Aluminum-silicon plastic refractory for rapid repair and preparation method thereof

A plastic and fast technology, used in furnace maintenance, lighting and heating equipment, furnaces, etc., to achieve wide adaptability, increased construction performance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

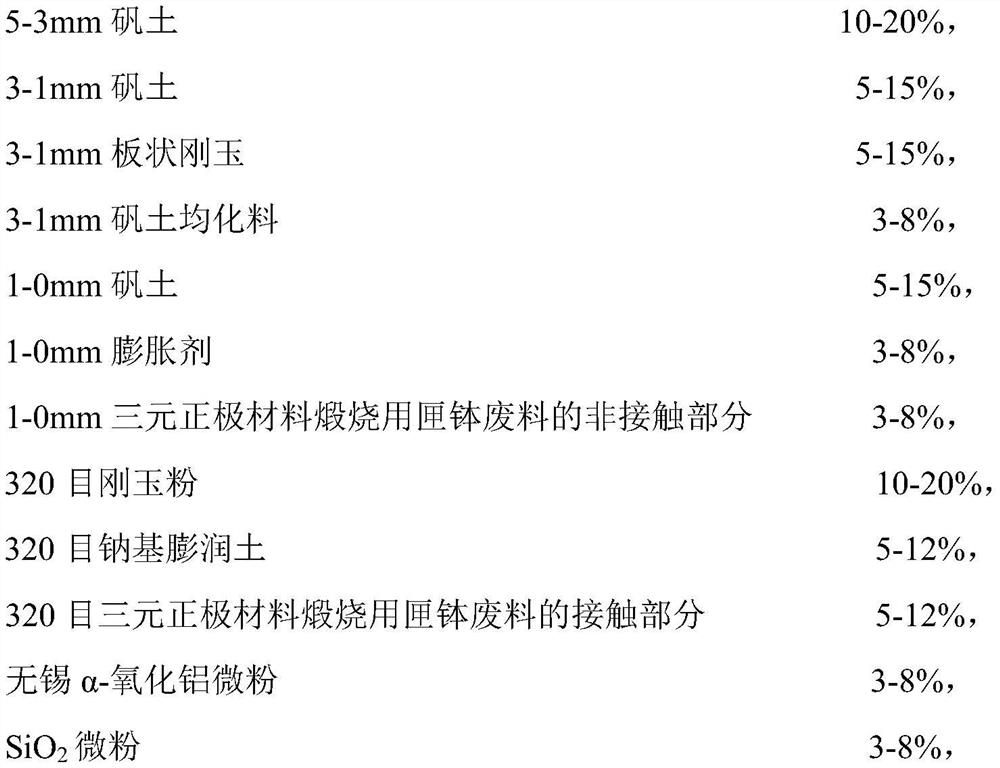

[0044] The present embodiment aluminum siliceous rapid repair is made up of plastic formula as follows:

[0045]

[0046]

[0047] The mass sum of the above components is 100%;

[0048] Plus the sum of the mass of the above components:

[0049] Solid phenolic resin powder 3%,

[0050] Aluminum dihydrogen phosphate solution 8%,

[0051] Sepiolite Viscosifying Suspension 10%.

[0052] The specific preparation method is as follows:

[0053] (1) Sodium bentonite modification treatment: mix calcium-based bentonite and sodium tripolyphosphate in a ratio of 100:3, and carry out sodiumization by co-grinding in a ball mill for more than 48 hours;

[0054] (2) Preparation of waste saggers for calcination of ternary positive electrode materials: Classify and screen waste saggars for calcination of ternary positive electrode materials, and separate the upper part of the facade around the sagger that is not in contact with the precursor of the positive electrode material, the bot...

