Emergency repair device and method of heating furnace side wall

An emergency repair and heating furnace technology, applied in the field of industrial furnaces and kilns, can solve the problems of large masonry workload, long production cycle, inward side walls, etc., to meet the requirements of emergency repair, low manufacturing cost, and short construction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

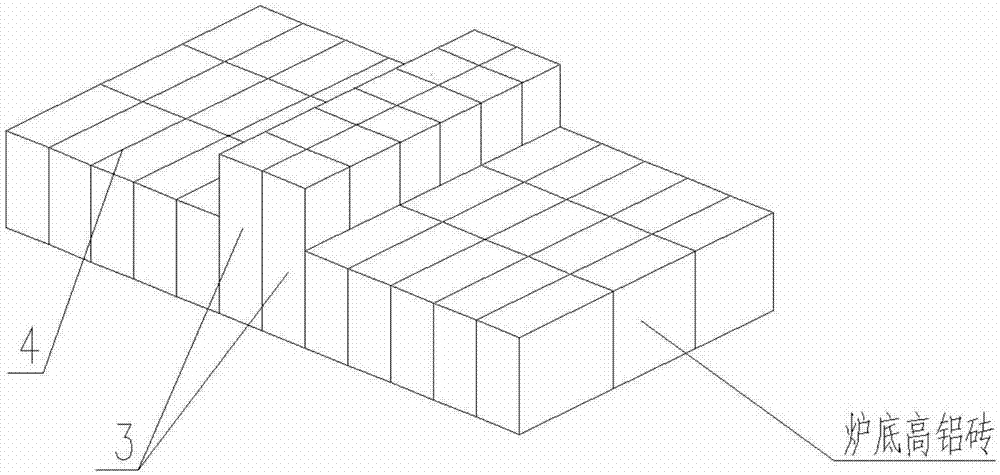

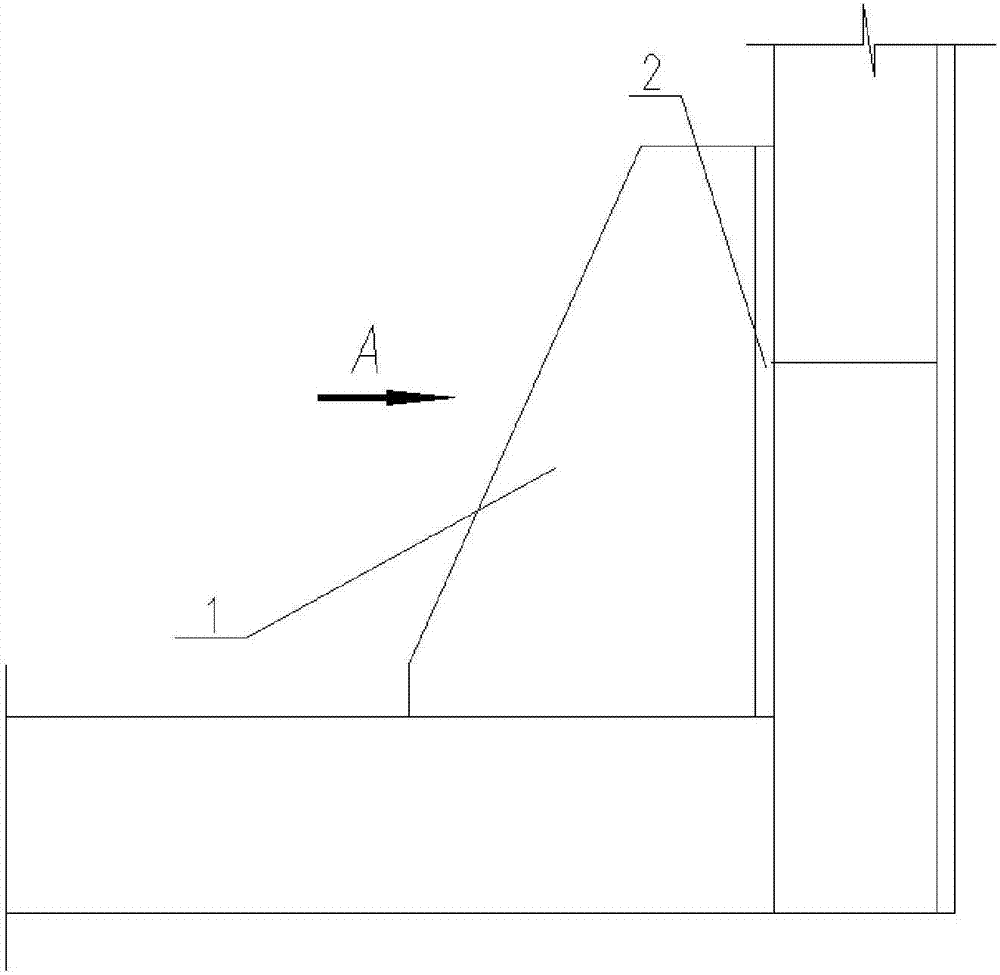

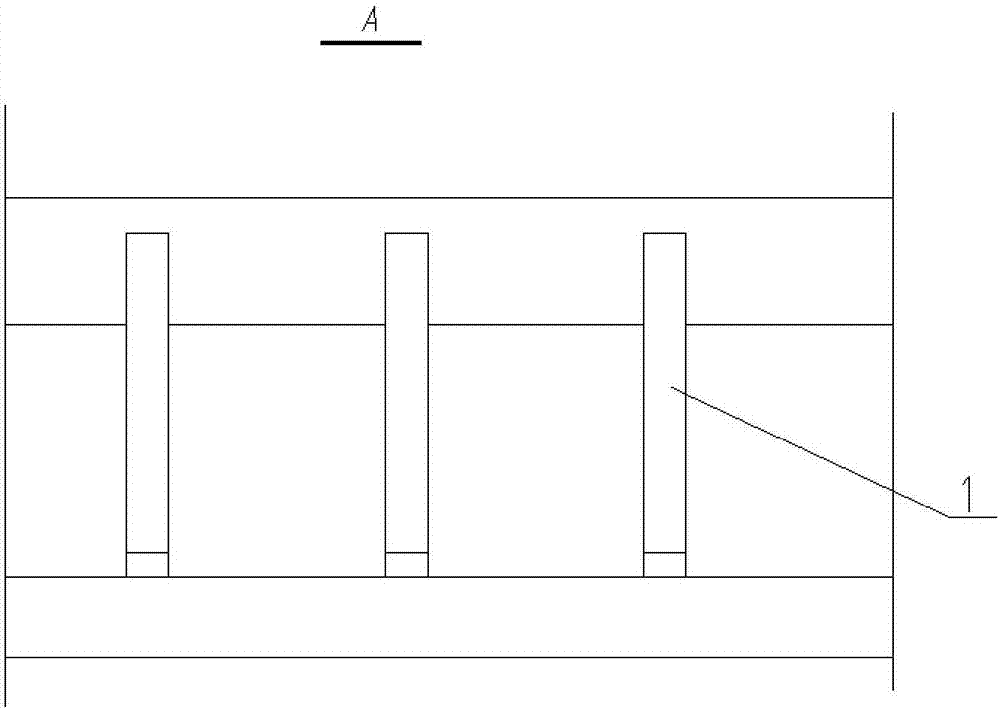

[0026] combine figure 1 , figure 2 and image 3 The emergency repair device for the side wall of the heating furnace of the present invention includes a plurality of supporting walls 1 for supporting the side wall of the heating furnace and rooting foundation walls 3 corresponding to the supporting walls; the rooting foundation walls 3 are arranged at the bottom of the heating furnace, and the The supporting wall 1 is arranged on the rooting foundation wall; the vertical side of the supporting wall is in contact with the side wall of the heating furnace.

Embodiment 2

[0028] As a specific solution of Example 1, the support wall 1 includes refractory clay bricks and refractory mud 4, and the section of the support wall along the direction perpendicular to the side wall of the heating furnace is trapezoidal.

[0029] Specifically, the refractory temperature of the refractory putty is not less than 1450°C.

Embodiment 3

[0031] As a specific solution of Example 1, a refractory fiber layer 2 is sandwiched between the supporting wall and the side wall of the heating furnace;

[0032] Specifically, the refractory fiber layer includes several layers of refractory fiber blankets woven from refractory fibers; the thickness of the refractory fiber layer is 25-30mm; the refractory temperature of the refractory fiber is not less than 1200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com