Method for maintaining cooling assembly of metallurgical furnace

A technology for cooling components and metallurgical furnaces, which is applied in the direction of furnace components, furnace cooling devices, furnace cooling, etc., and can solve problems such as urgent maintenance or replacement time and short furnace shutdown time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

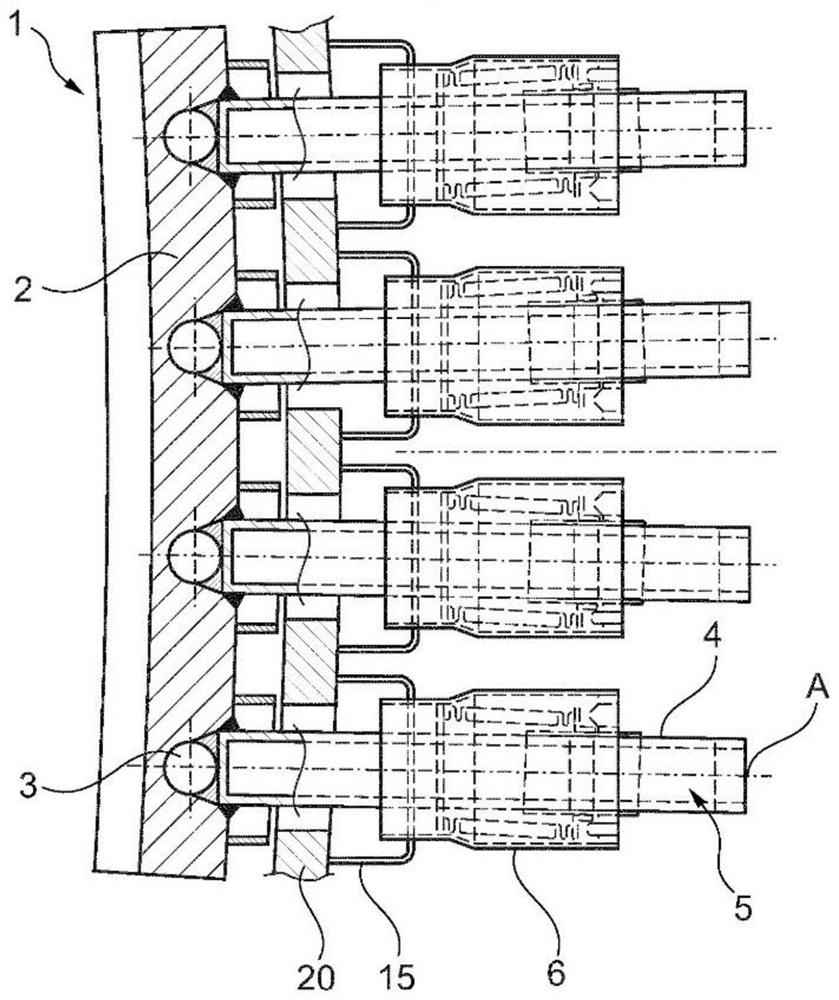

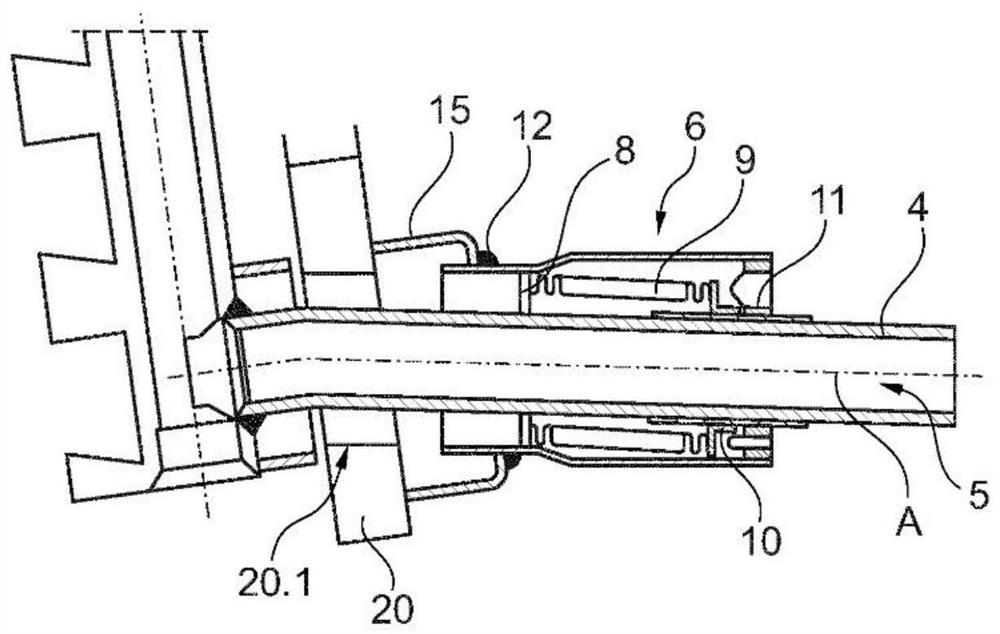

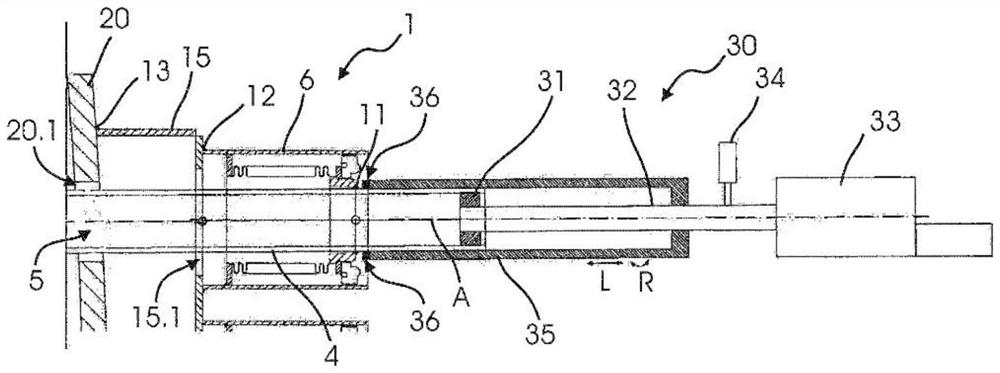

[0040] figure 1 A cross-sectional view of a cooling assembly 1 of a metallurgical furnace, such as a blast furnace, before maintenance is shown. cooling pack 1, in figure 2 Its details are also shown in the sectional view of , including the cooling plate 2 made of copper or copper alloy. The cooling plate 2 is arranged in the furnace shell 20 of the metallurgical furnace. The surface of the cooling plate 2 is shown here as flat, but it may include ribs and grooves to increase the surface area. Furthermore, it can also be provided with a refractory lining, which is not shown here for the sake of simplicity. A plurality of coolant channels 3 are provided in the cooling plate 2 .

[0041] The cooling assembly 1 also comprises a plurality of cooling tubes 4 each having a tube channel 5 connected to a cooling channel 3 . The cooling tube 4 can be made of the same material as the cooling plate 2 . Each cooling tube 4 passes through a housing opening 20 . 1 in the furnace hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com