Construction method of coke oven

A coking oven and block technology, which is applied in the coking oven brickwork, furnace, furnace lining, etc., can solve the problems of cracks and elongation, and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Next, a method for implementing the present invention will be specifically described. In addition, the following description shows one preferable embodiment of this invention, and this invention is not limited at all by the following description. It should be noted that in the following description, unless otherwise specified, the orientation of the shaped refractory and the block manufactured by stacking the shaped refractory are based on the orientation in the state of being installed in the coke oven. , down, horizontal, vertical and height terms.

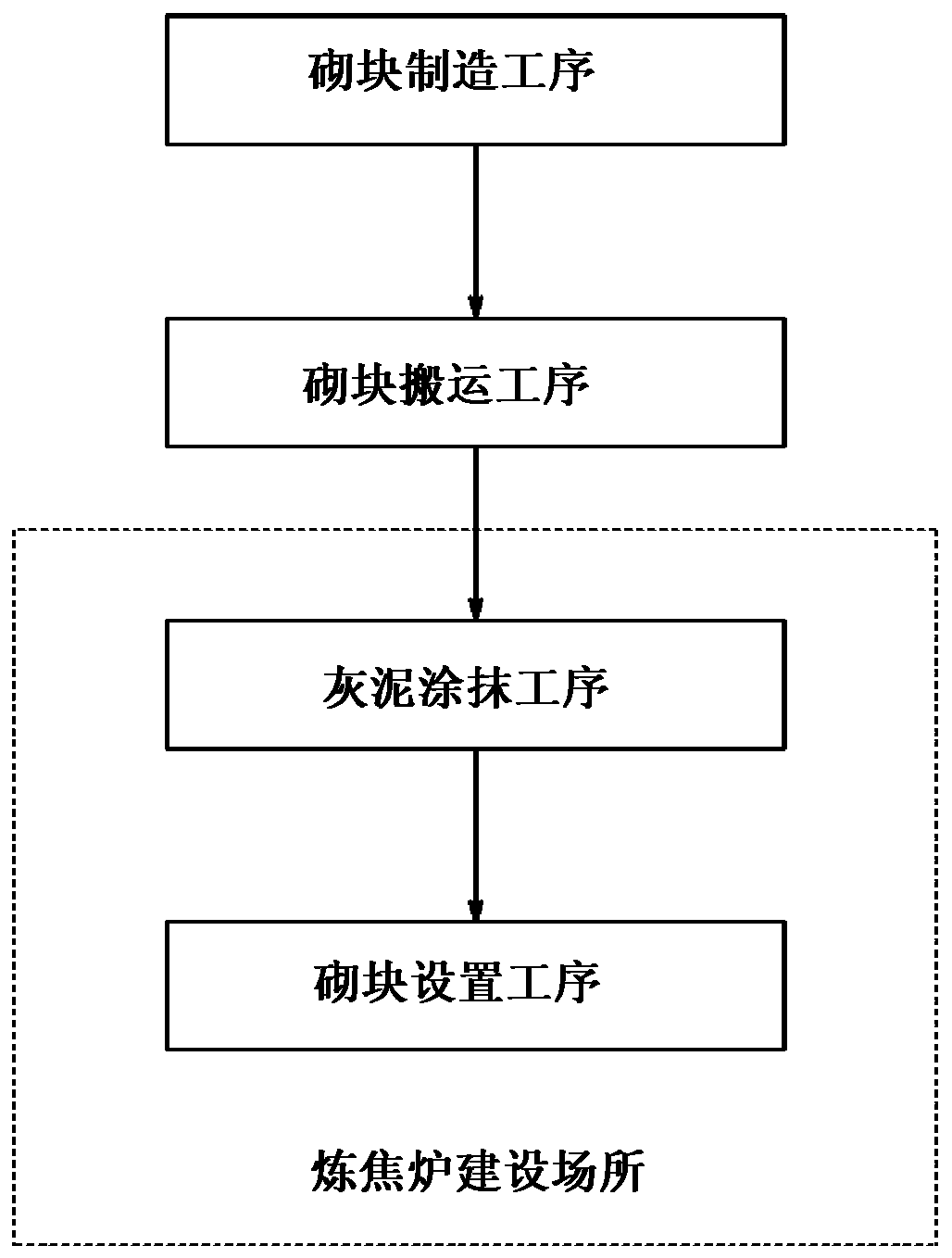

[0038] figure 1 It is a figure which shows the outline|summary of the construction method of the coke oven which concerns on one Embodiment of this invention as a flowchart. The construction method of the coke oven of the present invention is a method for renewing or newly establishing the coke oven, such as figure 1 As shown, at least the following steps (1) to (4) are included. Furthermore, it is characterized in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com