Patents

Literature

45results about How to "Meet toughness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

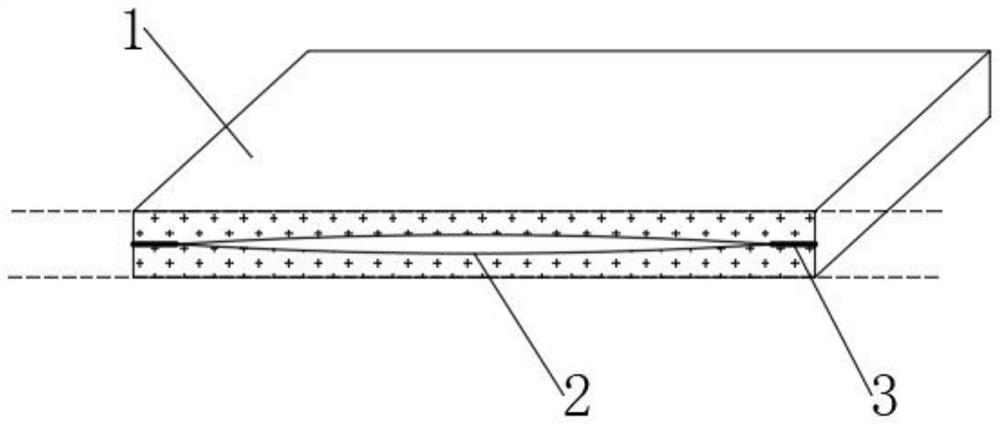

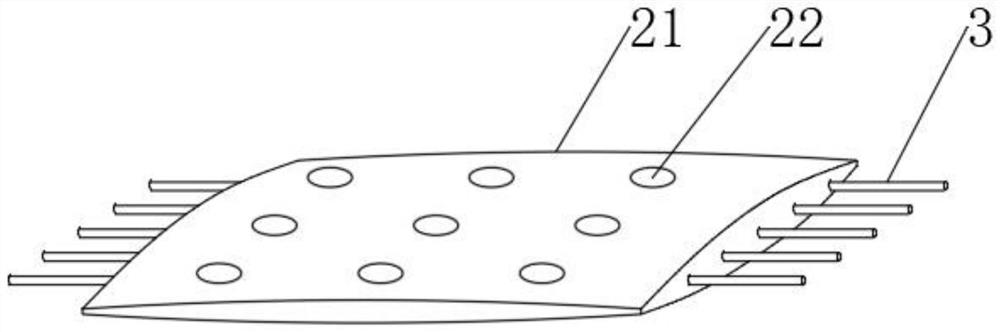

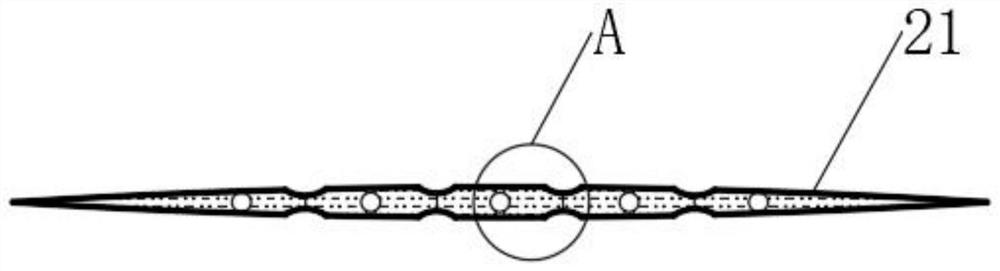

Anti-abrasion metal-ceramic composite product and preparation method thereof

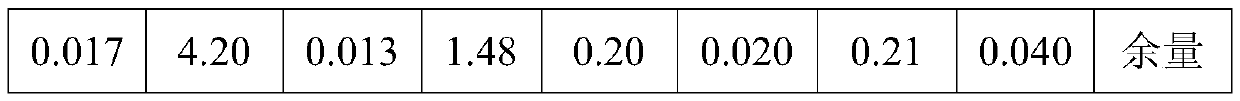

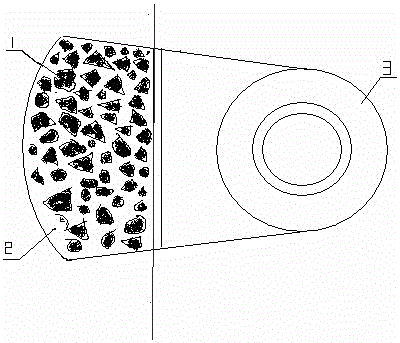

The invention provides an anti-abrasion metal-ceramic composite product and a preparation method thereof. The structural performance of the product is improved through at least one type of metallic oxides, metal nitrides or metal borides and intermetallic compounds. Metal-ceramic particle prefabricated parts made of ceramic particles and metal powder, or metal-ceramic particle prefabricated parts made of metal powder and mixtures which are obtained through uniform mixing of ceramic particles and metal powder with auxiliaries are subjected to high-temperature sintering thermal treatment to obtain the product. According to the anti-abrasion metal-ceramic composite product and the preparation method thereof, abrasion resistance of ceramic particles and mechanical performances of metal materials are perfectly combined, so that the hardness and the abrasion resistance of traditional metal materials are greatly improved. Compared with traditional anti-abrasion parts, the service life of metal grinding balls is increased by 1 time to 1.9 times, and the service life of liner plates and hammers is increased by more than 2.5 times, accordingly, a large number of metal materials are saved, and the production efficiency is improved.

Owner:湖北秦鸿新材料有限公司

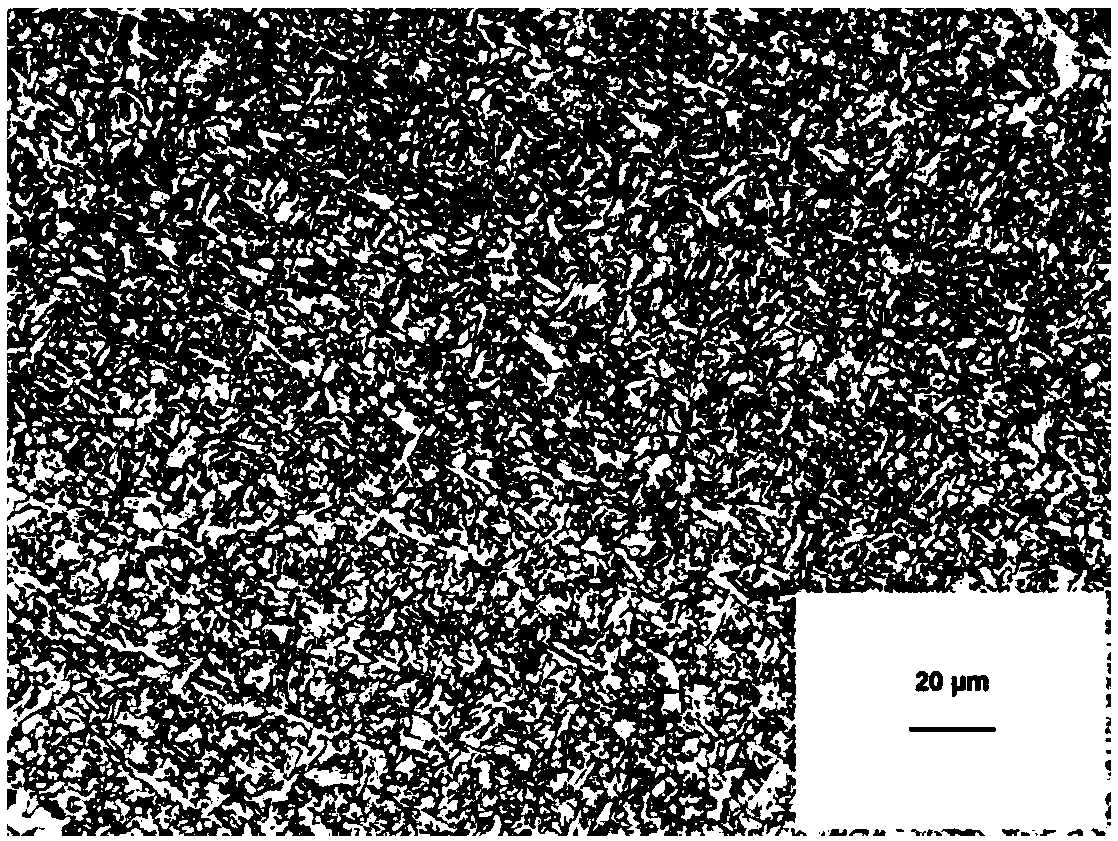

X80 large-diameter thick-wall longitudinal submerged arc welding pipe applicable to low temperature and manufacturing method thereof

ActiveCN108796364AReduce intakeHigh strengthArc welding apparatusWelding/cutting media/materialsX-rayWeld seam

The invention discloses an X80 large-diameter thick-wall longitudinal submerged arc welding pipe applicable to the low temperature and a manufacturing method thereof. A parent material of the weldingpipe comprises, by mass percentage, 0.04-0.08% of C, 0.15-0.30% of Si, 1.60-1.85% of Mn, less than or equal to 0.004% of S, less than or equal to 0.010% of P, 0.15-0.30% of Ni, 0-0.30% of Cr, 0.1-0.3%of Cu, 0.05-0.10% of Nb, 0.005-0.04% of V, 0.015-0.03% of Ti, 0.10-0.35% of Mo, 0.02-0.05% of Al, less than or equal to 0.008% of N and 0.0003-0.0005% of B. The manufacturing method comprises the steps of preparing a hot rolled steel plate according to the mass percentages of the chemical compositions; and conducting ultrasonic inspection, edge milling, pre-flanging, JCO formation, prewelding, inner welding, outer welding, welding seam X-ray inspection, steel pipe expanding, hydrostatic testing, welding seam ultrasonic testing, pipe end X-ray inspection, chamfering, pipe end magnetic particletesting and appearance quality inspection on the steel plate. A welding joint of the welding pipe is good in low-temperature toughness; and on the premise that heat treatment is not conducted on thewelding pipe after pipe manufacturing, the welding pipe can be directly used at the temperature of minus 45 DEG C or even lower.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

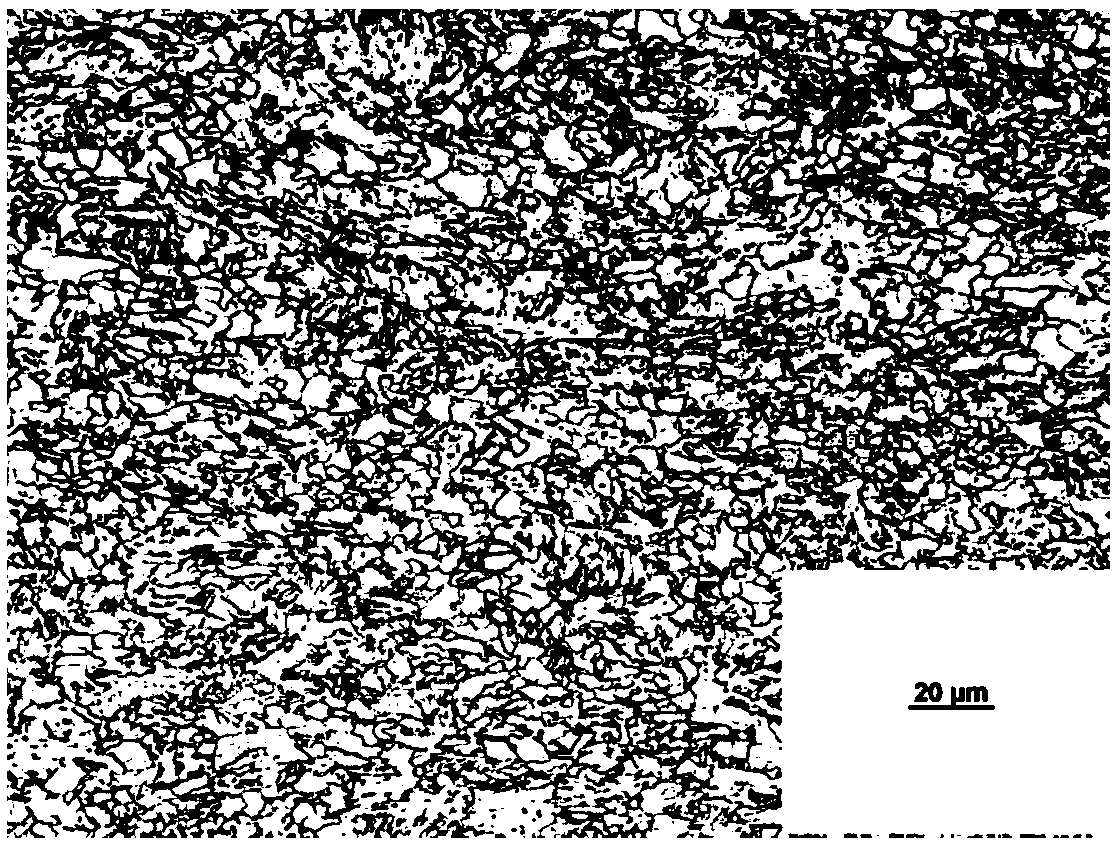

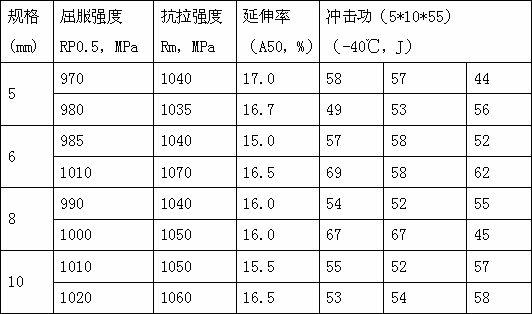

The manufacturing method of high-strength plate q960 produced by the steel coil rolling mill

InactiveCN102286687ALow yield ratioImprove low temperature toughnessChemical compositionSmelting process

The invention discloses a method for manufacturing high-strength plate Q960 produced by a coil rolling mill. In terms of smelting technology, converter steelmaking is adopted, and top-lower compound blowing is used for deep decarburization; RH vacuum treatment is used for further decarburization and microalloying. Obtain a steel billet that meets the requirements; the chemical composition weight percentage of the steel billet is: C0.12~0.20%, Mn0.80~1.60%, Si0.02~0.40, P≤0.015, S≤0.005, B0.001~0.003, and add Appropriate amount of Cr, Mo, V, Ni alloy elements, and satisfy carbon equivalent Ceq=+Mn / 6+Cr / 5+Mo / 4+V / 14+Ni / 40+Si / 24≤0.60; in terms of rolling process , controlled rolling is carried out by a steckel rolling mill, and the heating temperature of the steel billet before rolling is 1150-1250 °C; the invention has the characteristics of low carbon equivalent, excellent low-temperature toughness, smooth plate shape, and good welding performance, and is suitable for construction machinery, mining equipment, ports, etc. Machinery and other fields.

