Patents

Literature

30results about "Furnace repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

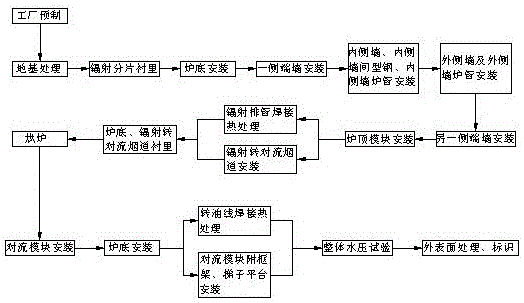

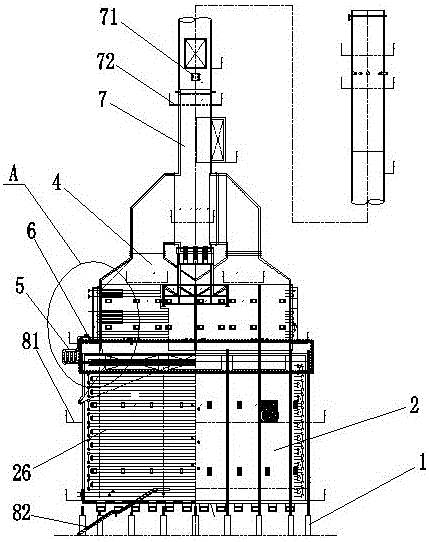

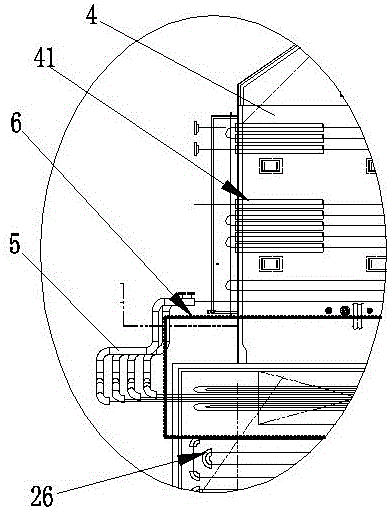

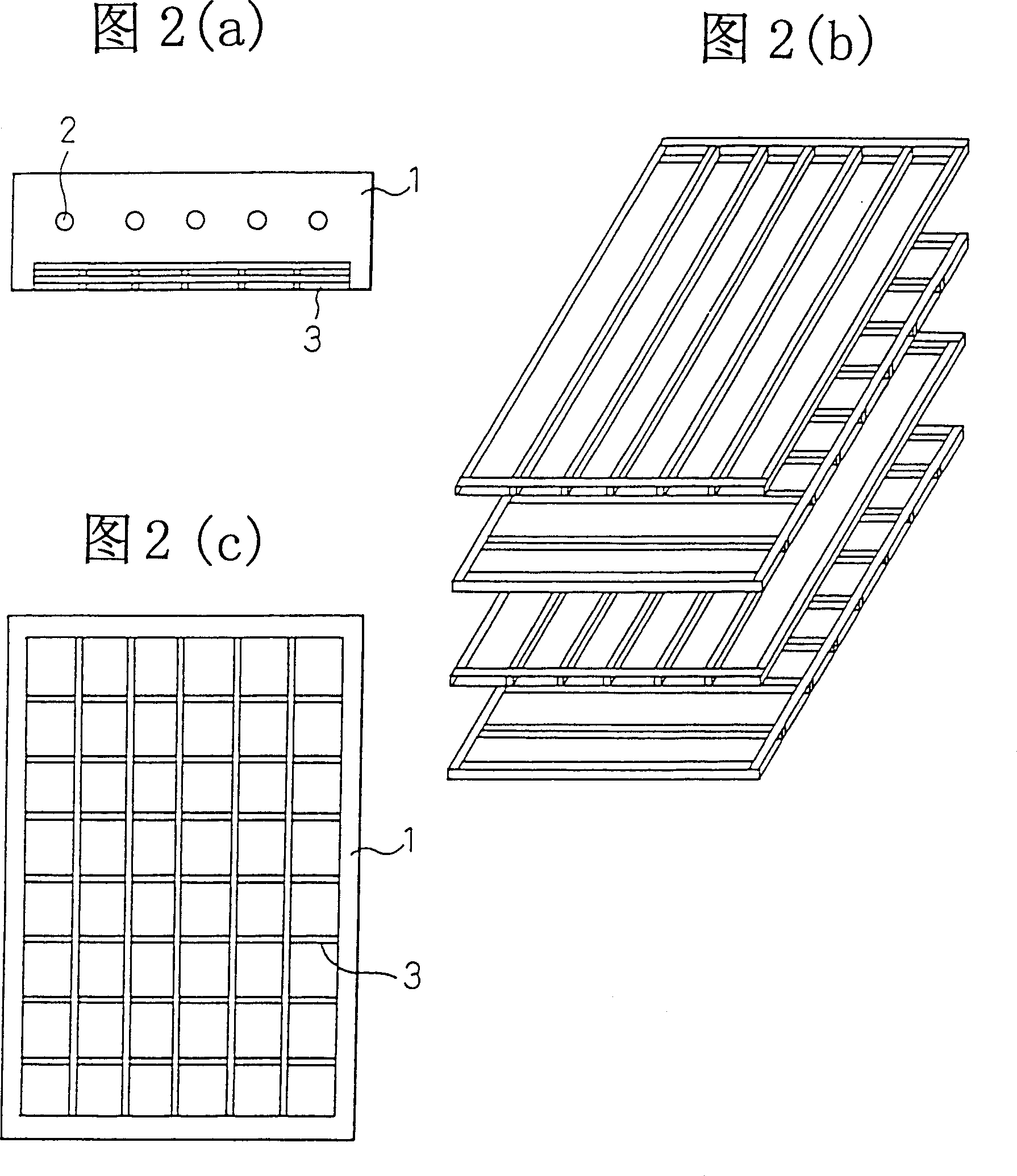

Modular manufacturing method for heating furnace and heating furnace manufactured through method

PendingCN106839775AShorten the manufacturing cycleReduce manufacturing costFurnace componentsFurnace repairRadiation transferHeating furnace

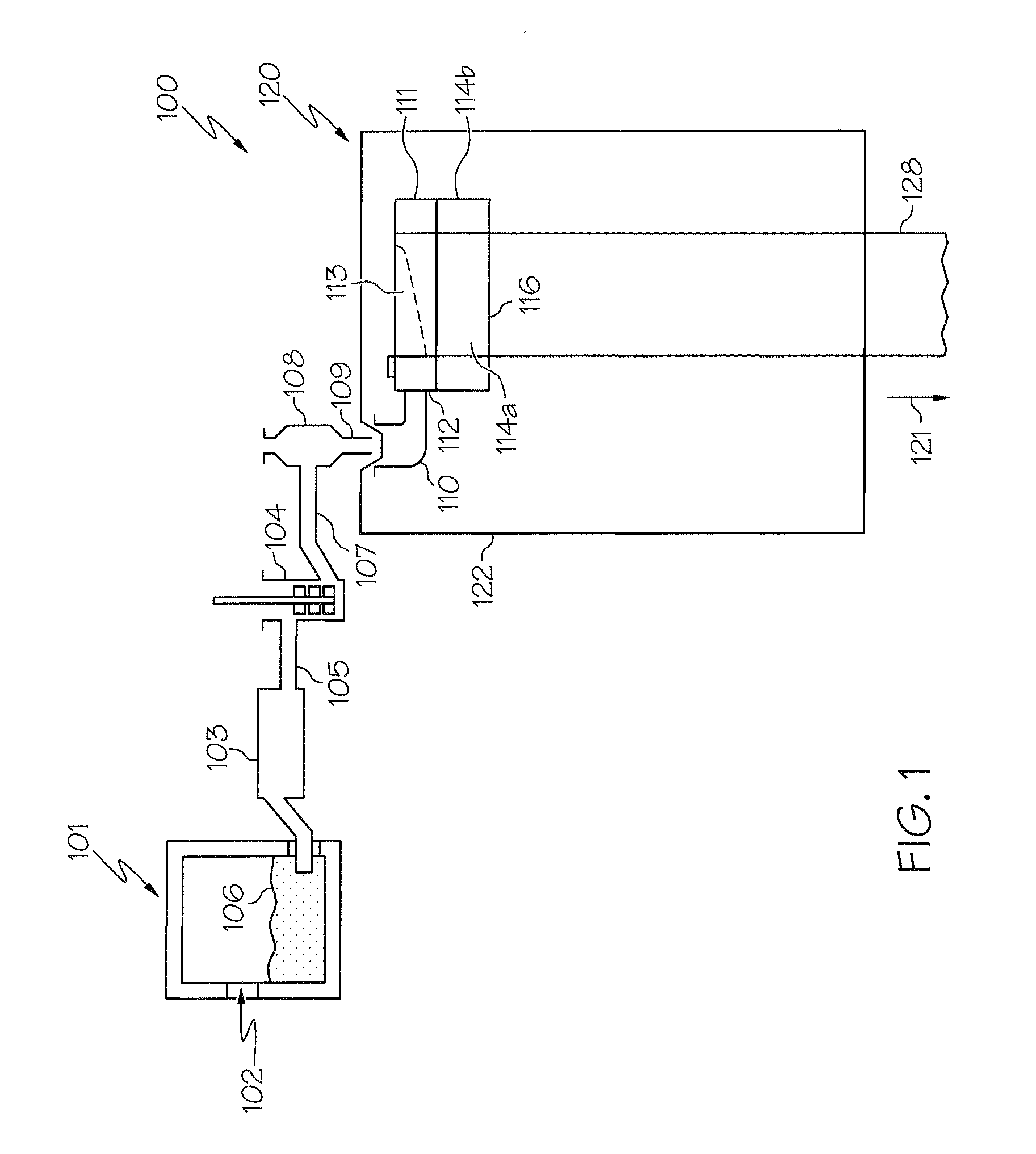

The invention discloses a modular manufacturing method for a heating furnace. The method comprises the following steps that all modules and radiation fragments are prefabricated in a factory; foundation treatment is performed; the radiation fragments are lined; a furnace bottom is mounted; end walls on one sides are mounted; inner side walls, connecting profile steel among the inner side walls and inner side wall furnace tubes are mounted; outer side walls and outer side wall furnace tubes are mounted; end walls on the other sides are mounted; furnace top modules are mounted; radiation exhaust pipes are subjected to welding heat treatment; a radiation transfer convection gas flue is mounted; the furnace bottom and the radiation transfer convection gas flue are lined; the furnace is baked; convection modules are mounted; a stack is mounted; oil transfer lines are subjected to welding heat treatment; a convection module attached frame and a ladder platform are mounted; an overall hydrostatic test is performed; and outer surface treatment is performed, and identifications are marked. The modular manufacturing method for the heating furnace has the advantages that advantages of modular manufacturing are fully played, the manufacturing period is shortened, the manufacturing cost is lowered, and the manufacturing quality is improved.

Owner:NINGBO LIANTONG EQUIP MFG

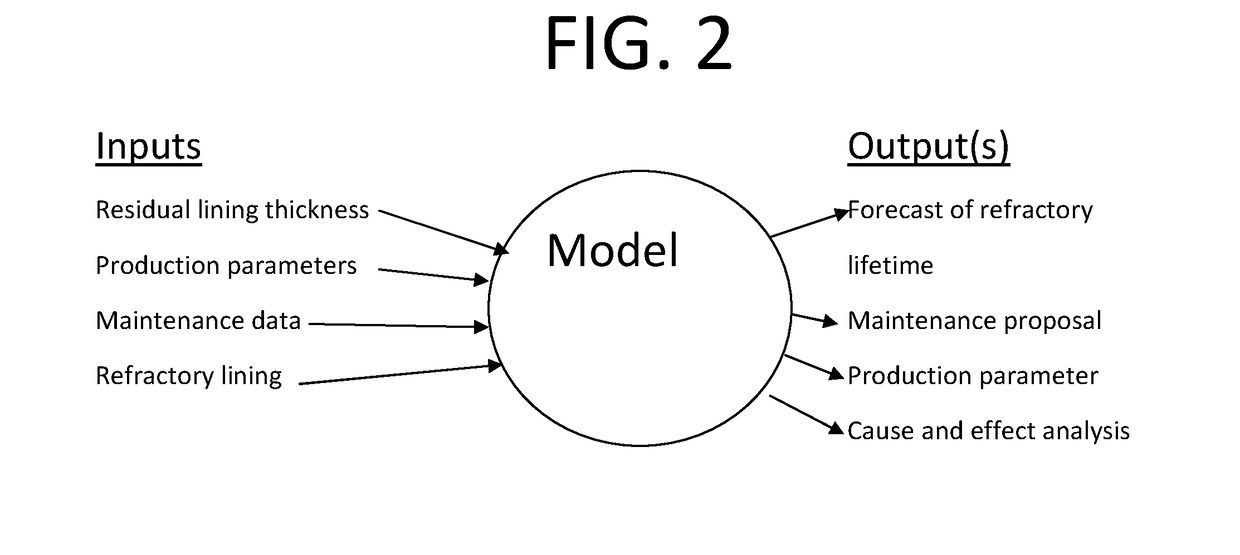

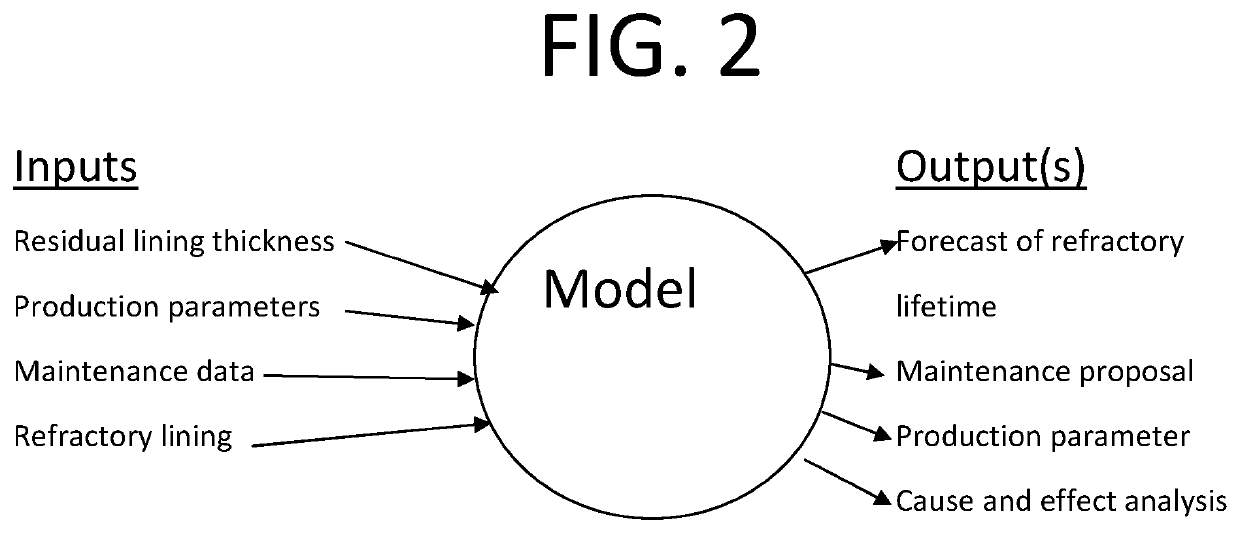

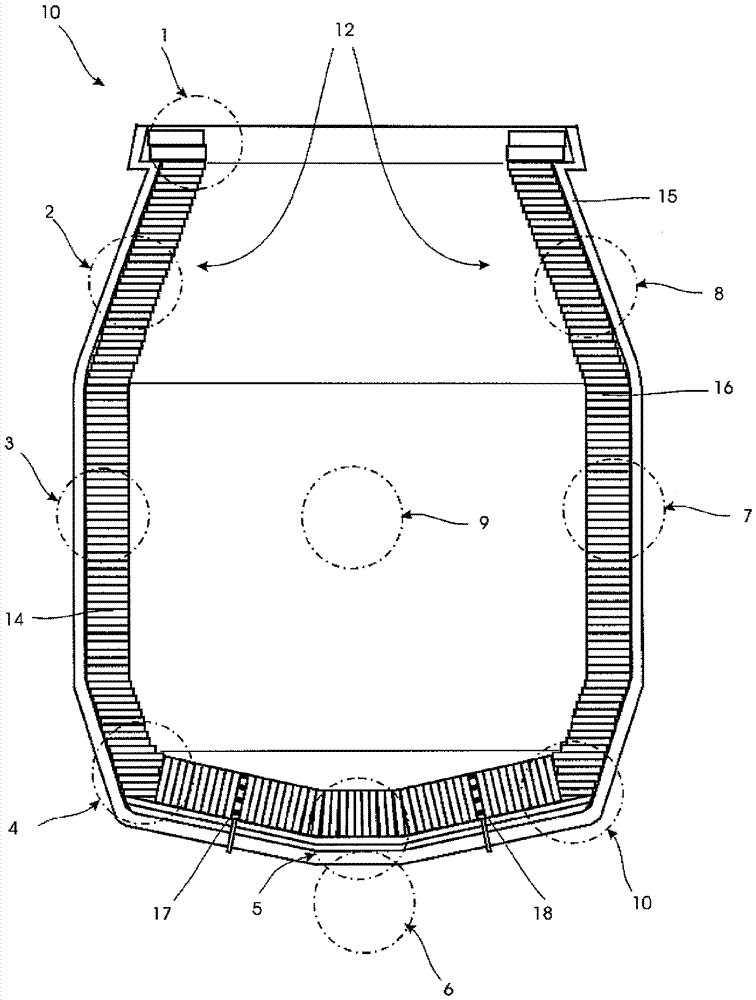

Method for determining the state of a refractory lining of a metallurgical vessel for molten metal in particular

ActiveUS20180347907A1Extended service lifeManual decisions for this purpose are reduced or practically eliminatedLinings repairSteel manufacturing process aspectsMarine engineeringAssessment data

Method for determining the state of a fire-resistant lining of a vessel containing molten metal in particular in which maintenance data, production data, and wall thicknesses at least at locations with the highest degree of wear are measured or ascertained together with additional process parameters of at least one identical / similar vessel after the vessel has been used. The data is collected and stored in a data structure. A calculating model is generated from at least some of the measured or ascertained data or parameters, and the data or parameters are evaluated using the calculating model using calculations and subsequent analyses. Thus, related or integral ascertaining processes and subsequent analyses can be carried out, on the basis of which optimizations relating to both the vessel lining as well as the complete process of the molten metal in the vessel are achieved.

