Method for preparing nano-ceramet-base metal ceramic

A technology of nano-cermets and cermets, which is applied in the coating process and coating of metal materials, can solve the problems of reduced toughness and toughness of cemented carbide, and achieve the effect of superior wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

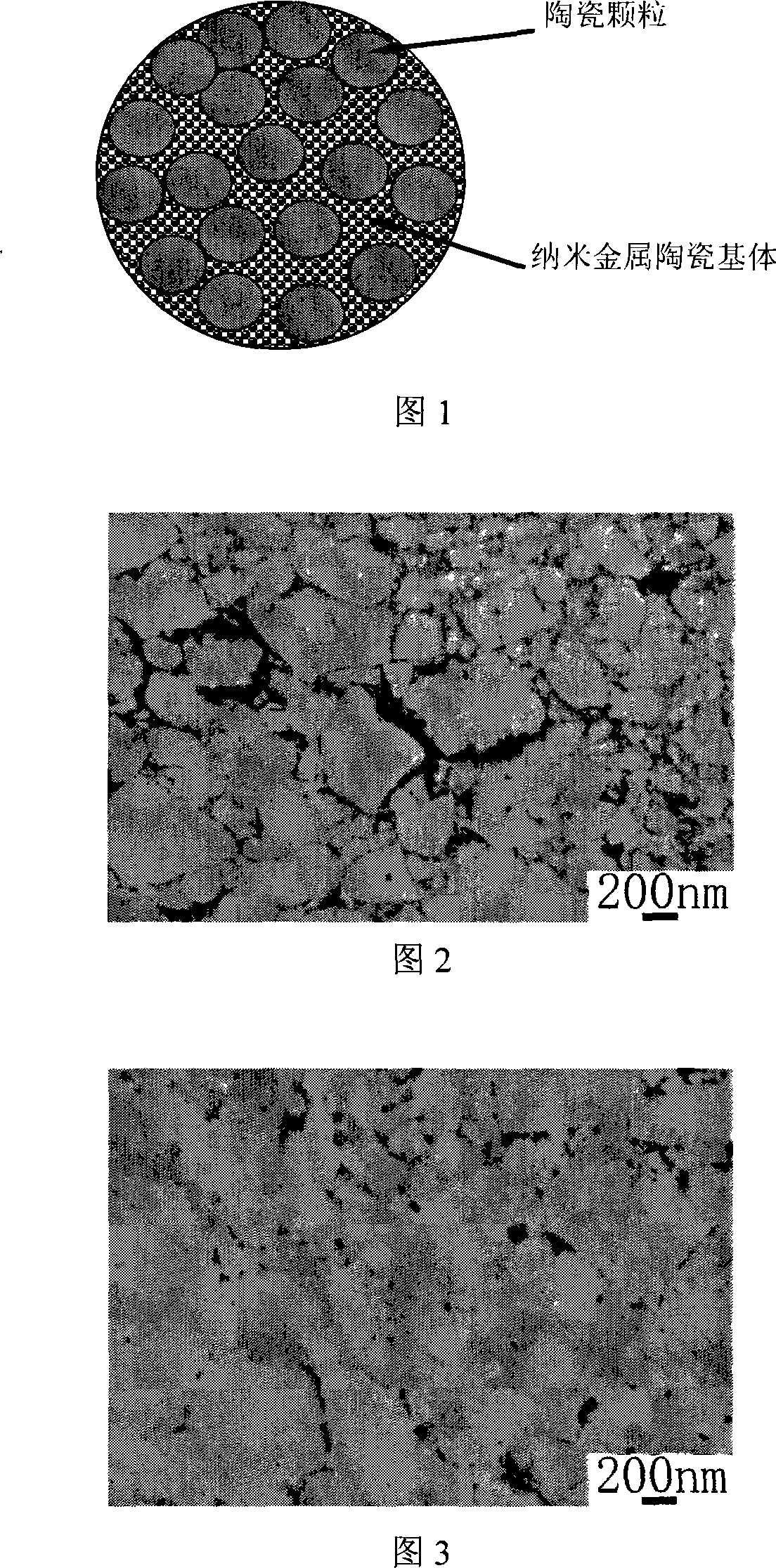

[0030] For the cermet material composed of WC and Co, nano-WC-Co-based WC-(nano-WC-Co) spray powder was used, and the CS-2000 cold spray system was used to prepare the coating, with helium as the accelerating gas. The WC-(nano-WC-Co) coating was prepared by deposition on the surface of the substrate. The analysis results of the microstructure of the coating (as shown in Figure 2) show that some larger particles of WC ceramic phases are distributed in the nano-WC-Co matrix of the coating. Hardness analysis shows that the average hardness of the coating exceeds 1800Hv in the sprayed state, which is close to the hardness of the nanostructured WC-Co alloy bulk material with the same composition. During the cold spraying process, the powder particle deformation process causes severe deformation in the area near the interface between the powders. The metal Co in this area forms a fine-grained metastable structure with high-density defects due to the severe deformation. Due to the ge...

Embodiment 2

[0033] For the cermet material composed of WC and Co, the traditional micron-structured WC-12Co cemented carbide powder was selected as the raw material. The typical initial particle size of WC in the powder is 0.3 μm to 1 μm, and the planetary ball mill was used for 72 hours at room temperature to obtain Part of the WC phase in the powder becomes nano-scale WC small particles due to ball milling, while the other part remains sub-micron. After sieving, 300-500-mesh spray powder is obtained, and the coating is prepared by a cold spray system. In order to accelerate the gas, the WC-(nano-WC-Co) coating was prepared by depositing on the surface of the substrate. The analysis results of the microstructure of the coating (as shown in Figures 4 and 5) show that some larger particles of WC ceramic phases are distributed in the nano-WC-Co matrix of the coating. . Hardness analysis shows that the average hardness of the coating is 1715Hv in the as-sprayed state, which is close to the ...

Embodiment 3

[0035] For cBN, Cr 3 C 2, NiCrAl composed of cermet materials, select nano-scale cBN, micron-scale Cr 3 C 2 Mix with NiCrAl alloy according to the volume ratio of 20:40:40 and then ball mill to obtain composite powder, which is sieved to obtain 600-400-mesh composite powder, and the coating is prepared by cold spraying system, using nitrogen as the accelerating gas, on the aluminum substrate Thick coatings are prepared by surface deposition, and the aluminum substrate is removed by alkaline solution to obtain cBN-Cr 3 C 2 -NiCrAl bulk material, after 800℃ diffusion treatment for 2h, get nano-cBN-nano-Cr 3 C 2 -NiCrAl-based large-grained Cr 3 C 2 Reinforced high-strength and high-toughness cermets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com