Owner:NANJING IRON & STEEL CO LTD

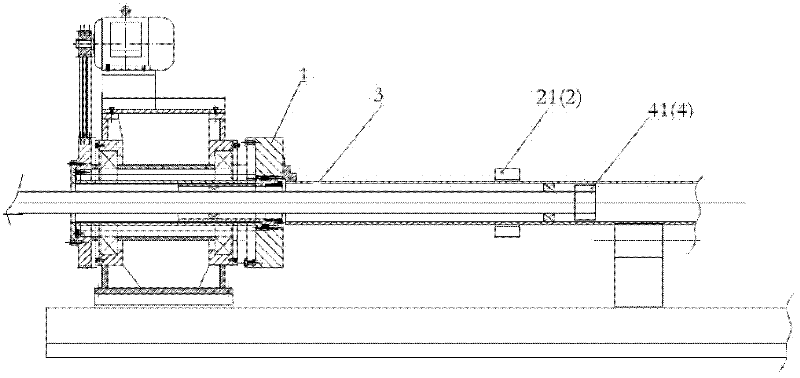

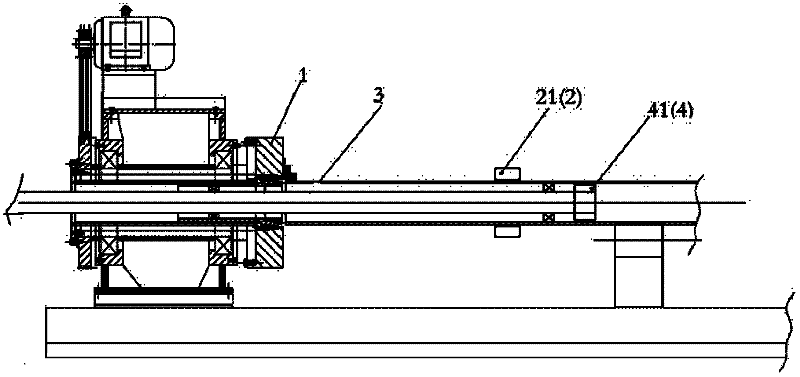

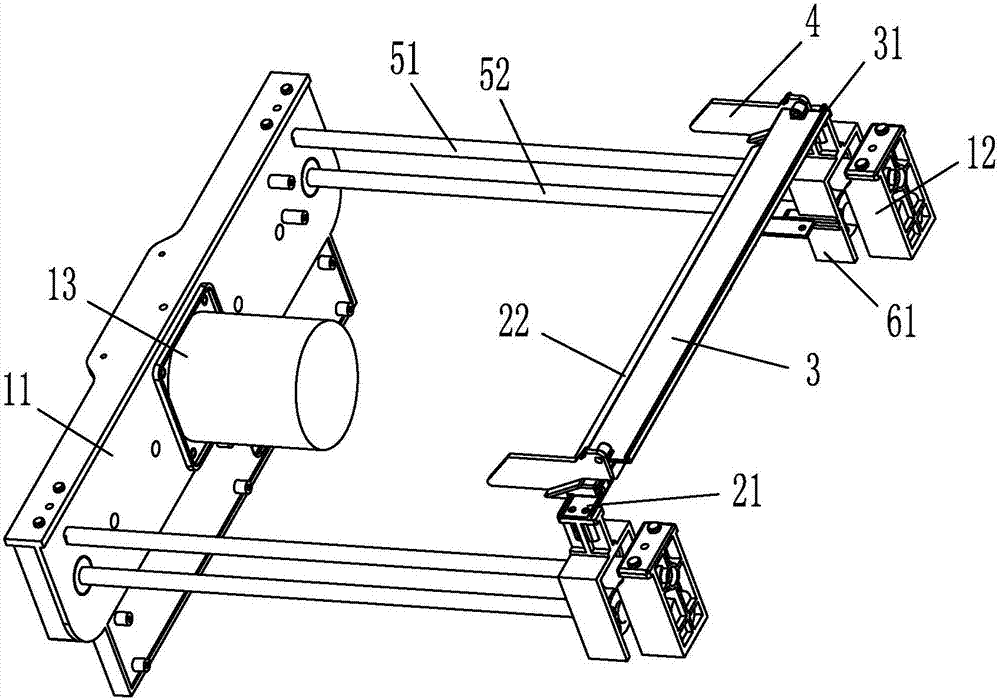

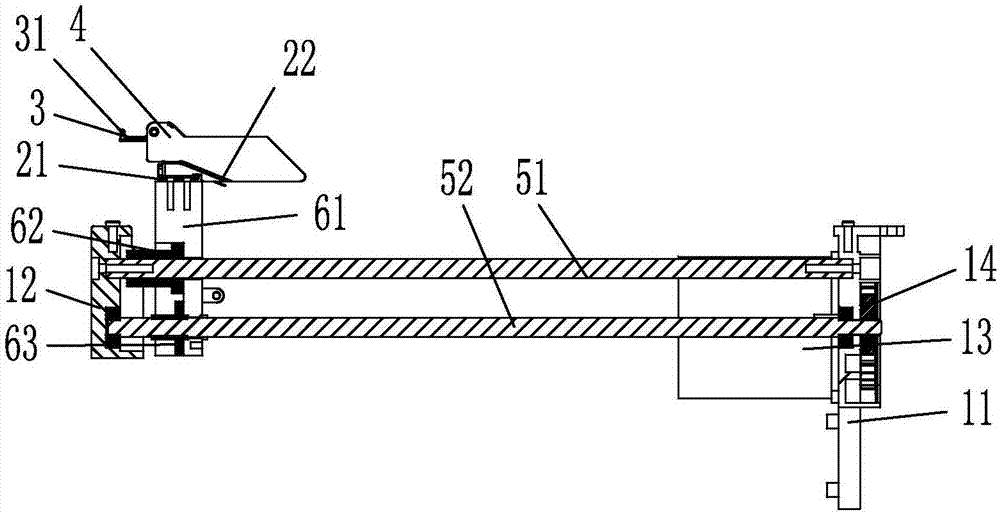

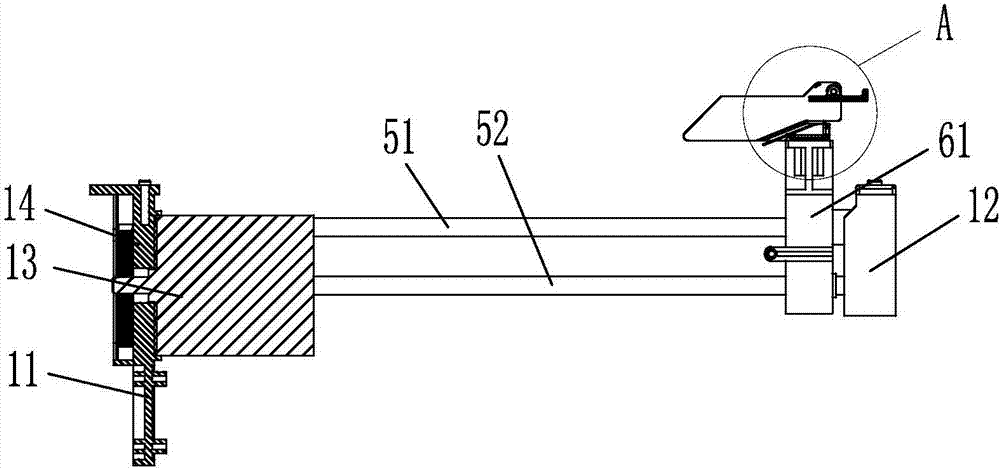

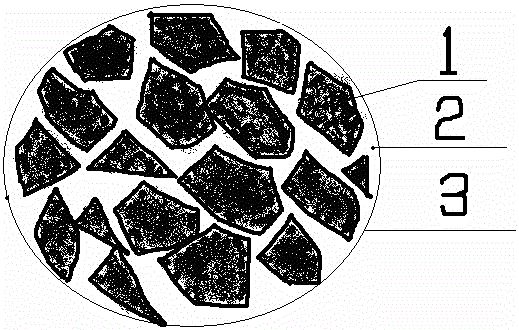

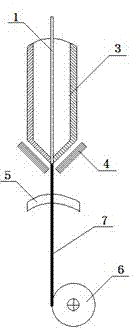

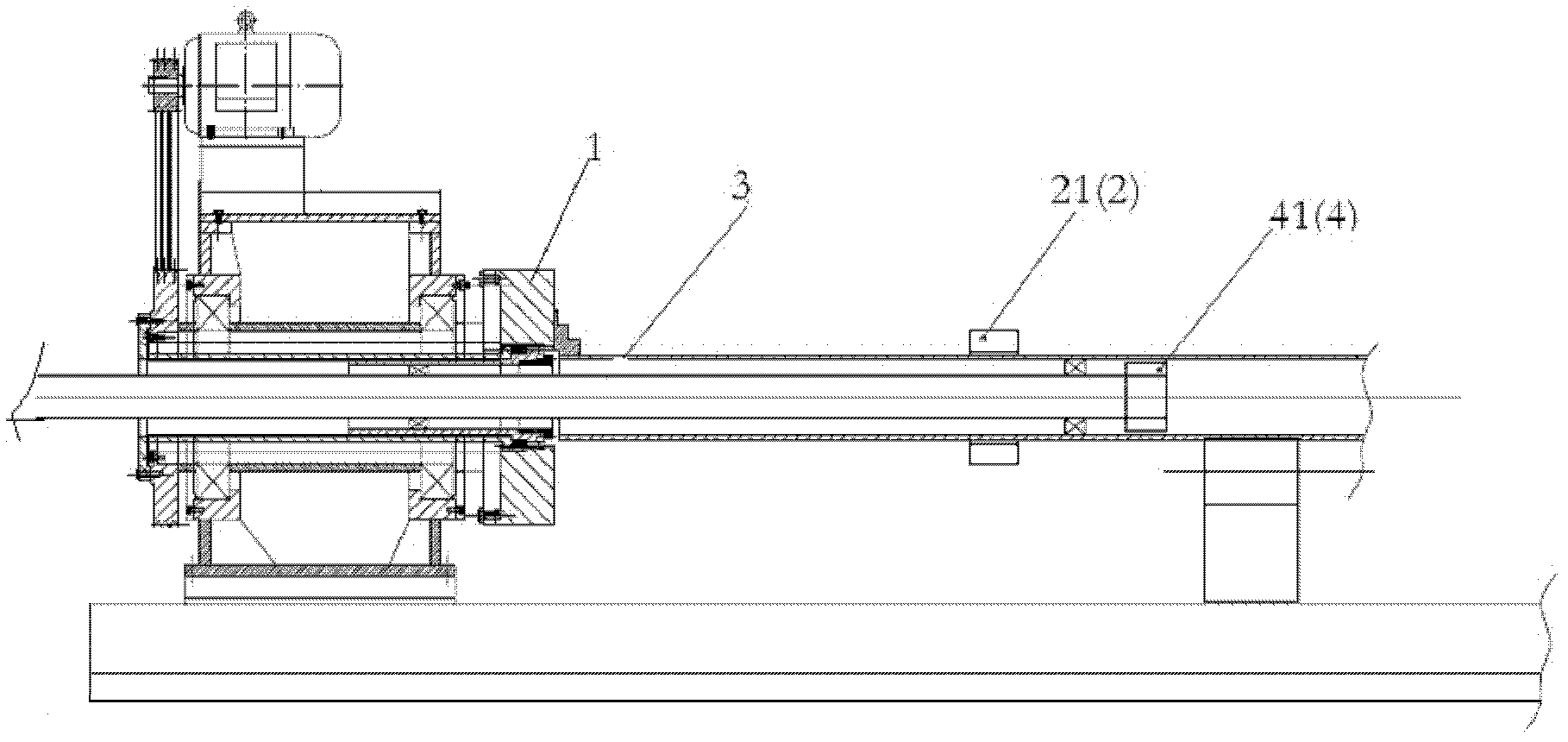

Steel tube as well as processing method and processing equipment for steel tube

ActiveCN102443691ATo achieve the purpose of wear resistanceEfficient processing methodIncreasing energy efficiencyFurnace typesWear resistantHardness

The invention discloses a processing method for a steel tube. The processing method comprises the following steps of: carrying out inner wall quenching on the steel tube to enable the steel tube to integrally form a martensite structure; carrying out medium-temperature tempering on the outer wall of the steel tube, which is processed by an inner wall quenching process, to enable the outer wall toform a tempered troostite structure; and meanwhile, carrying out low-temperature tempering on the inner wall to enable the inner wall and part of adjacent outer wall to form a tempered martensite structure. Therefore, the inner wall of the processed steel tube has higher hardness and wear resistant; the outer wall of the processed steel tube has higher toughness; and the processed steel tube can completely meet the requirements of wear resistance and toughness. The invention also discloses processing equipment for the steel tube. The processing equipment comprises a clamper for clamping the steel tube, an inner wall quenching device of a quenching sensor as well as an outer wall tempering device of a tempering sensor, wherein the inner wall quenching device can be moved inside the steel tube; and the outer wall tempering device can be moved on the outer wall of the steel tube. The processing equipment can be used for simultaneously finishing the inner wall quenching process and the outer wall tempering process and has high processing efficiency. The invention further provides the steel tube obtained by the processing method and the processing equipment disclosed by the invention.

