Novel inorganic insulation enameled wire

An inorganic insulation and enameled wire technology, applied in the direction of insulated cables, insulated conductors, conductors, etc., can solve problems such as the inability to fundamentally improve the technical and economic indicators of motors and electrical appliances, insufficient heat resistance of enameled wires, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

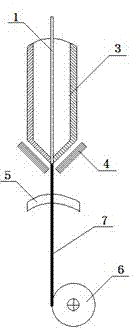

[0017] figure 1 It is a cross-sectional view of a novel inorganic insulating enameled wire according to an embodiment of the present invention; the enameled wire includes a nickel-plated copper wire 1 and a glass film covering it, and the enameled wire is prepared by a film-drawing method, and the diameter of the nickel-plated copper wire 1 is 2mm , the thickness of the glass film is 50-100um.

[0018] The new inorganic insulated enameled wire mentioned in the present invention is prepared by using molten glass-coated nickel-plated copper wire 1, and its glass film 2 is made by melting borosilicate glass tube 3 at a softening temperature of 560°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com