Submerged arc furnace body protection method

A technology for submerged arc furnaces and furnace bodies, which is applied in furnaces, furnace maintenance, furnace components, etc., can solve the problems of decreased service life of submerged arc furnaces, increased safety risks, furnace wall burn-through, etc. Reduction temperature and reduction speed, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

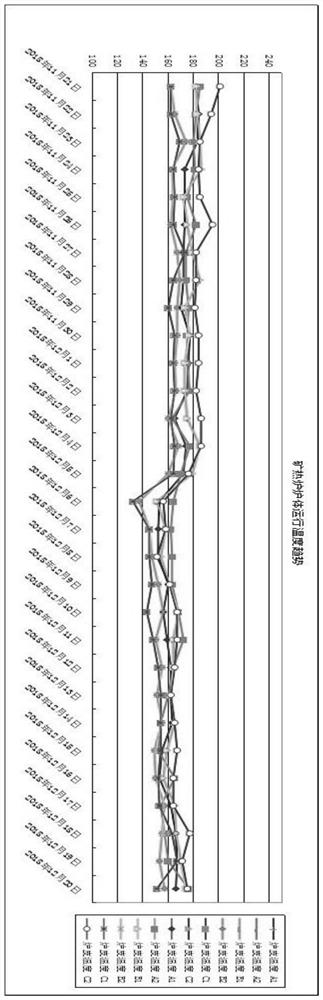

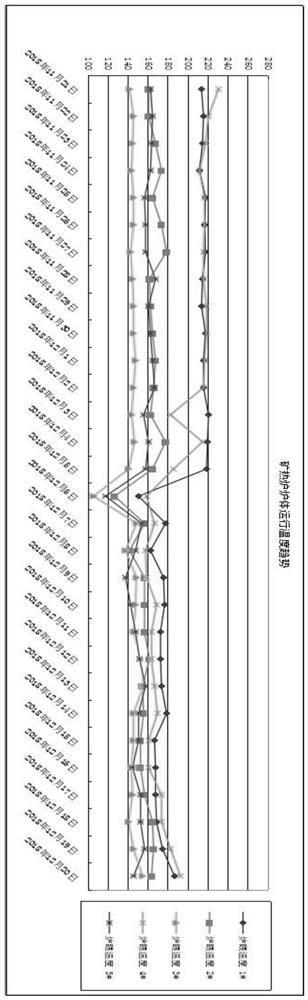

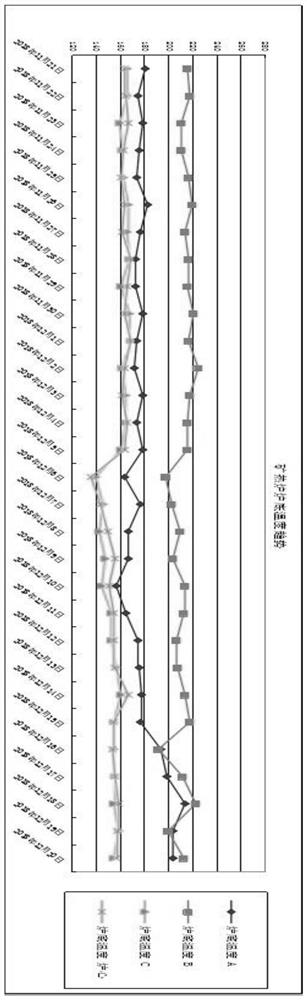

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

[0026] A method for protecting a furnace body of a submerged arc furnace, comprising the steps of:

[0027] 1) Through constant gear operation, the reference gear is controlled at 11 gears, and the number of adjustments per shift is less than 5 times. According to the chemical and physical components of the feed, the theoretical carbon amount is measured in time, and the actual carbon amount and the theoretical calculation value are controlled. The error is within ±5kg, realizing constant gear operation; reducing the amplitude and frequency of load adjustment, so that the crucible can be stabilized within a certain range, and by exploring the constant gear operation mode, the current fluctuation caused by material collapse can be reduced, thereby affectin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com