Owner:REFRACTORY INTELLECTUAL PRORERTY GMBH & CO KG

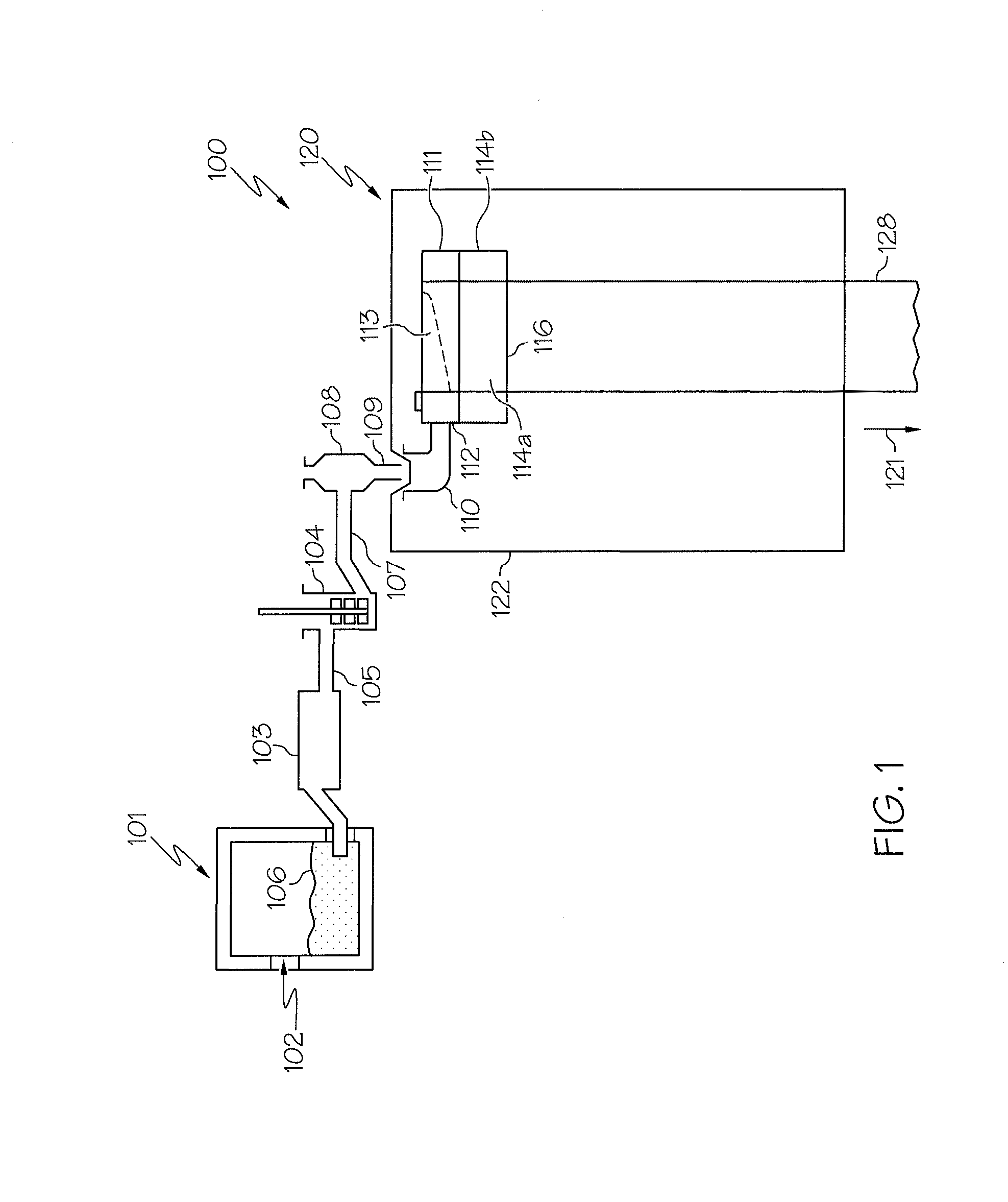

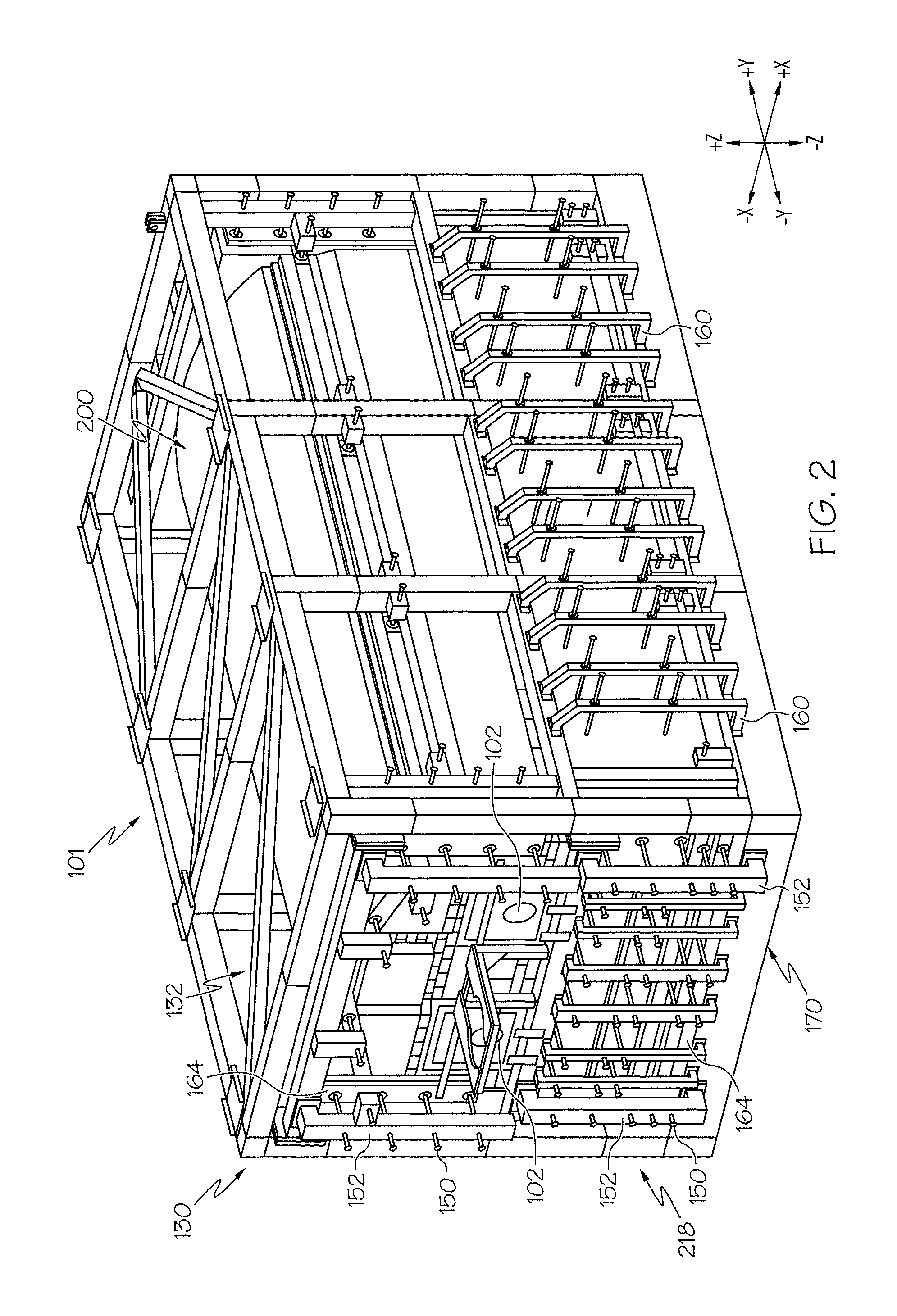

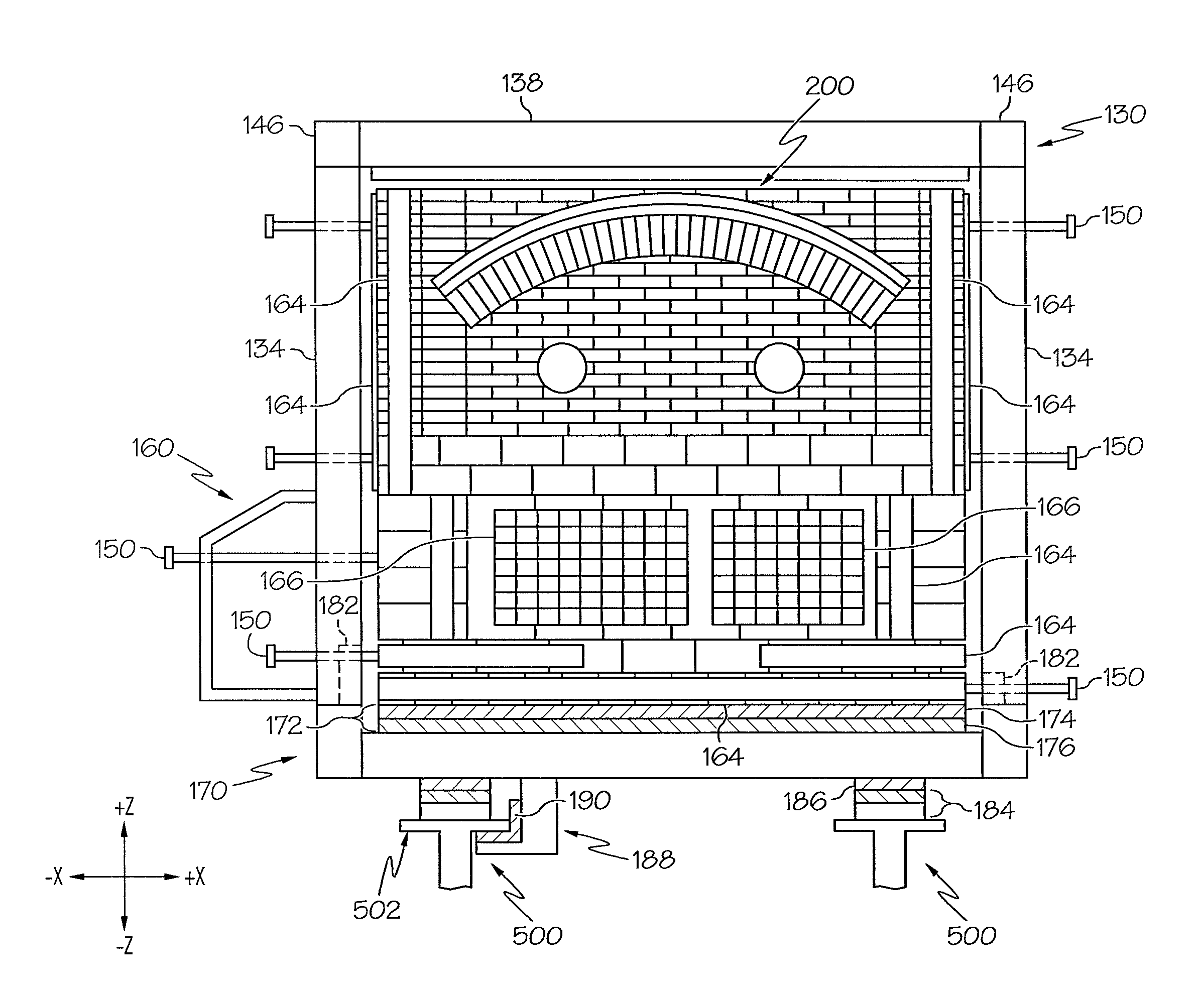

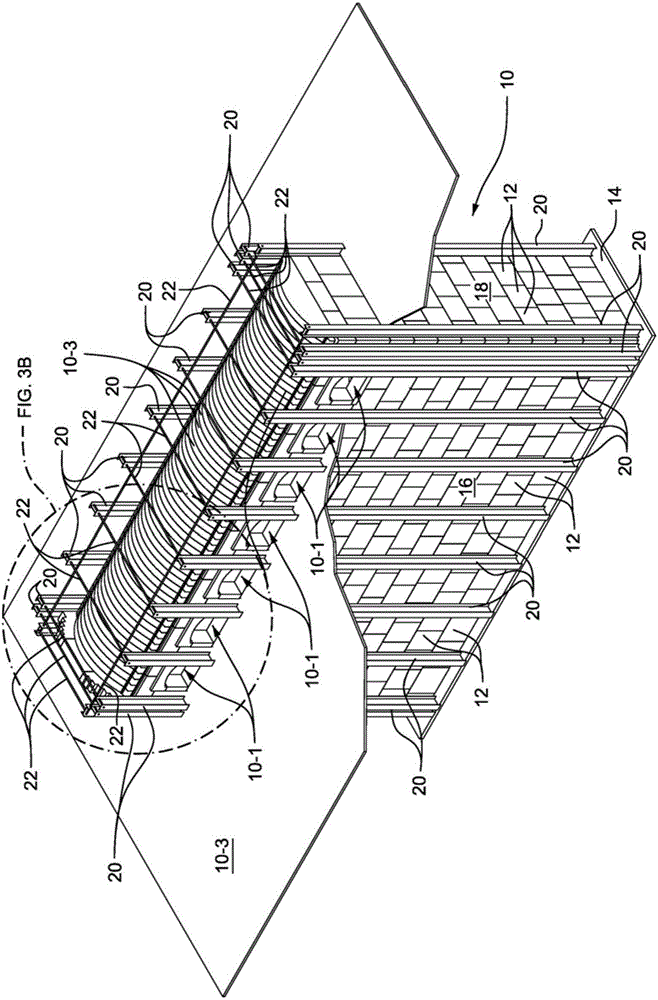

Melters for glass forming apparatuses

Melters for glass forming apparatuses and glass forming apparatuses comprising the same are disclosed. According to one embodiment, a melter for melting glass batch materials includes a base portion and a rigid exoskeleton rigidly attached to the base portion and comprising a plurality of upright members interconnected with a plurality of cross members defining an exoskeleton interior volume. Connection nodes formed at intersections of the plurality of cross members with upper ends of the plurality of upright members are constrained from movement relative to the base portion in a longitudinal direction, a transverse direction, and a vertical direction. A tank assembly is positioned on the base portion in the exoskeleton interior volume and coupled to the rigid exoskeleton. In some embodiments, the melter has a dynamic resistance greater than 0.3.

Owner:CORNING INC

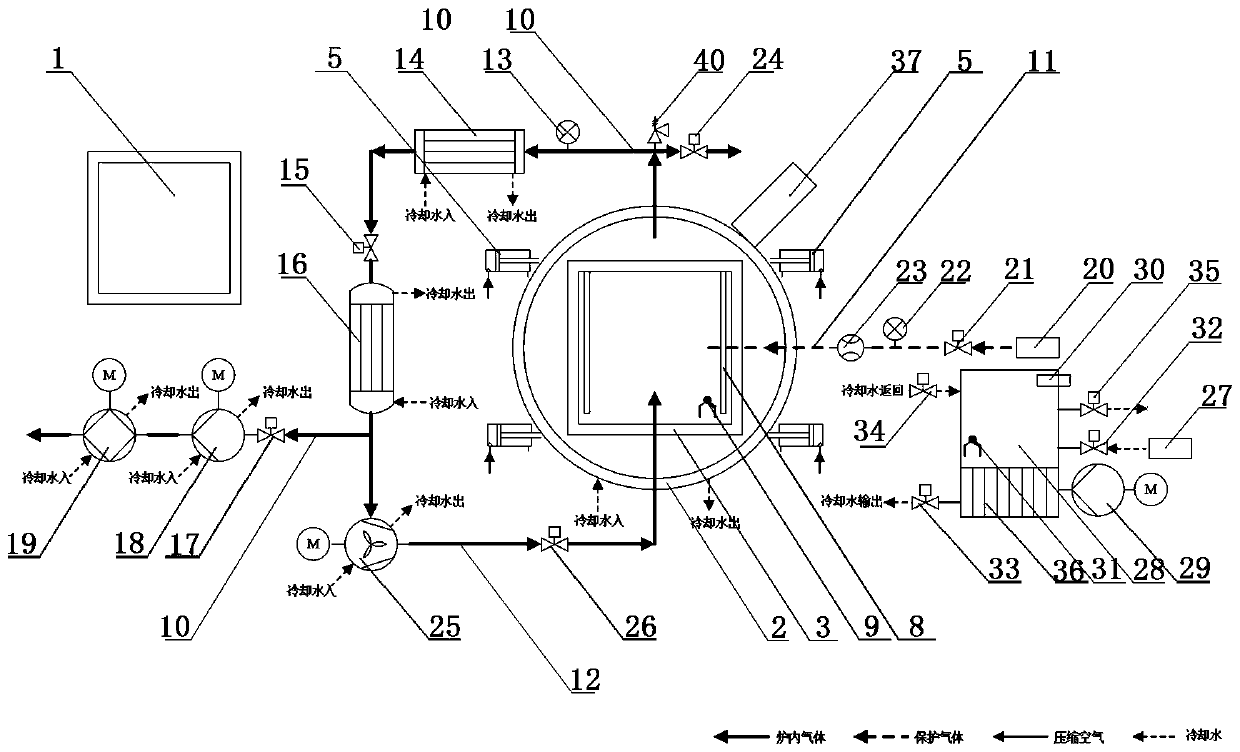

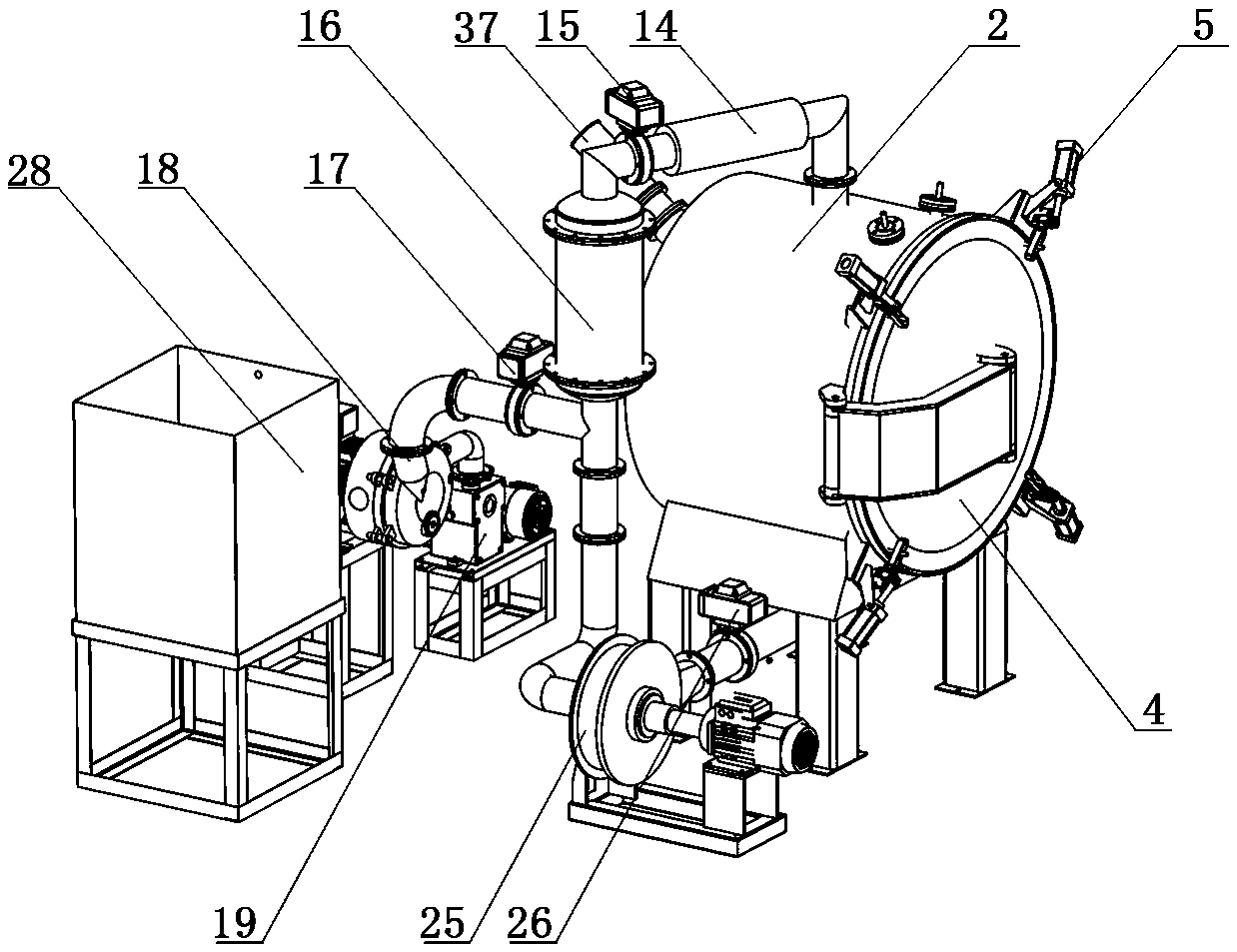

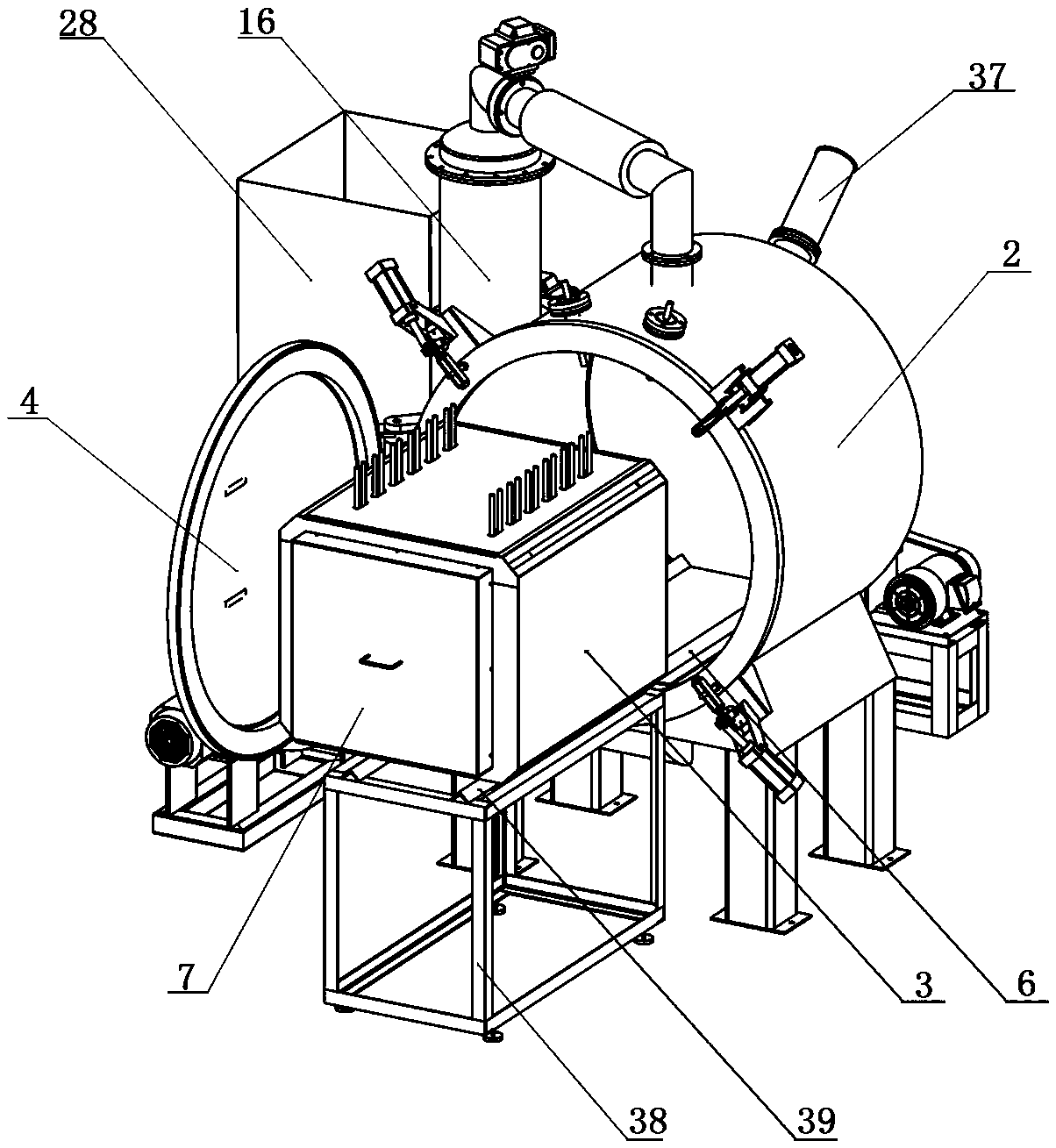

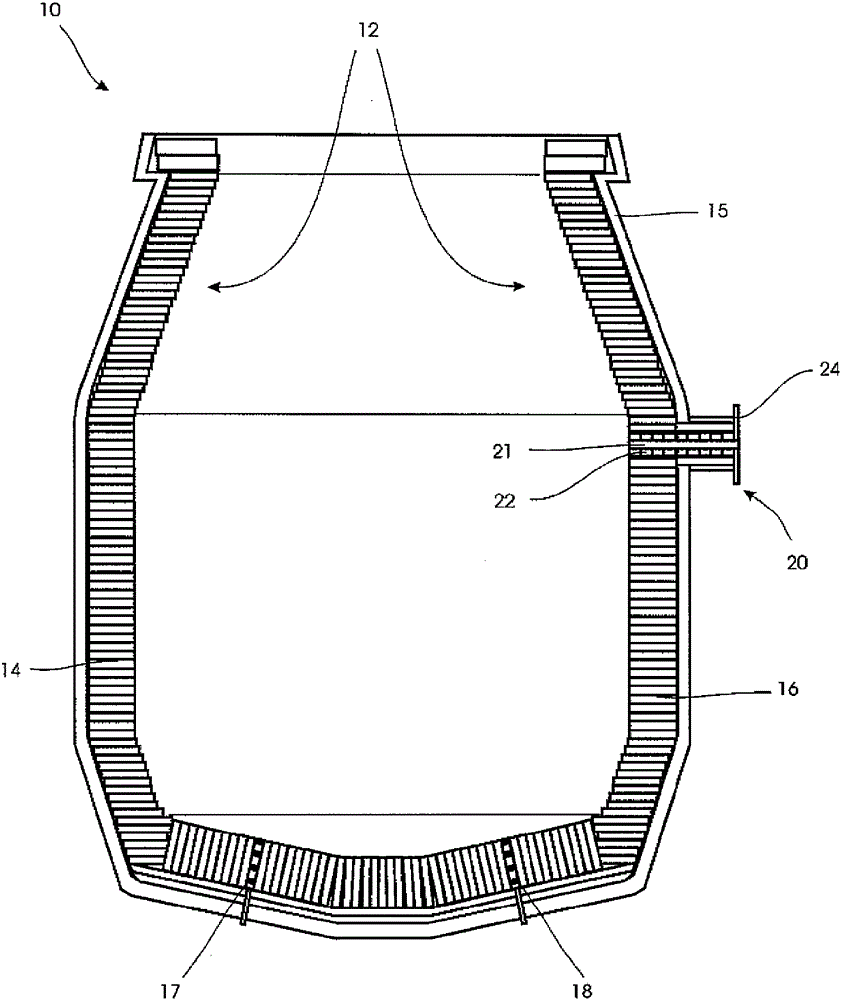

High temperature electric heating furnace for furnace body replacement and rapid material cooling

PendingCN111578710AReasonable structural designFunction increaseFurnace safety devicesMaintainance of heating chambersElectronic control systemHeating furnace

The invention relates to a high temperature electric heating furnace for furnace body replacement and rapid material cooling. The high temperature electric heating furnace for the furnace body replacement and rapid material cooling comprises an electronic control system, a heating furnace body, a vacuum atmosphere system and a water cooling system. A replaceable furnace body structure is adopted to adapt to the different protective atmosphere required for different materials, vacuum, inert gas, reducing gas, oxidizing gas, nitrogen and other protective atmospheres can be separately heated at high temperature on one equipment. A function of rapid cooling is further provided, parts can be quickly cooled under the protection of protective atmosphere, and the requirements of heat treatment process of different parts are met. The device has the advantages of compact massive structure, powerful function, high production efficiency, high heating temperature, high monitoring ability and the like, and is suitable for atmosphere sintering and heating production of various materials of different properties.

Owner:洛阳炬星窑炉有限公司

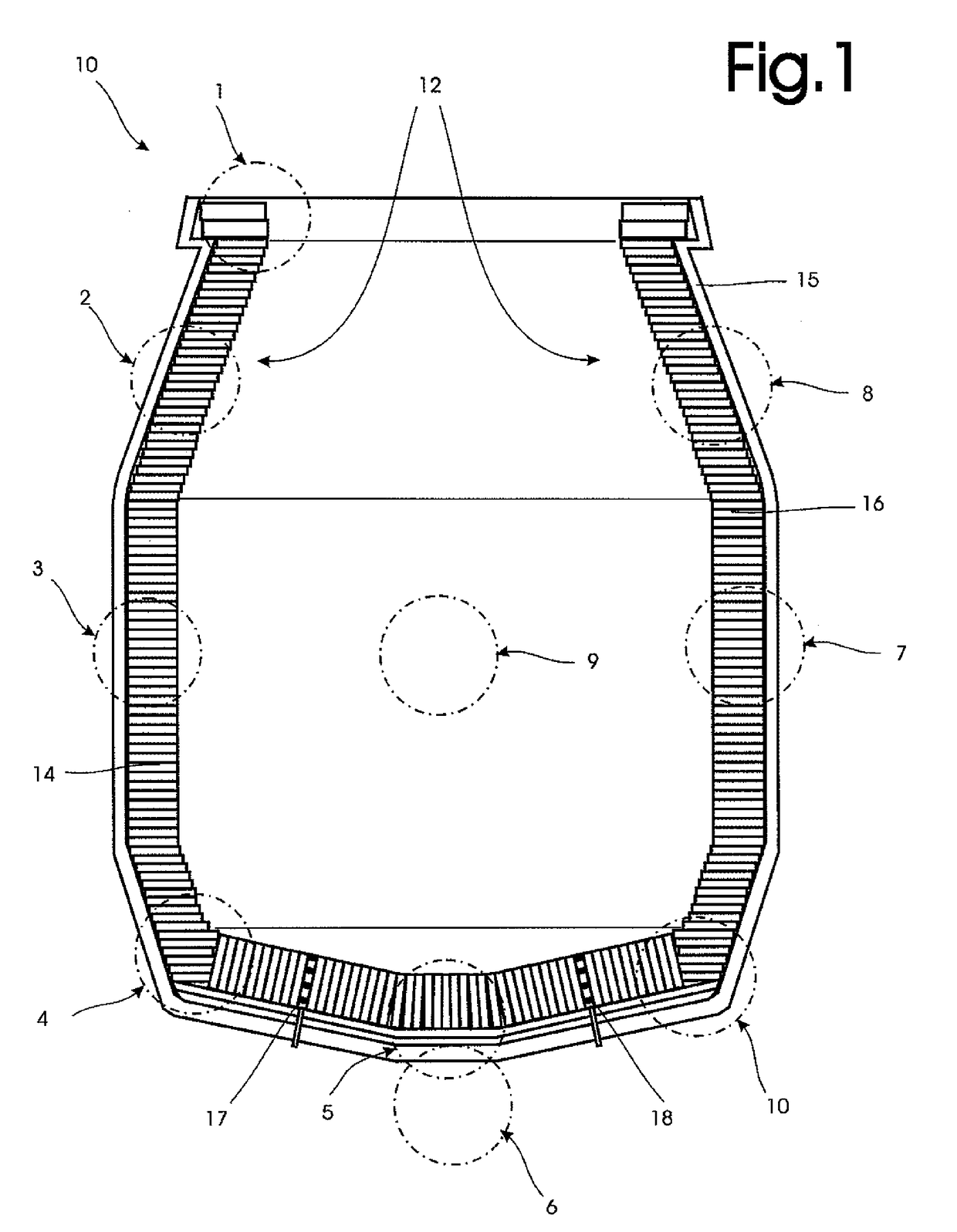

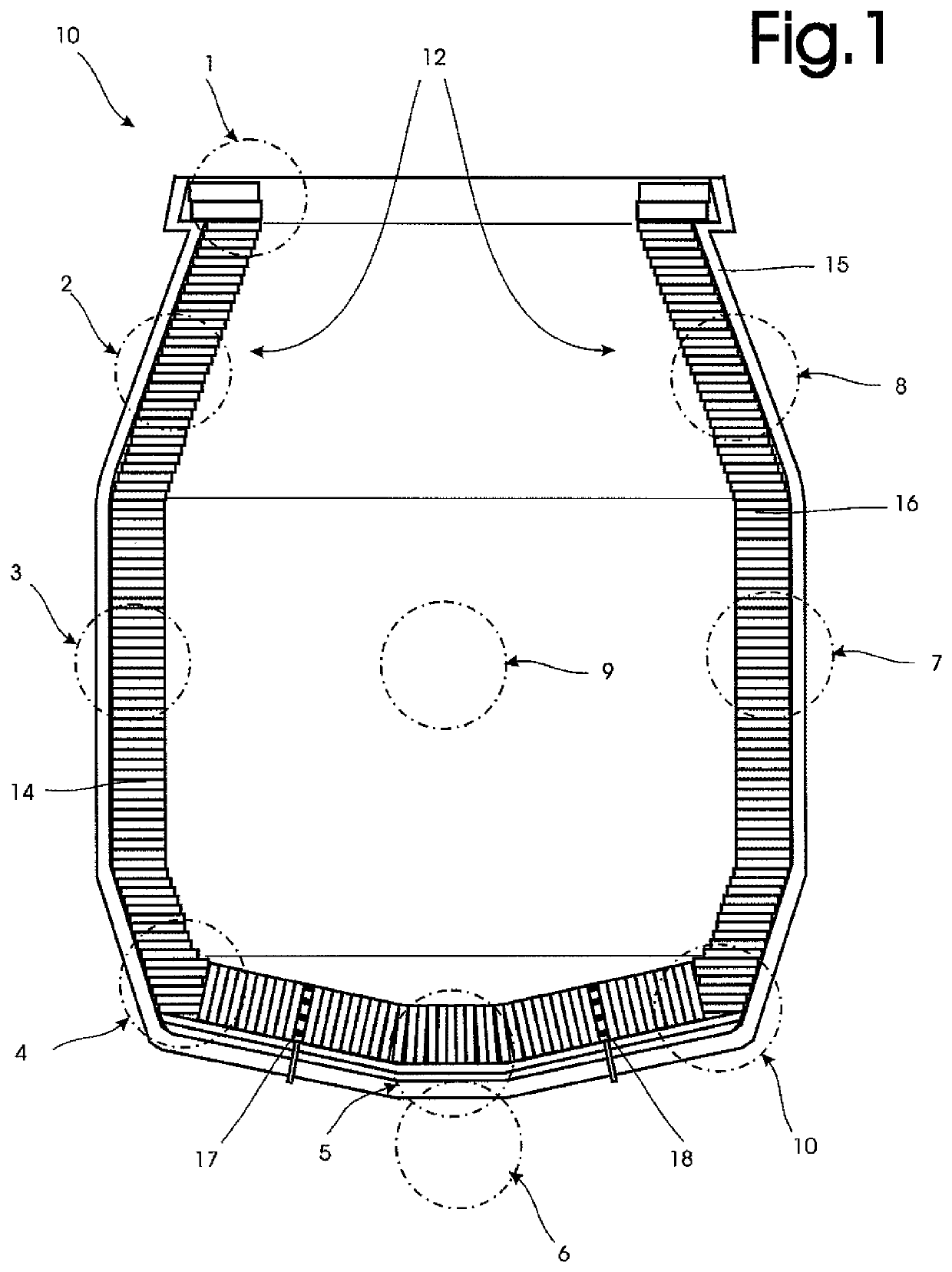

Method for determining the state of the tap of metallurgical vessel in particular

InactiveCN105102915AThe process steps are simpleRefractory lining optimizationLinings repairCharge manipulationMarine engineeringMolten metal

The invention relates to a method for determining the state of a fire-resistant lining of a vessel (10) containing molten metal in particular. In the process, maintenance data, production data, and wall thicknesses at least at locations with the highest degree of wear are measured or ascertained together with additional process parameters of a vessel (10) after the vessel (10) has been used. Said data is then collected and stored in a data structure. A calculating model is generated from at least some of the measured or ascertained data or parameters, and said data or parameters are evaluated by means of the calculating model using calculations and subsequent analyses. Thus, related or integral ascertaining processes and subsequent analyses can be carried out, on the basis of which optimizations relating to both the vessel lining as well as the complete process of the molten metal in the vessel are achieved.