Owner:ZOOMLION HEAVY IND CO LTD

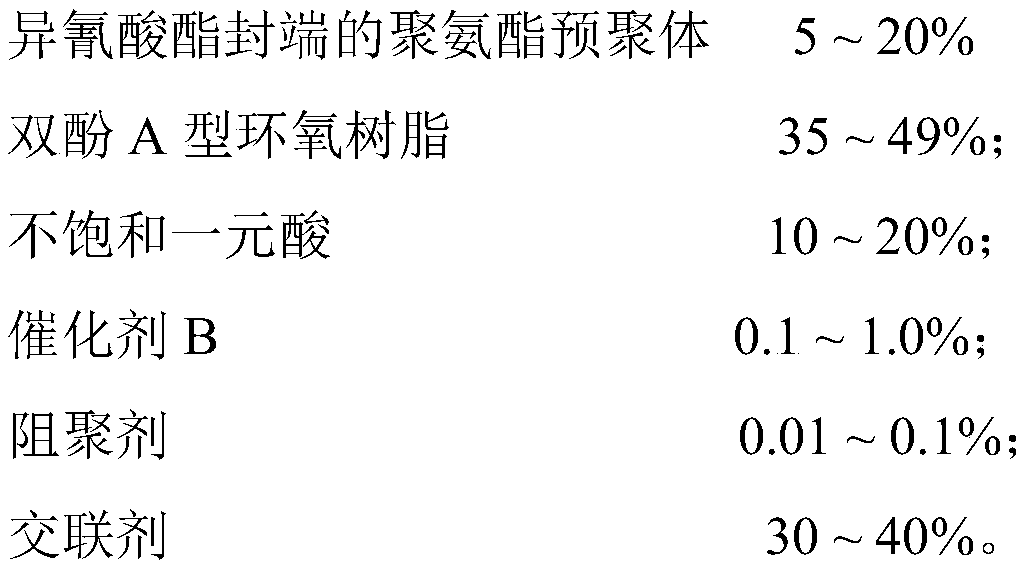

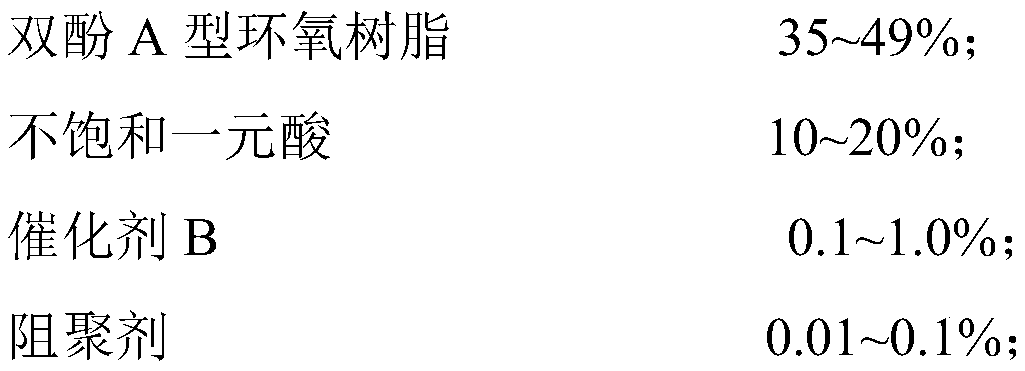

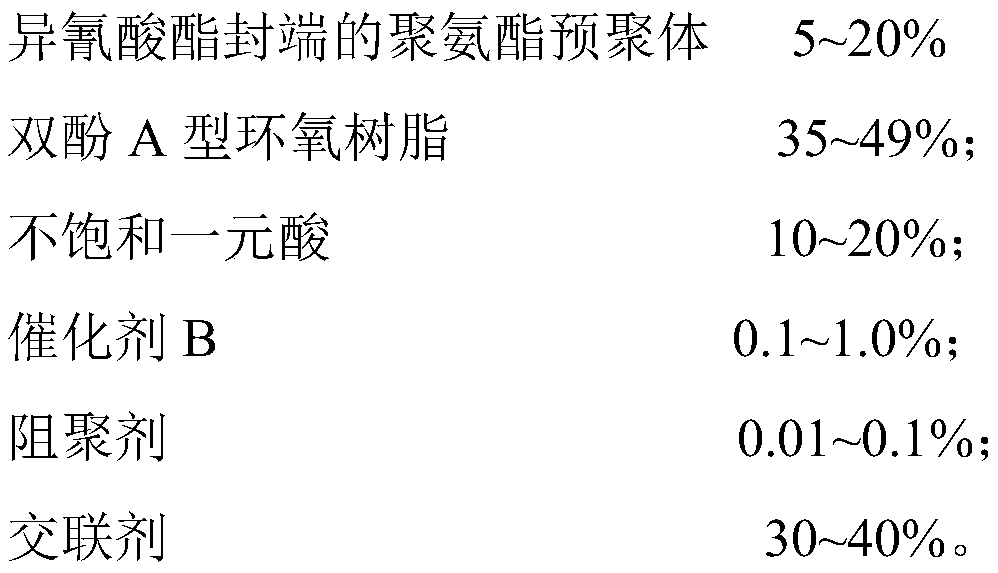

Toughened modified vinyl ester resin and synthesis method thereof

The invention relates to a toughened modified vinyl ester resin and a synthesis method thereof. The method comprises the following steps: (1) adding diisocyanate and flexible dihydric alcohol into a reaction kettle, adding a catalyst A, and taking the point at which the content of isocyanate reaches 1-9% as a reaction endpoint so as to prepare an isocyanate-terminated polyurethane prepolymer; (2)adding 35-49% of epoxy resin, 10-20% of unsaturated monocarboxylic acid, 0.1-1.0% of a catalyst B and 0.01-0.1% of a polymerization inhibitor into another reaction kettle, and performing a reaction until the acid value is reduced to 12 mgKOH / g or below; and (3) lowering the temperature, adding 5-20% of the polyurethane prepolymer and 0.05-0.2% of the catalyst A performing a reaction until the content of isocyanate groups is zero to reach a reaction endpoint, and finally adding 30-40% of a cross-linking agent to obtain the polyurethane toughened and modified vinyl ester resin. Compared with theprior art, the preparation method has the advantages of completeness in chain extension reaction, good toughening effect, few side reactions, safety, environmental protection and stable quality through optimizing the molecular structure by reacting the isocyanate-terminated polyurethane prepolymer with the vinyl ester resin and introducing a flexible group is introduced into the molecular chain.

Owner:EAST CHINA UNIV OF SCI & TECH

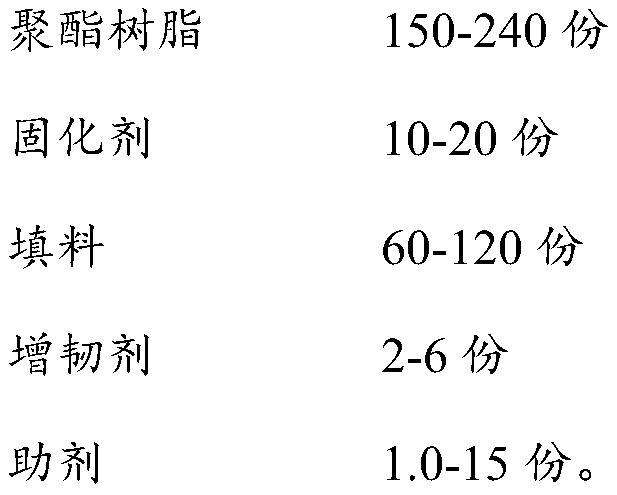

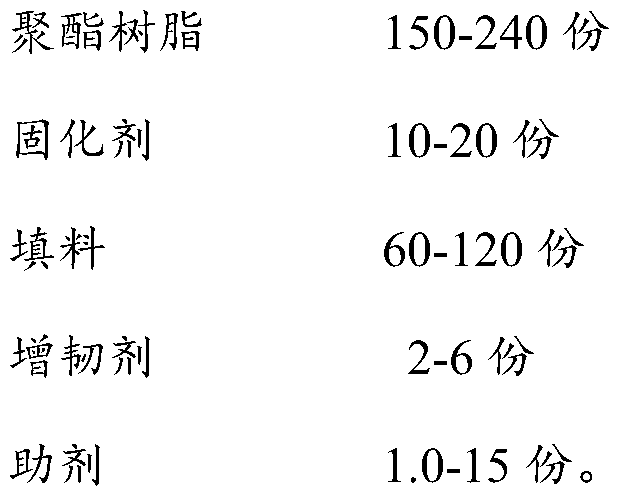

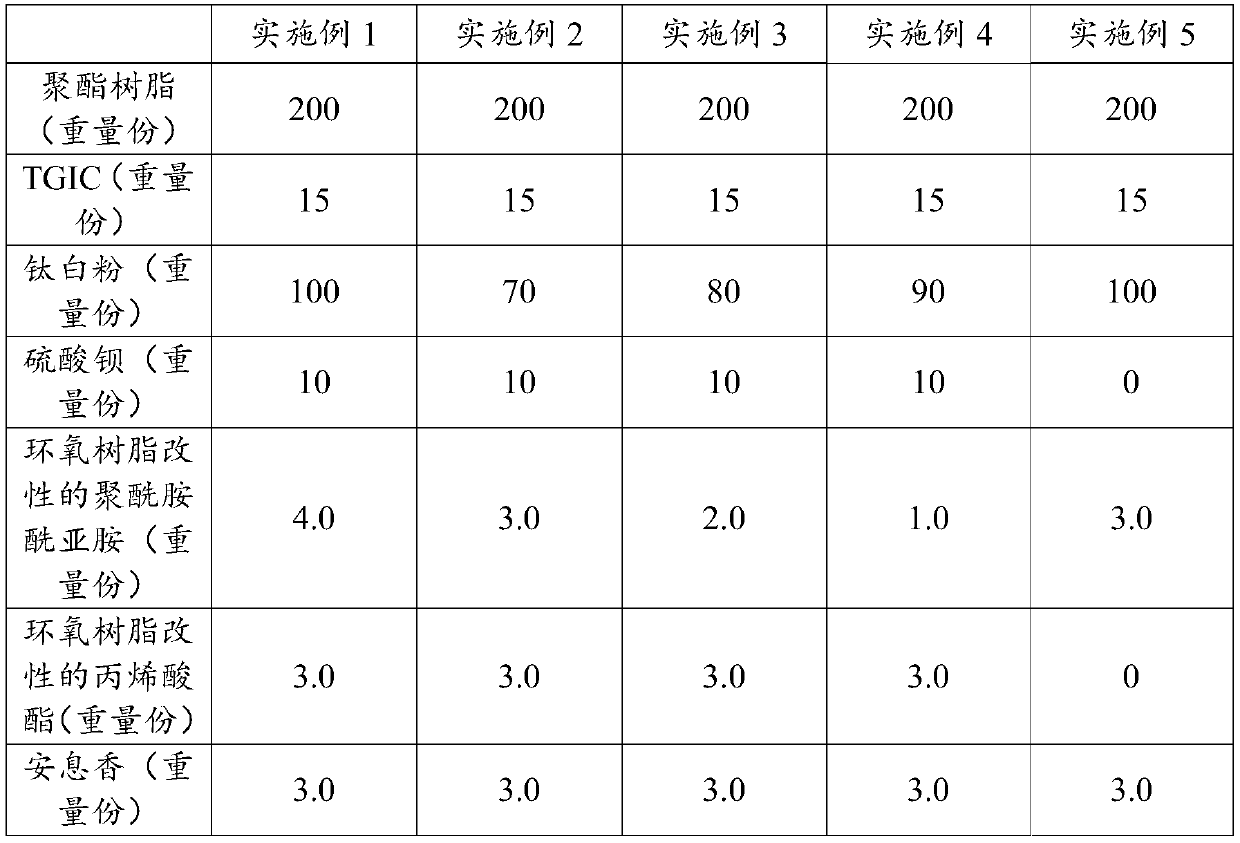

Powder coating capable of forming high-toughness coating

ActiveCN110746865AImprove deformation resistanceImprove toughnessPolyurea/polyurethane coatingsPowdery paintsElastomerImide

The invention belongs to the field of materials and discloses a powder coating capable of forming a high-toughness coating. The powder coating comprises polyester resin, a curing agent, a filler, a toughening agent and an auxiliary agent, wherein the toughening agent is at least one selected from epoxy resin modified polyamideimide, and nylon or thermoplastic elastomers. The powder coating provided by the method can be used to prepare a coating by spraying and curing. Polyester resin and the curing agent are used as a film forming system, so that the reaction cross-linking density is proper, and the formed coating has large deformation resistance. The toughening agent is added to further improve toughness of the coating, so that the coating still has good toughness even if the coating reaches 130-180 microns, and requirements of parts on toughness of the coating in a stamping forming process can be met. Thickness of the high-toughness coating formed by the powder coating is 130 micronsor above, and the coating has good weather resistance.

