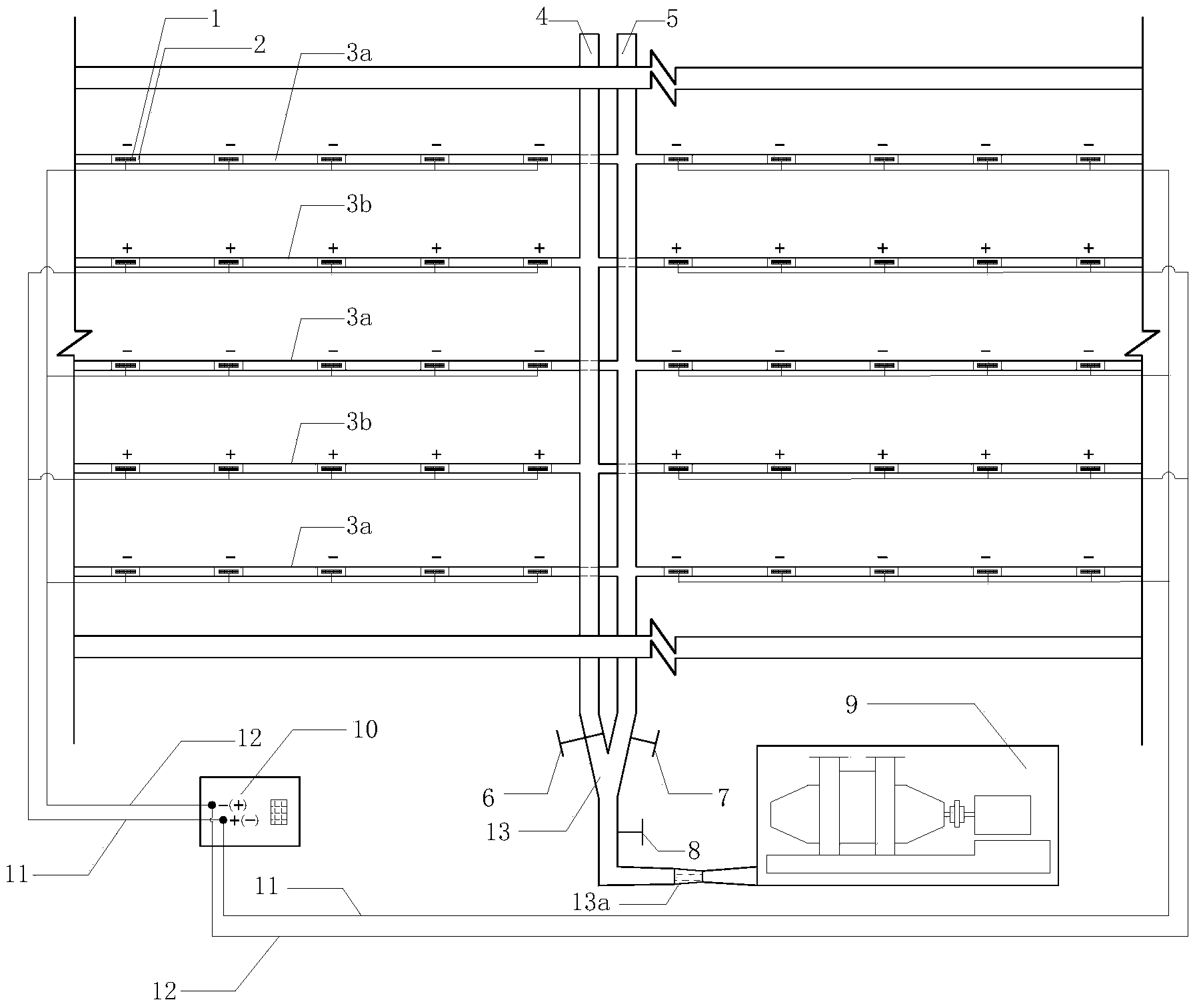

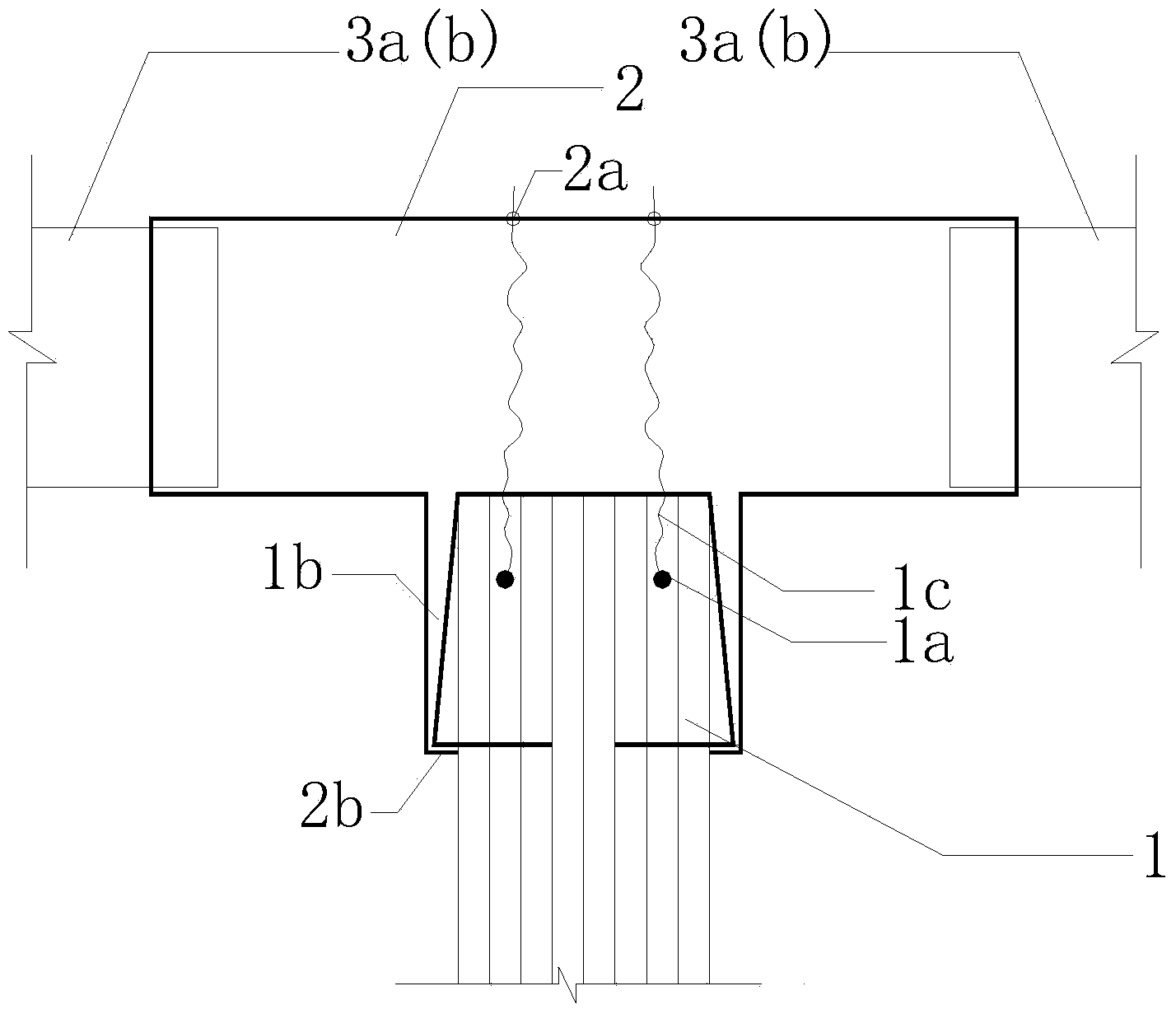

Method and device for accelerating ultra-soft soil solidification through dual-passage variable-polarity vacuum electroosmosis

A dual-channel, variable-pole technology, used in soil protection, infrastructure engineering, construction, etc., can solve the problems of not considering the energy offset effect, low vacuum transfer efficiency, and increased energy consumption per unit time, to avoid energy Cancellation effect, avoidance of containment effect, effect of short load time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Located in a dredger reclamation area in Ezhou, Hubei, the average depth of dredger reclamation is about 3~6m. The newly dredged silt has the characteristics of high water content, high compressibility, poor water permeability and extremely low initial bearing capacity. Before treatment, the moisture content of the soil in the test area was greater than 150%, and the wet density was 1.43g / cm 3 , liquid limit 92.6%, plastic limit 39.1%; particles larger than 0.075mm accounted for 2.7%, 0.075mm~0.005mm accounted for 52.1%, less than 0.005mm accounted for 45.2%; The force is close to 0, and it needs to be used as a foundation after treatment. The bearing capacity of the treated foundation is required to be greater than 55kPa. In addition to forming a shallow hard crust of about 1m, the reinforcement depth is also required to be at least 2m.

[0048] A method for accelerating supersoft soil consolidation by double-channel variable pole vacuum electroosmosis, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com