Owner:REFRACTORY INTELLECTUAL PRORERTY GMBH & CO KG

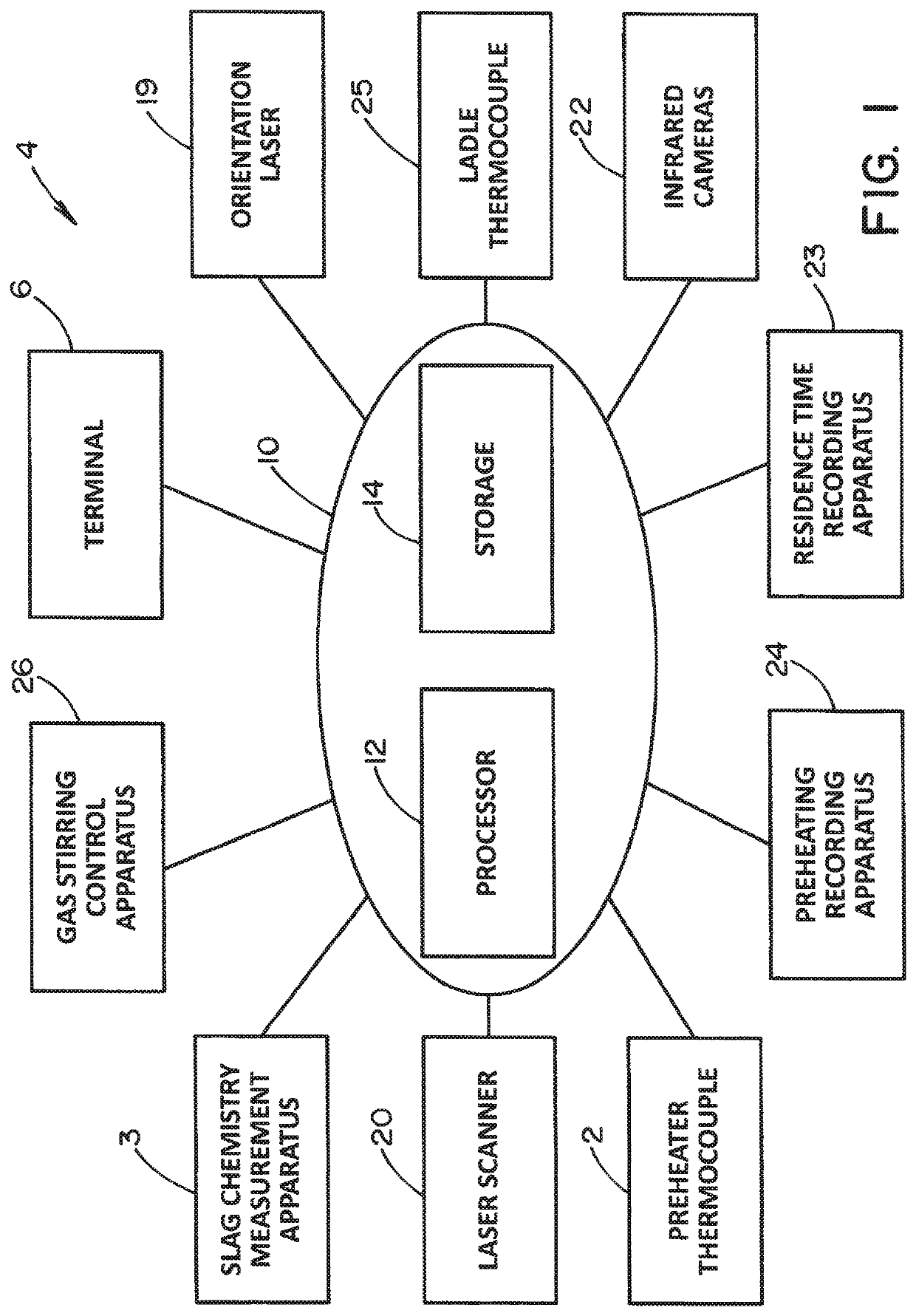

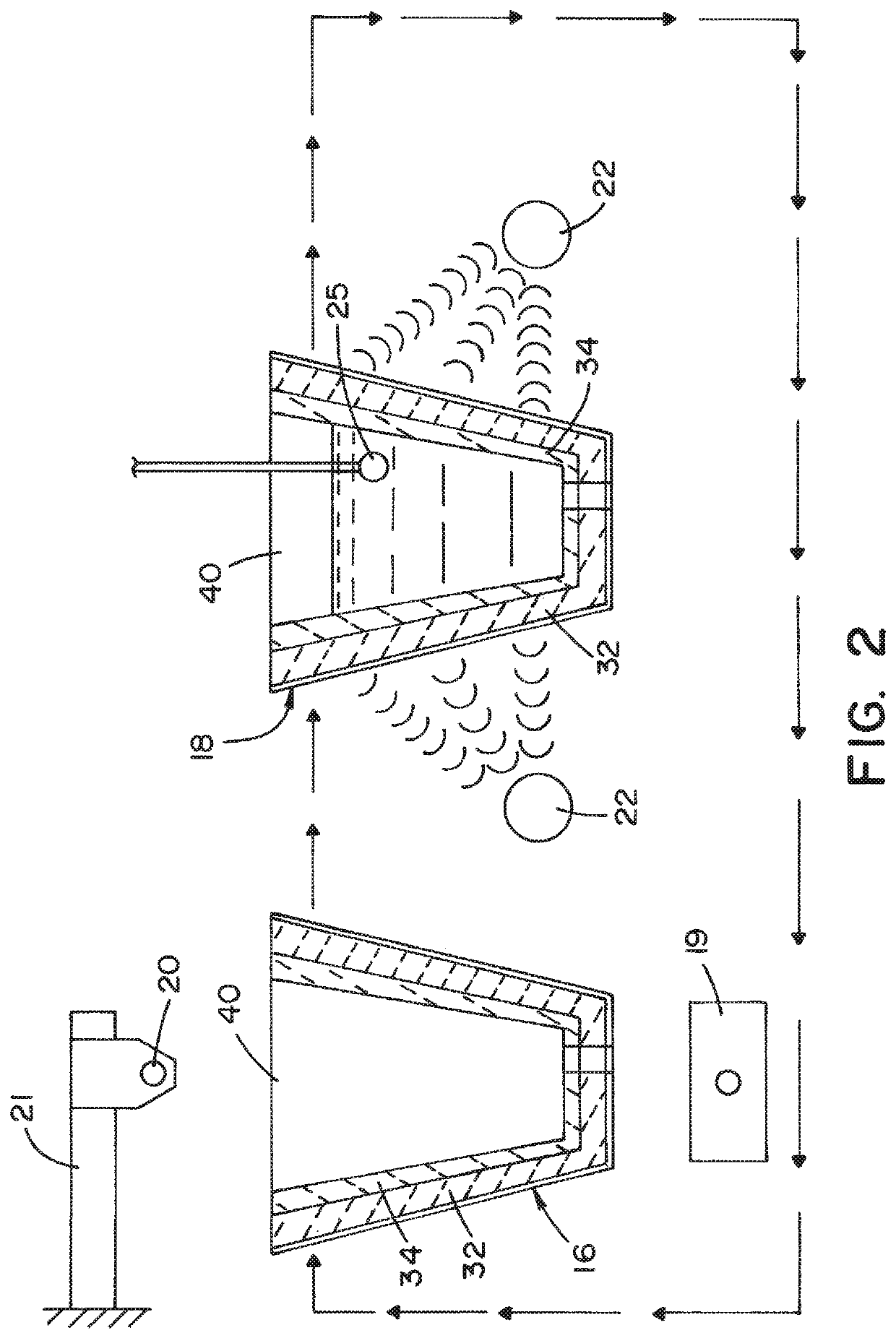

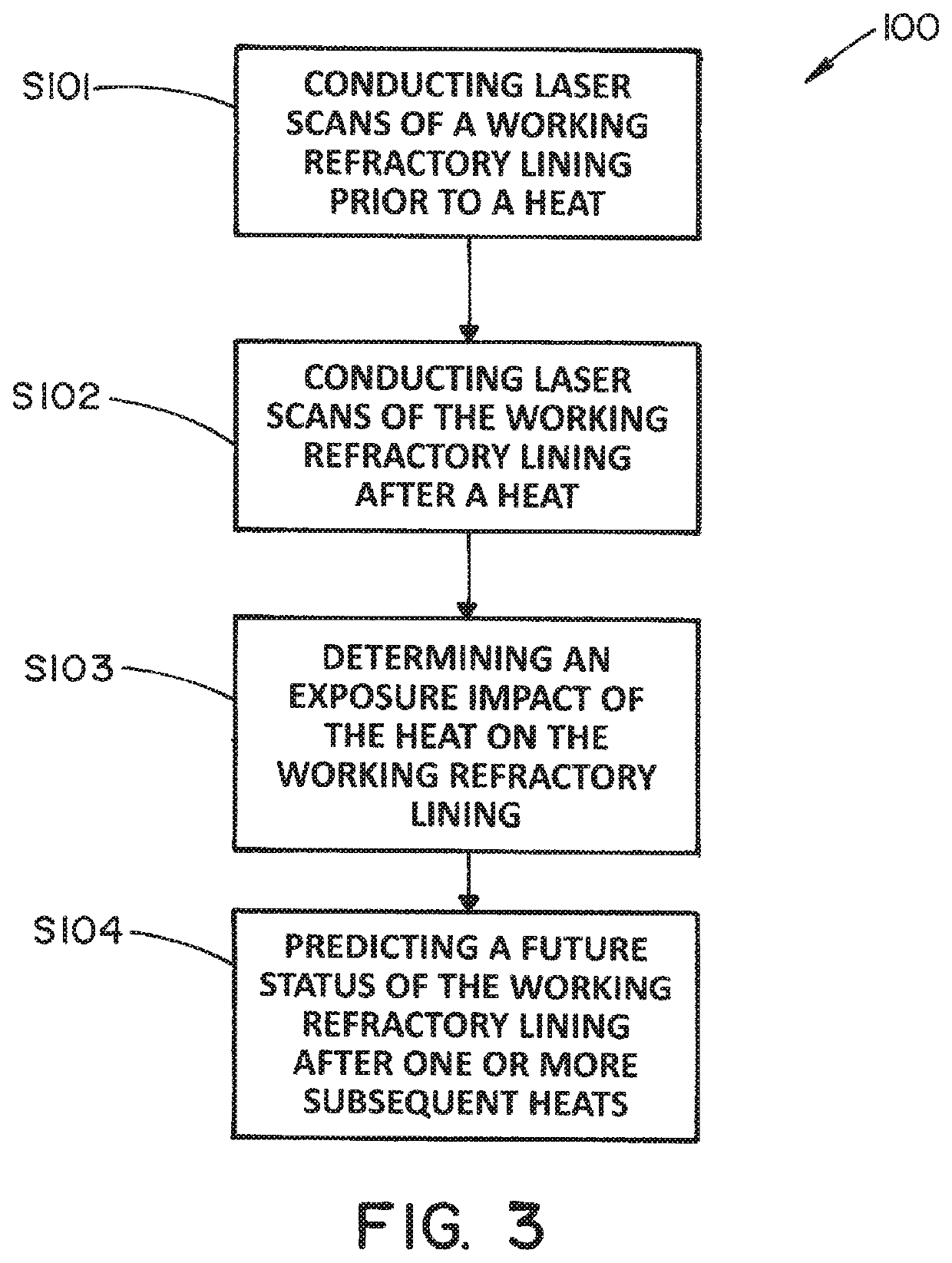

Predictive refractory performance measurement system

ActiveUS10859316B1Precise refractory lining measurementOperational securityRadiation pyrometryLinings repairLaser scanningRefractory

A measurement system is provided for predicting a future status of a refractory lining that is lined over an inner surface of an outer wall of a metallurgical vessel and exposed to a heat during which the refractory lining is exposed to molten metal. The system includes one or more laser scanners and a processor. The laser scanners are configured to conduct a plurality of laser scans of the refractory lining when the metallurgical vessel is empty. At least one of the laser scanners is configured to laser scan the refractory lining prior to the heat to collect data related to pre-heat structural conditions of the refractory lining. At least one of the laser scanners is configured to laser scan the refractory lining after the heat to collect data related to post-heat structural conditions of the refractory lining. The processor is configured to predict the future status of the lining.

Owner:HARBISONWALKER INT INC

Method for determining the state of a refractory lining of a metallurgical vessel for molten metal in particular

ActiveUS10935320B2Manual decisions for this purpose are reduced or practically eliminatedExtended service lifeLinings repairSteel manufacturing process aspectsMechanical engineeringMechanics

Owner:REFRACTORY INTELLECTUAL PRORERTY GMBH & CO KG

Submerged arc furnace body protection method

InactiveCN111947473ARealize safe operation of productionGuaranteed uptimeFurnace safety devicesCharge manipulationMechanical engineeringIron alloys

The invention relates to a protection method in an iron alloy smelting production system, and in particular to a submerged arc furnace body protection method. The submerged arc furnace body protectionmethod aims to stabilize an electrode and a displacement interval range through optimization of a corresponding data analysis trend and an operation process and corresponding technical improvement inproduction operation of an existing iron alloy submerged arc furnace. By means of constant-gear operation control and return slag addition, erosion of the furnace eye and the furnace wall is controlled within a certain range, the erosion amount is reduced, meanwhile, the furnace wall and the furnace eye are repaired, the bonding degree with furnace wall carbon bricks is achieved, and the self-repairing effect is achieved; and secondly, manual plugging operation is replaced, the situation that due to the fact that the mud plugging depth is too small, high temperature moves outwards, molten iron scours furnace eye openings in the inner side is reduced, in addition, input of low-pressure compensation is introduced, the structural proportion of furnace charge is changed, discharging of furnace slag in the tapping process is reduced, the furnace slag is fully subjected to a reduction reaction in the furnace, productivity is released, the service life of the submerged arc furnace is prolonged, and security risks are reduced.

Owner:嘉峪关宏电铁合金有限责任公司

Melters for glass forming apparatuses

Melters for glass forming apparatuses and glass forming apparatuses comprising the same are disclosed. According to one embodiment, a melter for melting glass batch materials includes a base portion and a rigid exoskeleton rigidly attached to the base portion and comprising a plurality of upright members interconnected with a plurality of cross members defining an exoskeleton interior volume. Connection nodes formed at intersections of the plurality of cross members with upper ends of the plurality of upright members are constrained from movement relative to the base portion in a longitudinal direction, a transverse direction, and a vertical direction. A tank assembly is positioned on the base portion in the exoskeleton interior volume and coupled to the rigid exoskeleton. In some embodiments, the melter has a dynamic resistance greater than 0.3.

Owner:CORNING INC

Method for determining the state of a fire-resistant lining of a metallurgical vessel for molten metal in particular

The invention relates to a method for determining the state of a fire-resistant lining of a vessel (10) containing molten metal in particular. In the process, maintenance data, production data, and wall thicknesses at least at locations with the highest degree of wear are measured or ascertained together with additional process parameters of a vessel (10) after the vessel (10) has been used. Said data is then collected and stored in a data structure. A calculating model is generated from at least some of the measured or ascertained data or parameters, and said data or parameters are evaluated by means of the calculating model using calculations and subsequent analyses. Thus, related or integral ascertaining processes and subsequent analyses can be carried out, on the basis of which optimizations relating to both the vessel lining as well as the complete process of the molten metal in the vessel are achieved.