Owner:GUANGZHOU KINTE IND

Scraper knife cake lifting device for household intelligent automatic pancake machine

ActiveCN106901619AGuaranteed accuracy requirementsSimple production processFrying pansReciprocating motionEngineering

The invention discloses a scraper knife cake lifting device for a household intelligent automatic pancake machine. The scraper knife cake lifting device comprises a drive motor, two groups of screw guide rail mechanisms and a scraper knife which are in transmission connection in sequence, wherein two ends of the scraper knife are in transmission connection with each group of screw guide rail mechanisms separately; and the drive motor drives the scraper knife to move back and forth on the screw guide rail mechanisms through the screw guide rail mechanisms. The scraper knife moves once back and forth on the screw guide rail mechanisms, so that shoveling of a cake can be achieved, the cake making time is greatly saved, and meanwhile, the integrity of a cake body is ensured.

Owner:UROICA GUANGDONG PRECISION INFORMATION ENG TECH RES INST CO LTD

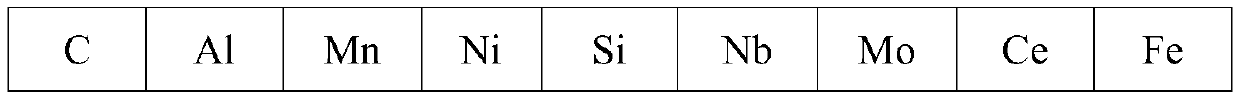

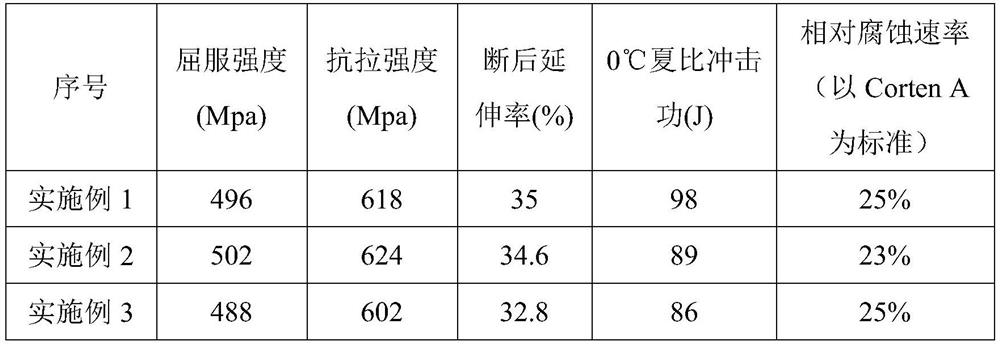

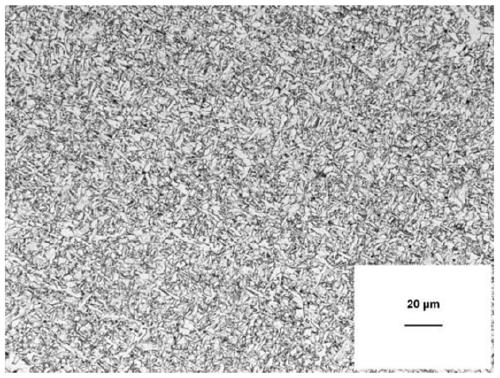

A kind of high corrosion resistance high aluminum content low density steel and its preparation method

The invention provides a preparation method of a high-corrosion-resistance high-aluminum-content low-density medium-thickness plate for an ocean platform. Steel, comprises, by weight, 0.010%-0,035% ofC, 4.01%-6.00% of Al, 0.010%-0.20% of Mn, 1.00%-3.00% of Ni, 0.010%-0.30% of Si, 0.008%-0.020% of Nb, 0.10%-0.80% of Mo, 0.00%-0.050% of Ce, less than or equal to 0.015% of P, and less than or equalto 0.005% of S, and other Fe and impurities. Components and tissue are controlled, so that the corrosion resistance of the steel in the marine atmospheric environment can be higher 50% or above than that of common alloy steel Corten-A, and the density is reduced by 6% or above.

Owner:UNIV OF SCI & TECH BEIJING

A metal-ceramic composite wear-resistant product and its preparation method

The invention provides an anti-abrasion metal-ceramic composite product and a preparation method thereof. The structural performance of the product is improved through at least one type of metallic oxides, metal nitrides or metal borides and intermetallic compounds. Metal-ceramic particle prefabricated parts made of ceramic particles and metal powder, or metal-ceramic particle prefabricated parts made of metal powder and mixtures which are obtained through uniform mixing of ceramic particles and metal powder with auxiliaries are subjected to high-temperature sintering thermal treatment to obtain the product. According to the anti-abrasion metal-ceramic composite product and the preparation method thereof, abrasion resistance of ceramic particles and mechanical performances of metal materials are perfectly combined, so that the hardness and the abrasion resistance of traditional metal materials are greatly improved. Compared with traditional anti-abrasion parts, the service life of metal grinding balls is increased by 1 time to 1.9 times, and the service life of liner plates and hammers is increased by more than 2.5 times, accordingly, a large number of metal materials are saved, and the production efficiency is improved.