Embodiment 2

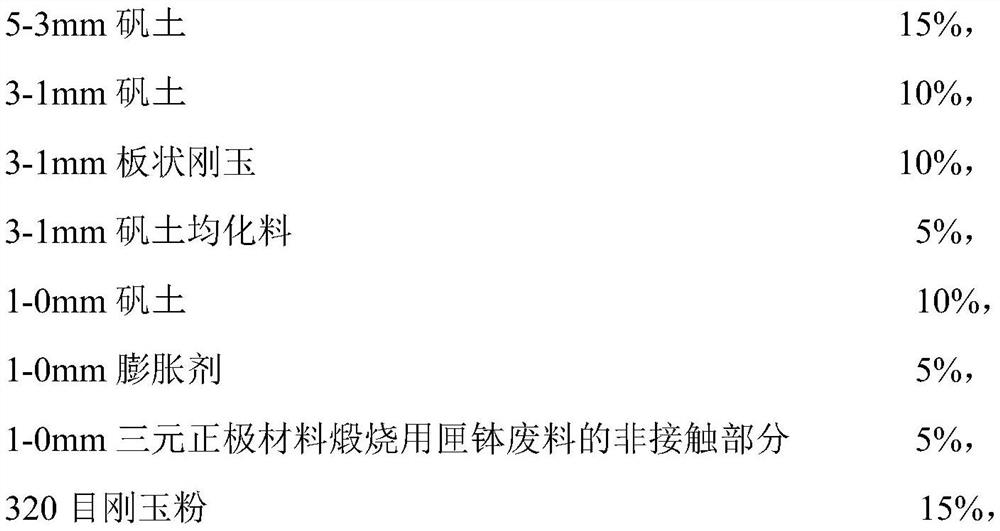

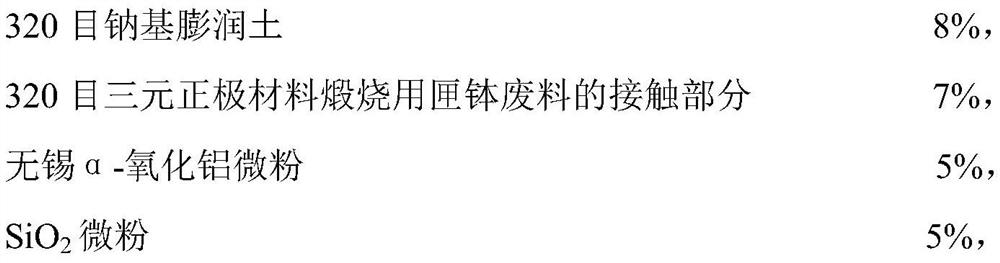

[0058] The present embodiment aluminum siliceous rapid repair is made up of plastic formula as follows:

[0059]

[0060] The mass sum of the above components is 100%;

[0061] Plus the sum of the mass of the above components:

[0062] Solid phenolic resin powder 5%,

[0063] Aluminum dihydrogen phosphate solution 10%,

[0064] Sepiolite Viscosified Suspension 7%.

[0065] The specific preparation method is as follows:

[0066] (1) Sodium bentonite modification treatment: mix calcium-based bentonite and sodium tripolyphosphate in a ratio of 100:3, and carry out sodiumization by co-grinding in a ball mill for more than 48 hours;

[0067] (2) Preparation of waste saggers for calcination of ternary positive electrode materials: Classify and screen waste saggars for calcination of ternary positive electrode materials, and separate the upper part of the facade around the sagger that is not in contact with the precursor of the positive electrode material, the bottom of the sa...

Embodiment 3

[0071] The present embodiment aluminum siliceous rapid repair is made up of plastic formula as follows:

[0072]

[0073] The mass sum of the above components is 100%;

[0074] Plus the sum of the mass of the above components:

[0075] Solid phenolic resin powder 4%,

[0076] Aluminum dihydrogen phosphate solution 5%,

[0077] Palygorskite viscosifying suspension 13%.

[0078] The specific preparation method is as follows:

[0079] (1) Sodium modification of bentonite: mix calcium-based bentonite with sodium tripolyphosphate in a ratio of 100:4, and co-mill for more than 48 hours in a ball mill for sodium treatment;

[0080] (2) Preparation of waste saggers for calcination of ternary positive electrode materials: Classify and screen waste saggars for calcination of ternary positive electrode materials, and separate the upper part of the facade around the sagger that is not in contact with the precursor of the positive electrode material, the bottom of the sagger and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com