Owner:REFRACTORY INTELLECTUAL PRORERTY GMBH & CO KG

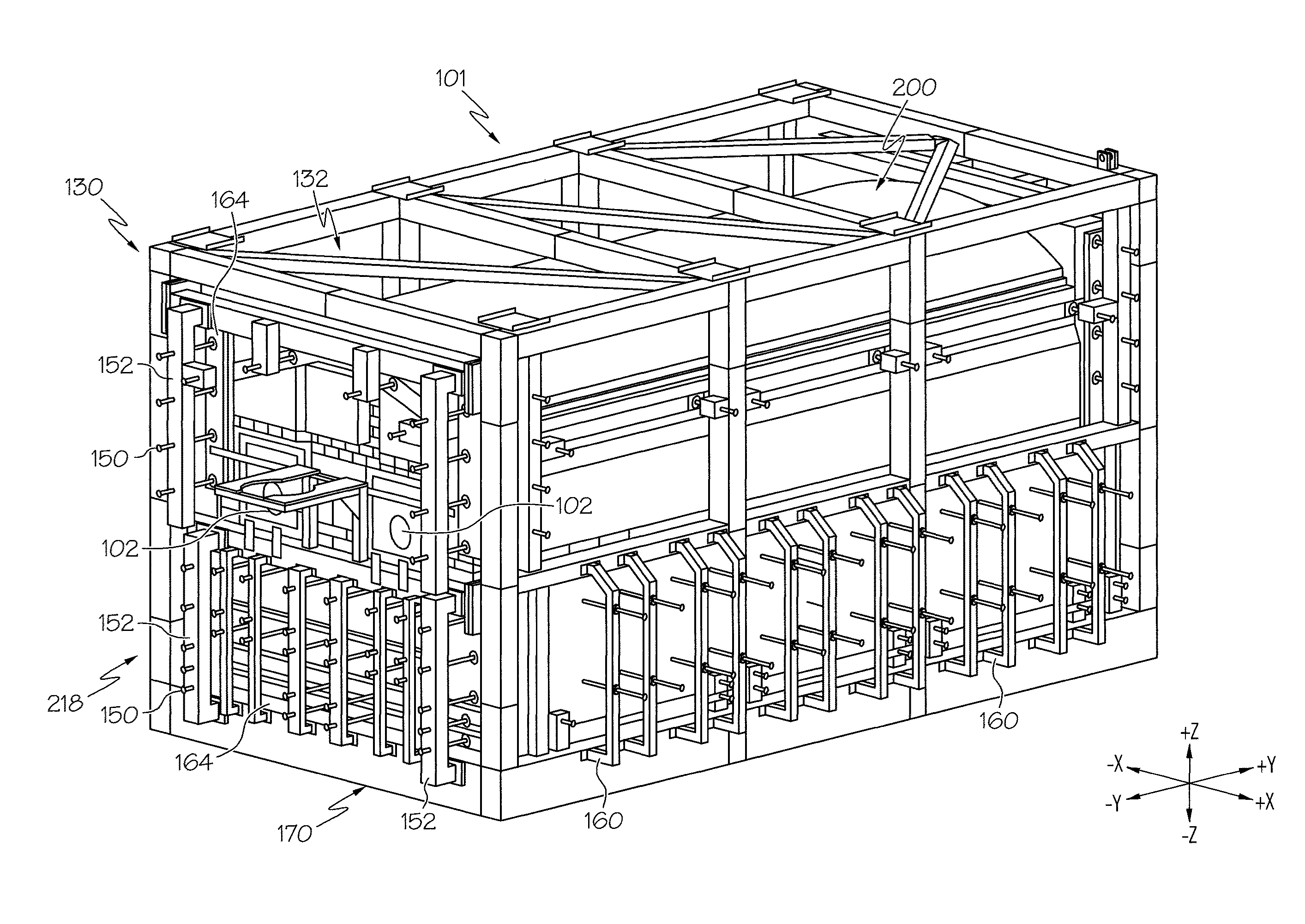

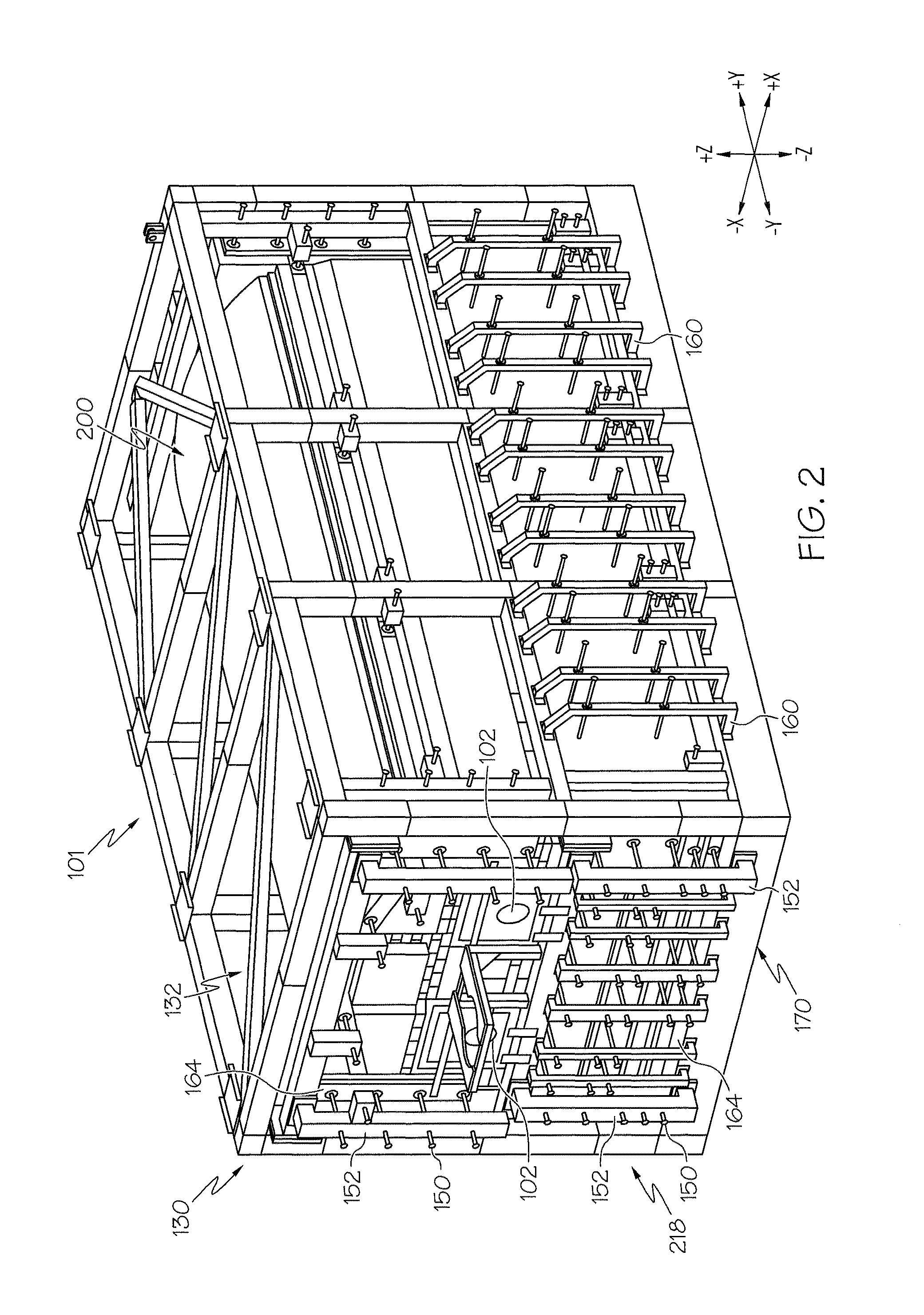

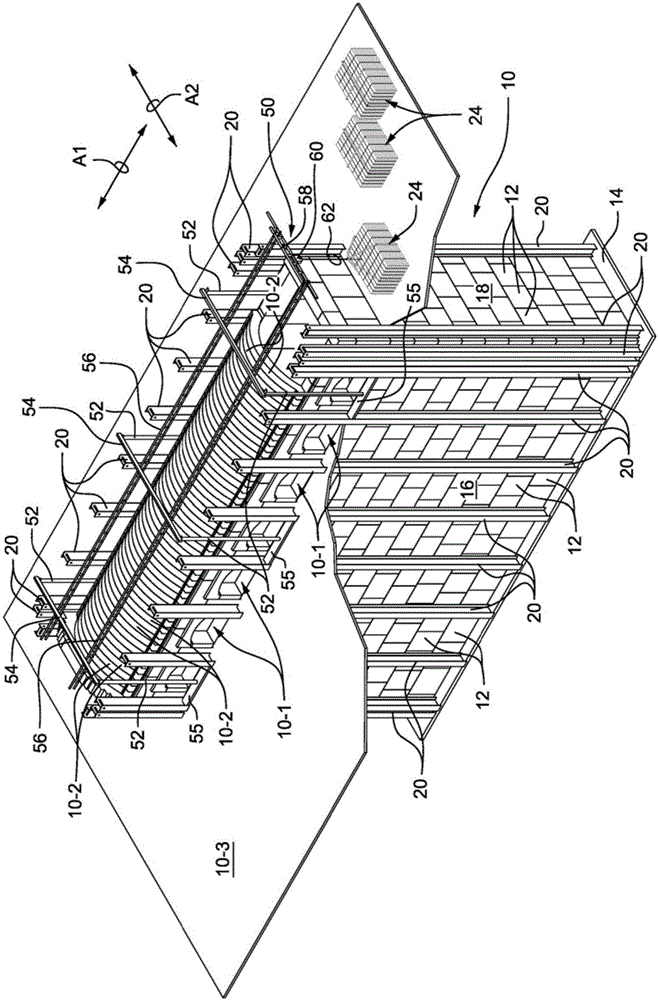

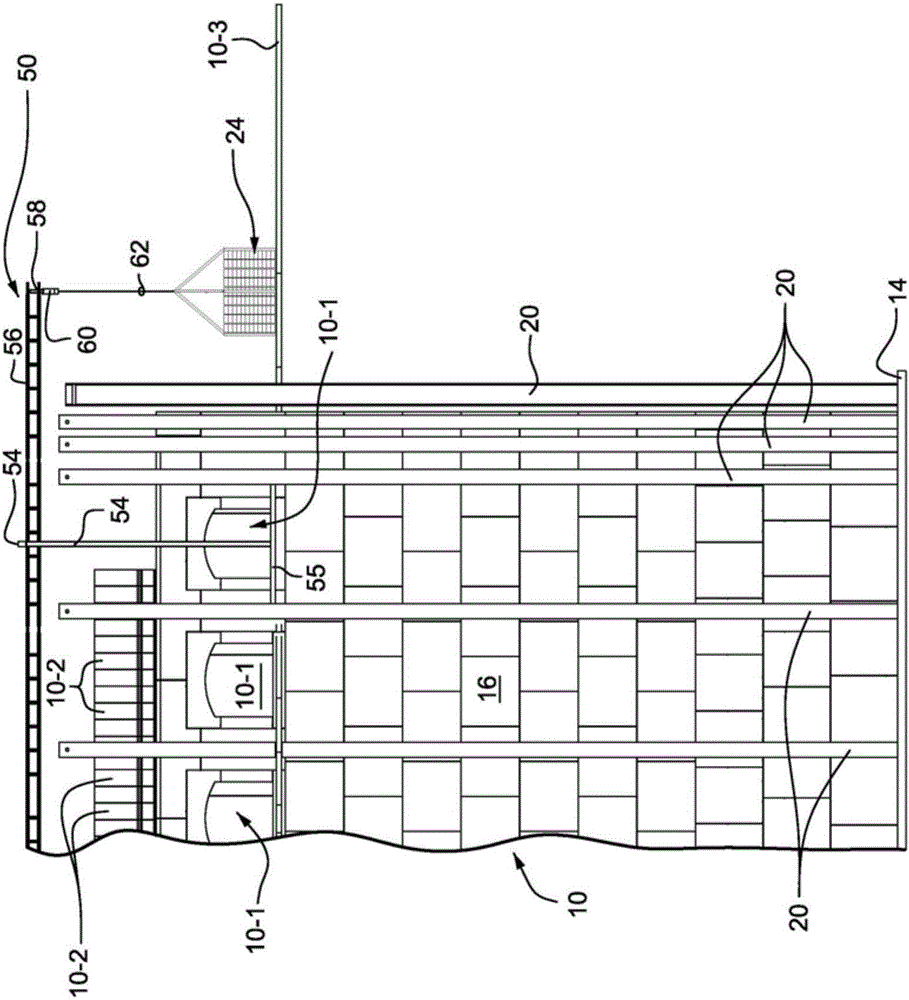

Methods and apparatus for constructing glass furnace structures

Methods and apparatus for constructing refractory structures, e.g., glass furnace regenerator structures and / or glass furnace structures having walls formed of refractory block and buck stays externally supporting the walls are provided. Opposed pairs of supports are connected to at least a respective one of the vertically oriented buck stays with cross-support beams spanning the refractory structure between a respective pair of the supports. An overhead crane assembly is supported by the cross-support beams. In such a manner, refractory components of the refractory structure (e.g., refractory wall blocks and / or refractory checker bricks) may be installed using the overhead crane assembly.

Owner:FOSBEL

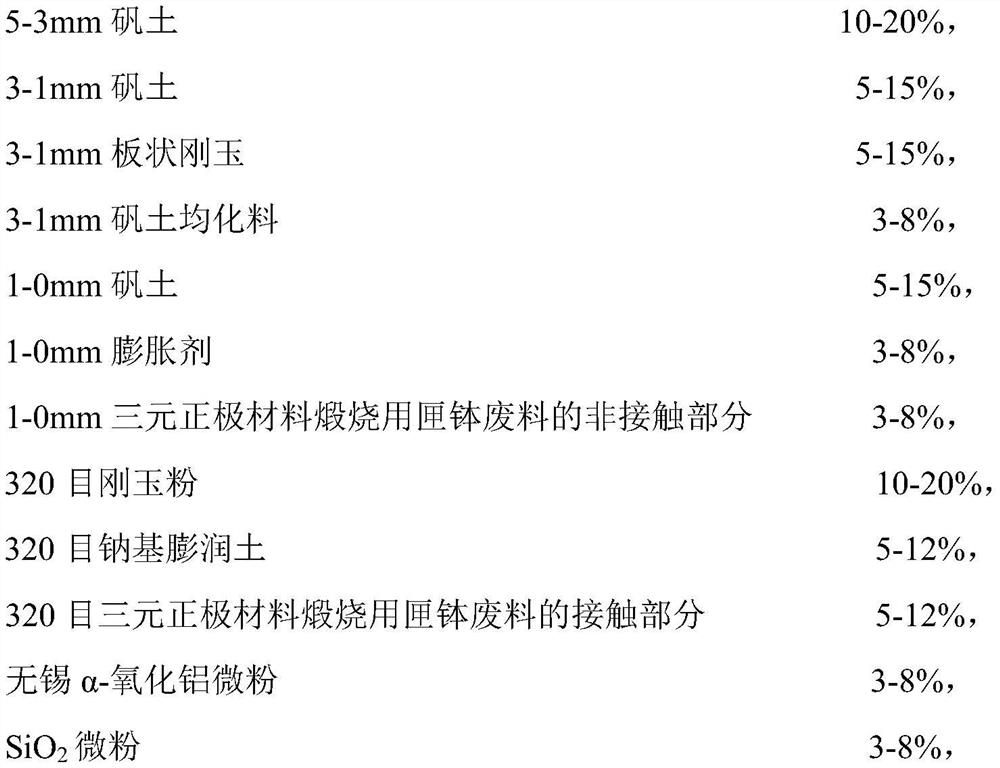

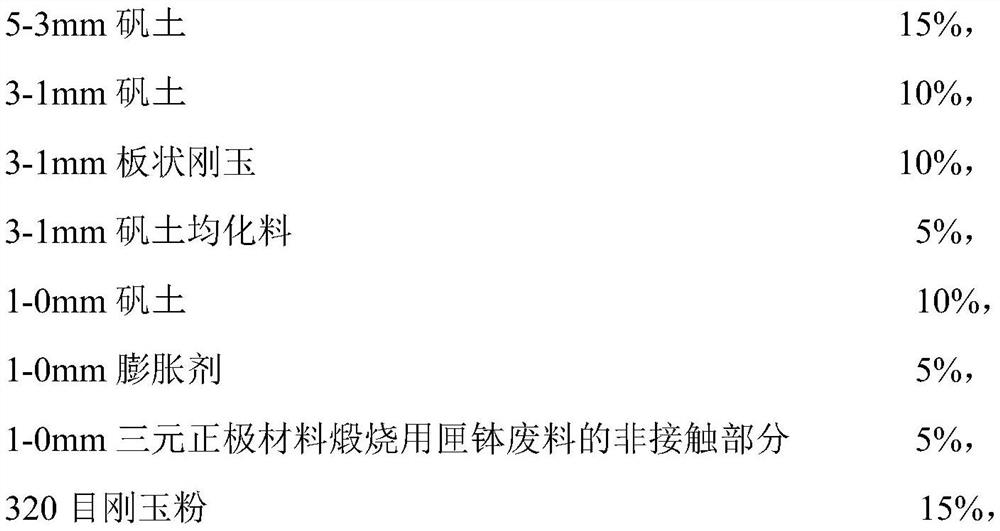

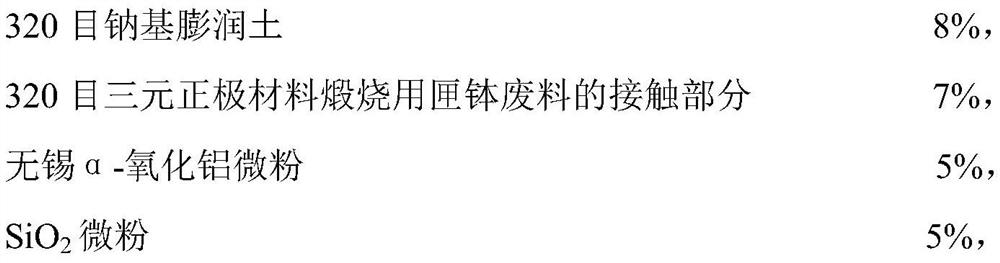

Aluminum-silicon plastic refractory for rapid repair and preparation method thereof

The preparation method comprises the following steps: introducing Li, Ni, Co and Mn into a sagger waste material for calcining a ternary positive electrode material to provide a burning promoter, and effectively adjusting the linear change after burning; a phenolic resin and aluminum dihydrogen phosphate composite binder is adopted, and respective bonding and hardening mechanisms are comprehensively utilized, so that plasticity, viscosity, construction performance, rapid repair and physical properties after hardening are realized; the characteristics that sepiolite and palygorskite are extremely easy to disperse in water and form viscous suspension liquid are utilized, so that the construction performance is improved; the characteristic that sepiolite and palygorskite are rich in magnesium ions is utilized, the hardening effect of sepiolite and palygorskite on aluminum dihydrogen phosphate is achieved, a traditional cement hardening method is replaced, and the purpose of rapid repairing is achieved. The refractory material has a certain micro-expansion effect after burning, can fully fill a damaged part, introduces expanding agents at different temperatures, realizes repair of kiln aluminum-silicon refractory materials at different temperatures, and has wide adaptability.

Owner:宜兴瑞泰耐火材料有限公司 +1

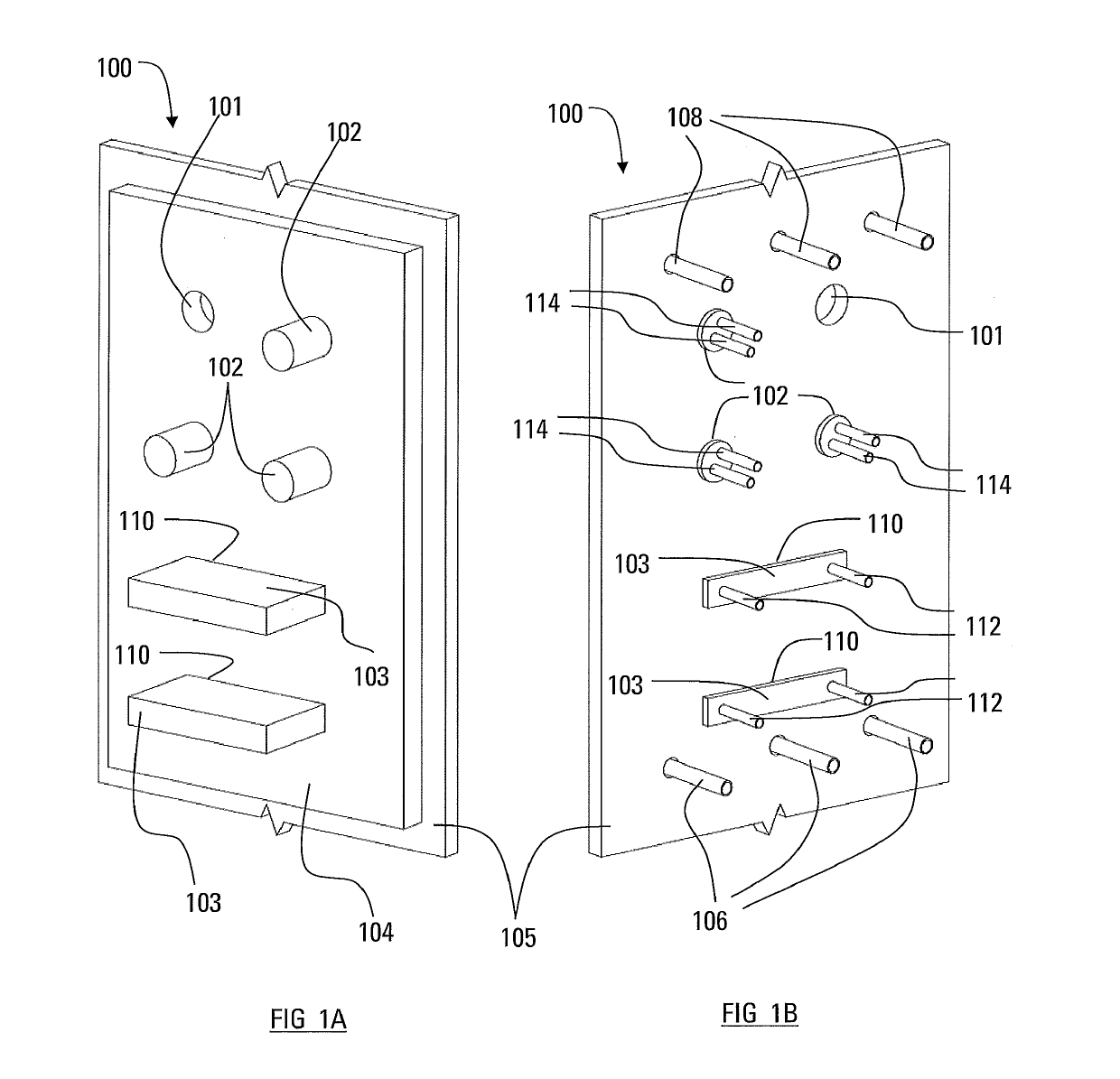

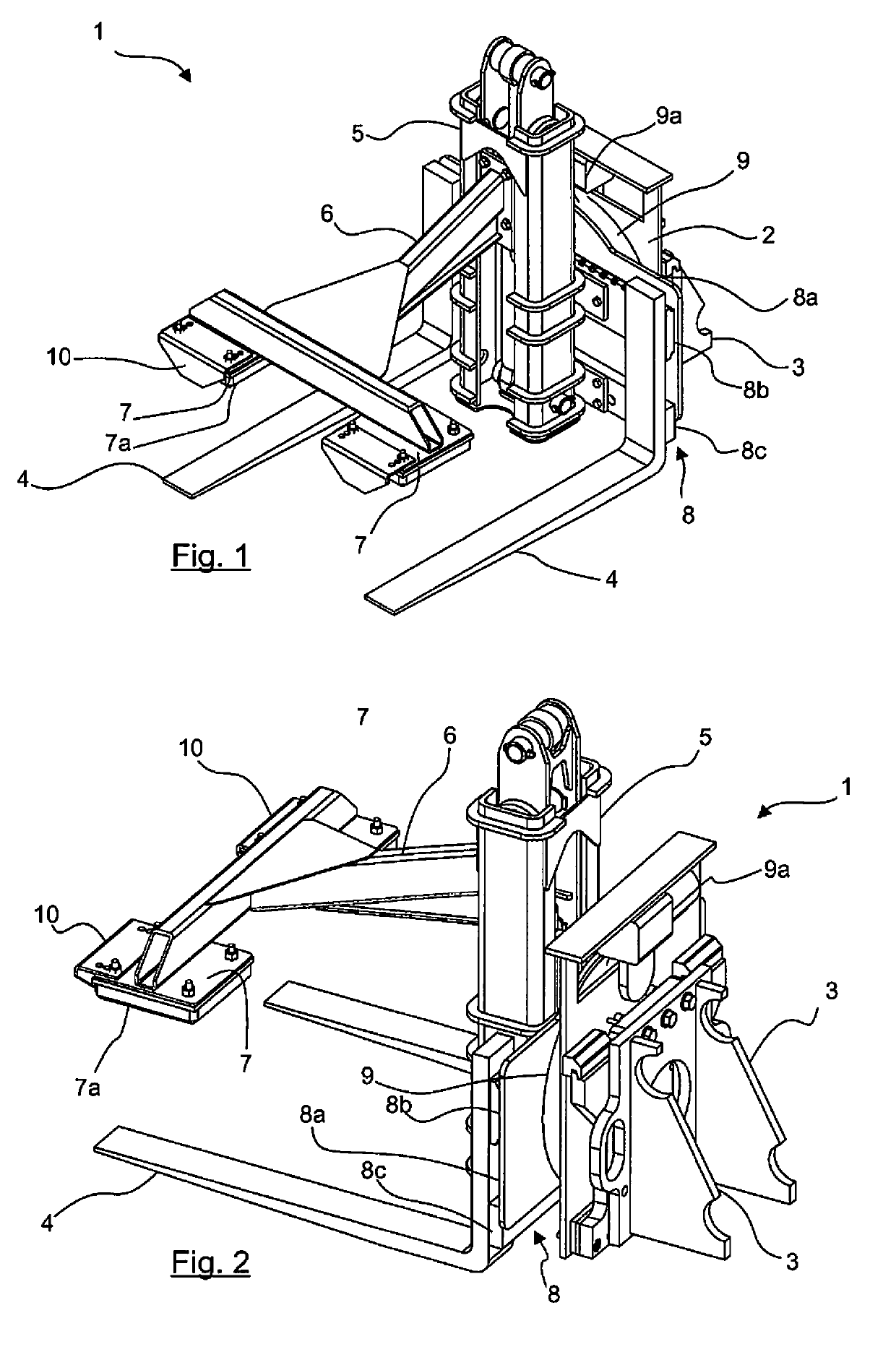

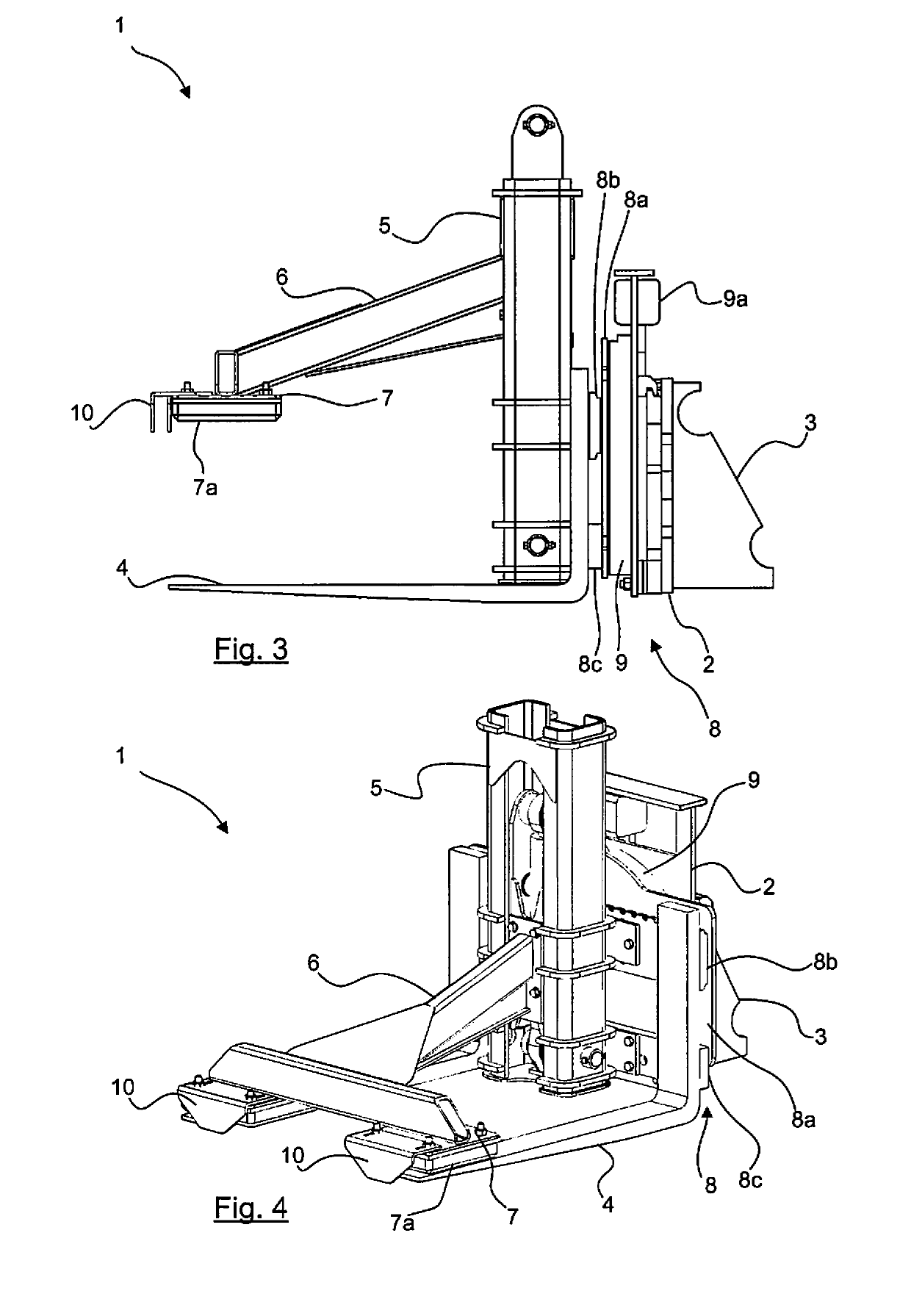

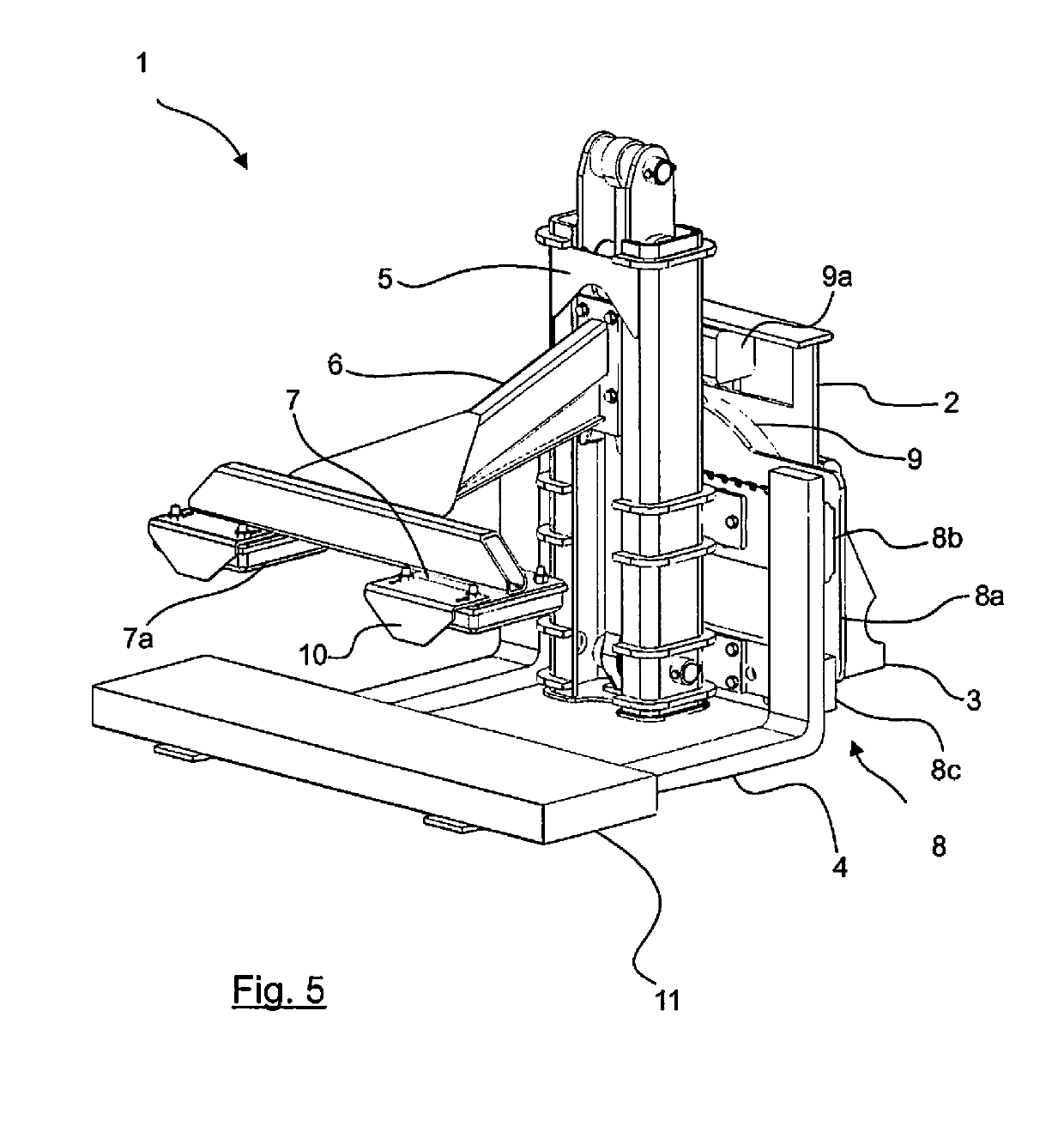

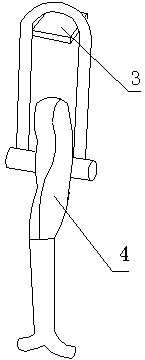

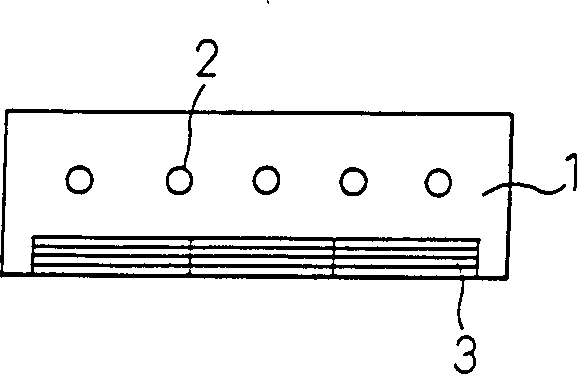

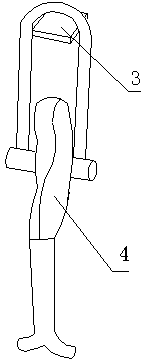

Gripping tool and a method for removing a heat exchanger plate from a furnace wall

InactiveUS20190128610A1Easy to disassembleOptimize timingLinings repairFurnace repairCantileverMechanical engineering

A gripping tool for removing a heat exchanger plate from a furnace wall, the gripping tool including a base having a mechanical attachment device for releasably fixing to a tool end of a boom, and a gripping assembly carriage equipped with at least a fork extending, when in use, substantially horizontally from the gripping assembly carriage. The gripping assembly carriage further includes a clamp assembly having a clamp arm equipped with at least a clamp pad, wherein said clamp arm extends substantially in the direction of the at least one fork and is movable towards and away from the at least one fork for clamping a heat exchanger plate between the fork and the clamp pad.