Owner:湖北秦鸿新材料有限公司

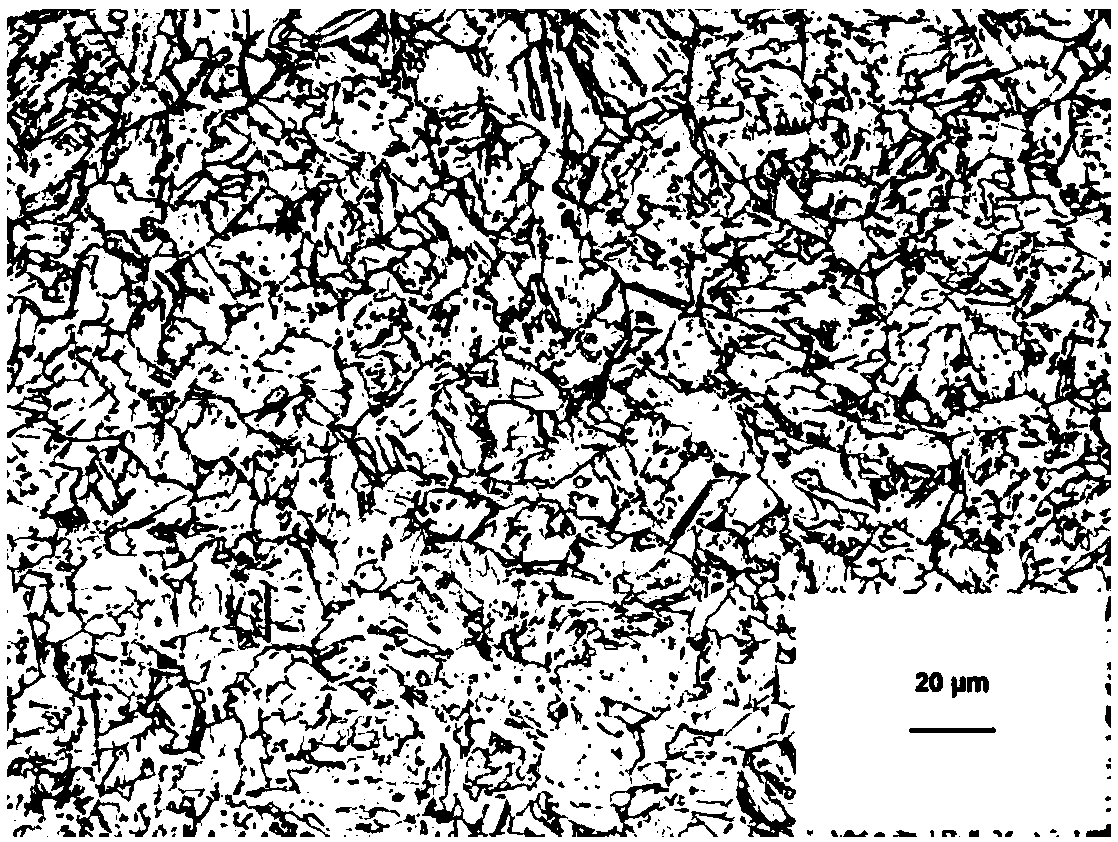

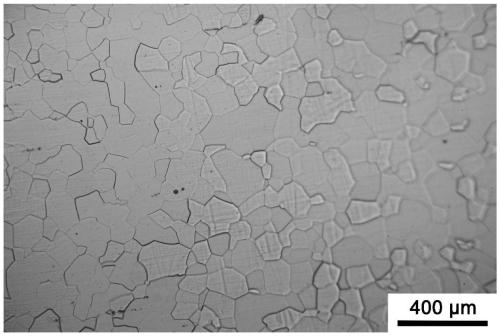

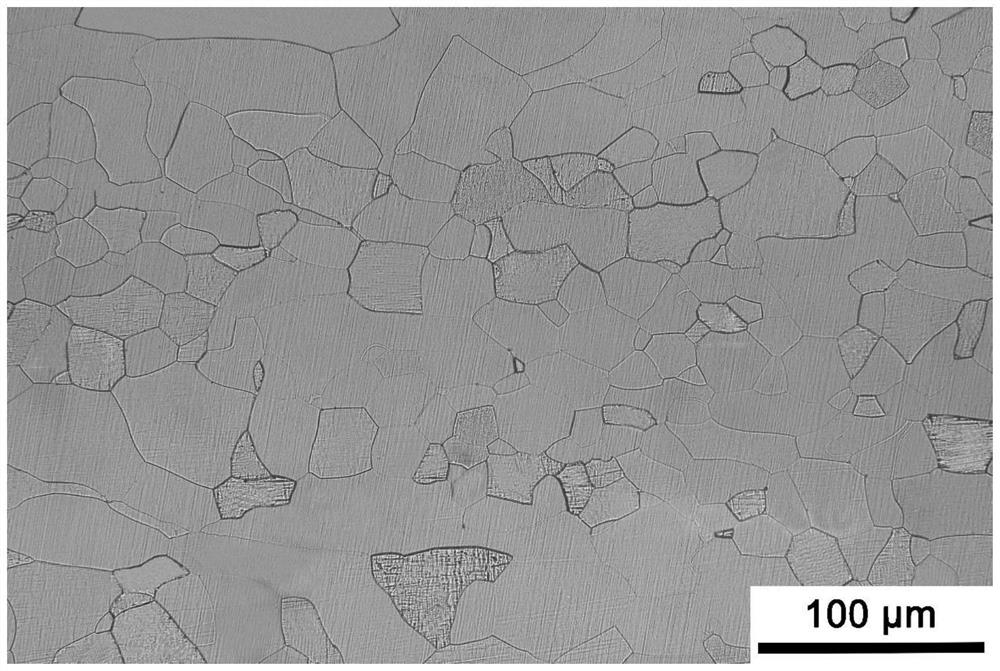

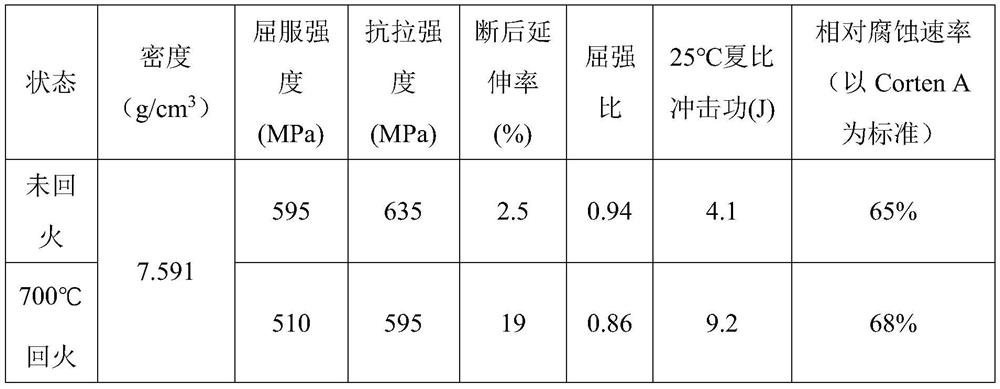

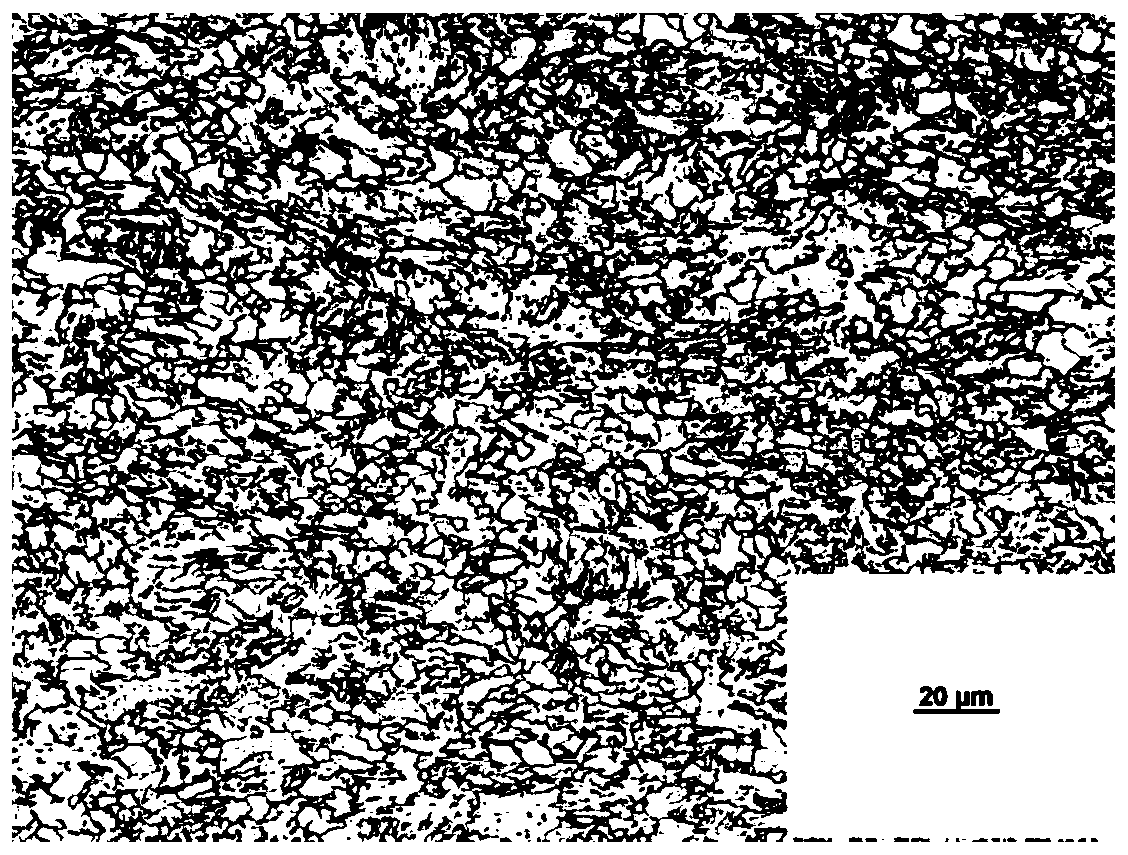

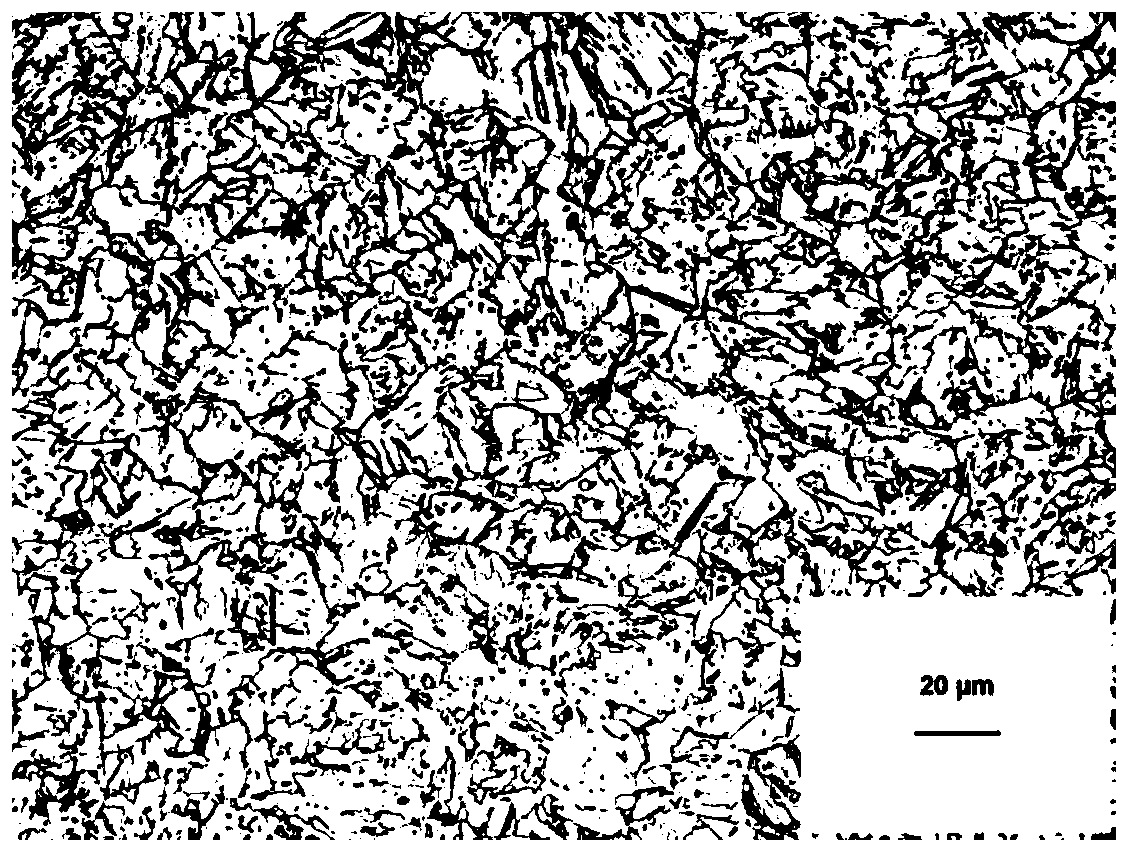

High-aluminum-content fine-grain low-density full-high-temperature ferrite steel and preparation method thereof

ActiveCN112226701AGood mechanical propertiesHigh strengthFurnace typesIncreasing energy efficiencyChemical compositionWeathering steel

The invention provides a high-aluminum-content fine-grain low-density full-high-temperature ferrite medium-thickness plate for an ocean platform and a preparation method for the high-aluminum-contentfine-grain low-density full-high-temperature ferrite medium-thickness plate. The steel is prepared from the following chemical components in percentage by mass: 0.01-0.039 percent of C, 4.01-6.00 percent of Al, 0.01-1.40 percent of Mn, 0.01-2.00 percent of Cr, 0.002-0.003 percent of B, 0.02-0.06 percent of Ti, 0.01-0.39 percent of Ni, less than or equal to 0.007 percent of Nb, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S and the balance of Fe and other inevitable impurities. For the high-aluminum-content fine-grain low-density full-high-temperature ferritemedium-thickness plate and preparation method thereof, by controlling the components and a structure, the corrosion resistance in a marine atmospheric environment is better than that of currently commonly used weathering steel Corten-A by 70 percent or above, and the average grain size of the steel is refined to 50 microns or below.

Owner:UNIV OF SCI & TECH BEIJING

Large-aggregate mixed steel fiber second-level matched concrete and preparation method

The invention discloses large-aggregate mixed steel fiber second-level matched concrete and a preparation method. The concrete comprises a cementing material, steel fibers, coarse aggregate, fine aggregate and water, the steel fibers are different in length, and second-level matched coarse aggregate are adopted as the coarse aggregate; the preparation method comprises the following steps that 1, cement, steel fibers, coarse aggregate, fine aggregate and water are obtained according to a proportion, the steel fibers with the length of 60 mm are placed in the weighed water, dispersed and taken out; 3, the weighed coarse aggregate, fine aggregate and cement are stirred for 1 minute, two kinds of steel fibers different in length are added to the mixture during stirring, the weighed water is added to the mixture after even stirring, stirring continues for 1 minute, and the large-aggregate mixed steel fiber second-level matched concrete is obtained. The preparation method is simple, and theprepared second-level matched concrete has high strength and toughness.

