Surface insulation structure of a high temperature device

A high-temperature device and insulation layer technology, which is applied in the direction of heat preservation, pipeline protection, and pipeline protection through heat insulation, can solve problems such as poor compatibility between thermal insulation materials and the surface size of high-temperature devices, poor thermal insulation and waterproof performance, and poor overall strength , to achieve excellent heat insulation ability, reduce thickness, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

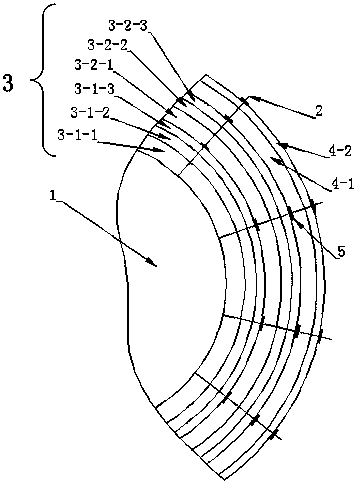

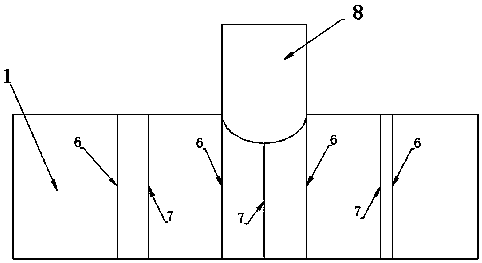

[0019] Such as figure 1 As shown, the present invention takes a steam turbine shell as an example, first welding a number of insulation nails 2 on the steam turbine casing main body 1, and then laying an inner insulation layer 3, which is composed of one or more sets of composite material insulation structures. Adopted two groups of composite material insulation structures in the example, first make the sprayed ceramic fiber layer-3-1-1 in the first group of insulation structures, then lay the nanoporous airgel insulation layer-3-1 in the first group of insulation structures 1-2, the nanoporous airgel insulation layer 1-3-1-2 adopts two layers of nano-silica airgel insulation blanket in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com