Owner:OUTOTEC FINDLAND OY

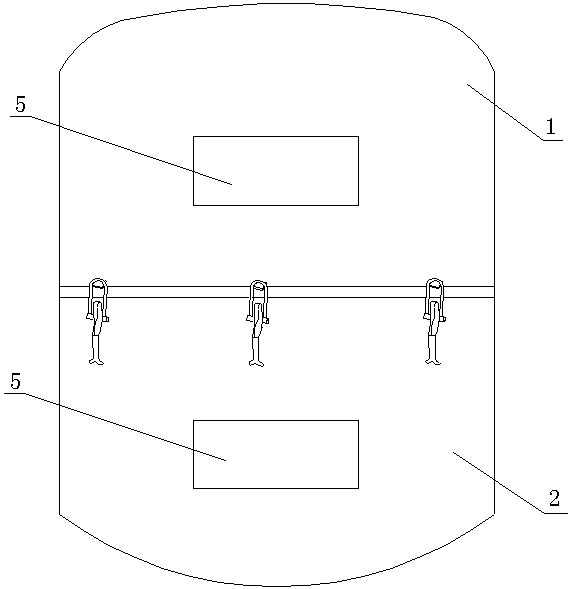

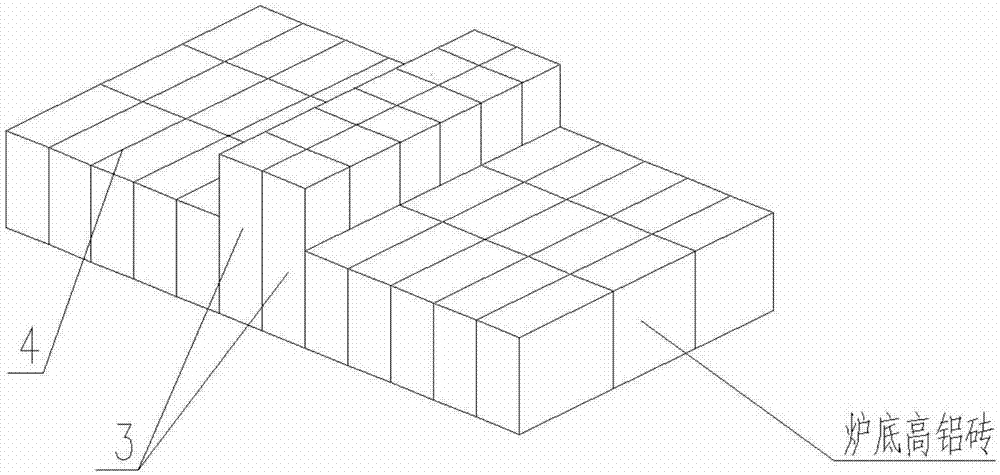

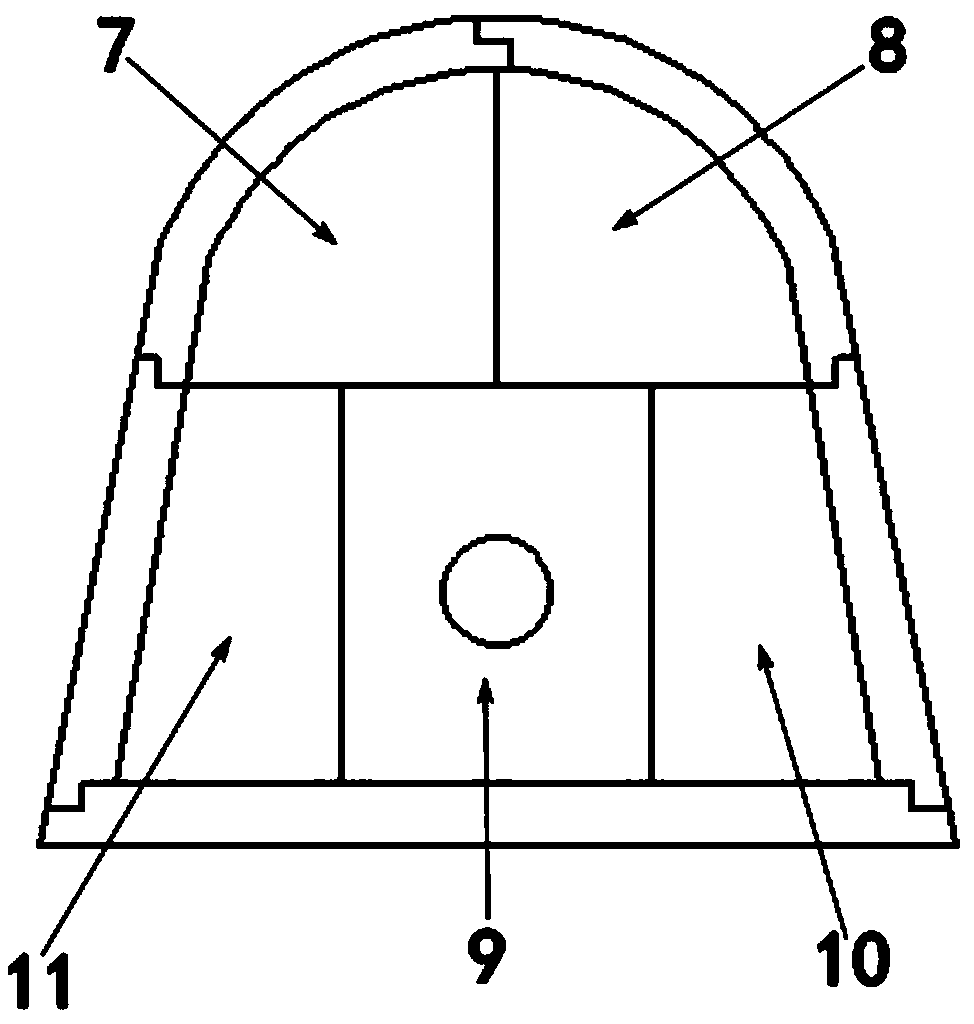

Multi-functional aluminum scrap smelting furnace

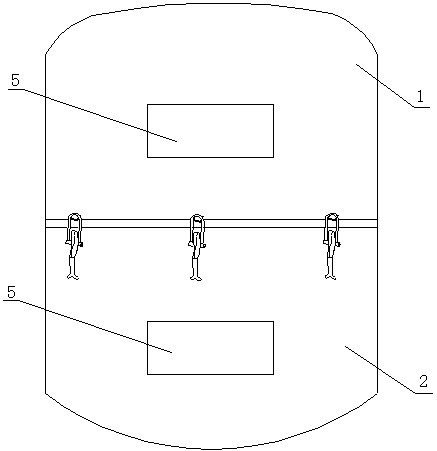

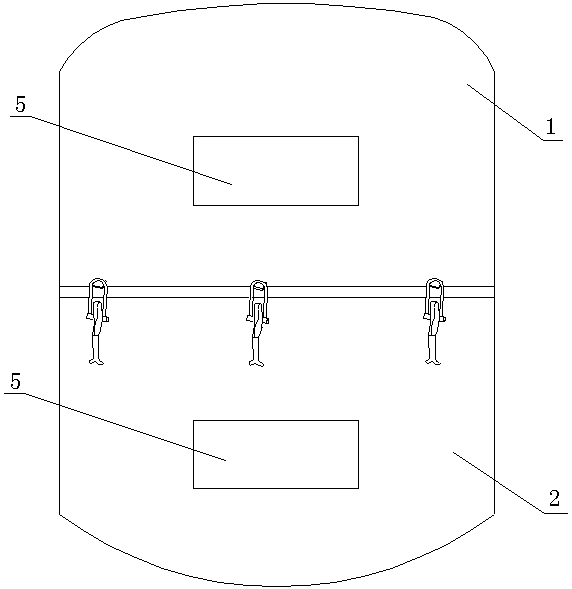

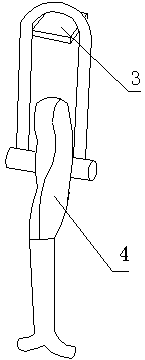

InactiveCN107655335AEasy to assemble and disassembleImprove disassembly efficiencyFurnace componentsFurnace repairCorrosion resistantMelting furnace

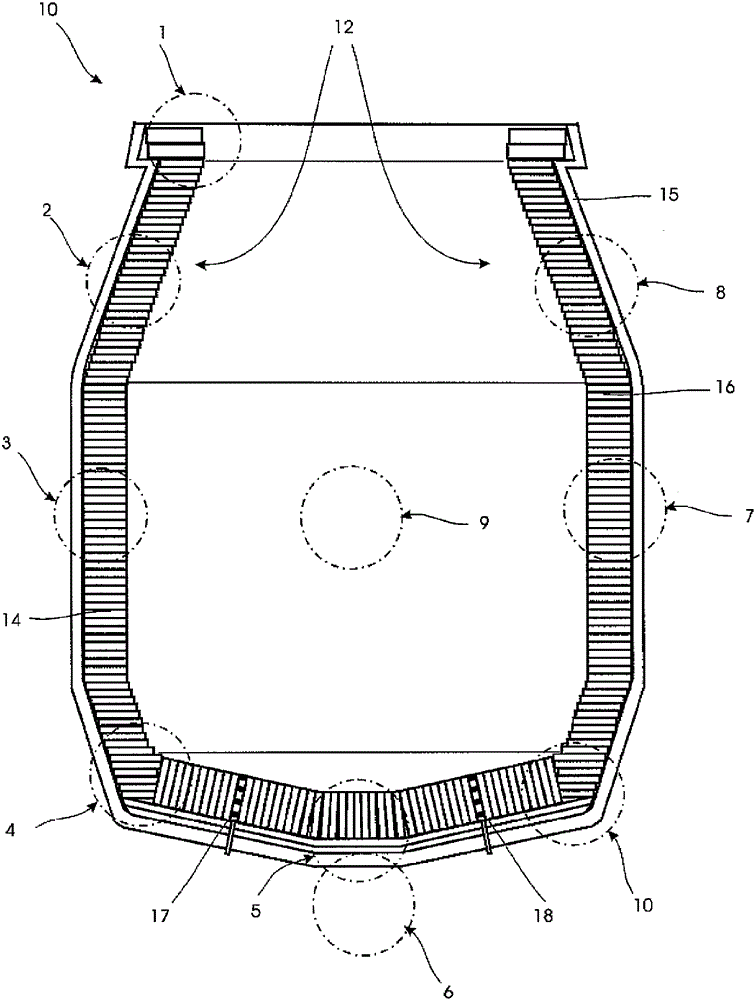

The invention relates to a multifunctional scrap aluminum smelting furnace, which is characterized in that it comprises an upper furnace body (1) and a lower furnace body (2), and a plurality of protrusions are arranged on the side wall of the lower part of the upper furnace body (1) (3), the upper side wall of the lower furnace body (2) is provided with several box buckles (4), the box buckles (4) are matched with the bumps (3), and the upper furnace body (1) Both the upper furnace body (1) and the lower furnace body (2) are equipped with observation ports (5), the top of the upper furnace body (1) is provided with a lifting mechanism, and the exterior of the upper furnace body (1) and the lower furnace body (2) are both There is an anti-corrosion layer. This multi-functional scrap aluminum smelting furnace is provided with bumps on the side wall of the lower part of the upper furnace body, and a box buckle is provided on the side wall of the upper part of the lower furnace body. , as long as the box buckle is fastened to the protrusion or pulled apart, it can be easily completed, which makes the disassembly and assembly of the upper furnace body and the lower furnace body convenient and the disassembly and assembly efficiency is high.

Owner:JIANGYIN DIXIN METAL IND

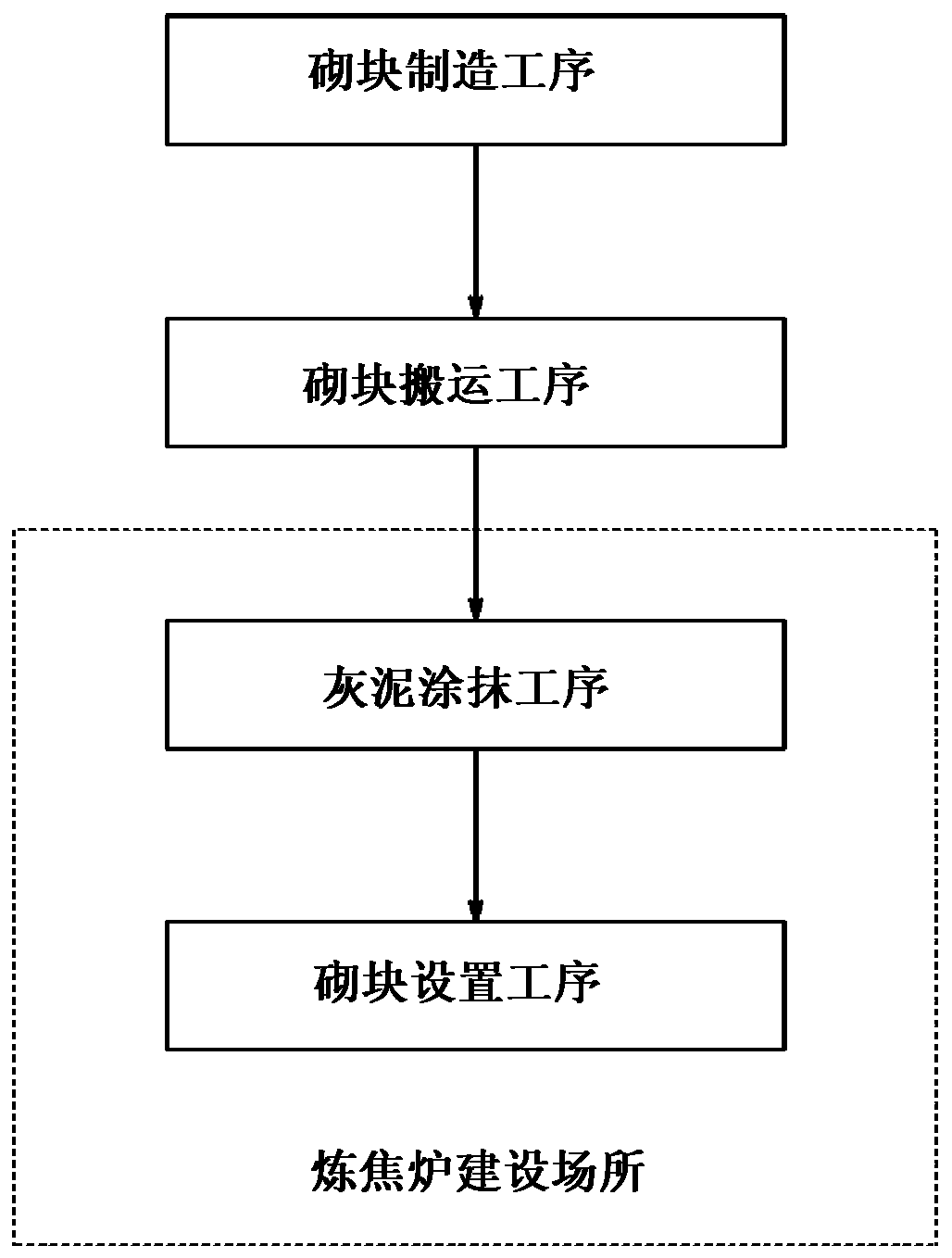

Construction method of coke oven

ActiveCN107429166BReduce the burden onBrick-hot blast stovesCoke oven brickworkBrickProcess engineering

To provide a construction method of a coke oven that can reduce the burden on an operator without using large modular bricks, stack shaped refractories with high precision, and efficiently construct a coke oven. It is a construction method of a coke oven for updating or newly installing a coke oven, and has the following steps: a block manufacturing process of stacking a plurality of shaped refractories at a place other than the construction site of the coke oven to manufacture blocks; a block conveying process, which transports the blocks to the coke oven construction site; a plaster application process, which applies plaster to the position where the blocks are installed; and a block setting process, which installs the plaster to the position where the The above block, the length of the block in the longitudinal direction is not less than 1 / 4 and not more than 2 / 3 of the furnace length of the coke oven, and the height of the block is less than 2m.

Owner:JFE STEEL CORP

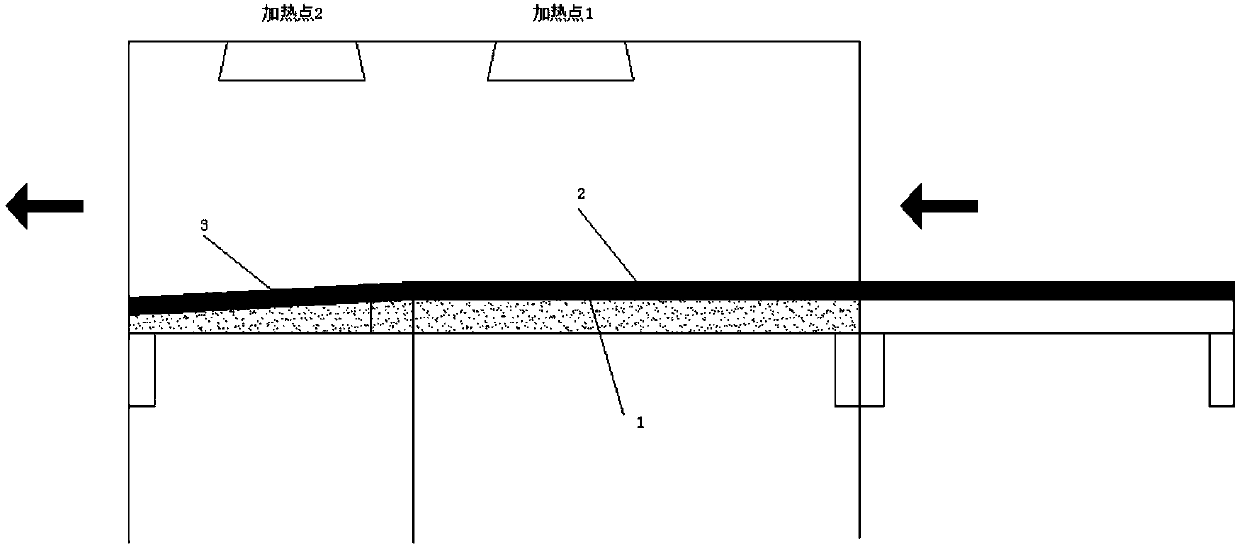

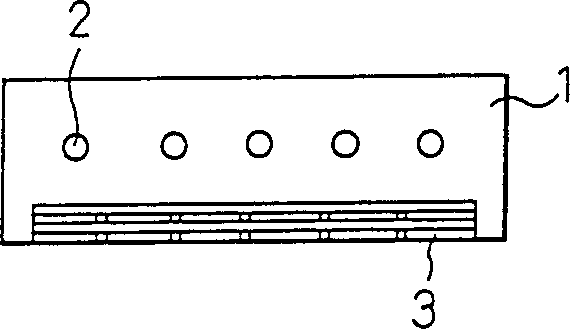

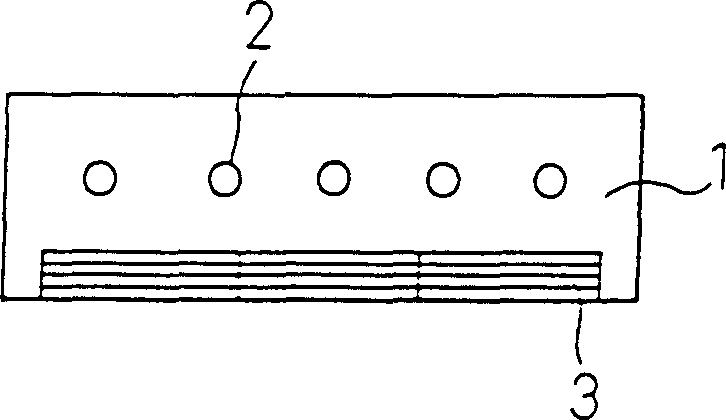

Furnace inner base plate for natural gas heating furnace

InactiveCN109556408ASimple structureEasy to manufactureFurnace componentsFurnace repairBrickEngineering

The invention discloses a furnace inner base plate for a natural gas heating furnace. The furnace inner base plate comprises a base plate body made of gray cast iron, the base plate body is provided with a lower surface matched with a bottom surface of a hearth, the base plate body sequentially comprises a plane heating area and a downhill discharging area from a feeding port to a discharging port, the plane heating area corresponds to a preheating section and a heating section inside a furnace body, the downhill discharging area corresponds to a uniform heating section inside the furnace body, the plane heating area is provided with a smooth upper surface, the downhill discharing area is provided with a smooth upper surface which is inclined downwards in the direction from the feeding port to the discharging port, and the base plate body is laid on the bottom surface of the hearth of the heating furnace. The gray cast iron of HT10-26 is selected to be laid on the bottom surface of thehearth built of refractory bricks, the friction between the blank and the bottom surface is reduced, the service life of the hearth is prolonged, meanwhile, the frequency of frequently repairing thehearth is reduced, the repair time and the baking time caused by the fact that the hearth is repaired are avoided, so that the production rhythm is kept.

Owner:NANJING CHENWEI MACHINERY MFG CO LTD

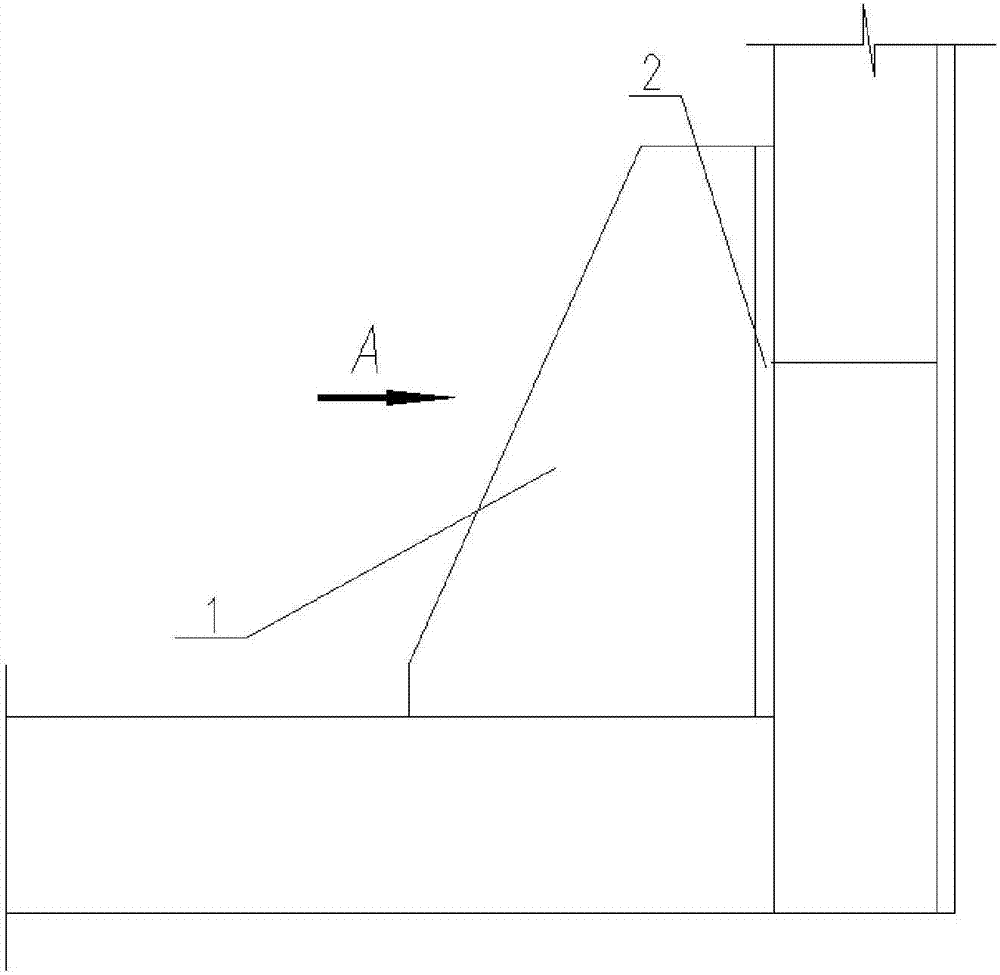

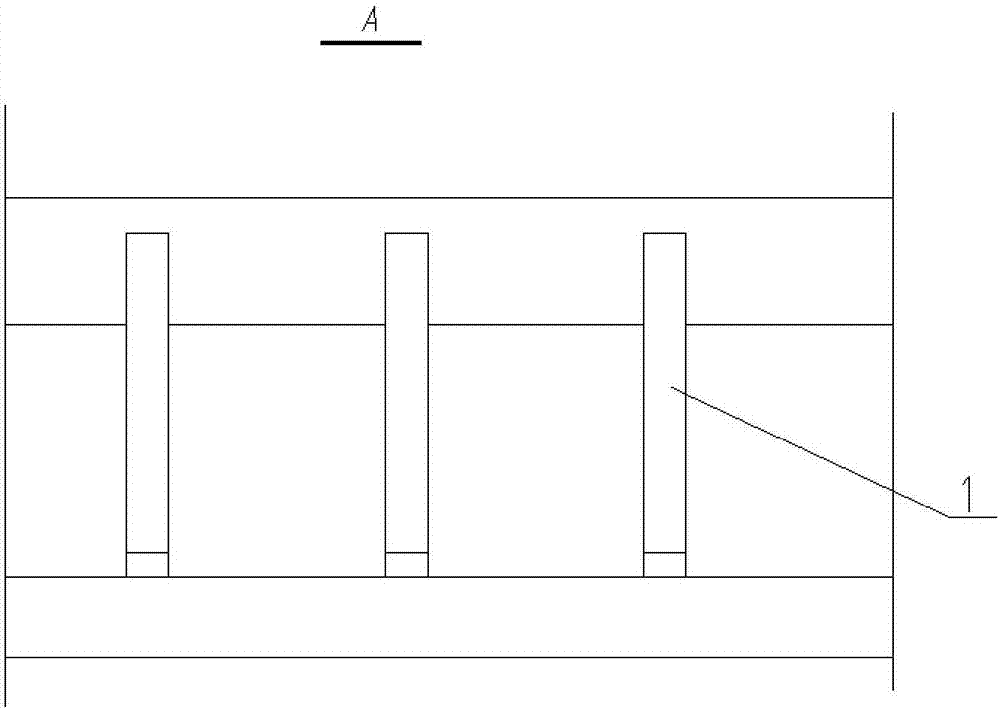

Emergency repair device and method of heating furnace side wall

ActiveCN106979689AMeet emergency repair needsImprove stabilityFurnace repairFurnace liningsHeating furnaceEmergency situations

The invention discloses an emergency repair device and method of a heating furnace side wall. The device and the method are mainly designed for solving the problem of inward inclination of the heating furnace side wall. The device comprises a plurality of supporting walls for supporting the heating furnace side wall. All the supporting walls are arranged on a rooting foundation wall at the bottom of a heating furnace at preset intervals. The side faces, in the vertical direction, of the supporting walls are in contact with the heating furnace side wall. The emergency repair device is simple in structure, low in manufacturing cost and short in construction time, the heating furnace side wall inclining inwards can be supported and protected by arranging the supporting walls, the requirement for conducting emergency repair on the heating furnace side wall within the short shutdown time can be met, and the requirement of the heating furnace side wall for emergency repair is effectively met.

