Surface layer polyurethane resin for waterproof and moisture permeable synthetic leather and preparation method of polyurethane resin

A waterproof and moisture-permeable, synthetic leather technology, applied in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., can solve problems such as technical deficiencies, and achieve excellent wear resistance, excellent waterproof and moisture-permeable performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

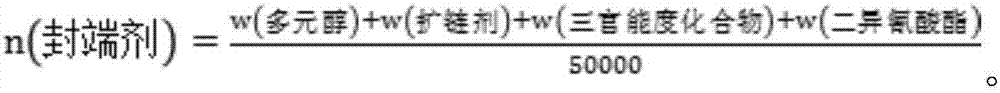

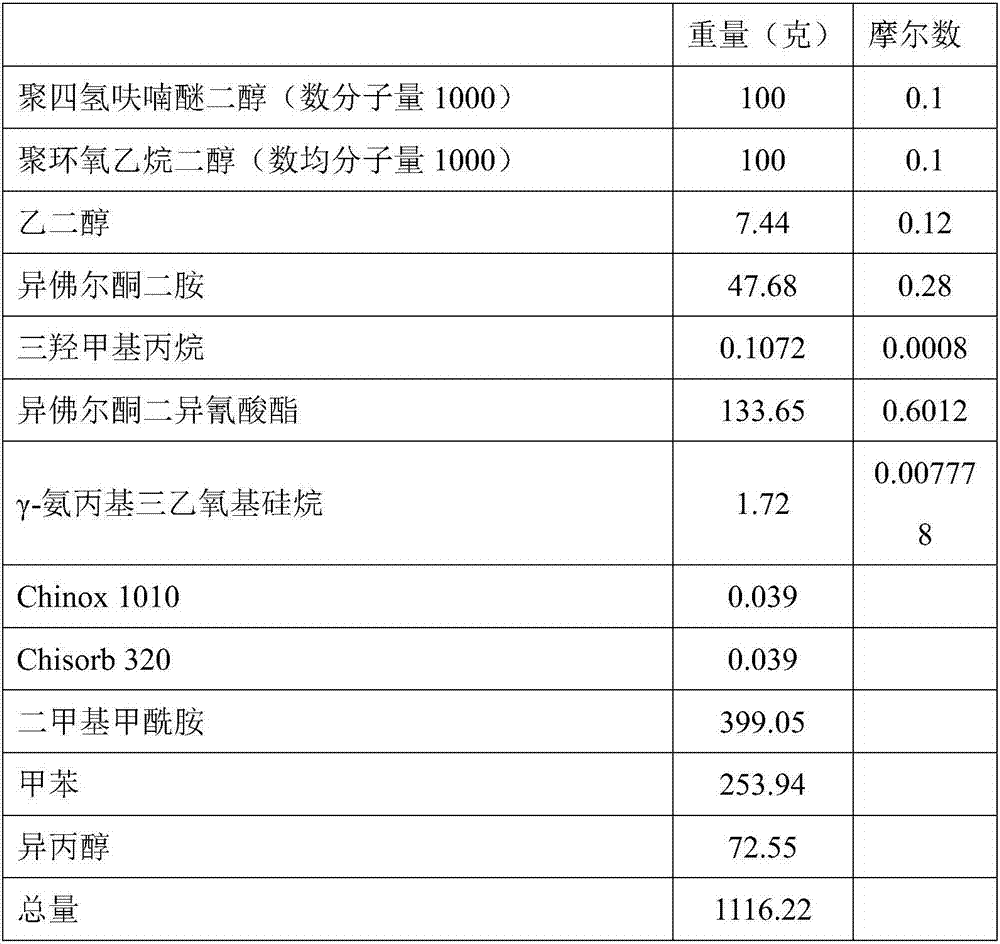

[0038] The raw materials used in this embodiment and their weight are shown in Table 1.

[0039] Table 1

[0040]

[0041] The preparation method is as follows:

[0042] (1) Mix 0.039g Chinox 1010, 100g polytetrahydrofuran ether glycol, 100g polyethylene oxide glycol, 0.1072g trimethylolpropane, 7.44g ethylene glycol, and 79.81g dimethylformamide at 60°C ;

[0043] (2) Then add 133.65g of isophorone diisocyanate, heat up to 105°C, prepolymerize for 3 hours, then cool down to 40°C, add 319.24g of dimethylformamide and 253.94g of toluene, and stir for 30 minutes;

[0044] (3) Add 47.68g of isophoronediamine, react at 40°C for 5 hours, add 72.55g of isopropanol and 1.72g of γ-aminopropyltriethoxysilane, stir for 30 minutes and add 0.039g of Chisorb 320 to obtain The surface layer polyurethane resin is used for the waterproof and moisture-permeable synthetic leather.

Embodiment 2

[0046] The raw materials used in this embodiment and their weight are shown in Table 2.

