Protective plastic plate and production method thereof

A technology of plastic plates and protective strips, applied in the direction of springs/shock absorbers, vibration suppression adjustment, mechanical equipment, etc., can solve problems such as insufficient rigidity, decreased flexibility of plastic plates, and limit the application of plastic plates, so as to improve rigidity and toughness , Improve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

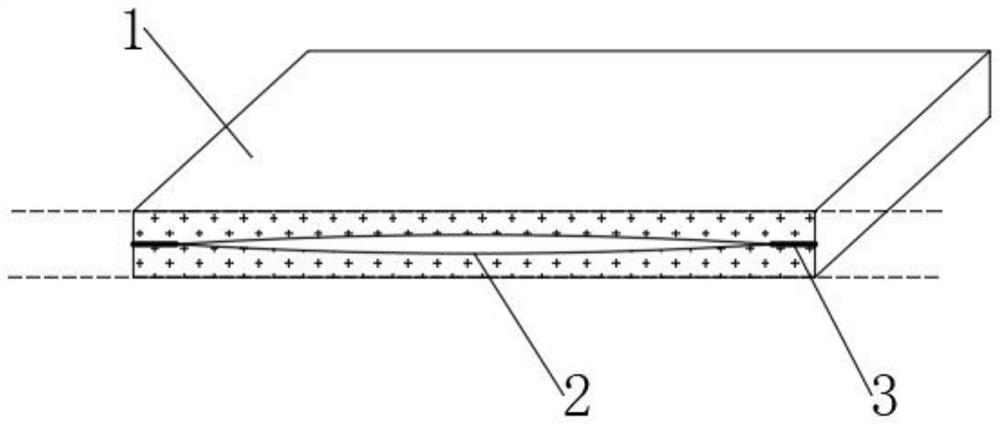

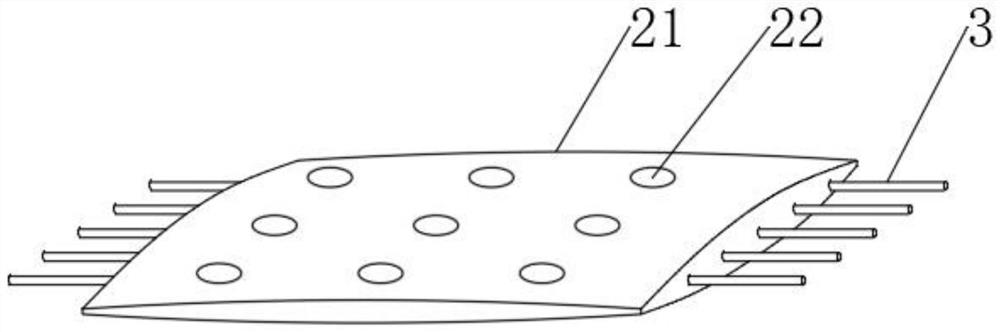

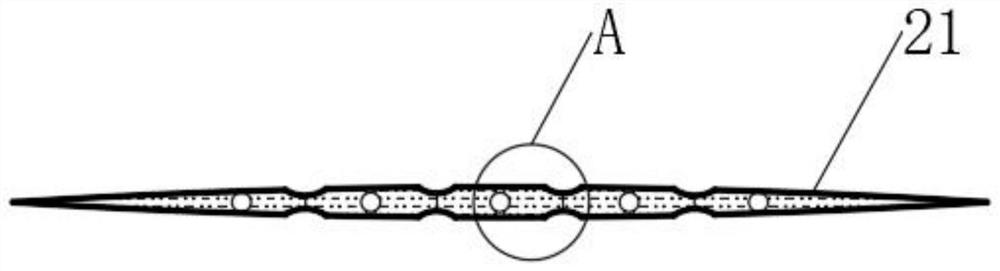

[0044] see Figure 1-4 , a protective plastic plate, comprising a plastic plate body 1, the plastic plate body 1 is inlaid with a protective bag 2, the left and right ends of the protective bag 2 are fixedly connected with a plurality of evenly distributed extension steel wires 3, the protective bag 2 includes an outer The bag body 21, the outer bag body 21 is formed with a plurality of uniformly distributed inner parts 22, and the upper and lower corresponding inner parts 22 are fixedly connected with pull wires 23, and the inner end of the outer bag body 21 is fixedly connected with a plurality of evenly distributed Pre-shedding column 4, and the pre-shedding column 4 is distributed along the vertical direction, and the inner side of the outer bag body 21 is filled with phase change fluid.

[0045] The phase change fluid adopts D3O material or P4U material. Under normal conditions, D3O material and P4U material are in a soft elastic flow state. After being impacted, they wil...

Embodiment 2

[0053] see Figure 8 , the protective bag 2 is replaced by a plurality of protective strip bags 24 and a plurality of elastic pressure columns 25, the plurality of protective strip bags 24 are connected to each other, and the elastic pressure columns 25 are symmetrically distributed up and down at the connection between the protective strip bags 24, and the protection The inner side of the strip bag 24 is also filled with phase change fluid, and the plastic plate body 1 is divided by the protective strip bag 24, and then the connection is reinforced by the elastic pressure column 25, which can also play a good protective effect.

[0054] Compared with Embodiment 1, the production cost of this embodiment is lower, but the protective effect is lower than that of Embodiment 1, and technicians can choose according to different usage scenarios.

[0055] A production method of a protective plastic plate, comprising the following steps:

[0056] S1. Prepare a corresponding mold, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com