Owner:HUATIAN ENG & TECH CORP MCC +1

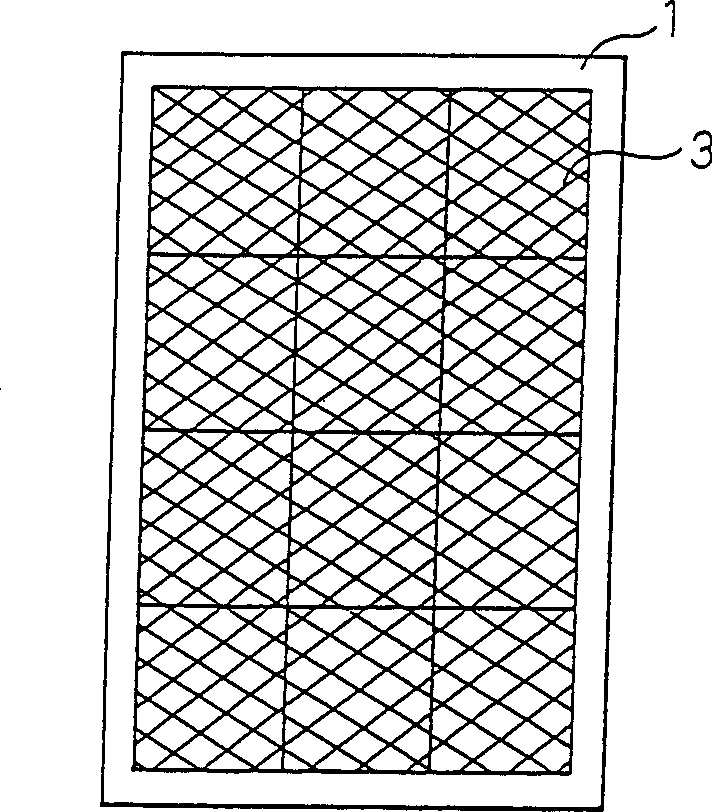

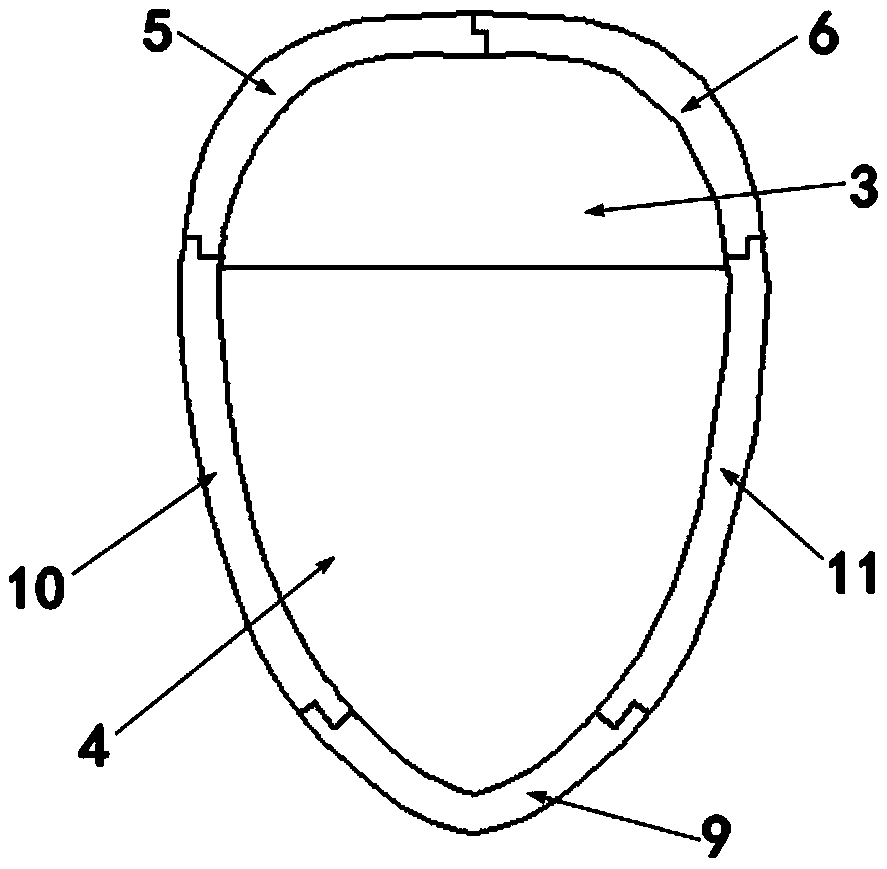

Block structure, container and method for constructing block structure

InactiveCN110036120AIncreased durabilityEasy to useRotary drum furnacesBlast furnace detailsEngineeringBlock structure

The present invention provides a block structure, a container comprising the same, and a construction method applied thereto. The block structure comprises: a main body having one surface extending inone direction and in another direction that intersects with the one direction; and a plurality of blocks which are each coupled to the one surface while being in contact with each other, wherein theplurality of blocks have coupling grooves and coupling protrusions formed on surfaces facing each other in at least one direction of the one direction and the other direction, such that a force applied by a charging material can be evenly dispersed around.

Owner:POHANG IRON & STEEL CO LTD

Method for determining the state of refractory linings of metallurgical furnaces, especially for melting metals

The invention relates to a method for determining the state of a refractory lining of a furnace (10), in particular containing molten metal. In the method, maintenance data, production data and wall thicknesses are measured or confirmed after the furnace ( 10 ) has been used at least at the locations with the highest degree of wear, together with additional process parameters of the furnace ( 10 ). The data is then collected and stored in a data structure. A computational model is generated from at least some of the measured or validated data or parameters, and the data or parameters are evaluated by means of the computational model using calculations and subsequent analysis. As a result, relevant or indispensable confirmation processes and subsequent analyzes can be carried out, based on which the optimization of the complete process with respect to the furnace lining as well as the molten metal in the furnace is achieved.

Owner:REFRACTORY INTELLECTUAL PRORERTY GMBH & CO KG

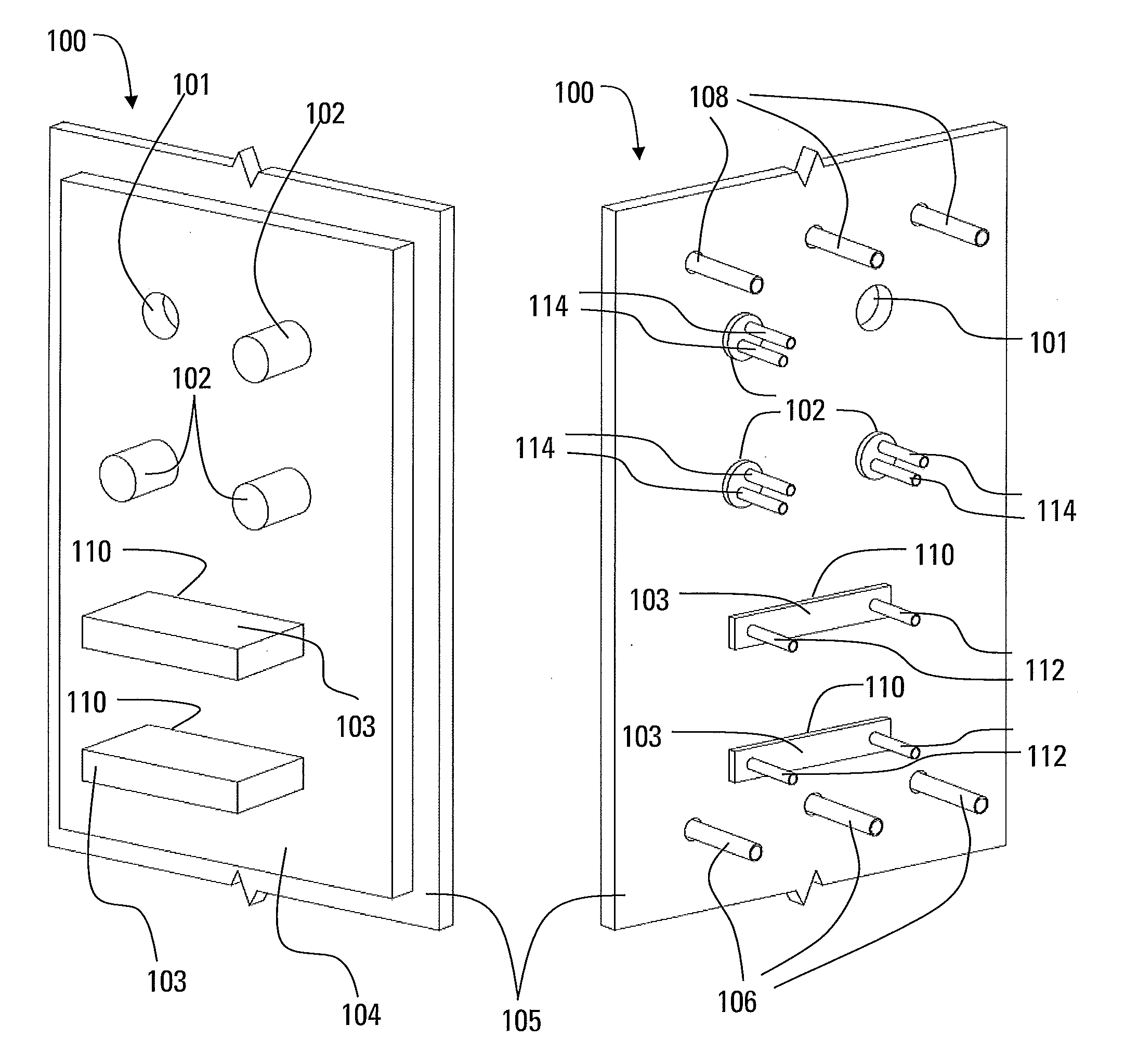

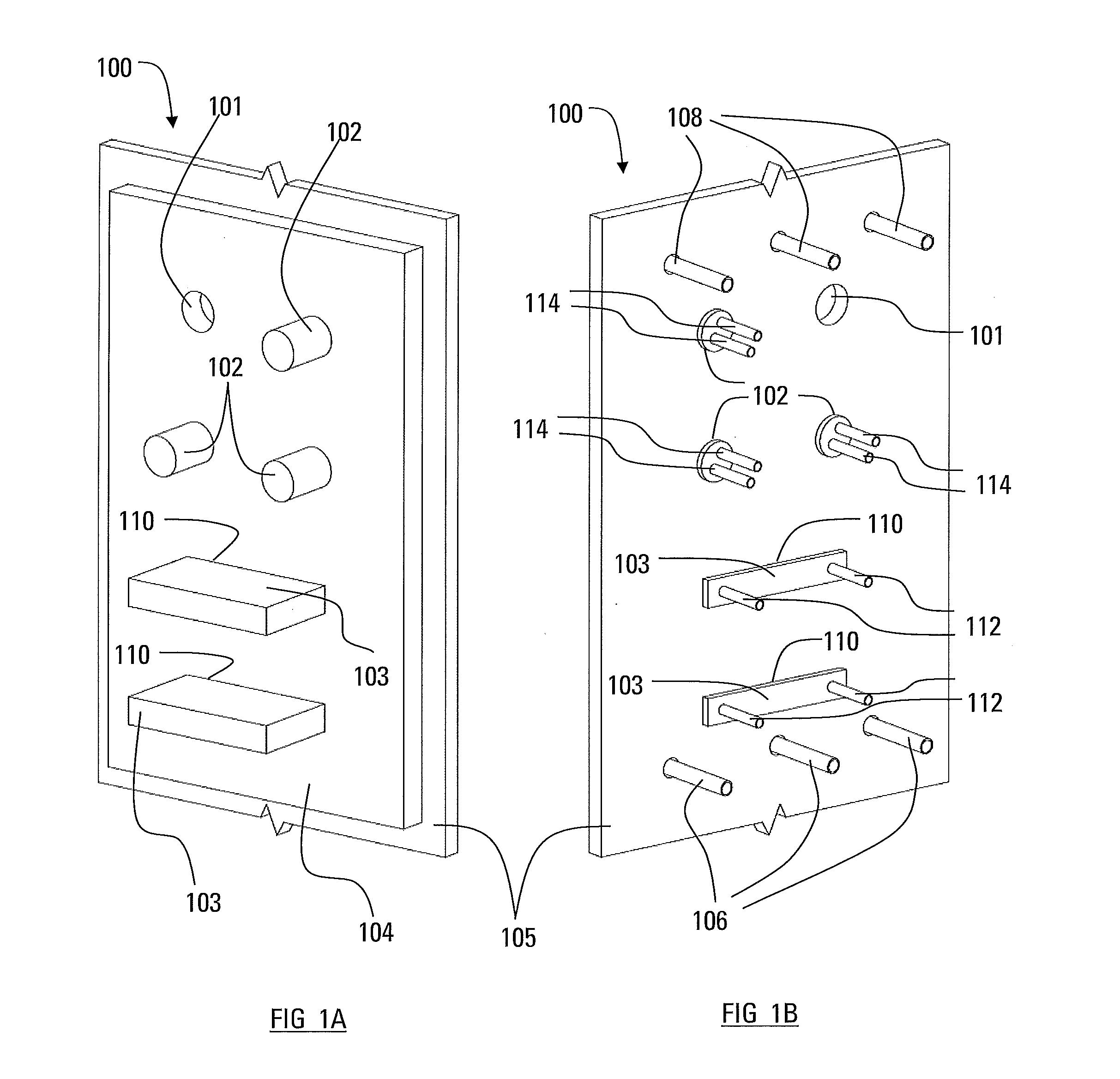

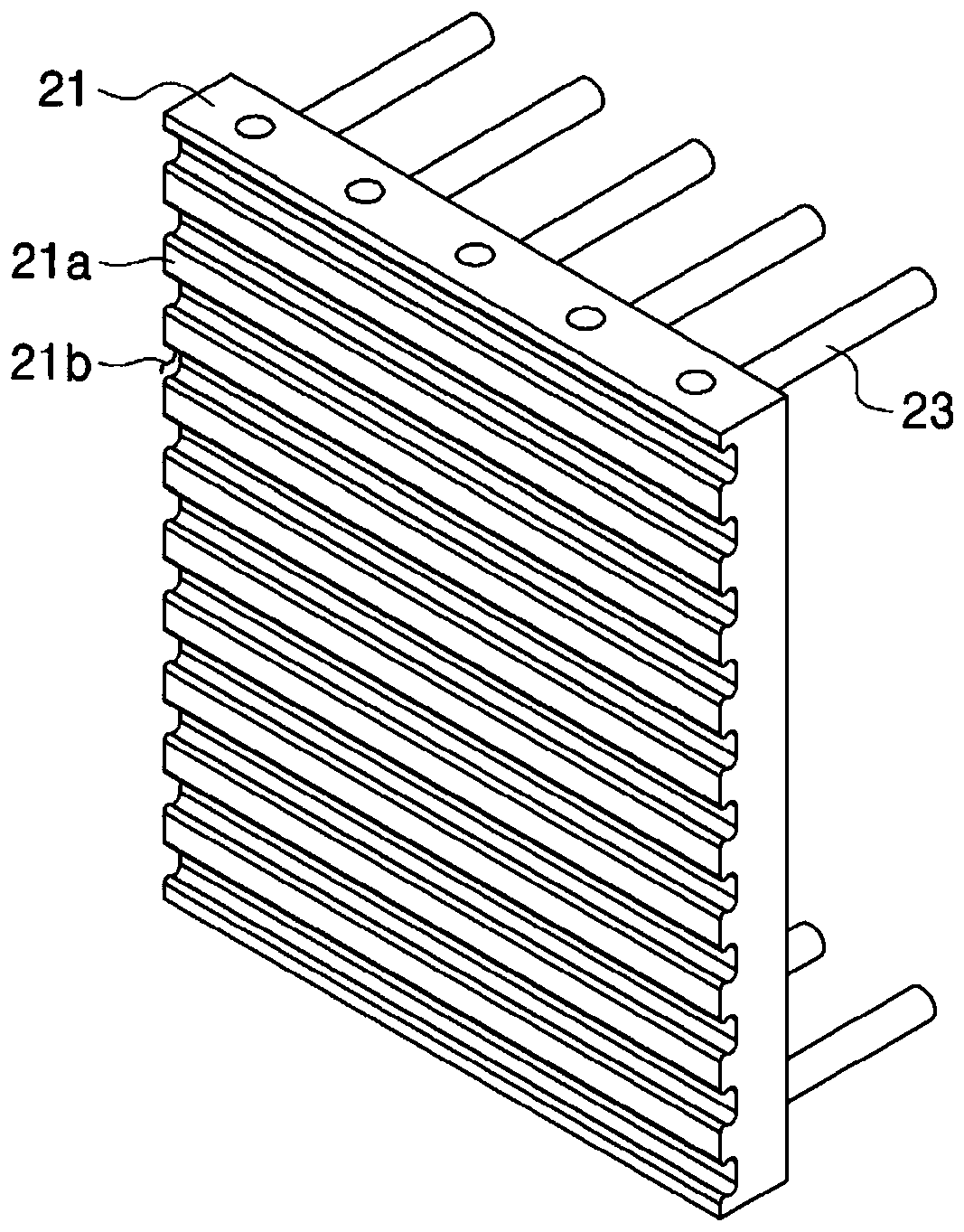

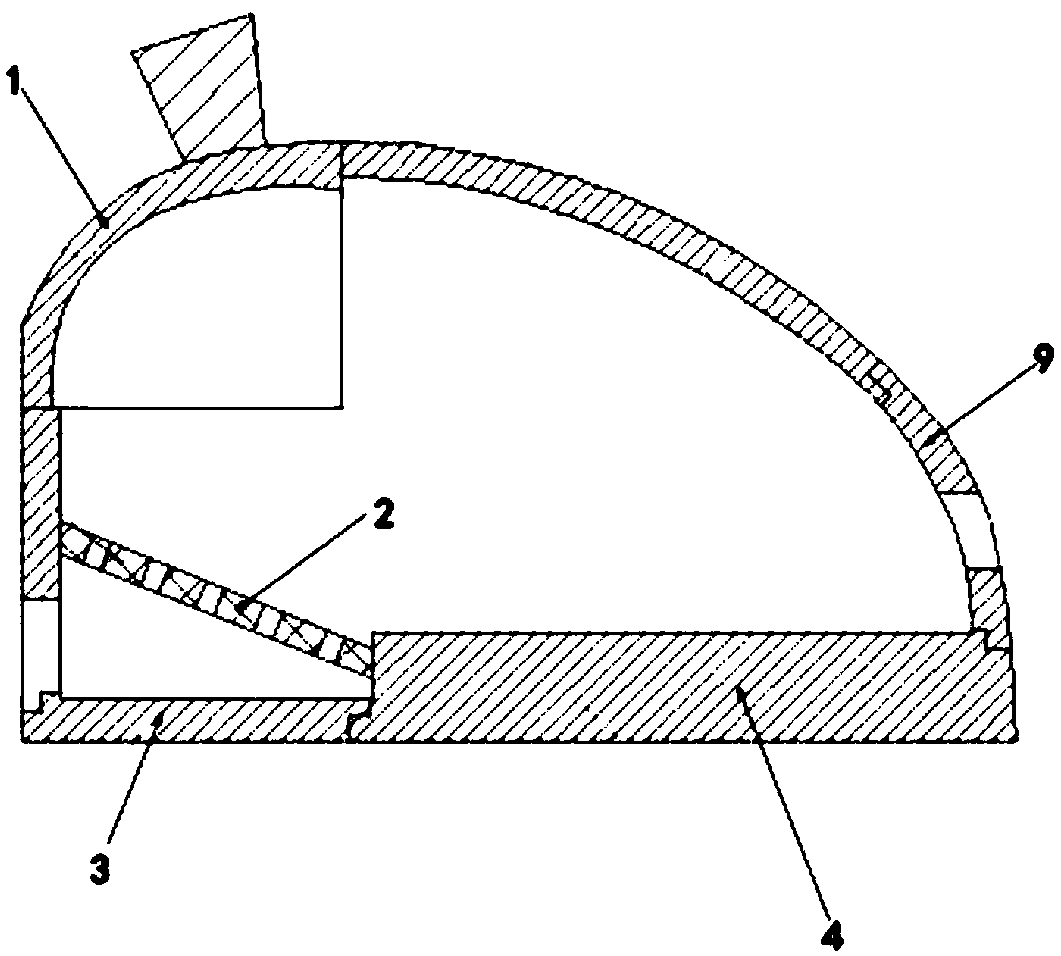

Stave cooler

InactiveCN1341202AExtended service lifeMaintain insulation propertiesFurnace cooling arrangementsCooling devicesThermal expansionCooling pipe

A stave cooler used for cooling a furnace wall of a metallurgical furnace such as a blast furnace, having a structure in which cooling pipes to cool a metal base are cast on the side opposite the furnace interior side of the metal base and a heat resistant steel plate having openings or a lamination of heat resistant steel plates having openings is cast, in a prescribed thickness, in the furnace interior side surface of the metal base. It is acceptable to form the lamination suitably into a rectangular parallelepiped and cast it, in a plurality, in the furnace interior side of the metal base. The wear rate of the furnace interior side surface of the stave cooler is small, and its structure prevents the heat resistant steel plate(s) from falling out by thermal expansion of the stave cooler proper or wearing locally.

Owner:NIPPON STEEL CORP

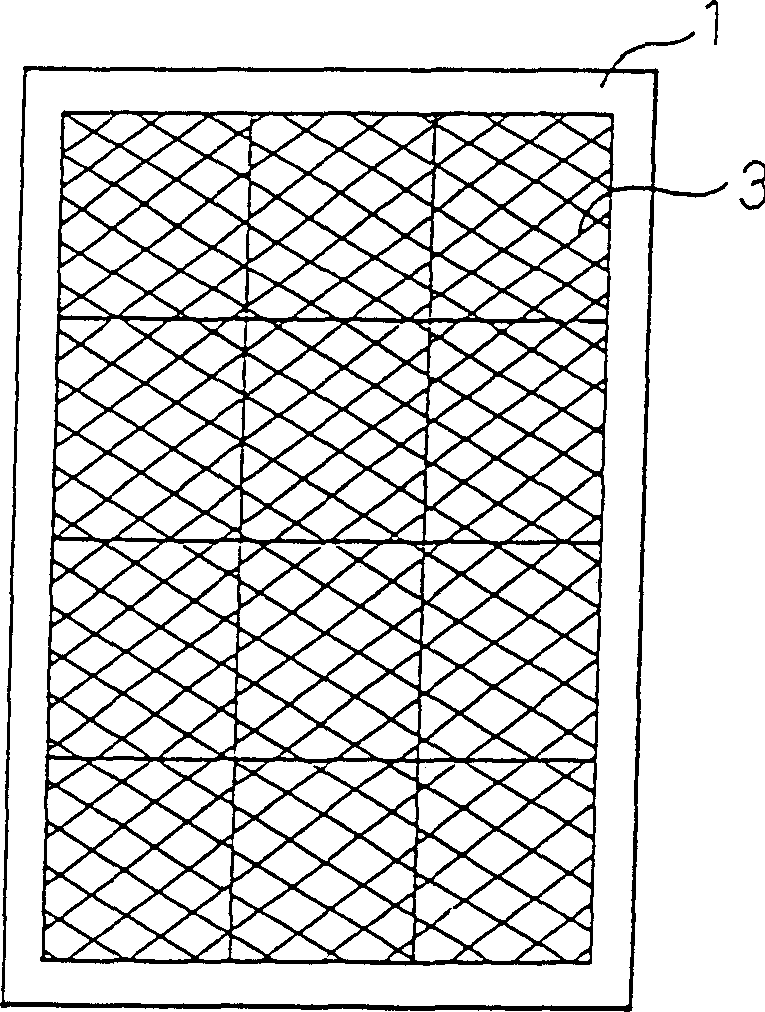

Mini-kiln manufacturing process

InactiveCN108917399AImprove stabilityIncreased durabilityLinings repairFurnace repairKilnManufacturing engineering

The invention belongs to the technical field of kilns, and particularly relates to a mini-kiln manufacturing process which includes module division, special die manufacture, module manufacture, moduleassembly and secondary fixation. A mini-kiln manufactured by the method is simple in manufacturing process, a manufactured special die can be repeatedly used, the mini-kiln can be repaired by replacing a module when any module of the mini-kiln is damaged, and the mini-kiln is stable in structure and strong in practicability.

Owner:张立明

Waste aluminum melting furnace coated with anti-corrosion layer

InactiveCN107664424AEasy to assemble and disassembleImprove disassembly efficiencyFurnace componentsFurnace repairCorrosion resistantMelting furnace

The invention relates to a scrap aluminum smelting furnace with an anti-corrosion layer on the outside, which is characterized in that it comprises an upper furnace body (1) and a lower furnace body (2). There are several bumps (3), and several box buckles (4) are arranged on the upper side wall of the lower furnace body (2), and each box buckle (4) is arranged under the bumps (3), so The box buckle (4) is matched with the bump (3), the upper furnace body (1) and the lower furnace body (2) are provided with observation ports (5), and the upper furnace body (1) and the lower furnace body (2) An anti-corrosion layer is provided on the outside of the furnace body (2). This scrap aluminum smelting furnace with an anti-corrosion layer on the outside is provided with bumps on the side wall of the lower part of the upper furnace body, and box buckles are arranged on the side wall of the upper part of the lower furnace body. When it is necessary to disassemble the upper furnace body and When lowering the furnace body, it can be easily completed as long as the box buckle is fastened to the projection or pulled apart, so that the disassembly and assembly of the upper furnace body and the lower furnace body are convenient and the disassembly and assembly efficiency is high.

