X80 large-diameter thick-wall longitudinal submerged arc welding pipe applicable to low temperature and manufacturing method thereof

A technology of straight seam submerged arc welding and manufacturing methods, applied in the direction of manufacturing tools, arc welding equipment, welding media, etc., to achieve excellent low-temperature toughness, good low-temperature toughness, and the effect of eliminating undercut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

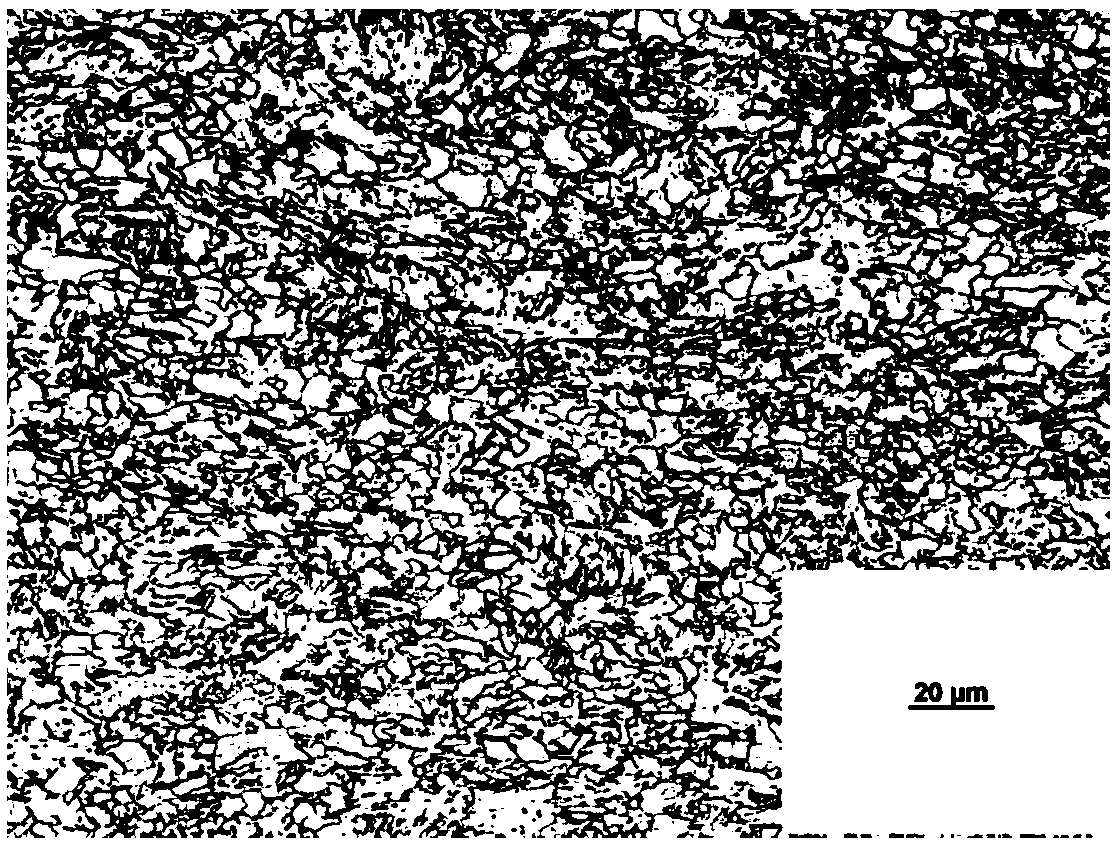

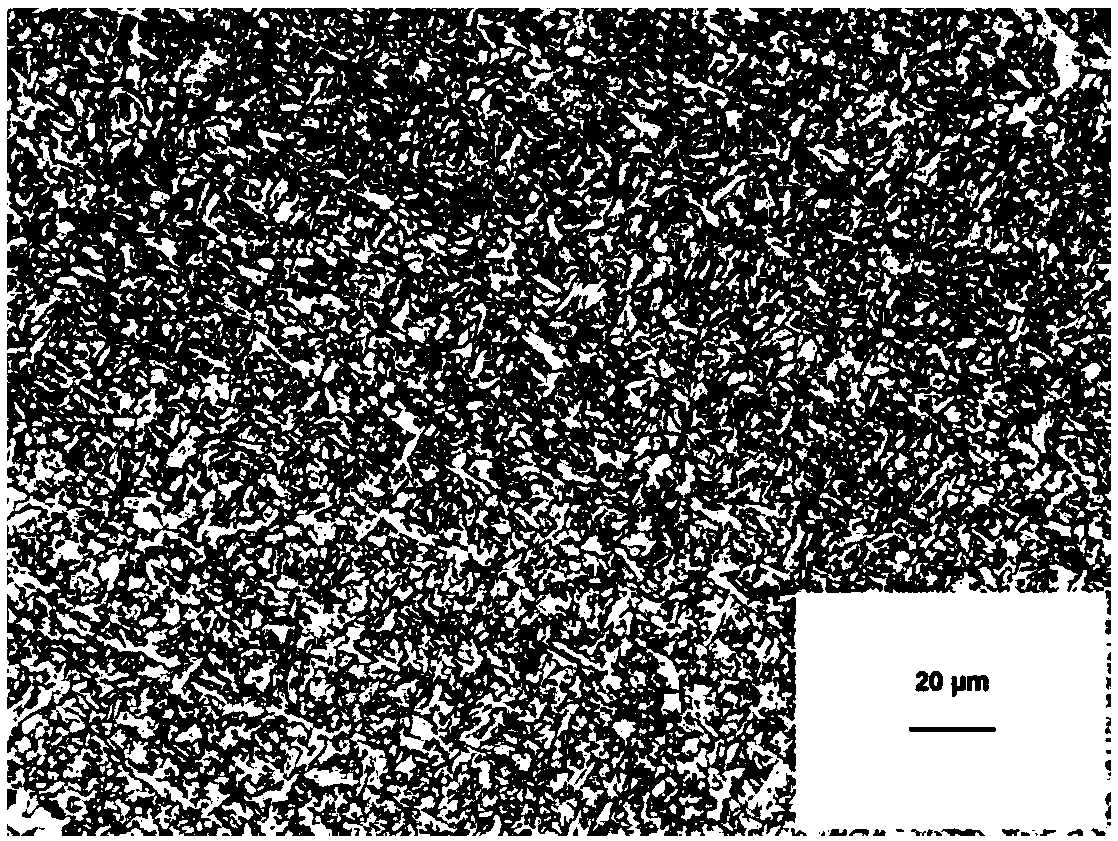

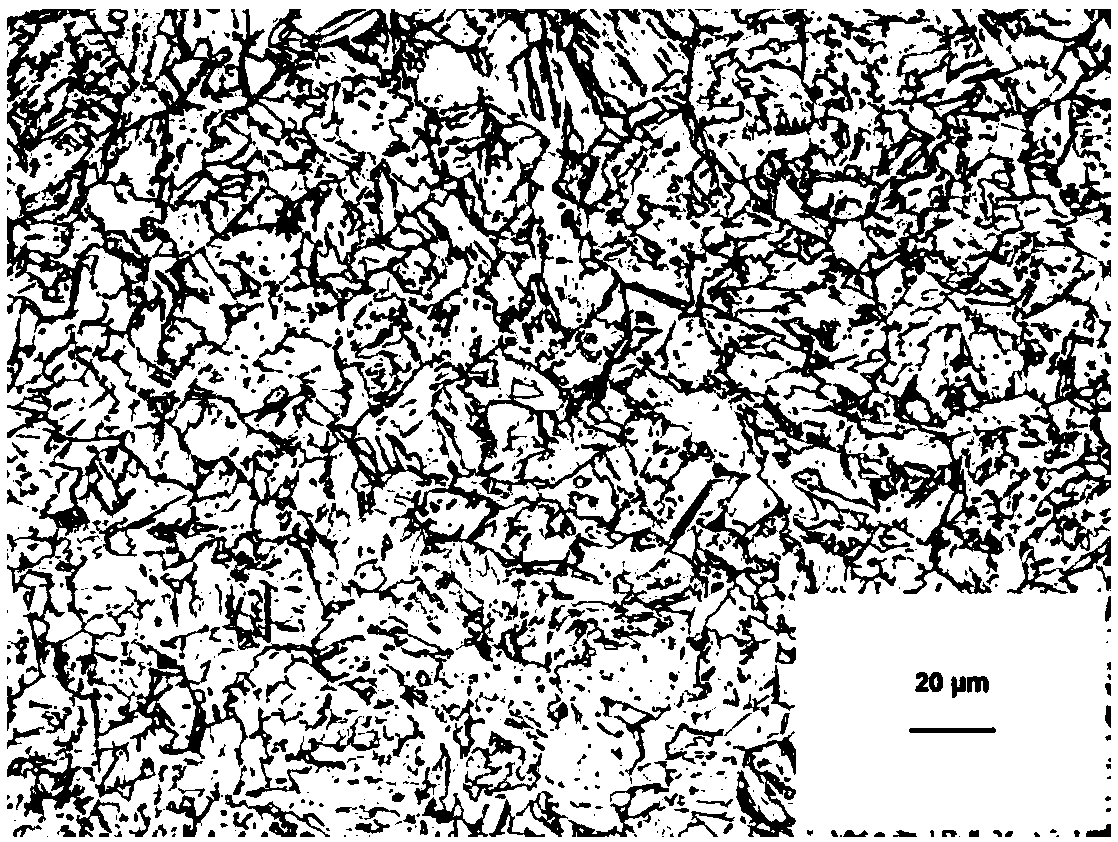

Image

Examples

Embodiment 1

[0034] Example 1: Manufacture of X80 steel grade Φ1422×30.8mm low temperature straight seam submerged arc welded pipe.

[0035] (1) The raw material is X80 steel grade hot-rolled steel plate with a wall thickness of 30.8mm, and its main alloy element content: C0.05%, Si 0.21%, Mn 1.67%, S 0.001%, P 0.010%, Ni 0.18%, Cr 0.16%, Cu 0.21%, Nb 0.07%, V 0.005%, Ti 0.016%, Mo 0.12%, Al 0.03%, N 0.006%, B 0.0003%, and the balance is Fe.

[0036] (2) Ultrasonic inspection of steel plates, 100% ultrasonic testing of steel plates.

[0037](3) Edge milling, the groove size is 70° for the upward groove, 70° for the downward groove, the depth of the downward groove is 11.5mm, and the blunt edge is 10.0mm.

[0038] (4) Pre-bending, use the pre-bending machine to pre-bend the edge of the plate, so that the curvature of the edge of the plate meets the requirements.

[0039] (5) JCO forming. On the forming machine, one side of the pre-bent steel plate is first pressed to form a "J" shape, and...

Embodiment 2

[0057] Example 2: Manufacture of X80 steel grade Φ1422×33.8mm low temperature straight seam submerged arc welded pipe.

[0058] (1) The raw material is X80 steel grade hot-rolled steel plate with a wall thickness of 33.8mm, and its main alloy element content: C0.07%, Si 0.25%, Mn 1.65%, S 0.002%, P 0.010%, Ni 0.19%, Cr 0.24%, Cu 0.12%, Nb 0.05%, V 0.04%, Ti 0.016%, Mo 0.20%, Al 0.03%, N 0.005%, B 0.0003%, and the balance is Fe.

[0059] (2) Ultrasonic inspection of steel plates, 100% ultrasonic testing of steel plates.

[0060] (3) For edge milling, the groove size is 70° for the upward groove, 70° for the downward groove, 12.5mm for the downward groove, and 10.0mm for the blunt edge.

[0061] (4) Pre-bending, use the pre-bending machine to pre-bend the edge of the plate, so that the curvature of the edge of the plate meets the requirements.

[0062] (5) JCO forming. On the forming machine, one side of the pre-bent steel plate is first pressed to form a "J" shape, and then t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com