[0047] Table 2

[0048]

[0049] The preparation method is as follows:

[0050] (1) Mix 0.55g Chinox 1035, 300g polytetrahydrofuran propylene oxide copolyether diol, 900g polytetrahydrofuran ethylene oxide copolyether diol, 6g trihydroxypolyether, 28.8g butanediol, 998.88g dimethylethylene glycol Amides are mixed evenly at 50°C;

[0051] (2) Then add 336.72g of hexamethylene diisocyanate, heat up to 95°C, prepolymerize for 2 hours, then cool down to 30°C, add 2330.72g of dimethylacetamide and 1664.8g of butanone, and stir for 25 minutes;

[0052] (3) Add 269.26g of 4,4'-diaminodicyclohexylmethane, react at 30°C for 4 hours, add 554.93g of isobutanol and 6.6g of γ-aminopropyltrimethoxysilane, stir for 30 minutes and then add 1.85g of Chisorb 292, the surface layer polyurethane resin for the waterproof and moisture-permeable synthetic leather can be obtained.

Embodiment 3

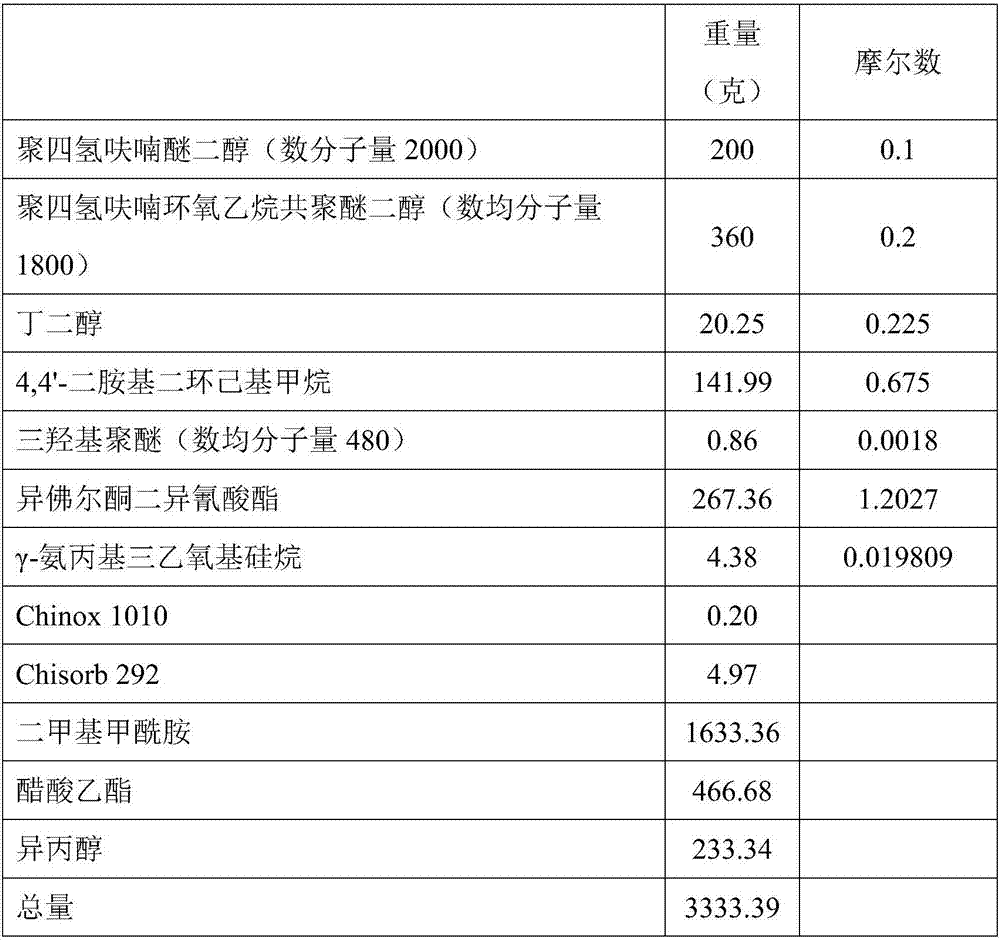

[0054] The raw materials used in this embodiment and their weight are shown in Table 3.

[0055] table 3

[0056]

[0057] The preparation method is as follows:

[0058] (1) 0.2g Chinox 1010, 200g polytetrahydrofuran ether diol, 360g polytetrahydrofuran oxirane copolyether diol, 0.86g trihydroxy polyether, 20.25g butanediol, 408.34g dimethylformamide in 60 ℃ mixed evenly;

[0059] (2) Then add 267.36g of isophorone diisocyanate, heat up to 95°C, prepolymerize for 3 hours, then cool down to 30°C, add 1225.02g of dimethylformamide and 466.68g of ethyl acetate, and stir for 25 minutes ;

[0060] (3) Add 141.99g of 4,4'-diaminodicyclohexylmethane, react at 40°C for 4 hours, add 233.34g of isopropanol and 4.38g of γ-aminopropyltriethoxysilane, stir for 30 minutes and then add 4.97g Chisorb 292, the polyurethane resin for the surface layer of the waterproof and moisture-permeable synthetic leather can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com