Owner:JIANGYIN DIXIN METAL IND

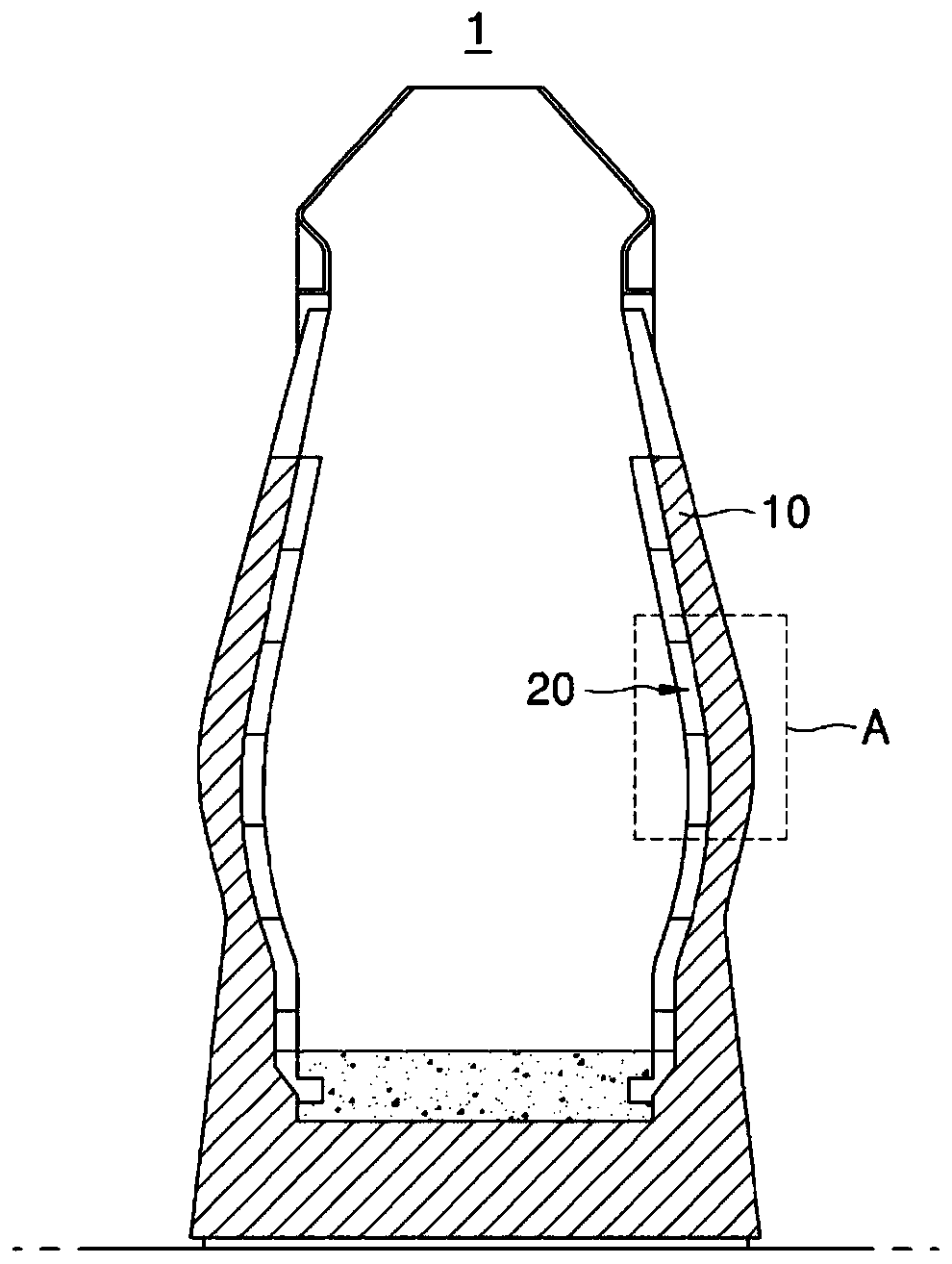

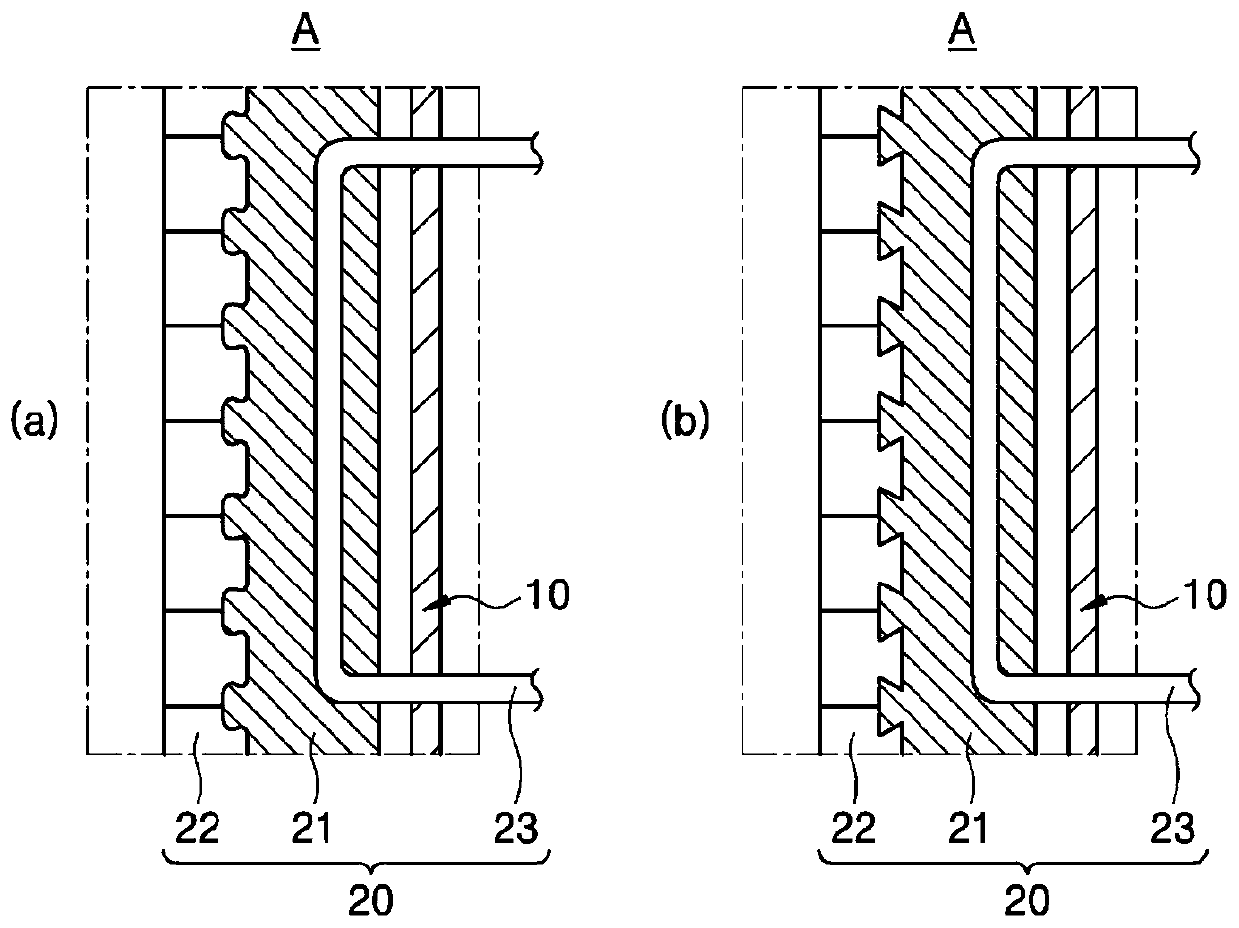

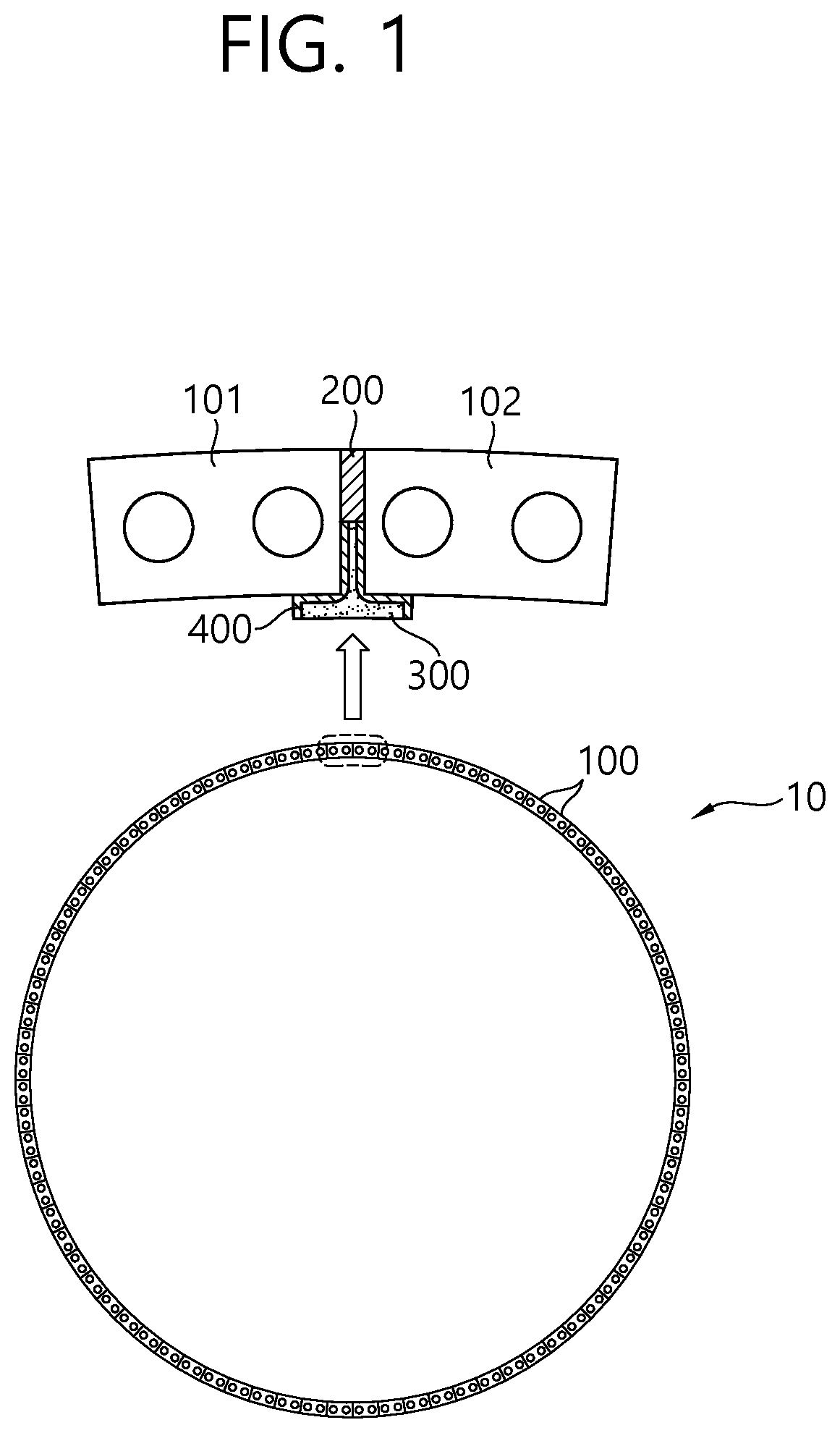

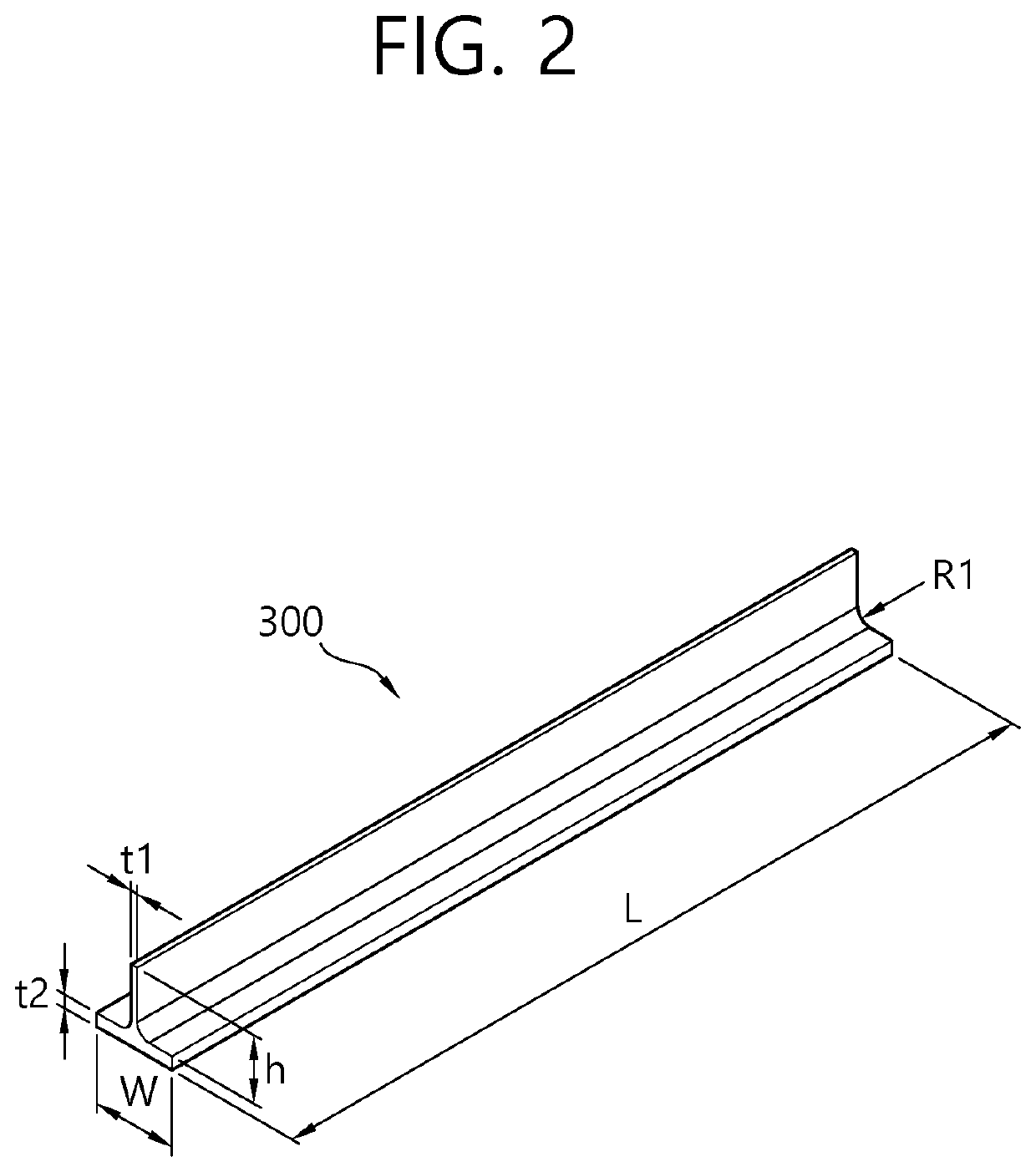

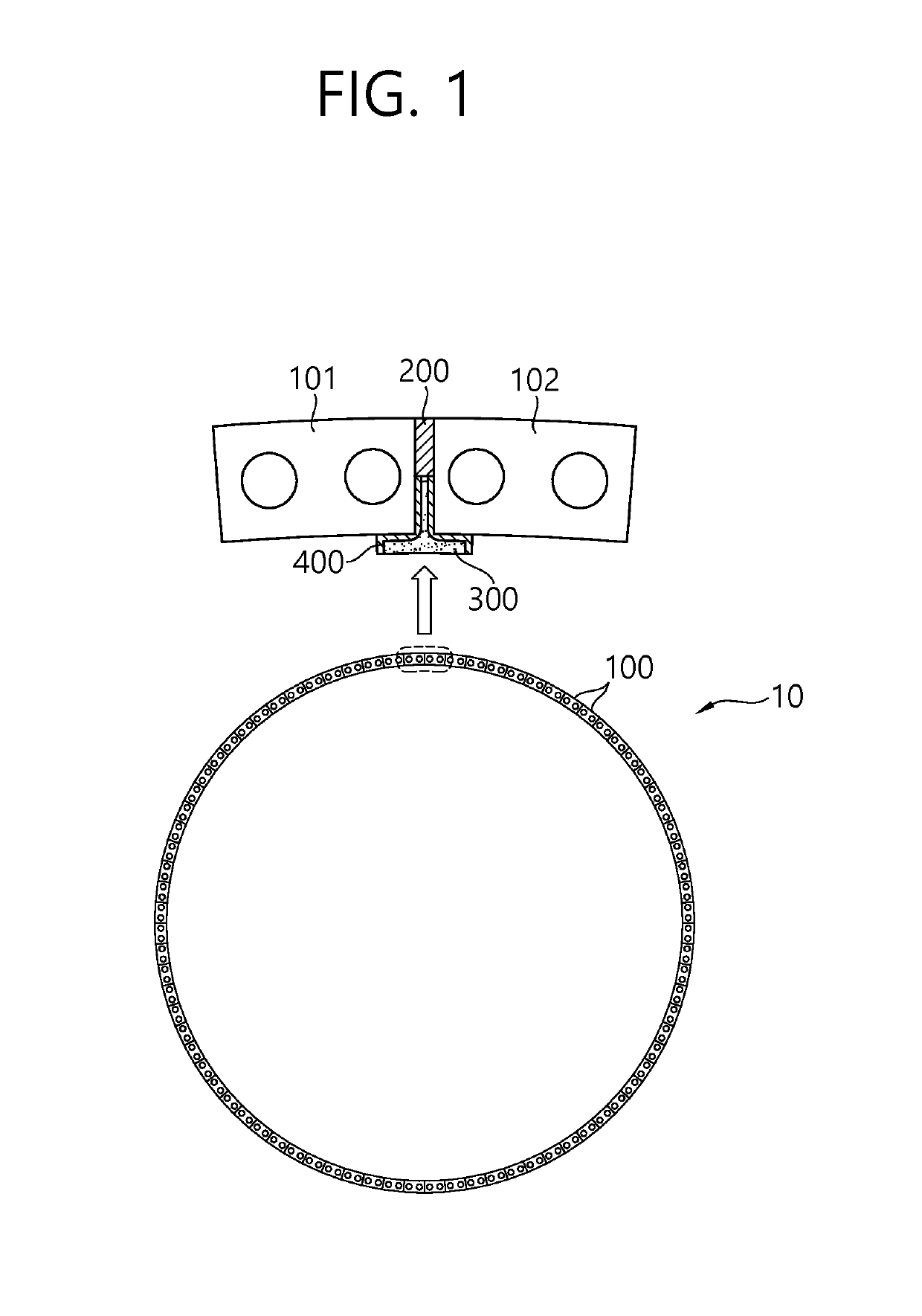

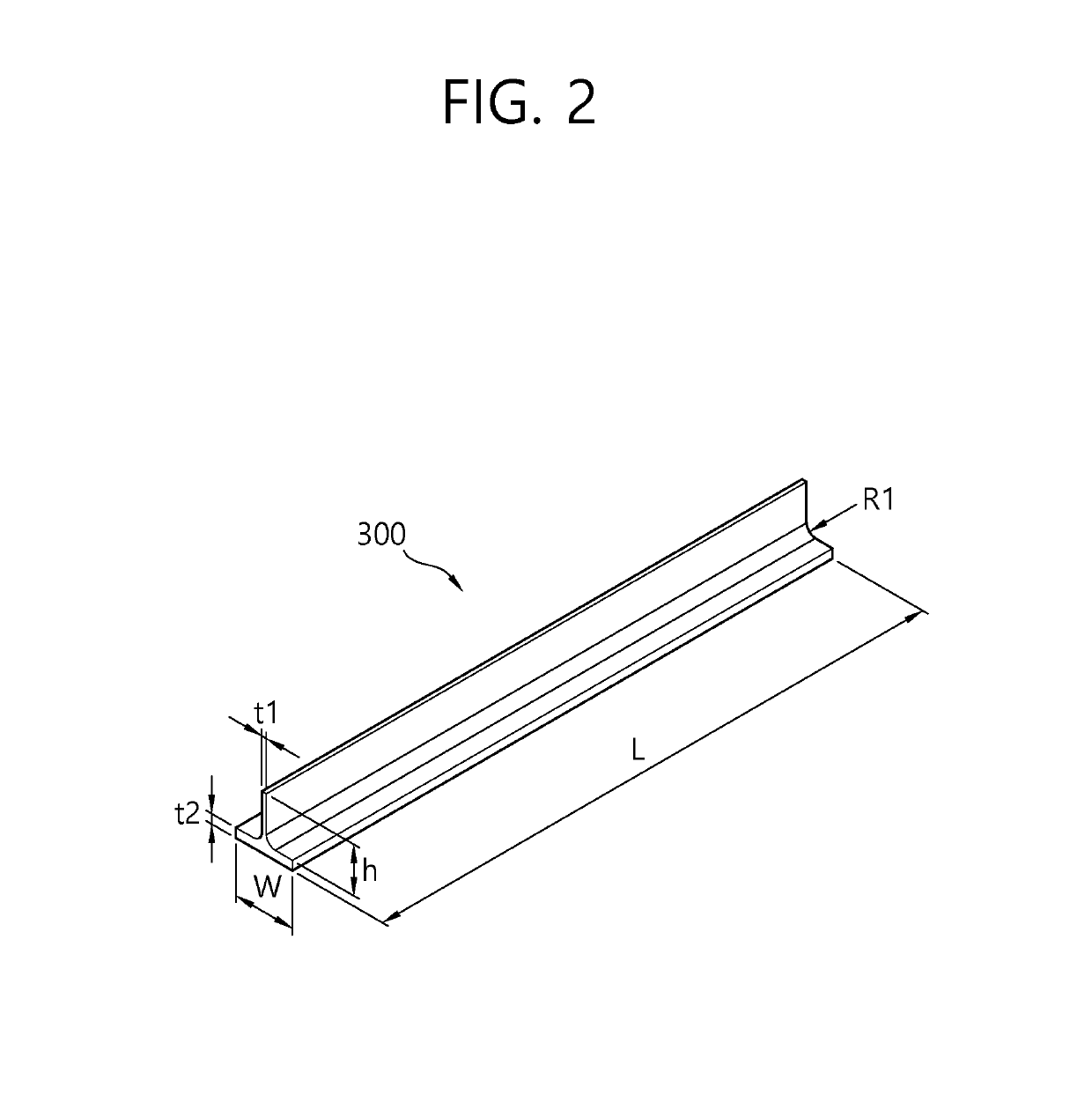

Cold crucible comprising metal oxide barrier and method for manufacturing same

ActiveUS11391516B2Easy maintenanceEasy to replaceFurnaces without endless coreGlass furnace apparatusCrucibleMetal

A metal oxide barrier and a connecting method for solving the problems in which sectors of an existing cold crucible are connected by means of a mica plate and the mica plate is damaged due to arcing and the like and in which the sectors are strongly connected by means of the mica plate and thus are difficult to replace and maintain. A cold crucible, comprising a metal oxide barrier, according to the present invention can prevent arcing, enables reduction of damage on the edge part of a water cooling sector due to a molten material and thus enhances durability. Moreover, the metal oxide barrier can easily be replaced compared to an existing mica plate and thus enables easy maintenance and repair.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

Stave cooler

InactiveCN1175238CExtended service lifeMaintain insulation propertiesFurnace cooling arrangementsCooling devicesThermal expansionCooling pipe

A stave cooler used for cooling a furnace wall of a metallurgical furnace such as a blast furnace, having a structure in which cooling pipes to cool a metal base are cast on the side opposite the furnace interior side of the metal base and a heat resistant steel plate having openings or a lamination of heat resistant steel plates having openings is cast, in a prescribed thickness, in the furnace interior side surface of the metal base. It is acceptable to form the lamination suitably into a rectangular parallelepiped and cast it, in a plurality, in the furnace interior side of the metal base. The wear rate of the furnace interior side surface of the stave cooler is small, and its structure prevents the heat resistant steel plate(s) from falling out by thermal expansion of the stave cooler proper or wearing locally.

