Preparation method and application of protective film in full lamination with mobile terminal

A technology of mobile terminal and protective film, applied in the field of optical film, can solve the problems of low thickness of mobile terminal and difficult to rewind the protective film, and achieve the effect of excellent tension, high tension and high tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

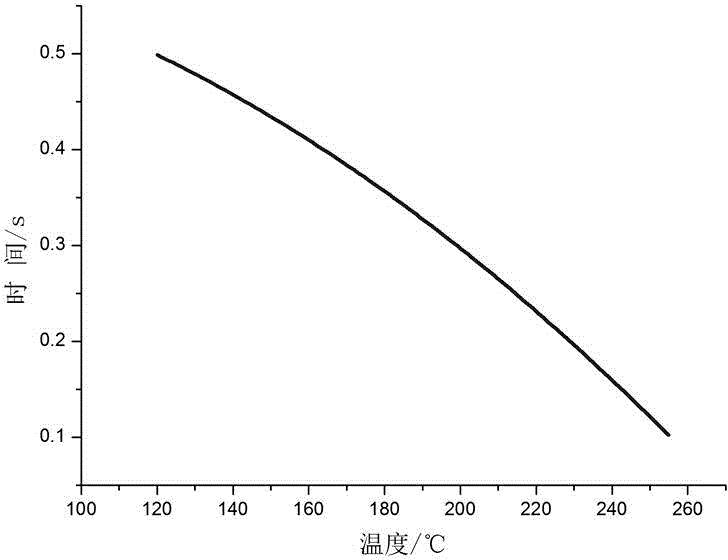

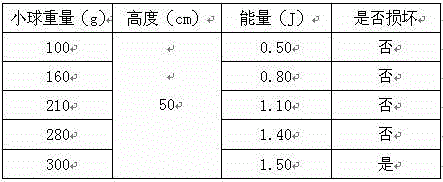

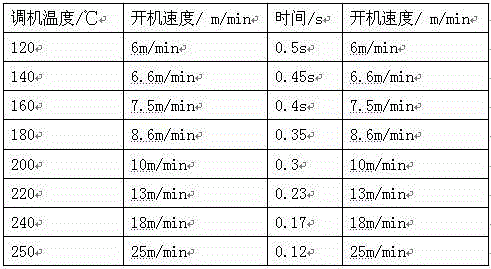

Embodiment 1

[0074] A protective film that can be fully attached to a mobile terminal in this embodiment, the protective film includes a polyester film base material, and the upper surface of the polyester film base material is bonded with a first release layer by hot pressing with a film pressing wheel. type film, the curve equation of the laminating temperature and time of the polyester film base material on the lamination pressing wheel is T=429X 2 -83X+(261~271) s, the hot pressing temperature of the film-coated pressing wheel is 100°C, the speed of the film-coated pressing wheel is 5m / min, the contact length of the two film-coated pressing wheels The lower surface of the polyester film substrate is provided with an adhesive layer, the lower surface of the adhesive layer is provided with a second release film, and the surface viscosity of the adhesive layer is No. 5 steel balls.

[0075] The adhesive layer is a silicone adhesive layer: the adhesive layer is coated with a comma-type doc...

Embodiment 2

[0090] A protective film that can be fully attached to a mobile terminal in this embodiment, the protective film includes a polyester film base material, and the upper surface of the polyester film base material is bonded with a first release layer by hot pressing with a film pressing wheel. type film, the curve equation of the laminating temperature and time of the polyester film base material on the lamination pressing wheel is T=429X 2 -83X+(261~271)s, the hot pressing temperature of the film-coated pressing wheels is 150°C, the speed of the film-coated pressing wheels is 15m / min, the contact length of the two film-coated pressing wheels The lower surface of the polyester film substrate is provided with an adhesive layer, the lower surface of the adhesive layer is provided with a second release film, and the surface viscosity of the adhesive layer is No. 9 steel balls.

[0091] The adhesive layer is an acrylic adhesive layer: the adhesive layer is coated with a comma-type d...

Embodiment 3

[0103] A protective film that can be fully attached to a mobile terminal in this embodiment, the protective film includes a polyester film base material, and the upper surface of the polyester film base material is bonded with a first release layer by hot pressing with a film pressing wheel. type film, the curve equation of the laminating temperature and time of the polyester film base material on the lamination pressing wheel is T=429X 2 -83X+(261~271) s, the hot pressing temperature of the film-coated pressing wheel is 250°C, the speed of the film-coated pressing wheel is 20m / min, the contact length of the two film-coated pressing wheels The lower surface of the polyester film substrate is provided with an adhesive layer, the lower surface of the adhesive layer is provided with a second release film, and the surface viscosity of the adhesive layer is No. 15 steel balls.

[0104] The adhesive layer is a PU adhesive layer: the adhesive layer is coated with a comma-type doctor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com