Owner:ZHENGZHOU UNIV

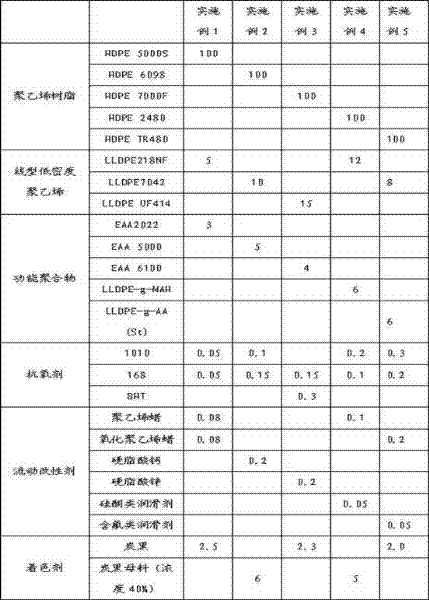

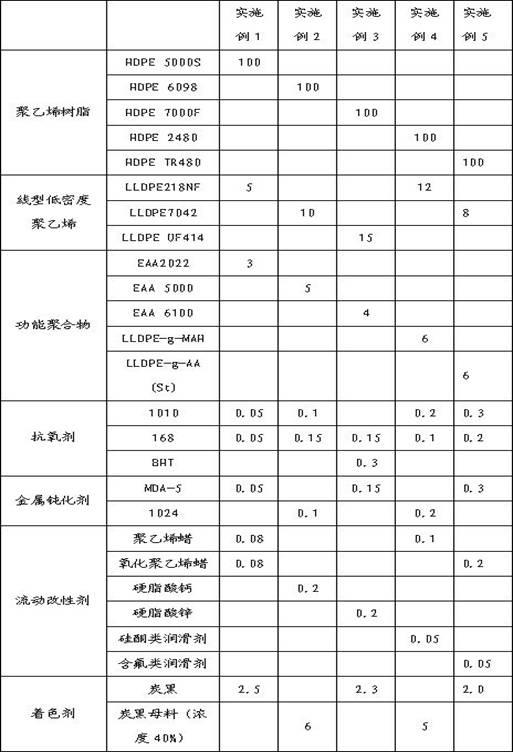

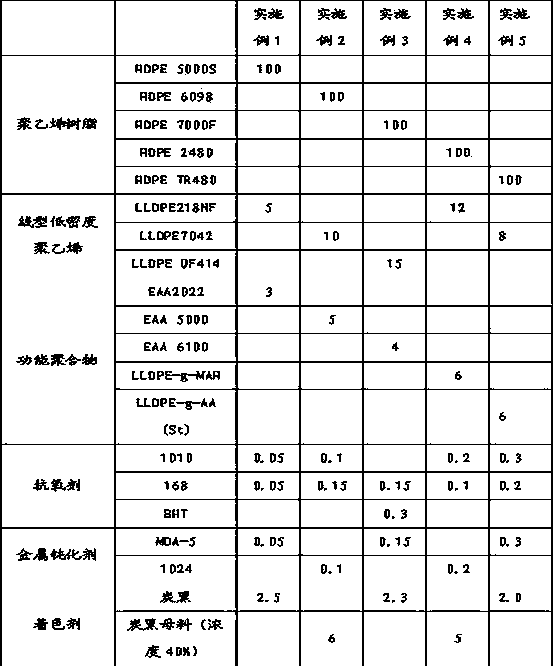

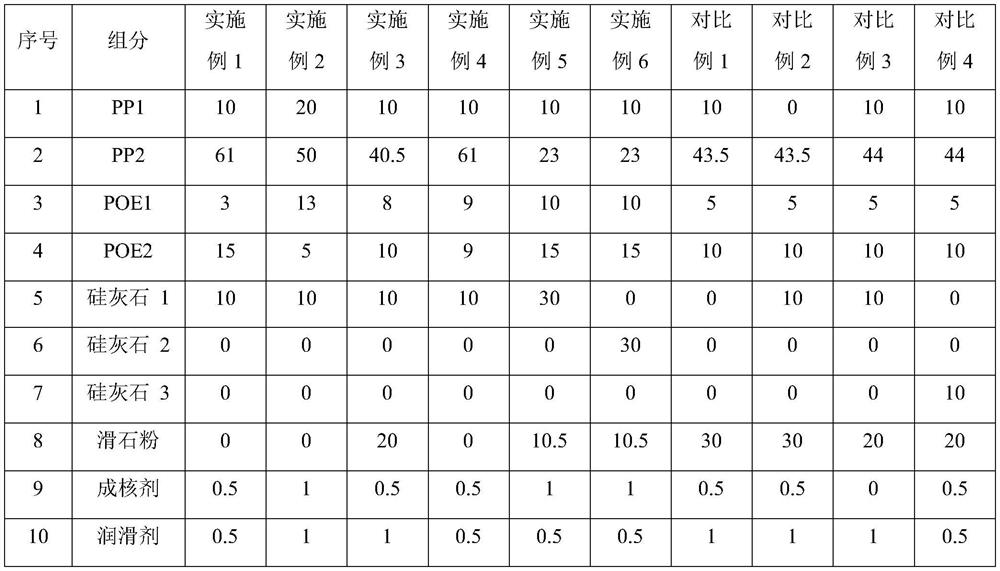

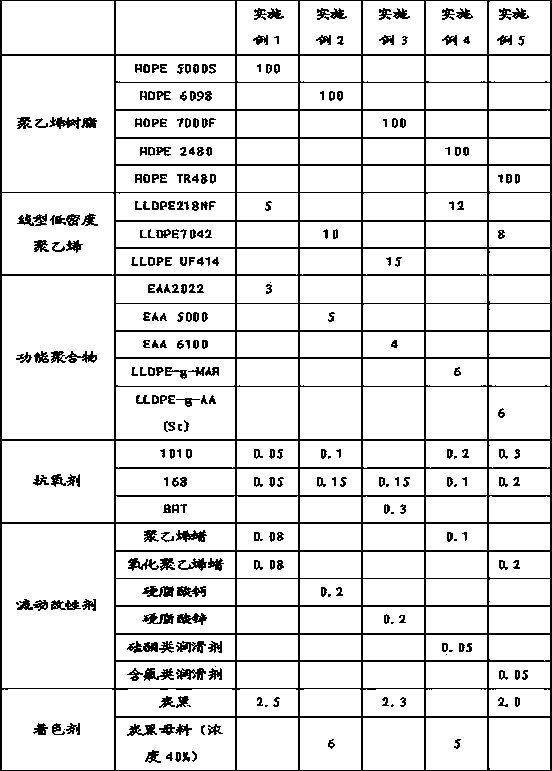

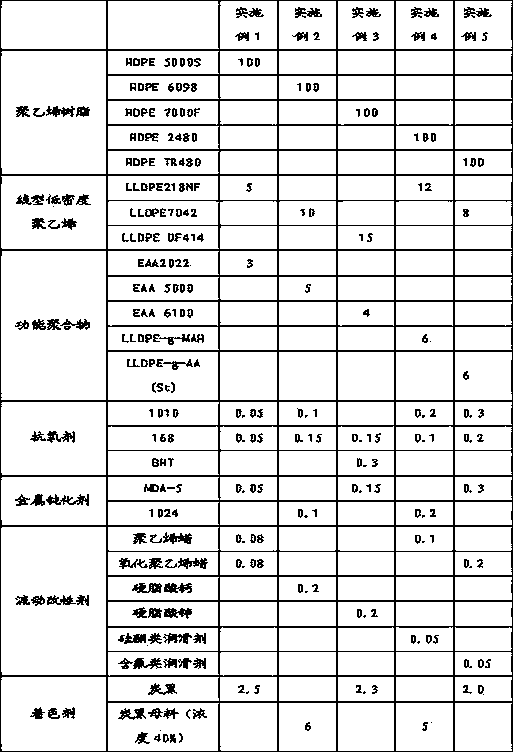

High-toughness polyethylene mixed material for electrolytic cathode plate sealing strip and preparation method thereof

InactiveCN102649853AExtend your lifeExtended shelf lifeOther chemical processesAdhesivesLinear low-density polyethyleneElectrolysis

The invention provides a high-toughness polyethylene mixed material for an electrolytic cathode plate sealing strip and a preparation method for the high-toughness polyethylene mixed material and belongs to the field of plastic process application and the field of wet electrolytic technology for metal such as copper. The high-toughness polyethylene mixed material for producing the electrolytic cathode plate insulating sealing strip comprises the following components in part by weight: 100 parts of polyethylene resin, 0.1 to 20 parts of linear low-density polyethylene resin, 0.1 to 10 parts of functional polymer, 0.1 to 1 part of antioxidant, 0.1 to 5 parts of flowing modifier and a proper amount of colorant. The high-toughness polyethylene mixed material has the characteristics of long service life, high toughness and the like.

Owner:LIAOCHENG UNIV

High-toughness strengthened steel with nanoparticles

The invention discloses high-toughness strengthened steel with nanoparticles. The strengthened steel is characterized by comprising the following substances by weight: 35 to 46 parts of copper, 15 to 32 parts of iron powder, 5 to 17 parts of nodular cast iron powder, 14 to 16 parts of an ethylene-vinyl acetate copolymer, 5 to 7 parts of an acrylic resin, 9 to 17 parts of nano-silver, 10 to 14 parts of alumina, 3 to 4 parts of polyurethane, 11 to 14 parts of nanometer silicon oxide, 3 to 8 parts of aluminum silicate, 12 to 23 parts of sand and 15 to 19 parts of a glass fiber. The strengthened steel provided by the invention has good toughness, a uniform structure and improved strength and toughness and meets requirements on strong toughness.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

Polyethylene compound used for electrolysis cathode plate sealing strip and preparation method thereof

InactiveCN102643475AExtend your lifeReduced catalytic degradationLinear low-density polyethyleneElectrolysis

The invention provides a compound used for an electrolysis cathode plate sealing strip and a preparation method thereof, belonging to the technical field of plastic processing and application and the technical field of wet electrolysis of metals such as copper. The components used for producing the electrolysis cathode plate sealing strip include 100 parts of polyethylene resin, 0.1-20 parts of linear low density polyethylene, 0.1-10 parts of functional polymer, 0.1-1 part of oxidization inhibitor, 0.05-1 part of metal deactivator, 0.1-5 parts of flow modifier and a proper amount of colorant according to weight parts. The compound has the characteristics of long service life, high adhesion strength with a cathode plate and smooth surface of the molded sealing strip.

Owner:LIAOCHENG UNIV

Novel inorganic insulation enameled wire

InactiveCN103594153AThin insulationImprove insulation performanceInsulated cablesInsulated conductorsHeat resistanceMicrometer

The invention discloses a novel inorganic insulation enameled wire. The novel inorganic insulation enameled wire comprises a nickel plating copper wire and a glass thin film which covers the nickel plating copper wire. The novel inorganic insulation enameled wire is manufactured through a film drawing method, the diameter of the nickel plating copper wire is 2mm, and the thickness of the glass thin film ranges from 50 micrometers to 100 micrometers. The surface of the enameled wire is compact and smooth, the novel inorganic insulation enameled wire has the small insulation thickness and good electrical insulation performance and heat resistance, and a manufacturing method of the novel inorganic insulation enameled wire is simple, low carbon and environmentally friendly, and can completely meet the flexible requirement for winding.