Owner:NIPPON STEEL CORP

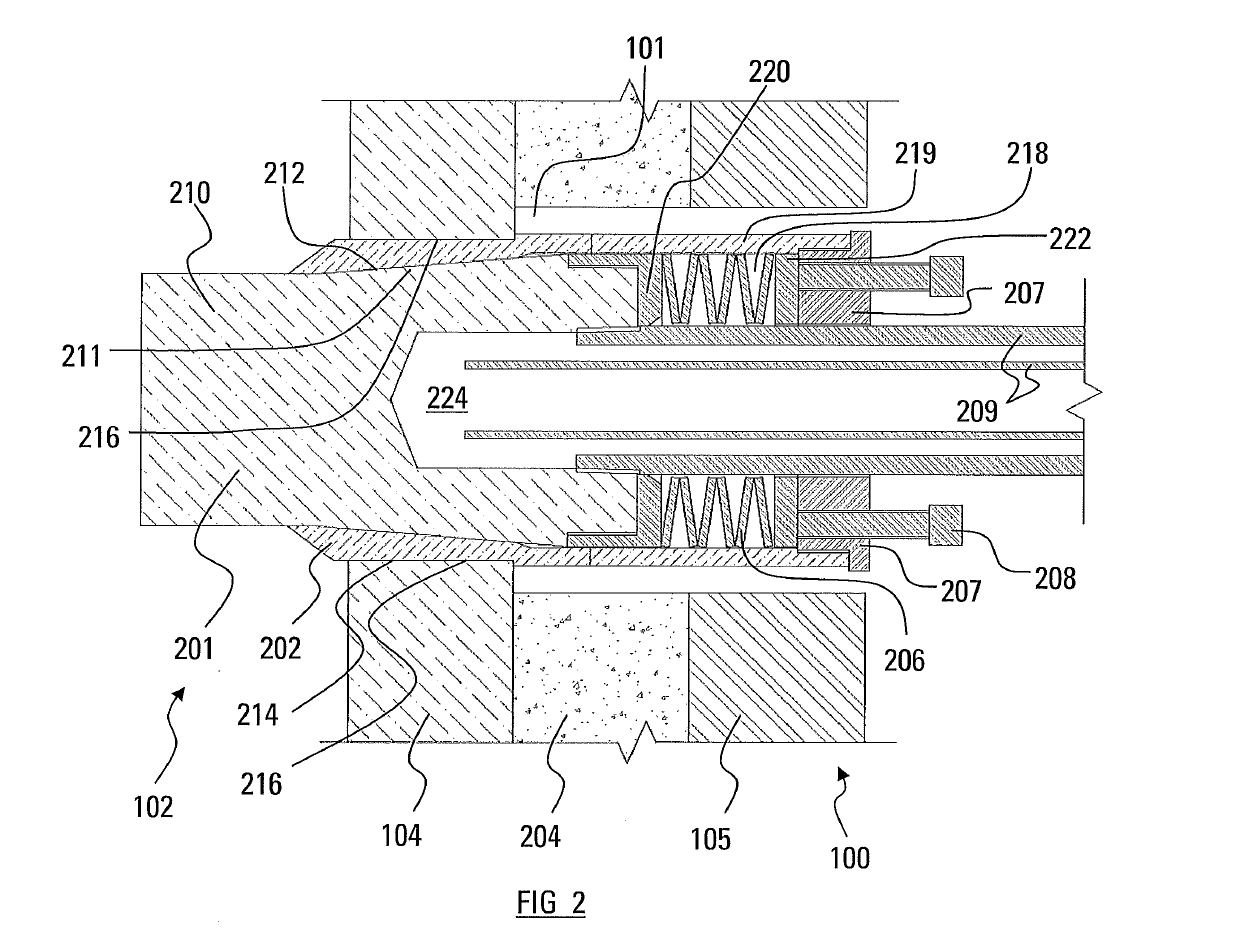

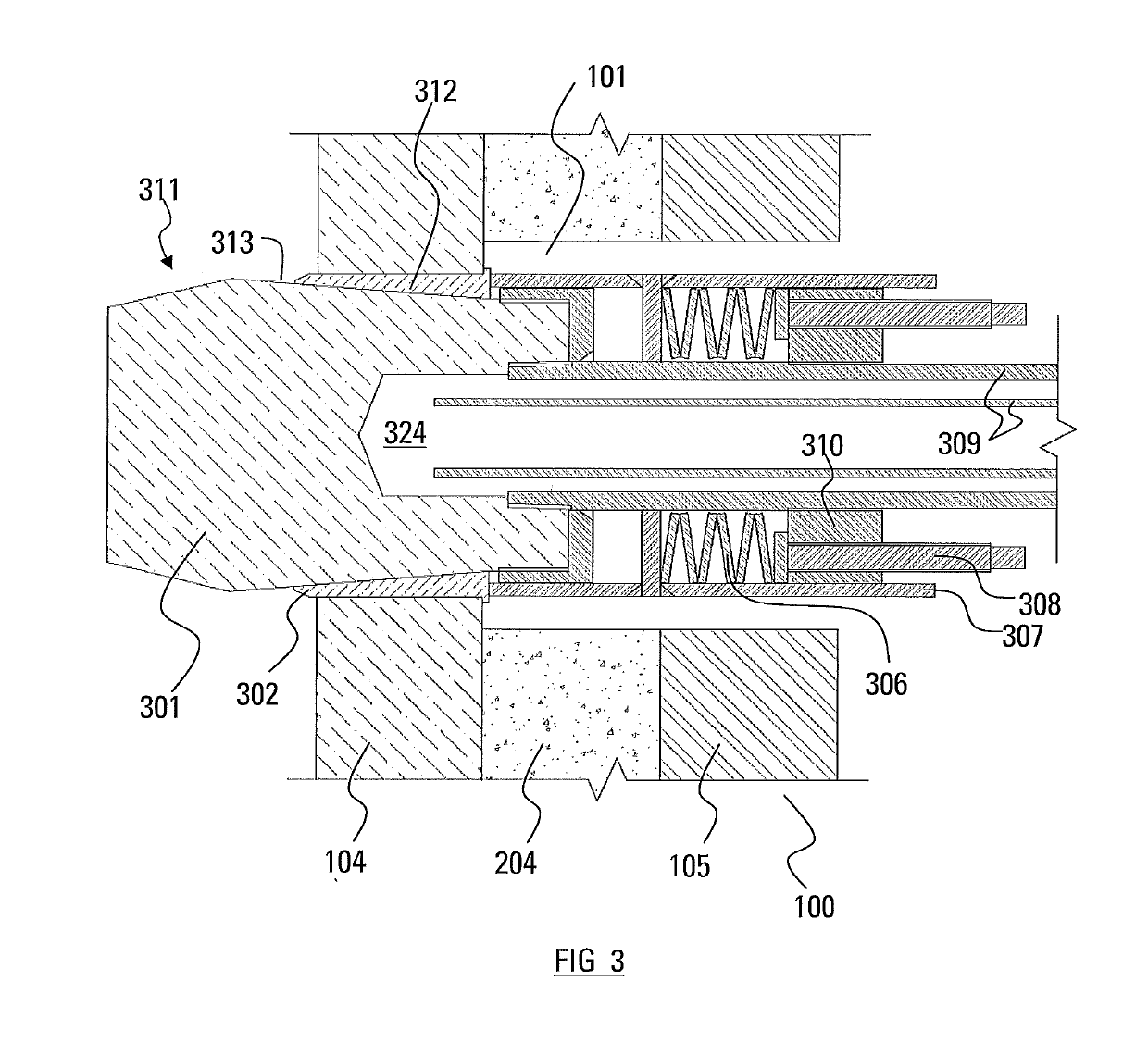

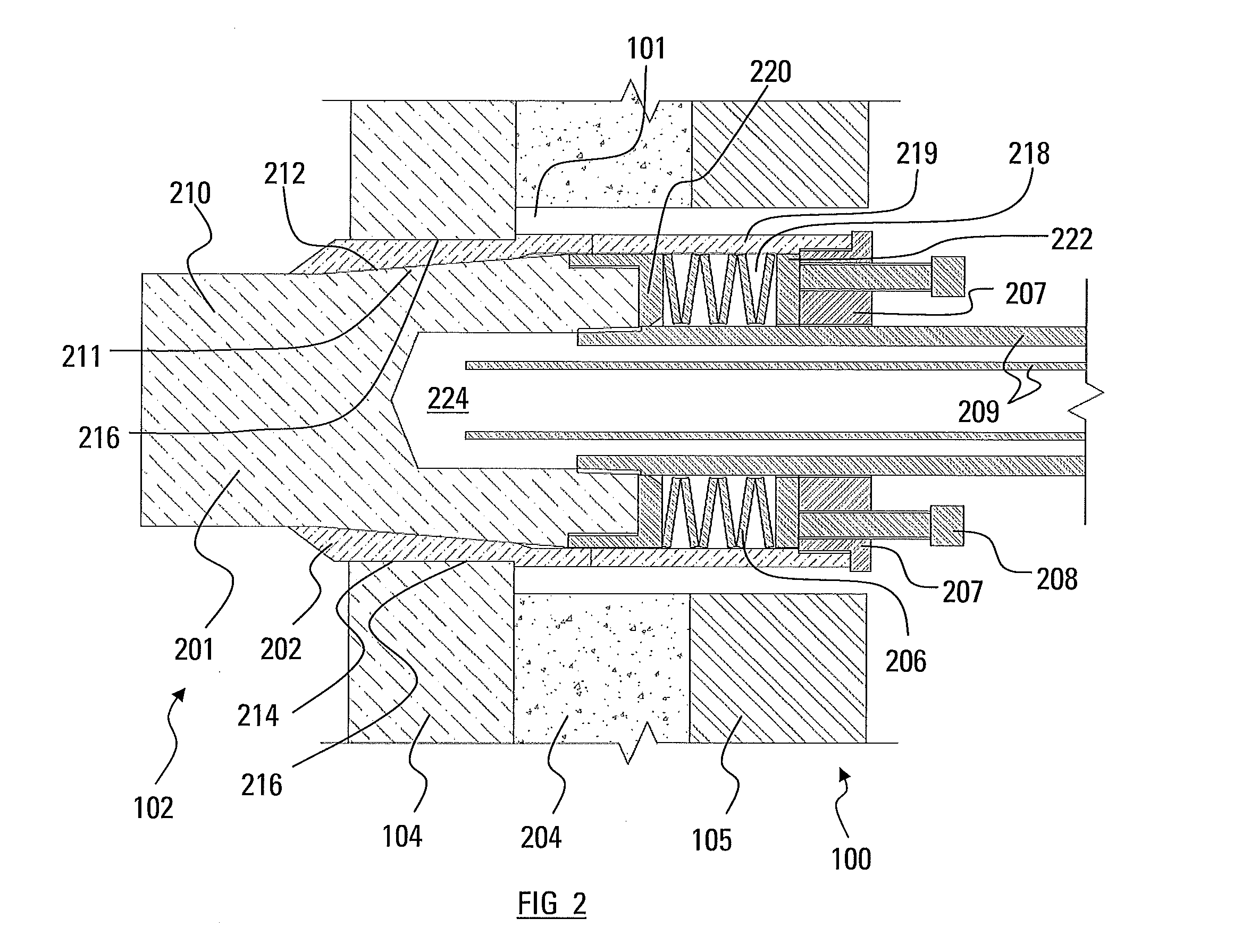

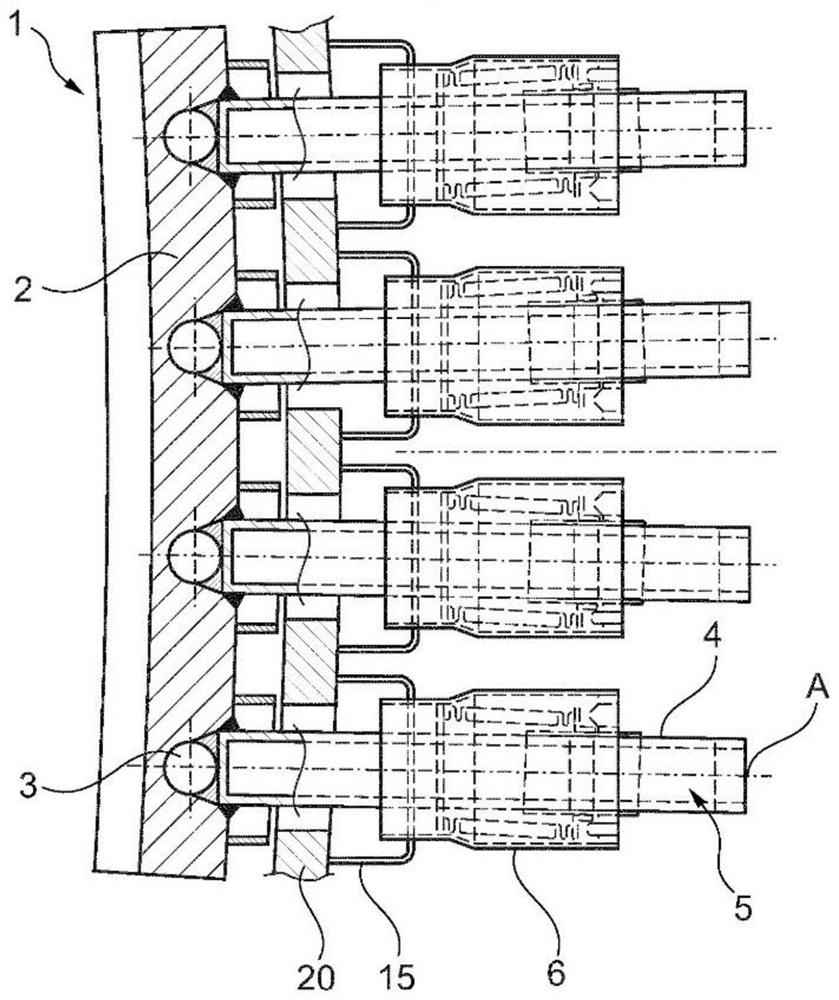

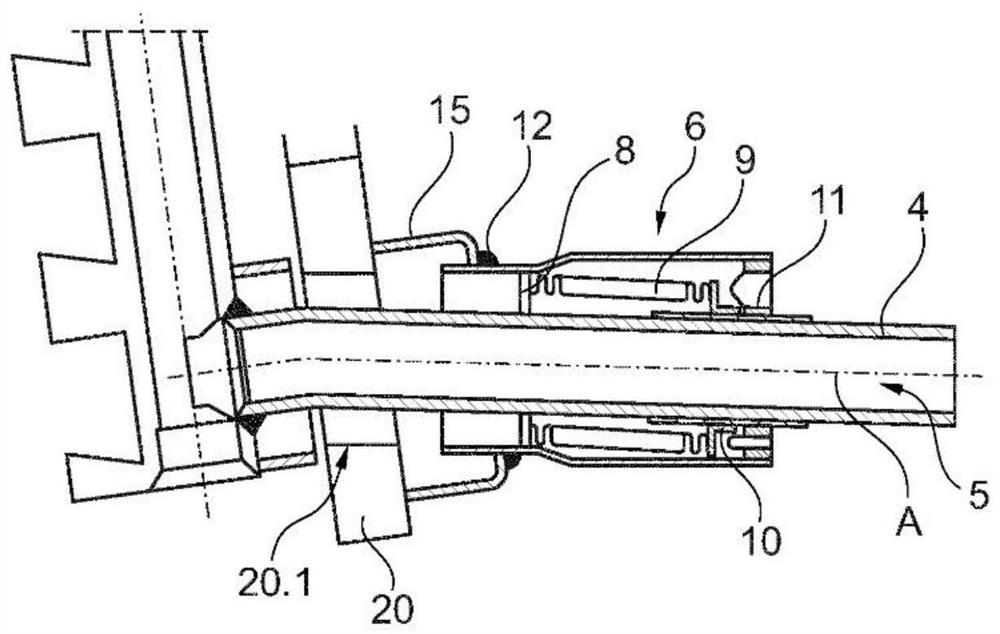

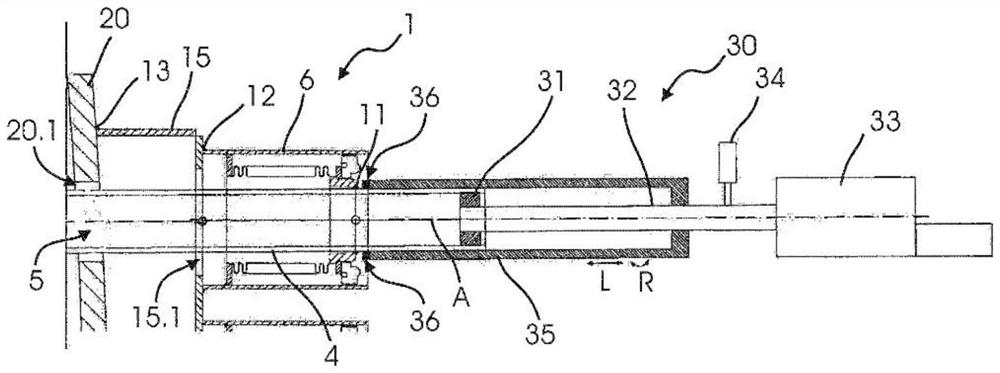

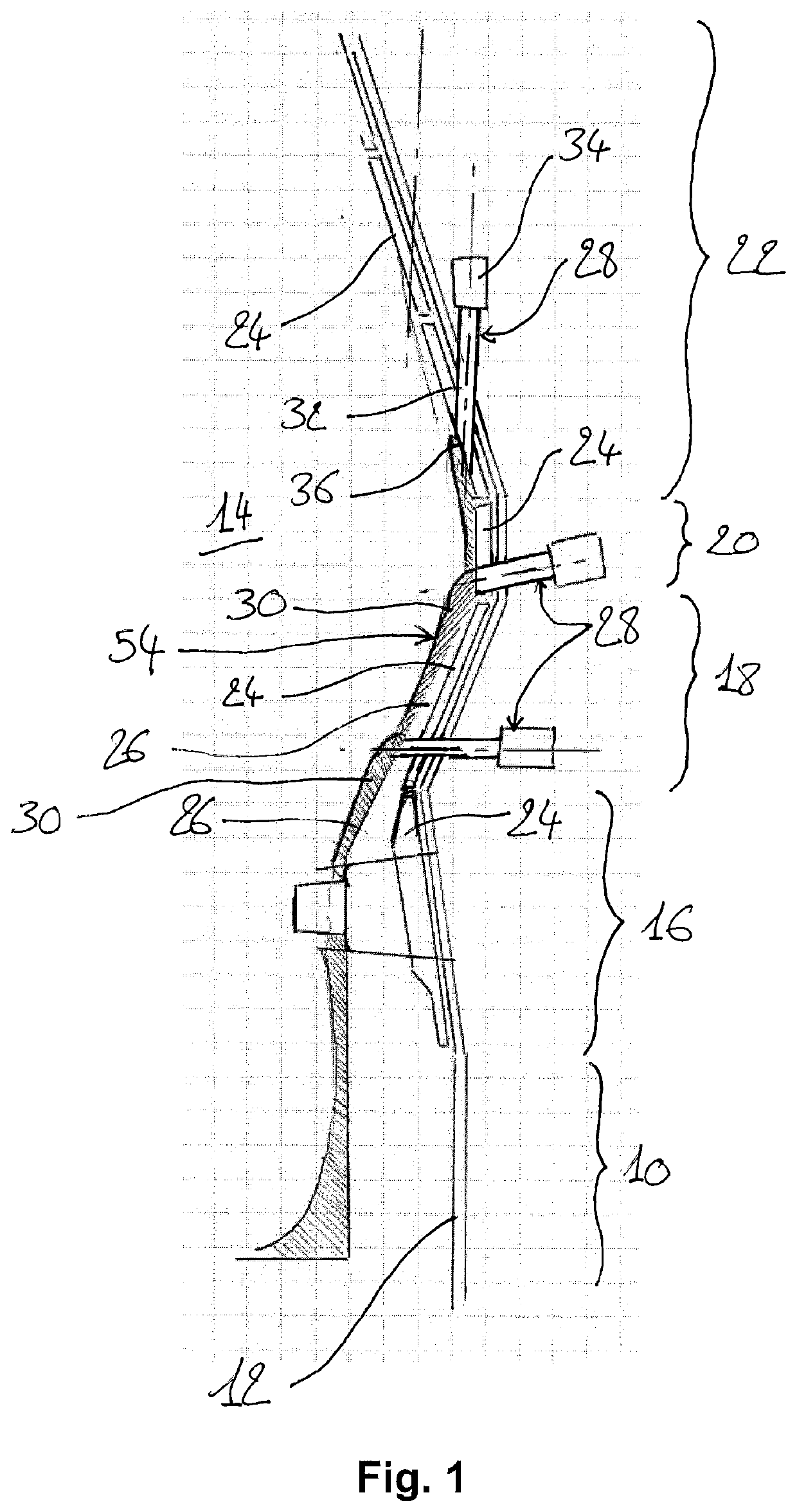

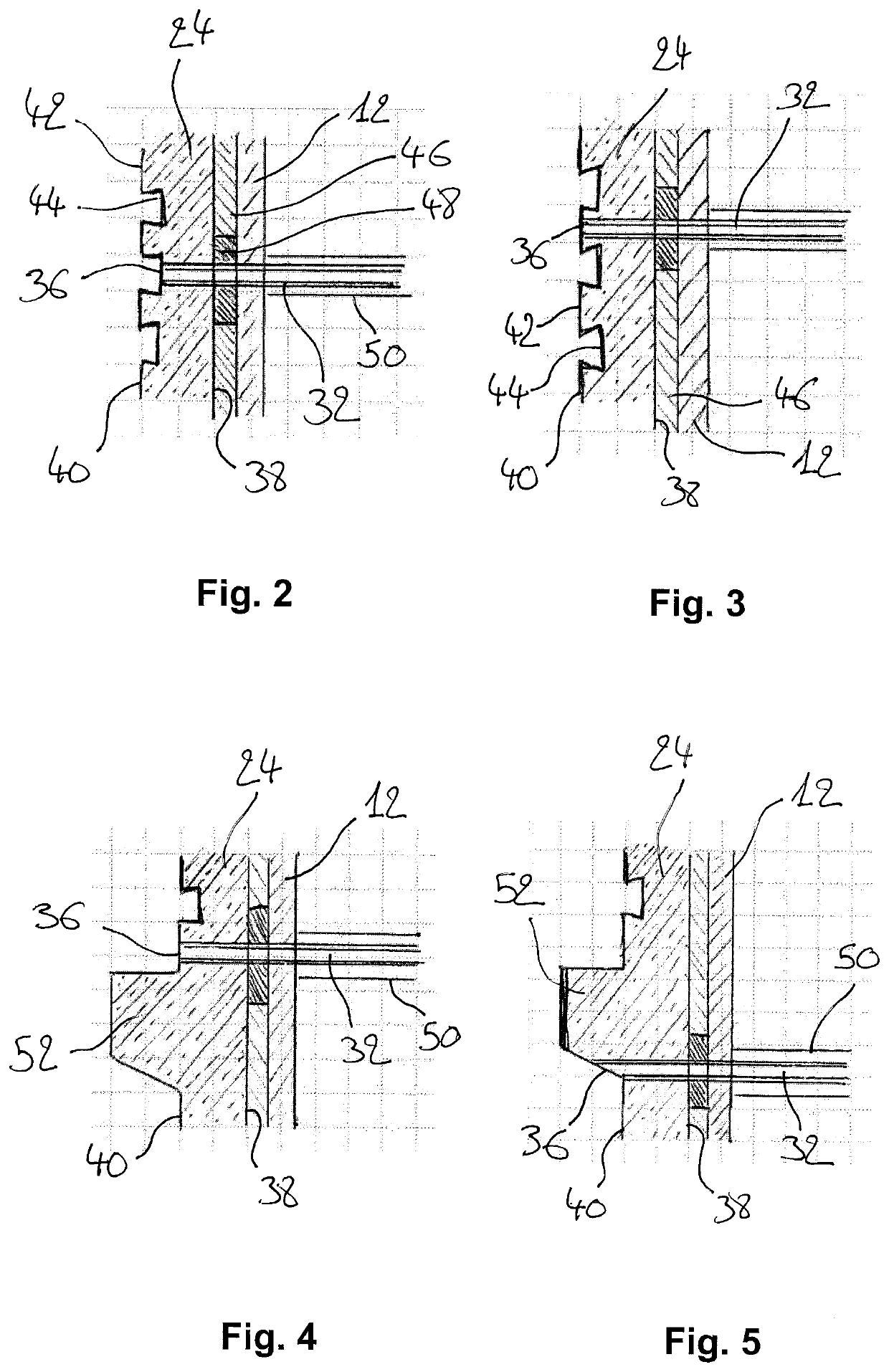

Method for maintaining cooling assembly of metallurgical furnace

The invention relates to a method for maintaining a cooling assembly (1) of a metallurgical furnace, said cooling assembly (1) comprising: a cooling plate (2) arranged inside a furnace shell (20) of the metallurgical furnace; -a cooling tube (4) which traverses a casing opening (20.1) in the furnace casing (20) and is connected to the cooling plate (2); and-a compensator (6) arranged around the cooling tube (4) for forming a seal between the cooling tube (4) and the furnace shell (20). In order to provide measures to facilitate maintenance of a cooling system of a metallurgical furnace, the invention provides a method comprising performing at least one cutting operation with a cutting device (30, 40) comprising a clamp (31, 41) and a cutting tool (36, 45) movably connected to the clamp (31, 41) for a guided movement relative to the clamp (31, 41), the clamp (31, 41) is mounted to the cooling tube (4), whereby the cutting device (30, 40) is aligned with respect to the cooling tube (4) and the cutting tool (36, 45) is moved in a guided manner when the cutting operation is performed.

Owner:PAUL WURTH SA +1

Cold crucible comprising metal oxide barrier and method for manufacturing same

ActiveUS20190331422A1Avoid damageEasy maintenanceFurnaces without endless coreGlass furnace apparatusCrucibleMetal

A metal oxide barrier and a connecting method for solving the problems in which sectors of an existing cold crucible are connected by means of a mica plate and the mica plate is damaged due to arcing and the like and in which the sectors are strongly connected by means of the mica plate and thus are difficult to replace and maintain. A cold crucible, comprising a metal oxide barrier, according to the present invention can prevent arcing, enables reduction of damage on the edge part of a water cooling sector due to a molten material and thus enhances durability. Moreover, the metal oxide barrier can easily be replaced compared to an existing mica plate and thus enables easy maintenance and repair.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

Anti-corrosion waste aluminum smelting furnace

InactiveCN107655340AEasy to assemble and disassembleImprove disassembly efficiencyFurnace componentsFurnace repairCorrosion resistantMelting furnace

The invention relates to a corrosion-resistant waste aluminum smelting furnace, which is characterized in that it comprises an upper furnace body (1) and a lower furnace body (2), and the lower side wall of the upper furnace body (1) is provided with several convex Block (3), the upper side wall of the lower furnace body (2) is provided with several box buckles (4), the box buckles (4) are matched with the bumps (3), and the upper furnace body (1 ) and the lower furnace body (2) are provided with observation ports (5), the upper furnace body (1) and the lower furnace body (2) are provided with a plurality of temperature measurement interfaces, and the temperature measurement interfaces are connected to the temperature measurement joints , the outer parts of the upper furnace body (1) and the lower furnace body (2) are provided with an anti-corrosion layer. This anti-corrosion scrap aluminum smelting furnace is provided with bumps on the side wall of the lower part of the upper furnace body, and a box buckle is provided on the side wall of the upper part of the lower furnace body. When it is necessary to disassemble the upper furnace body and the lower furnace body , it can be easily completed by fastening the box buckle to the projection or pulling it apart, which makes the disassembly and assembly of the upper furnace body and the lower furnace body convenient and the disassembly and assembly efficiency is high.

Owner:JIANGYIN DIXIN METAL IND

Method for protecting an inner wall of a shaft furnace

PendingUS20220074667A1Simple methodExtend service hoursBrick-hot blast stovesLinings repairEngineeringStructural engineering

A method for protecting an inner wall (12) of a shaft furnace, the method comprising the steps of: providing at least one injection device (28) through the inner wall (12) of the shaft furnace, the injection device (28) being configured to inject protective material into the shaft furnace; and injecting on demand the protective material into the shaft furnace through the injection device (28), in such a manner that the protective material builds up to form a protection wall between the interior of the shaft furnace and the furnace wall (12).

Owner:PAUL WURTH SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com