Owner:KUNSHAN FENFA INSULATING MATERIALS

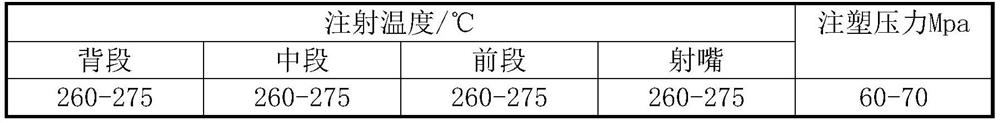

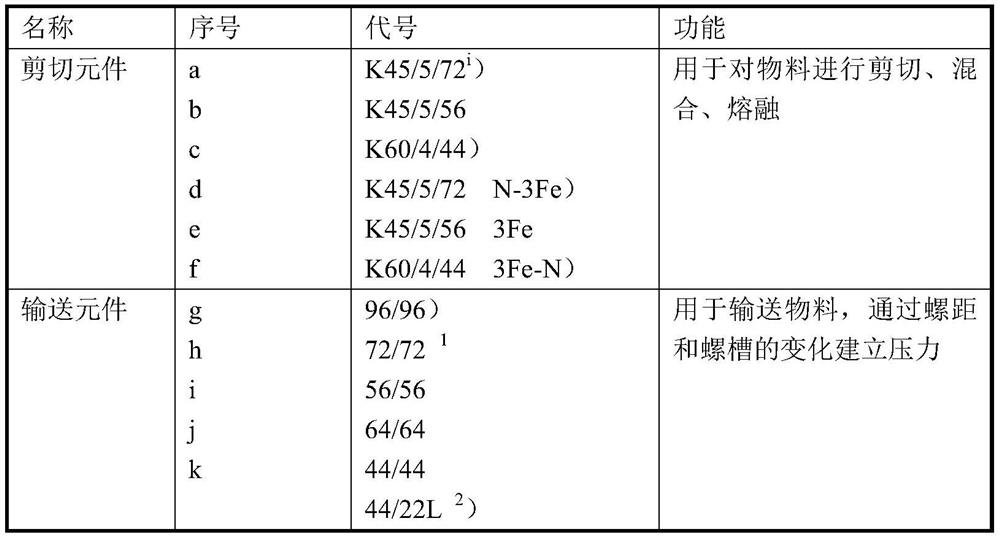

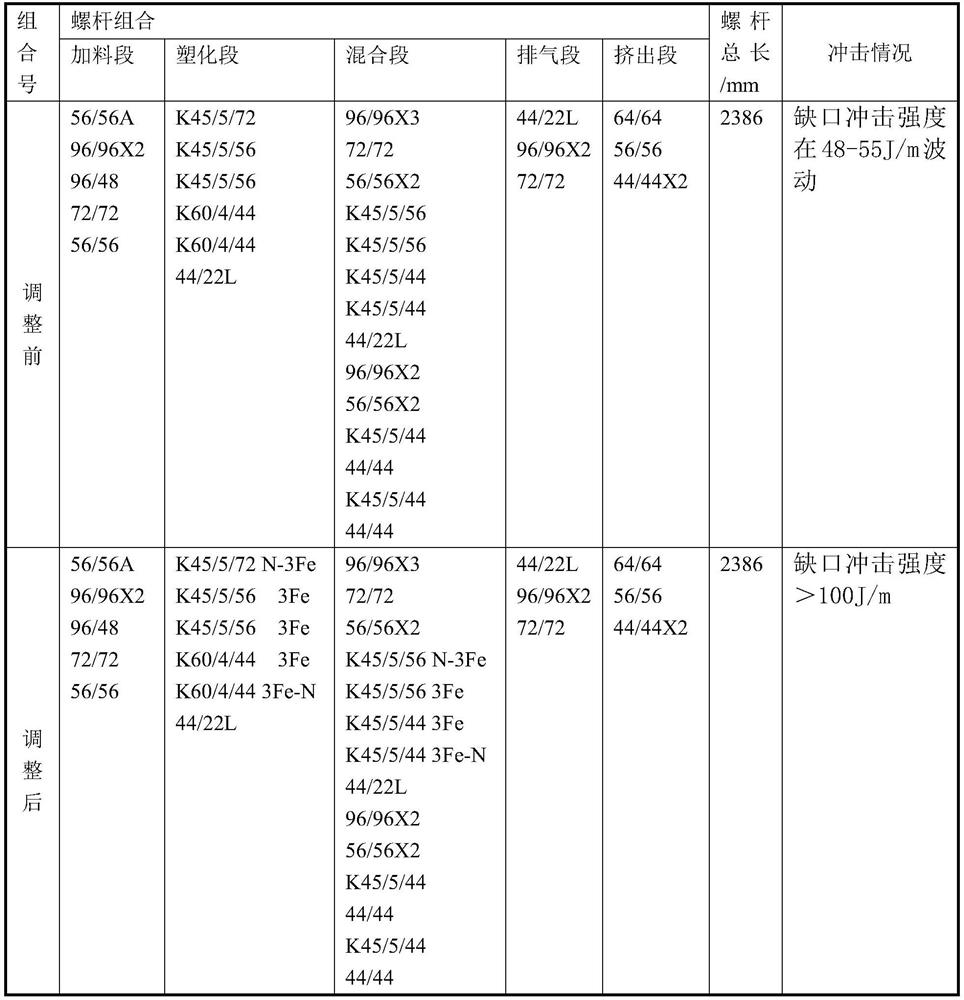

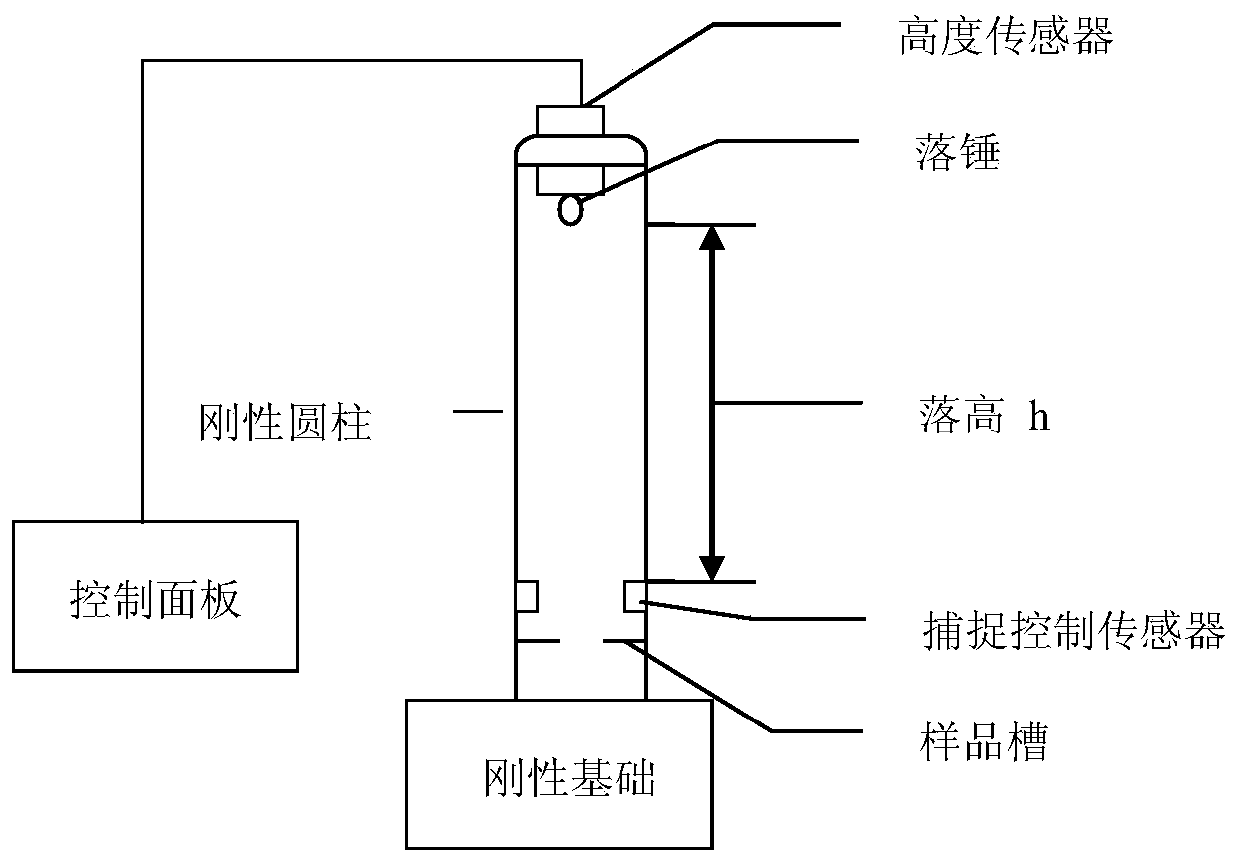

Method for improving impact performance of MCA flame-retardant PA66

The invention discloses a method for improving the impact performance of MCA flame-retardant PA66. The method comprises the following steps: 1) preparing raw materials according to a ratio; and (2) putting the raw materials into a double-screw extruder for melting and mixing, and carrying out extruding and granulating, wherein the length-diameter ratio of screws of the double-screw extruder is (40-44): 1, the temperature of a screw cylinder is 260-270 DEG C, and the rotating speed of the screws is 400-450 rpm. Each screw of the double-screw extruder is provided with main threads in the whole process and sequentially comprises a feeding section, a plasticizing section, a mixing section, an exhausting section and an extruding section, wherein three-head thread elements are arranged in the plasticizing section and the mixing section correspondingly. According to the method, the impact performance of the MCA flame-retardant PA66 can be improved by more than 100%.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

PC composite material and preparation method and application thereof

The invention discloses a PC composite material and a preparation method and application thereof. The PC composite material comprises the following components in parts by weight: 100 parts of polycarbonate; 1 to 5 parts of polyethylene-butyl acrylate grafted glycidyl acrylate; 2-6 parts of a toughening agent; the flexibilizer is selected from any one or more of core-shell structure polymers which take methyl methacrylate or polystyrene acrylonitrile as a shell and take acrylate or acrylate grafted organic silicon as a core. The polyethylene-butyl acrylate grafted glycidyl acrylate is added into the polycarbonate material, and meanwhile, the core-shell structure toughening agent with specific components is added, so that the bonding performance of the material and cloth can be remarkably improved, and meanwhile, good toughness is kept; the direct bonding of the material and the cloth is realized, and the bonding strength is high. The application range of the polycarbonate material is further widened, and the polycarbonate material can be used for preparing fabric electronic products such as fabric mobile phone shells and fabric loudspeaker box shells.

Owner:KINGFA SCI & TECH CO LTD

A kind of polymer resin and its application in high frequency circuit board

ActiveCN109082019BLow dielectric constantLow dielectric loss performanceLamination ancillary operationsSynthetic resin layered productsThermal dilatationPolymer science

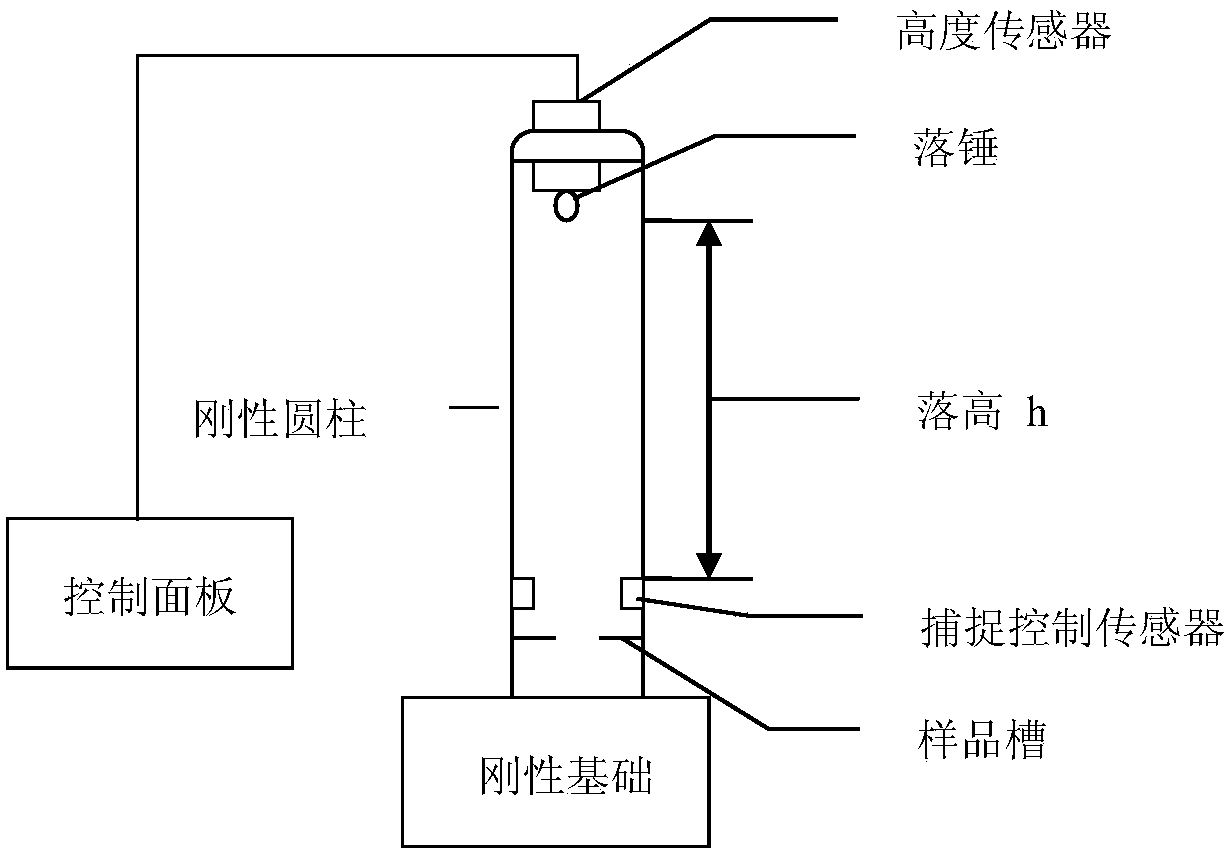

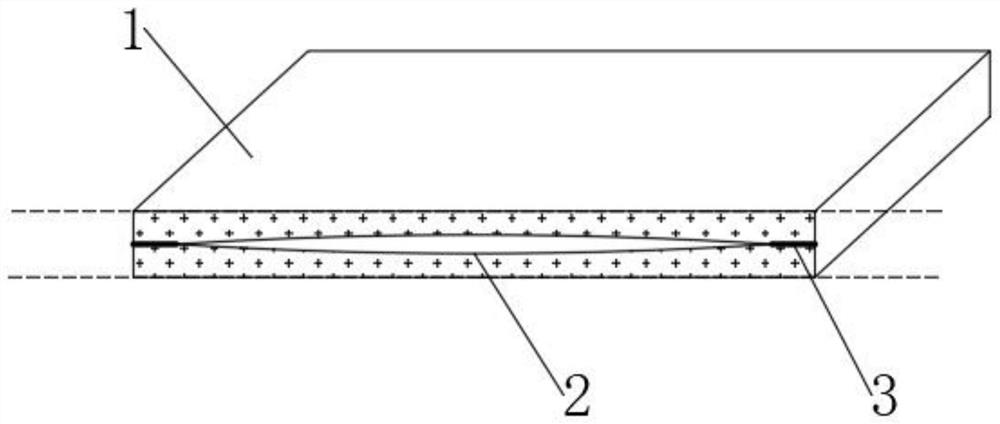

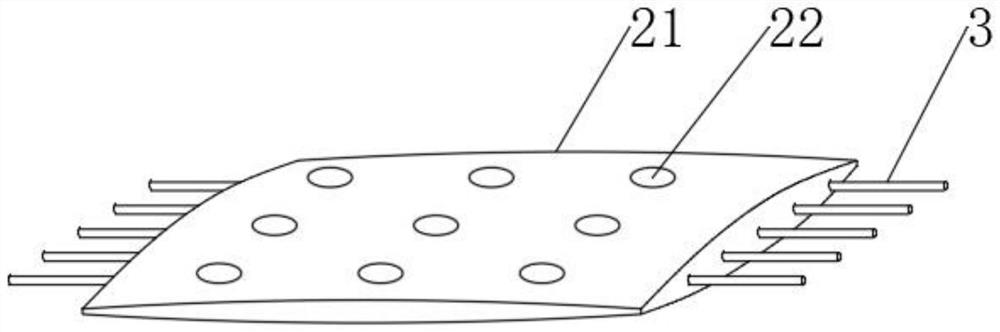

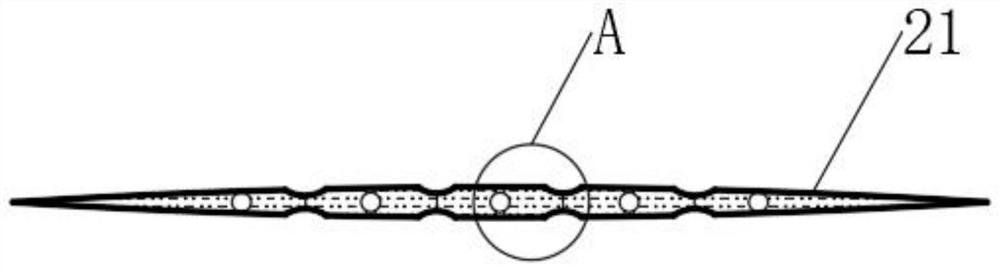

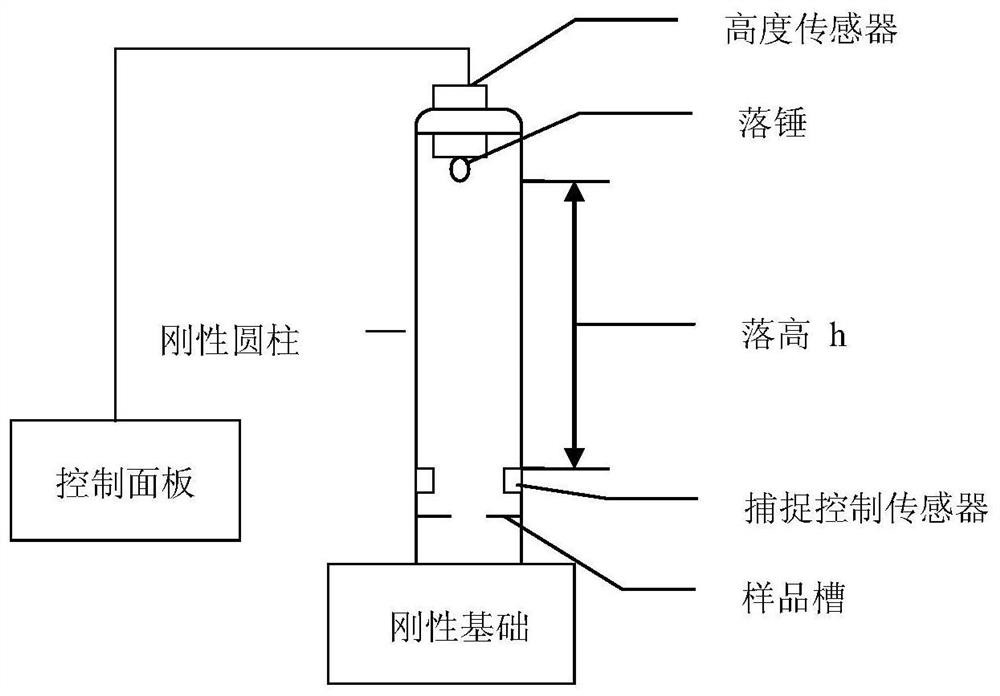

The present invention relates to a vinyl benzyl ether-modified poly(p-hydroxystyryl-styrene) polymer resin composition, comprising: (1) a vinyl benzyl ether-modified poly(p-hydroxystyryl-styrene) polymer resin; and (2) a vinyl-modified polyphenyl ether resin. The present invention further relates to a prepreg comprising the resin composition and the use thereof in a high-frequency circuit board. A substrate prepared by using the resin composition not only has comprehensive properties such as a high glass transition temperature, a low dielectric constant, a low dielectric loss and a low thermal expansion coefficient, but also has a small "十"-shaped falling trace area produced under the action of a drop-hammer impact load, and good toughness, and can thus meet the toughness requirements for copper-clad plates.

Owner:GUANGDONG SHENGYI SCI TECH

Polyethylene mixing material for high-cohesive-force electrolytic cathode plate sealing strip and preparation method thereof

InactiveCN102643474BExtend your lifeReduced catalytic degradationLinear low-density polyethyleneElectrolysis

The invention provides a polyethylene mixing material for a high-cohesive-force electrolytic cathode plate sealing strip and a preparation method thereof, which belong to the technical field of plastic processing and application and the technical field of wet electrolysis of metal including copper and the like. The polyethylene mixing material for producing the electrolytic cathode plate sealing strip comprises, by weight: 100 parts of polyethylene resin, 0.1-20 parts of linear low-density polyethylene resin, 0.1-10 parts of functional polymers, 0.1-1 part of antioxygen, 0.05-1 part of metal deactivator and appropriate parts of colorants. The mixing material has the advantages of being long in service life, high in cohesive strength with a cathode plate and the like.

Owner:LIAOCHENG UNIV

Steel tube as well as processing method and processing equipment for steel tube

ActiveCN102443691BTo achieve the purpose of wear resistanceEfficient processing methodFurnace typesIncreasing energy efficiencyWear resistantHardness

The invention discloses a processing method for a steel tube. The processing method comprises the following steps of: carrying out inner wall quenching on the steel tube to enable the steel tube to integrally form a martensite structure; carrying out medium-temperature tempering on the outer wall of the steel tube, which is processed by an inner wall quenching process, to enable the outer wall to form a tempered troostite structure; and meanwhile, carrying out low-temperature tempering on the inner wall to enable the inner wall and part of adjacent outer wall to form a tempered martensite structure. Therefore, the inner wall of the processed steel tube has higher hardness and wear resistant; the outer wall of the processed steel tube has higher toughness; and the processed steel tube can completely meet the requirements of wear resistance and toughness. The invention also discloses processing equipment for the steel tube. The processing equipment comprises a clamper for clamping the steel tube, an inner wall quenching device of a quenching sensor as well as an outer wall tempering device of a tempering sensor, wherein the inner wall quenching device can be moved inside the steel tube; and the outer wall tempering device can be moved on the outer wall of the steel tube. The processing equipment can be used for simultaneously finishing the inner wall quenching process and the outer wall tempering process and has high processing efficiency. The invention further provides the steel tube obtained by the processing method and the processing equipment disclosed by the invention.

Owner:ZOOMLION HEAVY IND CO LTD

Polymer resin composition and application thereof to high-frequency circuit boards

ActiveCN109082021ALow dielectric constantLow dielectric loss performanceElectrical equipmentCircuit susbtrate materialsPolymer resinDielectric loss

The invention relates to a vinyl benzyl ether modified poly(p-hydroxystyrene-styrene) polymer resin composition and further relates to a prepreg containing the resin composition and application of theprepreg to high-frequency circuit boards. The resin composition comprises (1) vinyl benzyl ether modified poly(p-hydroxystyrene-styrene) polymer resin and (2) olefin resin, wherein the weight ratio of additive butadiene of 1 and 2 sites in a molecular structure of the olefin resin is smaller than 20%. Besides having comprehensive performances including low dielectric constant, low dielectric loss, low thermal expansion coefficient and the like, a substrate prepared from the resin composition is small in cross-shaped mark area under the action of drop hammer impact loads, high in toughness andcapable of meeting the requirement of copper-clad plates on toughness.

Owner:GUANGDONG SHENGYI SCI TECH

A kind of protective plastic plate and its production method

ActiveCN113586658BImprove the protective effectHigh strengthSpringsVibration suppression adjustmentsEngineeringUltimate tensile strength

The invention discloses a protective plastic board and a production method thereof, which belong to the technical field of plastic boards. The invention can embed a protective bag in the plastic board, which can be deformed under normal conditions, and the plastic board body is not damaged. The impact of the original toughness is almost negligible, but after a severe impact, the phase change fluid inside the protective bag changes from soft to hard, absorbing and digesting the external impact, thus forming an embedded protective layer, which will recover after the external force disappears to its initial soft elastic flow state, and use the built-in pre-shedding column to assist the protective bag to bulge toward the center, further improving the protection, and reserve it in the protective bag to assist in improving the strength under normal conditions, which is different from the existing technology Compared with the method of directly embedding steel wire mesh, the present invention can simultaneously improve rigidity and toughness.

Owner:森钠普环保材料江苏有限公司

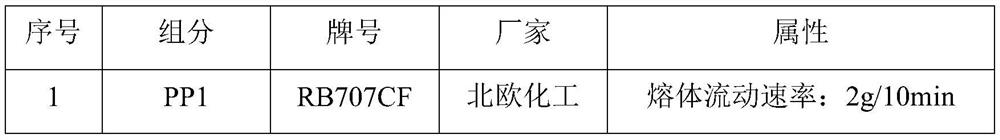

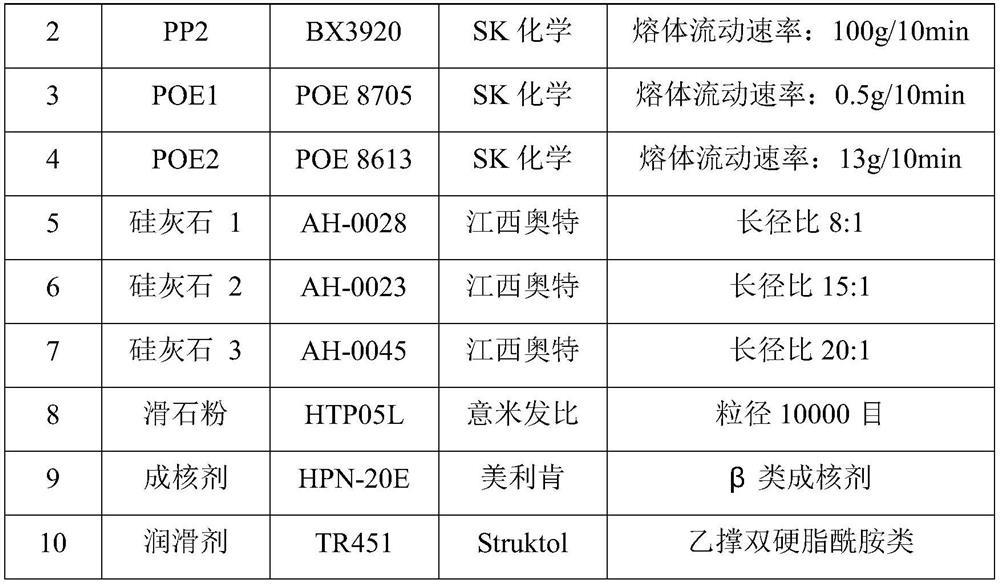

A kind of anti-tiger skin texture polypropylene resin composition and preparation method thereof

The invention discloses an anti-tiger skin texture polypropylene resin composition and a preparation method thereof. ‑15% second toughening agent, 10‑30% wollastonite, 0‑20% talc, 0.5‑1% nucleating agent and 0.5‑1% lubricant by weight The melt flow rate of the first polypropylene is 0.5-3g / 10min, and the melt flow rate of the second polypropylene is 30-100g / 10min; at 190°C, 2.16kg of the first toughening agent The melt flow rate is 0.5-1g / 10min, and the melt flow rate of the second toughening agent is 10-30g / 10min. The polypropylene resin composition of the present invention can avoid the appearance of tiger skin lines and flow marks when the wall is thinned.

Owner:ORINKO NEW MATERIAL CO LTD

High-toughness polyethylene mixed material for electrolytic cathode plate sealing strip and preparation method thereof

InactiveCN102649853BExtend your lifeExtended shelf lifeOther chemical processesAdhesivesLinear low-density polyethyleneMixed materials

Owner:LIAOCHENG UNIV

A kind of polymer resin composition and its application in high-frequency circuit board

ActiveCN109082021BLow dielectric constantLow dielectric loss performanceElectrical equipmentCircuit susbtrate materialsThermal dilatationPolymer science

The present invention relates to a vinyl benzyl ether modified poly(p-hydroxystyryl-styrene) polymer resin composition, comprising: (1) a vinyl benzyl ether modified poly(p-hydroxystyryl-styrene) polymer resin; (2) an olefin resin in which the weight ratio of butadiene having a 1,2-addition in the molecular structure is not less than 20%. The present invention also relates to a prepreg comprising the resin composition and an application thereof in a high frequency circuit board; a substrate prepared by using the resin composition has a low dielectric constant, low dielectric loss, a low thermal expansion coefficient and like comprehensive properties, and the area of a "+"-shaped drop mark formed on the substrate under a falling weight impact load is small, while the substrate has good toughness, and may satisfy the requirements for toughness of a copper-clad board.

Owner:GUANGDONG SHENGYI SCI TECH

Ball carrying plate for steel ball strengthening machine and manufacturing method for ball carrying plate

InactiveCN105441652AExtend working lifeImprove wear resistance and corrosion resistanceFurnace typesHeat treatment furnacesGypsumMaterial type

The invention discloses a ball carrying plate for a steel ball strengthening machine. The ball carrying plate comprises, by weight, 10-20 parts of nylon, 30-40 parts of ferrite, 6-10 parts of gypsum, 0.5-0.9 part of chromic oxide and 3-7 parts of titanium dioxide. The ball carrying plate has the beneficial effects that according to the obtained composite material type ball carrying plate, the ferrite is used as a base body which is covered with the gypsum, the nylon and other materials layer by layer, the rigidity requirement for the ball carrying plate can be met, and enough kinetic energy can be provided for steel balls; besides, the toughness requirement for the ball carrying plate can be met, and the working service life of the ball carrying plate is prolonged; the surface of the ball carrying plate is coated with a trace amount of chromic oxide and titanium dioxide so that the abrasion resistance and the corrosion resistance of the ball carrying plate can be improved, and the reliability of the ball carrying plate is further improved.

Owner:TONGLING MINGCHENG FOUNDRY

Protective plastic plate and production method thereof

ActiveCN113586658AImprove the protective effectHigh strengthVibration suppression adjustmentsUltimate tensile strengthMechanical engineering

The invention discloses a protective plastic plate and a production method thereof, and belongs to the technical field of plastic plates. The protective plastic plate can deform in a normal state by embedding a protective bag in a plastic plate body, the influence on the original toughness of the plastic plate body can be almost negligible, after the plastic plate body is violently impacted, phase change fluid in the protective bag becomes hard from soft and absorbs and digests external impact, so that an embedded protective layer is formed and returns to the initial soft and elastic flowing state after external force disappears, embedded pre-falling-off columns are used for assisting the protective bag in bulging towards the center, the protection performance is further improved, and the embedded pre-falling-off columns are reserved in the protective bag to assist in improving the strength in the normal state. Compared with the mode that a steel wire mesh is directly embedded in the prior art, the rigidity and the toughness can be improved at the same time.

Owner:森钠普环保材料江苏有限公司

Polyethylene compound used for electrolysis cathode plate sealing strip and preparation method thereof

InactiveCN102643475BExtend your lifeReduced catalytic degradationLinear low-density polyethyleneElectrolysis

Owner:LIAOCHENG UNIV

A kind of x80 large-diameter thick-walled straight seam submerged arc welded pipe suitable for low temperature and its manufacturing method

ActiveCN108796364BReduce intakeHigh strengthArc welding apparatusWelding/cutting media/materialsThick wallPipe

The invention discloses an X80 large-diameter thick-wall longitudinal submerged arc welding pipe applicable to the low temperature and a manufacturing method thereof. A parent material of the weldingpipe comprises, by mass percentage, 0.04-0.08% of C, 0.15-0.30% of Si, 1.60-1.85% of Mn, less than or equal to 0.004% of S, less than or equal to 0.010% of P, 0.15-0.30% of Ni, 0-0.30% of Cr, 0.1-0.3%of Cu, 0.05-0.10% of Nb, 0.005-0.04% of V, 0.015-0.03% of Ti, 0.10-0.35% of Mo, 0.02-0.05% of Al, less than or equal to 0.008% of N and 0.0003-0.0005% of B. The manufacturing method comprises the steps of preparing a hot rolled steel plate according to the mass percentages of the chemical compositions; and conducting ultrasonic inspection, edge milling, pre-flanging, JCO formation, prewelding, inner welding, outer welding, welding seam X-ray inspection, steel pipe expanding, hydrostatic testing, welding seam ultrasonic testing, pipe end X-ray inspection, chamfering, pipe end magnetic particletesting and appearance quality inspection on the steel plate. A welding joint of the welding pipe is good in low-temperature toughness; and on the premise that heat treatment is not conducted on thewelding pipe after pipe manufacturing, the welding pipe can be directly used at the temperature of minus 45 DEG C or even lower.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-toughness reinforced steel

The invention discloses high-toughness reinforced steel which comprises the following substances in parts by weight: 22-31 parts of silicon oxide, 45-60 parts of nickel oxide, 11-14 parts of fiber brucite, 11-17 parts of molybdenum, 3-6 parts of hafnium, 9-13 parts of aluminum silicate, 10-25 parts of copper, 10-17 parts of polyurethane, 5-6 parts of nodular cast iron powder, 12-23 parts of sand, 5-14 parts of aluminum oxide and 41-50 parts of glass fiber. The high-toughness reinforced steel is relatively good in toughness and uniform in texture, and both the strength and the toughness are improved and can meet the requirement of high toughness.

Owner:QINGDAO JINXIU SHUIYUAN COMMERCE & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com